Titanium noarmen dielen

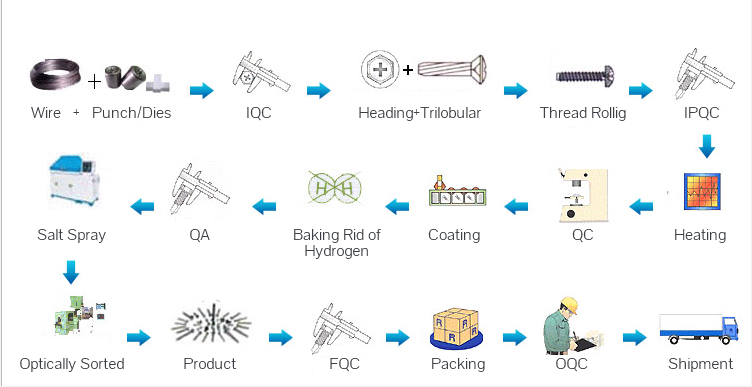

Produksje fan DIN, ANSI / AMSE, ISO, JIS en oare noarmen en net-standert hege sterkte titanium befestigingen.Meastentiids omfetsje bouten, skroeven, moeren, ringen, behâldring, en ferskate spesjale-foarmige stikken.As earste sille wy de waarmtebehandeling, testen fan gemyske gearstalling, testen fan meganyske eigenskippen fan titaniumbalken, titaniumplaten en oare basismaterialen dwaan.Nei it proses fan rjochtsjen, nivellerjen en polearjen, snijje yn 'e passende grutte.En gean dan troch mei draaien, hot stamping, kompresje skroef, waarmtebehanneling, polearjen, skjinmeitsjen, ynspeksje, en in searje prosedueres, úteinlik om de hege kwaliteit titanium befestigingen te produsearjen.Wy hawwe de avansearre produksjeapparatuer dy't ús produkten soarge om it bêste te berikken yn elke produksjekeppeling.

Us bedriuw hat in protte ynventarisaasje fan titanium befestigingen, dy't de wrâldwide lytse hoemannichte bestellingen en dy klanten mei driuwende leveringseasken kinne foldwaan.Tagelyk leverje wy ek net-standert produkten neffens tekeningen levere troch klanten.

Oanfraach

Petroleum, metallurgy, gemysk, elektroanysk, farmaseutysk, marine-technyk, auto-ûnderdielen, motorfytsdielen, fytsûnderdielen, jachtaccessoires, oerlibjen foar bûten, sportguod en oare fjilden.

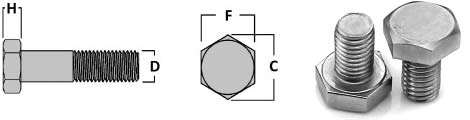

Titanium bout

| Produkt | Titanium en Titanium alloy bout |

| Grutte | Diameter: M1.6-M30, Lingte: 10mm-300mm (0.39"-11.8") |

| Materiaal | Gr.1, Gr.2, Gr.5, Gr.7 ensfh |

| Standert | DIN 912, DIN 6912, DIN 933, DIN 931 ensfh |

Titanium hex moer

| Produkt | Titanium en Titanium alloy moer |

| Grutte | M8-M 80 x 6 |

| Materiaal | Gr1, Gr2, Gr5, Gr7, Ti6Al4V ELI, ensfh |

| Standert | DIN, ISO, JIS, ensfh. |

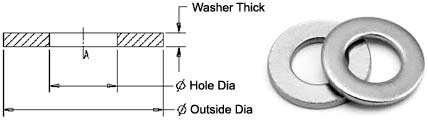

Titanium waskmasine

| Produkt | Titanium en titanium alloy washer |

| Grutte | OD: 5mm-200mm (0.20″-7.87″), ID: 1mm-100mm (0.04″-3.94″), Dikte: 0.1mm-30mm (0.004″-1.18″) |

| Materiaal | Gr.2, Gr.5 ensfh |

| Standert | DIN 125 ensfh |

Titanium skroef

| Produkt | Titanium en Titanium alloy screw |

| Grutte | M1 oant M42, Lingte: 10mm-300mm (0.39"-11.8") |

| Materiaal | Gr1, Gr.2, Gr.5, Gr.7, Gr.12 ensfh |

| Standert | DIN912, DIN933, DIN84, DIN85, DIN963, DIN7991, DIN6912, DIN931, ISO7380, ensfh. |

