slotted pipe

slotted fistulae armaturae utentes in exploratione olei utentes arenam 99% prohibere potest, minui 80% olei bene conservationem gravem, tum vires olei bene augere, integralitas et stabilitas arenam retinendi.Interim tech laser incisio potest facere socors lenis et subtilitas.Structura fistulae foraminis exemplum est, sed valde efficax operatur.

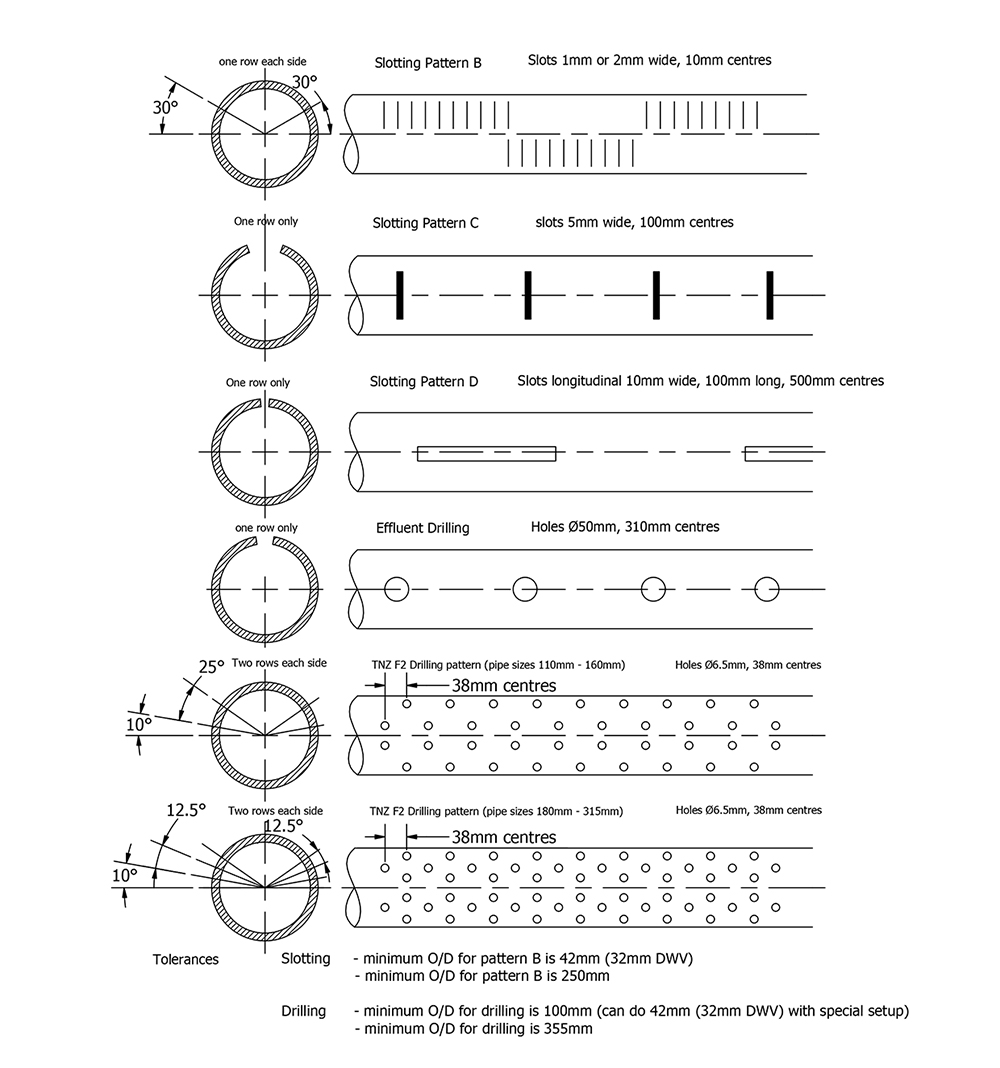

Processus tubi slotted est in alto robore corporis ferro frigido vel calido modos operandi, exsecans centena millia rimas longitudinales, rimas specierum communium pro: commissura latitudo 0,15 3 mm, etiam latior, hiatus longitudinis 50-200 mm.Cross sectio species sunt: rectangulae, scalae formatae, specificae et variae, etiam rotundum velum sulcus habet, apertura diametri specificationum 5—20 mm vagantium in metris. Slotted cribrum tubi commissurae incisurae qualitatis maxime pendet a praecisione latitudinis commissurae, transversis foraminis commissurae. sectionis figura, gradu concinno, in margine foraminis commissurae levitas et gradus corrosionis resistentia foraminis commissurae.

