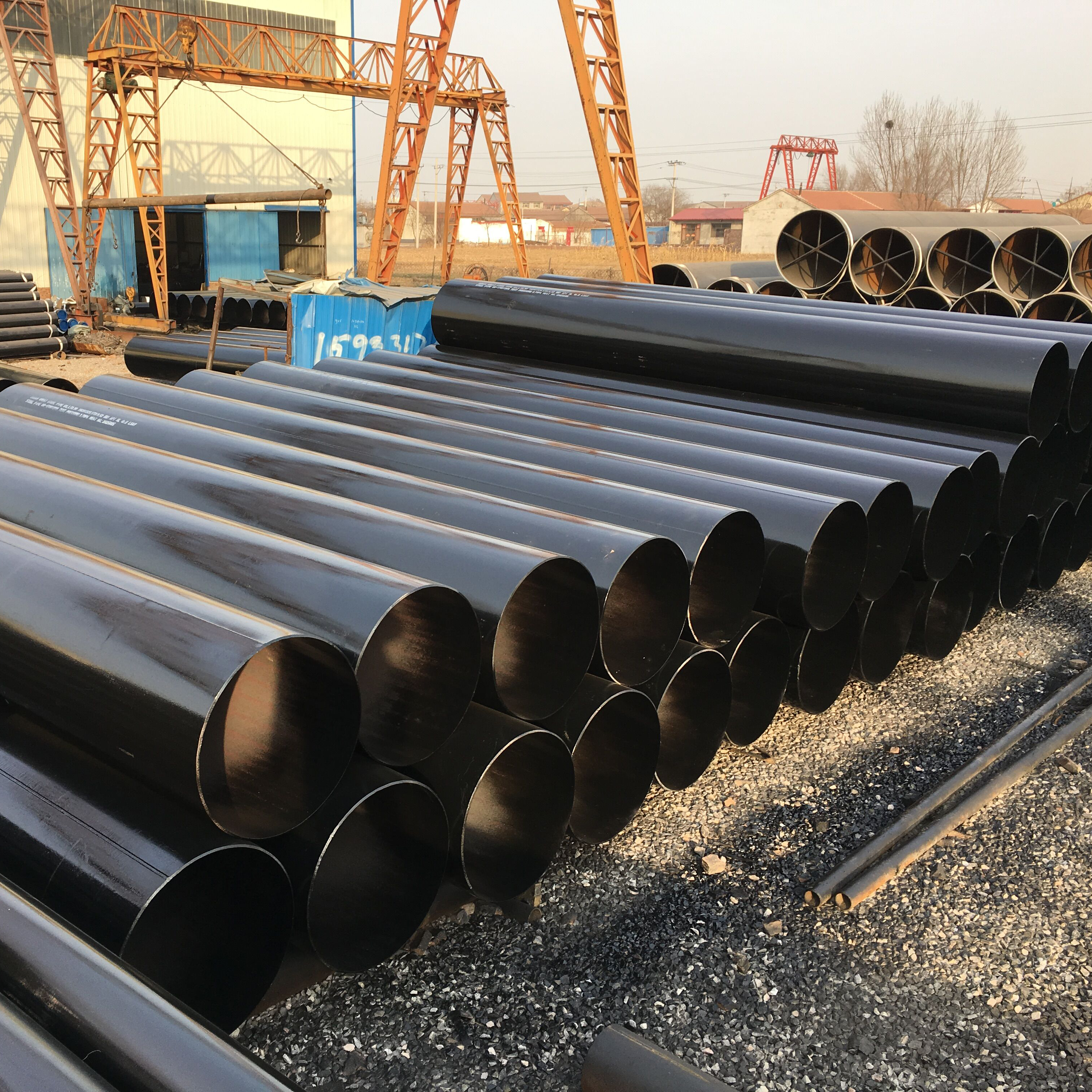

LSAW Steel Pipe

LSAW Steel Pipe (demersus Arcus longitudinalis Soam Pipe Welding)

UOE LSAW FERRUM PIPES

UOE molendini lineamenta antecedens technologiam et processum, altam efficiens efficientiam, producti stabilem qualitatem consequitur et omni inspectione instrumento instructa est.UOE molendinum adoptat U&O formans, fistulae formatae intus per quinque statio glutini interni cum tribus filis conflati, et extra per quatuor stationes glutinosas externas cum tribus filis conflati.Secundum varias exigentias clientium, fistula iuncta divulgari potest vel dilatari mechanica vel hydrostatica ad accurationem dimensivam emendare et residua accentus eliminare.