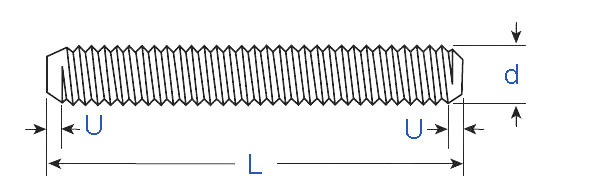

Titanium threaded stud

| Produkt | Titanium en titanium alloy threaded stud |

| Grutte | Diameter: M1.6-M30, Lingte: 10mm-300mm (0.39"-11.8") |

| Materiaal | Gr.1, Gr.2, Gr.5, Gr.7, Gr.23 ensfh |

| Standert | DIN912, DIN933, DIN7991, DIN7984, DIN6921, ISO 7380, JIS, BS ensfh. |

Titanium Hex Bolts Ofmjittings

| Swiere Hex Bolt Diameter | D | F | C | H | |||||

| Body Diameter | Breedte oer Flats | Breedte oer hoeken | Hichte | ||||||

| Max | Basic | Max | Min | Max | Min | Basic | Max | Min | |

| 1/2 | 0.515 | 7/8 | 0.875 | 0.850 | 1.010 | 0.969 | 11/32 | 0.364 | 0.302 |

| 5/8 | 0.642 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 27/64 | 0.444 | 0.378 |

| 3/4 | 0.768 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 1/2 | 0.524 | 0.455 |

| 7/8 | 0.895 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 37/64 | 0.604 | 0.531 |

| 1 | 1.022 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 43/64 | 0.700 | 0.591 |

| 1-1/8 | 1.149 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 3/4 | 0.780 | 0.658 |

| 1-1/4 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 27/32 | 0.876 | 0.749 |

| 1-3/8 | 1.404 | 2-3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 29/32 | 0.940 | 0.810 |

| 1-1/2 | 1.531 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1 | 1.036 | 0.902 |

| 1-3/4 | 1.785 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-5/32 | 1.196 | 1.054 |

| 2 | 2.039 | 3-1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1-11/32 | 1.388 | 1.175 |

| 2-1/4 | 2.305 | 3-1/2 | 3.500 | 3.388 | 4.041 | 3.862 | 1-1/2 | 1.548 | 1.327 |

| 2-1/2 | 2.559 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 1-21/32 | 1.708 | 1.479 |

Hex Nuts Ofmjittings

| ISO Titanium Hex Nut NB | Across Corners | MAX Dikte | MIN Dikte | MAX Across Flats | MIN Across Flats |