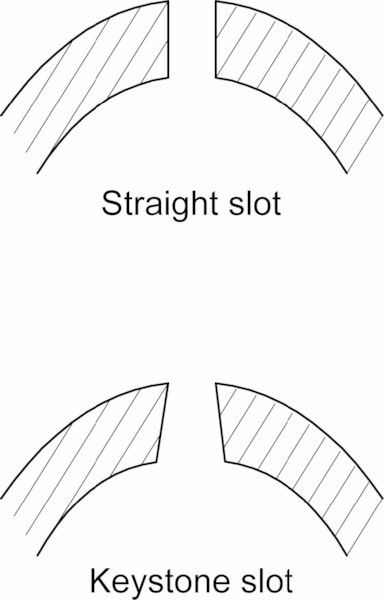

recta justo-Foramina pari latitudine per tibiae parietem tum ID et OD secantur.Certum est ubi granum arenae ad socoram variam maioris momenti non est, foramina recta magis obsistentes quam foramina angularis coagmentata sunt et minus pretiosos ad producendum.Communes applicationes foramina rectae secationis sunt ad productionem frigidam et ad puteos horizontales CBM praeter puteos injectores SAGD.

Seamed Keystone justo--are in organo interiore latius molitum et se purgare ad auxilium impediendum linamentis opus.In superficie lineola angusta et in latitudine interiore crescens, arenam ingrediens facile per foramina sine linamentis dimittunt.

| API Casing pipe | ID | Longitudo | socors Longitudo | Socors, No. | socors latitudo | Slot | Filtrum validum | Maximilianus. | ||

| Spec mm | Crassitudo | Per pondus | ||||||||

| 60.32 | 5 | 6.84 | 50.3 | 3 | 80 | 200 | 0.3 | ±50 | 48 | 512.54 |

| 73.02 | 5.5 | 9.15 | 62 | 240 | 57.6 | 688.55 | ||||

| 88.9 | 6.5 | 13.22 | 75.9 | 280 | 67.2 | 995.1 | ||||

| 101.6 | 6.5 | 15.22 | 88.6 | 300 | 72 | 1151.2 | ||||

| 114.3 | 7 | 18.47 | 100.3 | 10 | 320 | 76.8 | 1400.4 | |||

| 127 | 7.52 | 22.13 | 112 | 340 | 81.6 | 1673.8 | ||||

| 139.7 | 7.72 | 25.11 | 124.3 | 360 | 86.4 | 1900.2 | ||||

| 9.17 | 29.48 | 121.4 | 360 | 86.4 | 2232.4 | |||||

| 168.3 | 8.94 | 35.09 | 150.4 | 400 | 96 | 2672.95 | ||||

| 177.8 | 8.05 | 33.68 | 161.7 | 440 | 105.6 | 2559.2 | ||||

| 9.19 | 38.19 | 159.4 | 440 | 105.6 | 2940.7 | |||||

| Tibia spissa dimensio (in) | OD(mm) | Muri crassitudo (mm) | ID (mm) | SUO numero uniuscuiusque circuli | Width socors (mm) | Longitudo socors (mm) | Longitudo (mm) |

