Pipe quadrata

Figura:

cavum sectioniss: Quadratus, Rectangularis, Rotundus, Triangulus, Hexagonal, sectiones Elipticae Cavae

Pegmata

Consuetudinem:

Sectiones cavae:

Constructio: Aula Structura, Mare Trestle, Airport Structure, Navis, aedificatio, Securitas Portae Frames, Garage Ianua, Firmans Liners de Ferro Ianua et Fenestra, Muros Indoor Partes, Cables Pontem Structures et Expressway Custodes salutis, Balustrade, Decorantes, Residentiales, Ornamentales Pipes

Automotiva Partes:Motorcar Casus, Car et Bus Manufacture, Vehicula

Agricultural: Agricultural Equipment

Industry: Machinaria, Solaris Stent, Suboles Olei Campi, Meus Equipment, Electromechanical Hardware, , Gravis engineering, Mining and Resources, Process Engineering, Materials Handling, Mechanical Parts

Negotiatio: Ambulatio Rails, Roll-usque Ianua, Guardrail, Plaza Structura, Signage, Via Furniture, Dimicatio

Logistics Repono: Supermarket Repositoria, Vasa, onerariam Industria, Commercial Construction

Other: Ludis Apparatus, Otium Equipment, Furniture, Schola Furniture

Pegmata tube

Material Storage Racks, Pallets, Hydraulicis Platforms, Trusses, Columnae, Purlins, CONSERVATORIUM stat turres

Qualitas Latin:

Sectiones cavae:

GB/T 13793 resistentia longitudinalis electrici fistulae ferro iuncta

GB/T 6728 Frigidum chalybeum sectiones cavae formatae ad structuram generalem-dimensiones, figuras, pondus ac deviationes permissas.

ASTM A500 Frigidum formatum iuncta et inconsutilem Ferro Steel Structural Tubing in circuitu et figurae

ASTM A 53 Standard Specification for Pipe, Ferro, Nigro et Hot tincto, Cadmiae Coated, iuncta et Inconsutilis.

EN 10210 Hot confectae structurae sectiones cavae non-admixtae et subtilia structuris frumenti steels

EN 10219 Frigidum sectiones structurae concavae ex ferro non-admisceo et subtilibus grani conflati conflati

JIS G 3466 Carbon chalybe Quadratus ad proposita generalia fabrica

BS 1387 Ferro Tubes ad usum aquae, Gas, Air et Steam

BS 6323 PART5 inconsutilem et iuncta FERRUM TUBES AUTOMOBILE MACHINACUM ET GENERALE FABRICATOR

IS : 1161 Steel Tubes Pro structuris et Electric poles.

IS : 3601 Steel tubes for mechanical & general engineering purposes.

IS : 3074 Ferro tube pro automobile proposito.

IS : 4923 Ferri tube pro sectionibus cavis in structura positis

DIN MDCXXVI iuncta CIRCULARIBUS TUBES NON AMICTORIUM STEELS CUM

Qualis EQUIREMENTS

Signa MMCCCXCIV iuncta et SIZE ACCURATIO FERRUM TUBES

Pegmata tube

GB 15831 Ferro tubus scaenicus

En XXXIX solveris Steel tubulis tubi et coupler scaffolds

BS 1139 Metallum pegmatum

Ferro Gradus:

GB/T 13793, GB/T 6728, GB 15831:

Q195, Q215, Q235, Q275, Q295, Q345, 08F, 08, 08, 08F, 10F, 10, HG5, DF08

EN 10210, EN 10219, BS 1387: S185, S235, S235JR, S235 G2H, S275, S275JR, S355JRH, S355J2H, St12, St13, St14, St33, St37, St44, ST52

ASTM A500, ASTM A 53: Gr.A, Gr B, Gr C, Gr.D, DC01, DC03, 1008, 1010

JIS G 3466: SS330, SS440, SS490, SPHD, SPHE

Processus: ERW et Seamless

Magnitudo:

Sectiones cavae:

Quadratus: 10 mmx10mm - 500 mmx500mm

Retangularis: 10mm x 20mm - 600mmx400mm

Circum: 1/8″ – 4″

Murus Crassitudo: 0.5 – 20.0mm

Longitudo: 0.3 mtr - XVIII mtr ut elit requiratur

Pegmata tube

Diameter exterior: 38mm, 42mm, 48.3mm-48.6mm

Murus Crassitudo: 2.0mm, 2.5mm, 2.75mm, 3.0mm, 3.25mm, 3.85mm, 4.0mm

Longitudo: 0.3mtr -18 mtr

Processus:

Seamless: Hot Rolled, Hot Explored

Iuncta: ERW, HFW

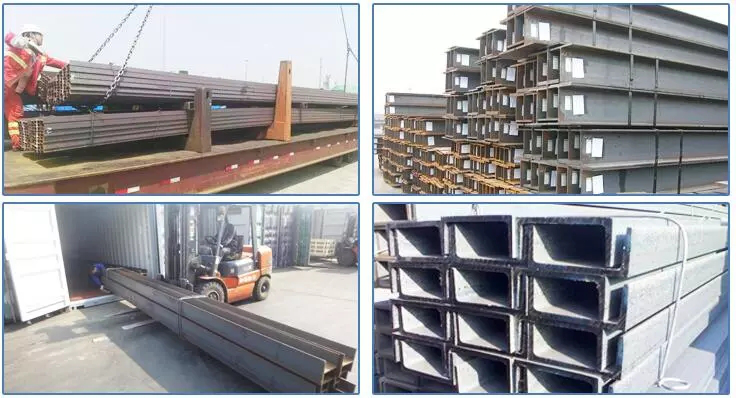

Coing: Calvarised Galvanised, Electrical Galvanized

Rudimentum:

Seamless: Pipe Billet (Hot Rolled, or Con-mittentes), Mater Pipe

Conflata: Hot Rolled Steel Coil (HRC), Cold Rolled Steel Coil (CRC), Pre-doluit Galvanized Ferro Strip

Finis: Quadratus cut, Burr remotus

Superficies: Leviter unctum, Calidum intinge galvanized, Electro galvanized, Black

Calor curatio: Bright Annealed, Niger Annealed

Packing: Plastic plugs in both ends, hexagonal fasciculi max.2,000kg cum aliquot fasciolis ferratis, in utroque fasciculo duae texturae, in charta IMPERVIUS convoluta, manica PVC et saccus cum aliquot fasciolis ferro

Test: Chemical Component Analysis, Proprietates Mechanicae (Virtus ultima distrahentes, Cedite

vis, Elongatio), Proprietates Technical (Flattening Test, Flaring Test, Tentatio Test, Duritas Test, Canite Test, Impact Test etc.), Exterior Inspectio Size

Molendinum Test Certificatorium: EN 10204/3.1B

Quadratus fistulae magnitudinum

| Magnitudo (mm) | Wall Crassitudo (mm) | Magnitudo (mm) | Wall Crassitudo (mm) |