| M 8 | 14.38 | 6.8 | 6.44 | 13 | 12.73 |

| M 10 | 17.77 | 8.4 | 8.04 | 16 | 15.73 |

| M 12 | 20.03 | 10.8 | 10.37 | 18 | 17.73 |

| M 14 | 23.35 | 12.8 | 12.1 | 21 | 20.67 |

| M 16 | 26.75 | 14.8 | 14.1 | 24 | 23.67 |

| M 18 | 29.56 | 15.8 | 15.1 | 27 | 26.16 |

| M 20 | 32.95 | 18 | 16.9 | 30 | 29.16 |

| M 22 | 37.29 | 19.4 | 18.1 | 34 | 33 |

| M 24 | 39.55 | 21.5 | 20.2 | 36 | 35 |

| M 27 | 45.2 | 23.8 | 22.5 | 41 | 40 |

| M 30 | 50.85 | 26.6 | 24.3 | 46 | 45 |

| M 33 | 55.37 | 28.7 | 27.4 | 50 | 49 |

| M 36 | 60.79 | 31 | 29.4 | 55 | 53.8 |

| M 39 | 66.44 | 33.4 | 31.8 | 60 | 58.8 |

| M 42 | 71.3 | 34 | 32.4 | 65 | 63.1 |

| M 45 | 76.95 | 36 | 34.4 | 70 | 68.1 |

| M 48 | 82.6 | 38 | 39.4 | 75 | 73.1 |

| M 52 | 88.25 | 42 | 40.4 | 80 | 78.1 |

| M 56 | 93.56 | 45 | 43.4 | 85 | 82.8 |

| M 60 | 99.21 | 48 | 46.4 | 90 | 87.8 |

| M 64 | 104.86 | 51 | 49.1 | 95 | 92.8 |

| M 68 | 110.51 | 54 | 52.1 | 100 | 97,8 |

| m72x6 | 116.16 | 58 | 56.1 | 105 | 102.8 |

| m76x6 | 121.81 | 61 | 59.1 | 110 | 107.8 |

| m80x6 | 127.46 | 64 | 62.1 | 115 | 112.8 |

Titanium Flat Washer Ofmjittings

| Ti Alloy Bolt Grutte | USS | SAE | ||||

| OD (yn.) | ID (yn.) | Dikte | OD (yn.) | ID (yn.) | Dikte | |

| 1/8 (#6) | - | - | - | 0.375 | 0.156 | .036/.065 |

| 5/32 (#8) | - | - | - | 0.438 | 0.188 | .036/.065 |

| 3/16 (#10) | 0.560 | 0.250 | .036/.065 | 0.500 | 0.220 | .036/.065 |

| 7/32 (#12) | - | - | - | 0.562 | 0.250 | .051/.080 |

| 1/4 (#14) | 0.734 | 0.312 | .051/.080 | 0.625 | 0.281 | .051/.080 |

| 5/16 | 0.875 | 0.375 | .064/.104 | 0.688 | 0.344 | .051/.080 |

| 3/8 | 1.000 | 0.438 | .064/.104 | 0.812 | 0.406 | .051/.080 |

| 7/16 | 1.250 | 0.500 | .064/.104 | 0.922 | 0.469 | .051/.080 |

| 1/2 | 1.375 | 0.562 | .086/.132 | 1.062 | 0.531 | .074/.121 |

| 9/16 | 1.469 | 0.625 | .086/.132 | 1.156 | 0.594 | .074/.121 |

| 5/8 | 1.750 | 0.688 | .108/.160 | 1.312 | 0.656 | .074/.121 |

| 3/4 | 2.000 | 0.812 | .122/.177 | 1.469 | 0.812 | .108/.160 |

| 7/8 | 2.250 | 0.938 | .136/.192 | 1.750 | 0.938 | .108/.160 |

| 1 | 2.500 | 1.062 | .136/.192 | 2.000 | 1.062 | .108/.160 |

| 1 1/8 | 2.750 | 1.250 | .136/.192 | 2.250 | 1.250 | .108/.160 |

| 1 1/4 | 3.000 | 1.375 | .136/.192 | 2.500 | 1.375 | .136/.192 |

| 1 3/8 | 3.250 | 1.500 | .153/.213 | 2.750 | 1.500 | .136/.213 |

| 1 1/2 | 3.500 | 1.625 | .153/.213 | 3.000 | 1.625 | .153/.213 |

| 1 5/8 | 3.750 | 1.750 | .153/.213 | - | - | - |

| 1 3/4 | 4.000 | 1.875 | .153/.213 | - | - | - |

| 1 7/8 | 4.250 | 2.000 | .153/.213 | - | - | - |

| 2 | 4.500 | 2.125 | .153/.213 | - | - | - |

| 2 1/4 | 4.750 | 2.375 | .193/.248 | - | - | - |

| 2 1/2 | 5.000 | 2.625 | .210/.280 | - | - | - |

| 2 3/4 | 5.250 | 2.875 | .228/.310 | - | - | - |

| 3 | 5.500 | 3.125 | .249/.327 | - | - | - |

Socket Head Cap Screw Ofmjittings

| Ti Alloy Screw Nom.Grutte Thread Pitch | Lichem | Holle | Holle | Chamfer | Hexagon | Spline | Kaai | Transysje | |||