| 2-3/8″ | 60.3 | 4.83 | 50.64 | 12~18 | 0.2~0.8 | 45~100 | 1000~ 12000 |

| 2-7/8″ | 73 | 5.51 | 61.98 | 20~24 | 45~100 | ||

| 3-1/2″ | 88.9 | 6.45 | 76 | 24~28 | 45~100 | ||

| 4″ | 101.6 | 6.65 | 88.29 | 24~30 | 45~100 | ||

| 4-1/2″ | 114.3 | 5.69 | 102.92 | 24~30 | 45~100 | ||

| 6.35 | 101.6 | 45~100 | |||||

| 7.37 | 99.57 | 45~100 | |||||

| 8.56 | 97.18 | 45~100 | |||||

| 5″ | 127 | 5.59 | 115.82 | 28~36 | 0.25~0.8 | 45~100 | |

| 6.43 | 114.15 | 45~100 | |||||

| 7.52 | 111.96 | 45~100 | |||||

| 9.19 | 108.61 | 45~100 | |||||

| 5-1/2″ | 139.7 | 6.2 | 127.3 | 30~38 | 45~100 | ||

| 6.99 | 125.73 | 45~100 | |||||

| 7.72 | 124.26 | 45~100 | |||||

| 9.17 | 121.36 | 45~100 | |||||

| 10.54 | 118.62 | 45~100 | |||||

| 7″ | 177.8 | 6.91 | 163.98 | 36~50 | 45~100 | ||

| 8.05 | 161.7 | 45~100 | |||||

| 9.19 | 159.41 | 45~100 | |||||

| 10.36 | 157.07 | 45~100 |

1. Fistula nostra perforata uti J55/K55/N80 armamentis et tubings vexilli API, cum altiore robore altiore, non ita facile ad deformationem.

2. Ora socors est verticalis, levis, sine lappa, et rima est uniformitas.

3. Fistula perforata apta est ad bene arenosum, cujus diameter arenae major quam 0,3mm.

4. Socors longitudinalis et transversalis esse potest, sectio socors typos trapezoidales et parallelos cum spatio patenti esse potest.

5. Tegumentum slotted fistula magnum habet diametrum interiorem.

API Spec 5CT-Specificatio 5CT/ISO 11960, Specificatio ad Casing et Tubing, VIII Editio, Petroleum et gasi - chalybei industriarum naturalium fistularum ad usum pro instrumento pro puteis armamentis vel Tubing.

| Standard | Gradus | Compositiones chemica | |||||||||

| API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34~0.39 | 0.20~0.35 | 1.25~1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34~0.38 | 0.20~0.35 | 1.45~1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11~0.16 | |

| L80 | 0.15~0.22 | ≤1.00 | 0.25~1.00 | ≤0.020 | ≤0.010 | 12.0~14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26~0.395 | 0.17~0.37 | 0.40~0.70 | ≤0.020 | ≤0.010 | 0.80~1.10 | ≤0.20 | ≤0.20 | 0.15~0.25 | ≤0.08 | |

Mechanica Properties

| Gradus | Type | Totalis elongationis sub onere (%) | Cedant vires (min) | Vires cede (max) | Min Mpa . vires distrahentes | Duritia Max (HRC) | Duritia Max (HBW) |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | - | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | - | 0.5 | 655 | 758 | 724 | - | - |

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 | - | - |

| Q125 | Omnis | 0.65 | 862 | 1034 | 931 | - | - |

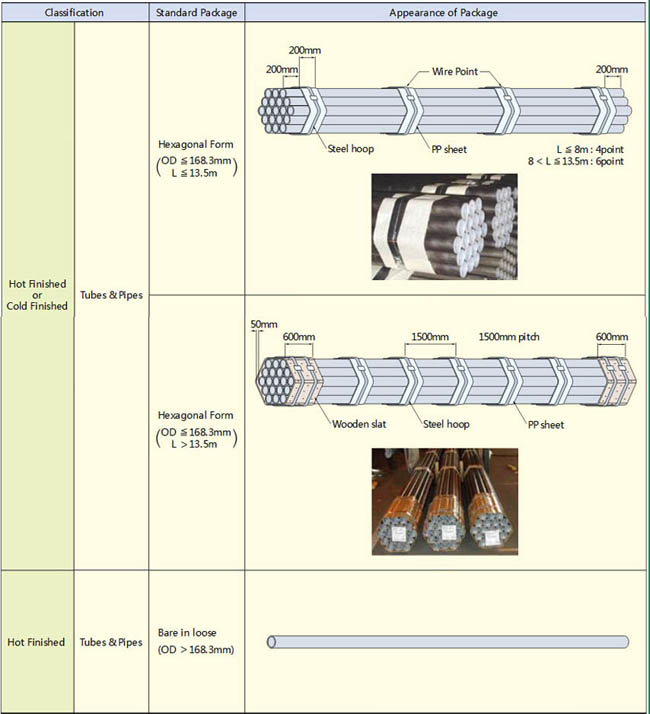

Unius cum bulla pera et deinde in casu ligneo (libellum suffitu).Utraque causa insignita est;

1. Nomen & idem signum fabrica-HuaDong Brand

2. Batch numerus

3. Date ex manufacturer

4. Material

5. Tutus calefactio & application temperatus