| 20*20 | 1.2 | 70*70 60*80 100*40 | 1.8 |

| 1.3 | 2 | ||

| 1.4-1.5 | 2.2 | ||

| 1.7 | 2.3 | ||

| 1.8 | 2.5-4.0 | ||

| 2 | 4.5-5.0 | ||

| 2.2 | 5.5-5.75 | ||

| 2.3 | 75*75 60*90 100*50 | 1.8 | |

| 2.5-2.75 | 2 | ||

| 25*25 20*30 | 1.2 | 2.2 | |

| 1.3 | 2.3 | ||

| 1.5 | 2.5-4.0 | ||

| 1.7 | 4.5-5.0 | ||

| 1.8 | 5.5-5.75 | ||

| 2 | 80*80 100*60 100*80 120*60 | 2 | |

| 2.3-2.3 | 2.2 | ||

| 2.5-3.0 | 2.3 | ||

| 30*30 30*40 25*40 20*40 | 1 | 2.5-4.0 | |

| 1.2 | 4.5-5.0 | ||

| 1.3 | 5.5-5.75 | ||

| 1.5 | 7.5-7.75 | ||

| 1.7 | 100*100 120*80 | 2 | |

| 1.8 | 2.2 | ||

| 2 | 2.3 | ||

| 2.2 | 2.5-5.0 | ||

| 2.3 | 5.5-5.75 | ||

| 2.5*2.75 | 7.5-7.75 | ||

| 3 | 120*120 140*80 150*100 160*80 | 2.5 | |

| 40*40 30*50 25*50 | 1.2 | 2.75 | |

| 1.3 | 3 | ||

| 1.4-1.5 | 3.25-5.0 | ||

| 1.7 | 5.5-7.0 | ||

| 1.8 | 7.5-7.75 | ||

| 2 | 140*140 150*150 200*100 | 3.5-4.0 | |

| 2.2-2.3 | 4.5-5.0 | ||

| 2.5-4.0 | 5.25-7.0 | ||

| 50*50 60*40 30*60 40*50 | 1.5 | 7.5-7.75 | |

| 1.7 | 160*160 180* 180

| 3 | |

| 1.8 | 3.5 | ||

| 2 | 3.75 | ||

| 2.2 | 4.0-5.0 | ||

| 2.3 | 5.25-5.75 | ||

| 2.5*-4.0 | 7.5-7.75 | ||

| 4.25-5.0 | 60*60 40*80 75*75 50*70 50*80 | 2.3 | |

| 60*60 40*80 75*45 50*70 50*80 | 1.5 | 2.5-4.0 | |

| 1.7 | 4.25-5.0 | ||

| 1.8 | 5.5-5.75 | ||

| 2 | / | ||

| 2.2-2.3 | / |

Praesto Qualitas signa

ASTM A500 Frigidum formatum iuncta et inconsutilem Ferro Steel Structural Tubing in circuitu et figurae

EN 10210 Hot confectae structurae sectiones cavae non-admixtae et subtilia structuris frumenti steels

EN 10219 Frigidum sectiones structurae concavae ex ferro non-admisceo et subtilibus grani conflati conflati

ASTM A53 adhibetur ut structural ferro vel humilis-pressurae plumbing

Standard Corner Radius (Structural Sizes:)

Maximilianus.3 x Nominal Wall Crassitudo

| Mechanica Amplitudo | Magnitudines structurales | ||

| Maximae Nominal Extra Dimensionem | Extra Tolerantia ad omnes partes in angulis | Maximae Nominal Extra Dimensionem | Extra Tolerantia ad omnes partes in angulis |

| 3/16 ad 5/8 | ± 0.004 | 2 1/2 and under- | ± 0.020 |

| super 5/8 ad 1 1/8 | ± 0.005 | super 2 1/2 ad 3 1/2 | ± 0.020 |

| super 1 1/8 ad 1 1/2 | ± 0.006 | super 3 1/2 ad 5 1/2 | ± 0.030 |

| super 1 1/2 ad 2 | ± 0.008 | super 5 1/2 | ± 1% |

| in II ad 3 | ± 0.010 | ||

| in III ad IV " | ± 0.020 | ||

| in IV ad VI " | ± 0.020 | ||

| supra VI ad VIII " | ± 0.025 | ||

rectitudo

Mechanica Sizes: Max.1/16″ in 3 pedibus

Magnitudines structurales: Max.1/8″ x numerus pedum longitudinis totalis divisae per 5 .

Murum crassitudine

Mechanica & structural Sizes: ± 10% nominal Wall Crassitudo

Quadratum laterum

Magnitudines mechanicae: Max: ± b = cx 0.006″

b = TOLERATIO pro e-of-quadrata

c = Communitas externa per blandit

Magnitudines structurales: latera adiacentia ab 90° ab ± 2° deflectere possunt

Maxime Twist (Mechanica & structural Sizes)

| Dimensio maxima, pollices | Maximilianus.Torquent *, pollices |

| super 1/2 ad 1 1/2 | 0.041 |

| super 1 1/2 ad 2 1/2 | 0.093 |

| super 2 1/2 ad 4 | 0.093 |

| in IV ad VI " | 0.093 |

| in IV ad VIII " | 0.100 |

Convexitas & concavum (Mechanical & structural sizes)

| Maximus Nominal OD, Inches | Tolerantia ± Unciarum |

| 2 1/2 and under- | ± 0.010 |

| super 2 1/2 ad 4 | ± 0.015 |

| in IV ad VIII " | ± 0.025 |

Structural Tubing A 500 Requirements

| Grades | Chemical | Corporalis | ||||||

| C. Max.% | Mn Max.% | P. Maximilianus.% | S Max.% | Cu Max.% | Roboris distrahentes, min.psi | Cedant vires, min.psi | Prolongatio in 2 in. | |

| Gradus B | 0.26 | / | 0.04 | 0.05 | 0.20 | 58,000 | 46,000 | 23 |

| Gradus C | 0.23 | 1.35 | 0.04 | 0.05 | 0.20 | 62,000 | 50,000 | 21 |

Clara Annealed, Niger Annealed

Plastic plugs in both ends, hexagonales fasciculos max.2,000kg cum aliquot fasciolis ferratis, in utroque fasciculo duae texturae, in charta IMPERVIUS convoluta, manica PVC et saccus cum aliquot fasciolis ferro

Inspectio: Chemical Component Analysis, Mechanica Properties