| Max | Min | Max | Min | Max | Min | Max | Nom. | Nom. | Min | Max | |

| M1,6 × 0,35 | 1.60 | 1.46 | 3.00 | 2.87 | 1.60 | 1.52 | 0.16 | 1.5 | 1.829 | 0,80 | 2.0 |

| M2 × 0,4 | 2.00 | 1.86 | 3.80 | 3.65 | 2.00 | 1.91 | 0.20 | 1.5 | 1.829 | 1.00 | 2.6 |

| M2,5 × 0,45 | 2,50 | 2.36 | 4,50 | 4.33 | 2,50 | 2.40 | 0.25 | 2.0 | 2.438 | 1.25 | 3.1 |

| M3 × 0,5 | 3.00 | 2.86 | 5,50 | 5.32 | 3.00 | 2.89 | 0.30 | 2.5 | 2.819 | 1,50 | 3.6 |

| M4 × 0,7 | 4.00 | 3.82 | 7.00 | 6.80 | 4.00 | 3.88 | 0.40 | 3.0 | 3.378 | 2.00 | 4.7 |

| M5 × 0,8 | 5.00 | 4.82 | 8,50 | 8.27 | 5.00 | 4.86 | 0,50 | 4.0 | 4.648 | 2,50 | 5.7 |

| M6 × 1 | 6.00 | 5.82 | 10.00 | 9.74 | 6.00 | 5.85 | 0,60 | 5.0 | 5.486 | 3.00 | 6.8 |

| M8 × 1,25 | 8.00 | 7.78 | 13.00 | 12.70 | 8.00 | 7.83 | 0,80 | 6.0 | 7.391 | 4.00 | 9.2 |

| M10 × 1,5 | 10.00 | 9.78 | 16.00 | 15.67 | 10.00 | 9.81 | 1.00 | 8.0 | … | 5.00 | 11.2 |

| M12 × 1,75 | 12.00 | 11.73 | 18.00 | 17.63 | 12.00 | 11.79 | 1.20 | 10.0 | … | 6.00 | 14.2 |

| M14 × 2b | 14.00 | 13.73 | 21.00 | 20.60 | 14.00 | 13.77 | 1.40 | 12.0 | … | 7.00 | 16.2 |