Specifications

Extra Diametrum 508mm- 1118mm (20"- 44")

Murus Crassitudo: 6.0-25.4mm 1/4"-1"

Qualitas signa: API.DNV.ISO.DEP.EN.ASTM.DIN.BS.JIS.GB.CSA

Longitudo: 9-12.3m (30'- 40')

Grades: API 5L A-X90,GB/T9711 L190-L625

JOCE LSAW ORGANUM (PRESSE CURVUS)

Haec magna diametri longitudinalis arcui demersa conflata (LSAW) linea productionis organorum in Sinis.Molendinum progressivum flexionis progressum capit, aequabiliter distributum formans accentus, altam dimensionis uniformitatem, magnitudines infinitas variationem & extensionem longitudinis, ac flexibilitatem altam, etc.

Specifications

Extra DiameterΦ406mm- 1626mm (16"- 64")

Murum crassitudine.6.0- 75mm (1/4" - 3")

Qualitas signa.API.DNV.ISO.DEP.EN.ASTM.DIN.BS.JIS.GB.CSA

Longitudo.3-12.5m ( 10'- 41' )

Grades.API 5L A-X100, GB/T9711 L190-L690

LSAW Steel Pipe Dimension

| Ex Diameter | Wall Crassitudo (mm) | ||||||||||||||||

| Inch | mm | 6.4 | 7.1 | 7.9 | 9.53 | 12.7 | 14.3 | 15.9 | 19.1 | 22.2 | 25.4 | 28.6 | 31.8 | 34.9 | 38.1 | 41.3 | 44.5 |

| 16 | 406.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 18 | 457 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 20 | 508 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 22 | 559 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 24 | 610 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 26 | 660 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 28 | 711 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 30 | 762 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 32 | 813 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 34 | 864 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 36 | 914 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 38 | 965 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 40 | 1016 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 42 | 1067 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 44 | 1118 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 46 | 1168 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 48 | 1219 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 52 | 1321 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 56 | 1422 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 60 | 1524 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 64 | 1626 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Tolerantia extra diametri et Wall Crassitudo

| Genera | Standard | |||||

| SY/T5040-2000 | SY/T5037-2000 | SY/T9711.1-1977 | ASTM A252 | AWWA C200-97 | API 5L PSL1 | |

| Tubus finis declinationis OD | ±0.5%D | ±0.5%D | -0.79mm~+2.38mm | <±0.1%T | <±0.1%T | ±1.6mm |

| murum crassitudine | ±10.0%T | D<508mm, ±12.5%T | -8%T~+19.5%T | <-12.5%T | -8%T~+19.5%T | 5.0mm |

| D>508mm, ±10.0%T | T≥15.0mm, ±1.5mm | |||||

Chemical Compositio et Mechanica Properties

| Standard | Gradus | Chemical Composition(max)% | Mechanica Properties (min) | |||||

| C | Mn | Si | S | P | Cede virtus (Mpa) | Distrahens fortitudo (Mpa) | ||

| GB/T700-2006 | A | 0.22 | 1.4 | 0.35 | 0.041 | 0.041 | 235 | 370 |

| B | 0.2 | 1.4 | 0.35 | 0.041 | 0.041 | 235 | 370 | |

| C | 0.17 | 1.4 | 0.35 | 0.041 | 0.041 | 235 | 370 | |

| D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

| GB/T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| BS En10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 | |

| S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 | |

| DIN 17100 | ST37-2 | 0.2 | - | - | 0.041 | 0.041 | 225 | 340 |

| ST44-2 | 0.21 | - | - | 0.041 | 0.041 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0.041 | 0.041 | 345 | 490 | |

| JIS G3101 | SS400 | - | - | - | 0.041 | 0.041 | 235 | 400 |

| SS490 | - | - | - | 0.041 | 0.041 | 275 | 490 | |

| API 5L PSL1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 | |

| X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 | |

| X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 | |

| X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 | |

| X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 | |

Leviter unctum, Calidum intinge galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rubigo oleum, Protective coatings