| M16 × 2 | 16.00 | 15.73 | 24.00 | 23.58 | 16.00 | 15.76 | 1.60 | 14.0 | … | 8.00 | 18.2 |

| M20 × 2,5 | 20.00 | 19.67 | 30.00 | 29.53 | 20.00 | 19.73 | 2.00 | 17.0 | … | 10.00 | 22.4 |

| M24 × 3 | 24.00 | 23.67 | 36.00 | 35.48 | 24.00 | 23.70 | 2.40 | 19.0 | … | 12.00 | 26.4 |

| M30 × 3,5 | 30.00 | 29.67 | 45,00 | 44.42 | 30.00 | 29.67 | 3.00 | 22.0 | … | 15.00 | 33.4 |

| M36 × 4 | 36.00 | 35.61 | 54,00 | 53.37 | 36.00 | 35.64 | 3.60 | 27.0 | … | 18.00 | 39.4 |

| M42 × 4,5 | 42.00 | 41.61 | 63,00 | 62.31 | 42.00 | 41.61 | 4.20 | 32.0 | … | 21.00 | 45,6 |

| M48 × 5 | 48,00 | 47.61 | 72,00 | 71.27 | 48,00 | 47.58 | 4.80 | 36.0 | … | 24.00 | |

Titanium threaded stud

| ANSI / ASMEB 18.31.2 Threaded Rods-Unit: inch | ||||

| d | pitch | |||

| UNC | UNF | 8 YN | ||

| 1/4 | 0.25 | 20 | 28 | / |

| 5/16 | 0.3125 | 18 | 24 | / |

| 3/8 | 0.375 | 18 | 24 | / |

| 7/16 | 0.4375 | 14 | 20 | / |

| 1/2 | 0.5 | 13 | 20 | / |

| 9/16 | 0.5625 | 12 | 18 | / |

| 5/8 | 0.625 | 11 | 18 | / |

| 3/4 | 0,75 | 10 | 16 | / |

| 7/8 | 0.875 | 9 | 14 | / |

| 1 | 1 | 8 | 12 | 8 |

| 1-1/8 | 1.125 | 7 | 12 | 8 |

| 1-1/4 | 1.25 | 7 | 12 | 8 |

| 1-3/8 | 1.375 | 6 | 12 | 8 |

| Ienheid: inch | ||||

| d | pitch | |||

| UNC | UNF | 8 YN | ||

| 1-1/2 | 1.5 | 6 | 12 | 8 |

| 1-5/8 | 1.625 | / | / | 8 |

| 1-3/7 | 1.75 | 5 | / | 8 |

| 1-7/8 | 1.875 | / | / | 8 |

| 2 | 2 | 4-1/2 | / | 8 |

| 2-1/4 | 2.25 | 4-1/2 | / | 8 |

| 2-1/2 | 2.5 | 4 | / | 8 |

| 2-3/4 | 2.75 | 4 | / | 8 |

| 3 | 3 | 4 | / | 8 |

| 3-1/4 | 3.25 | 4 | / | 8 |

| 3-1/2 | 3.5 | 4 | / | 8 |

| 3-3/4 | 3.75 | 4 | / | 8 |

| 4 | 4 | 4 | / | 8 |

| L | 1/2<L≤2-1/2 | 2-1/2<L≤4 | 4.L≤8 | 8.L≤16 | 16 l |

| Fastened stud lingte tolerânsje | ±0.04 | ±0.08 | ±0.10 | ±0.12 | ±0.18 |

| Standert | Beskriuwing | Standert | Beskriuwing |

| DIN 84 | Slotted tsiis holle screws | DIN 439 | Jam nuts |

| DIN 125 | Flat washers | DIN 963 | Slotted countersunk platte kop screws |

| DIN 127 | Spring slot washers | DIN 965 | Phillips platte kop masine screws |

| DIN 912 | Hex socket head cap screws | DIN 985 | Slotmoeren (mei net-metalen ynfoegje) |

| DIN 913/DIN 914/DIN 915/DIN 916 | Set screws | DIN 1665/DIN 6921 | Hex bouten mei flange |

| DIN 931 | Hex-kopskroeven (dieldraad) | DIN 6912/DIN 7984 | Hexagon socket tinne kop cap screws |

| DIN 933 | Hex-kopskroeven (folsleine thread) | DIN 7991 | Platte kop fersinken socket cap screws |

| DIN 934 | Hex nuts | DIN 9021 | Flat washer |

Materiaal lykweardige Graden Foar Titanium Fasteners

| STANDERT | WERKSTOFF NR. | UNS |

| Titanium Grade 2 | 3.7035 | R50400 |

| Titanium Grade 5 | 3.7165 | R56400 |

Meganyske skaaimerken fan Titanium Fasteners

| Klasse | Treksterkte (min) | Yield Strength 0,2% Offset | Ferlenging yn 2 inch of 50 mm % (min) | ||

| KSI | MPa | KSI | MPa | ||

| Gr.1 | 35 | 240 | 20 - 45 | 138 - 310 | 24 |

| Gr.2 | 50 | 345 | 40 – 65 | 275 - 450 | 20 |

| Gr.3 | 65 | 450 | 55 – 80 | 380 - 550 | 18 |

| Gr.4 | 80 | 550 | ≥70 | ≥483 | 15 |

| Gr.5 | 138 | 950 | ≥128 | ≥880 | 14 |

| Gr.7 | 50 | 345 | ≥40 | ≥275 | 24 |

| Gr.9 | 125 | 860 | ≥105 | ≥725 | 10 |

| Gr.12 | 70 | 483 | ≥50 | ≥345 | 18 |

| Gr.23 | 125 | 860 | ≥115 | ≥790 | 15 |

| Elemint | Tichtheid | Smeltpunt | Treksterkte | Opbringststerkte (0,2% offset) | Ferlinging |

| Titanium Gr.2 | 4,5 g/cm3 | 1665 °C (3030 °F) | Psi - 49900, MPa - 344 | Psi - 39900, MPa - 275 | 20 % |

| Titanium Gr.5 | 4,43 g/cm3 | 1632 °C (2970 °F) | Psi - 138000, MPa - 950 | Psi - 128000, MPa - 880 | 14 % |

Gemysk materiaal Gearstalling fan Titanium Fasteners

| Klasse | Fe% | C% | N% | H% | O% | Al% | V% | Mo% | Ni% | Pd% | Ti |

| Gr1 | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 | - | - | - | - | - | BAL. |

| Gr2 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | - | - | - | BAL. |

| Gr3 | 0.3 | 0.08 | 0.05 | 0.015 | 0,35 | - | - | - | - | - | BAL. |

| Gr4 | 0.3 | 0.08 | 0.05 | 0.015 | 0.40 | - | - | - | - | - | BAL |

| Gr5 | 0.25 | 0.08 | 0.03 | 0.015 | 0.02 | 5,5 - 6,75 | 3.5 – 4.5 | - | - | - | BAL |

| gr7 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | - | - | 0,12 – 0,25 | BAL. |

| gr9 | 0.25 | 0.08 | 0.03 | 0.015 | 0.15 | 2.5 – 3.3 | 2.0 – 3.0 | - | - | - | BAL. |

| Gr12 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | 0,2 – 0,4 | 0,6 – 0,9 | - | BAL. |

| Gr23 | 0.3 | 0.08 | 0.03 | 0.015 | 0.13 | 5,5 - 6,75 | - | - | - | - | B |