ASTM A335 Steel Pipe

| Produkt Namme | Alloy Steel Pipe |

| Materiaal | Legearre stiel |

| Pipe Lengte | Single Random Length en dûbele Willekeurige Length.SRL:3M-5.8M DRL:10-11.8M of As kliïnten frege lingte |

| Grutte | Grutte 1/4”oan 24”Outside Diameter 13,7 mm oan 609,6 mm |

| dikte fan de muorre | SCH10, SCH20, SCH30, STD, SCH40, SCH60, SCH80, SCH100 SCH120, SCH160, XS, XXS |

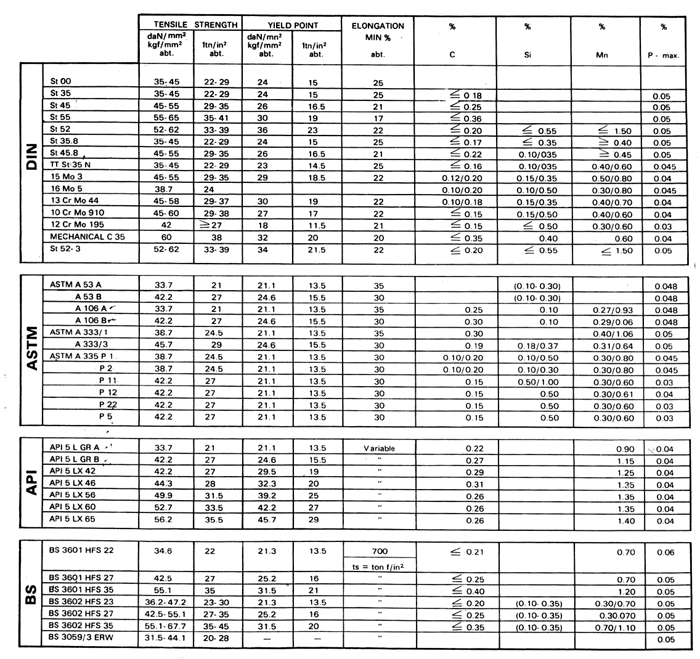

| Standert | ASTM A 335 Grade P1, P2, P5, P9, P9A, P11, P22.ASTM A213 T1B, T1, T2, T5, T9, T9A, T11, T12, T22.A199 T5, T9, T11, T22.BS 3604 Grade 621, 622, 625, 629-470, 629-590, 660, 762.DIN 17175 15 Mo 3, 13 Cr Mo 44, 10 Cr Mo 910, 14 Mo V 63, X 20 Cr Mo V 3039. , 620-460, 622-490, 629-470, 629-590, 762. JISG3458/G3462/3467 en DIN17175-79. |

| Oanfraach | 1. Fluid pipe 2. Power Plant 3. Struktuerpipe 4. Hege en lege druk Boiler tube 5. Seamless stielen buizen foar petroleum cracking 6. Conduit pipe 7. Steigers pipe farmaseutyske en skip gebou etc |

| Sertifikaat | ISO/PED/TUV/SGS/LR/BV |

| Haadmerk | Azië, Midden-Easten, Jeropa, Amearika, Afrika, Austraalje, ensfh |

Gemyske gearstalling(%):

| Klasse | UNS oantsjutting | Gearstalling, % | |||||||

| Koalstof | Mangaan | Fosfor, | Sulphur | Silisium | Chromium | Molybdenum | Oaren | ||

| max | max | ||||||||

| P1 | K11522 | 0.10–0.20 | 0.30–0.80 | 0.025 | 0.025 | 0,10-0,50 | - | 0,44–0,65 | - |

| P2 | K11547 | 0.10–0.20 | 0.30–0.61 | 0.025 | 0.025 | 0.10–0.30 | 0,50–0,81 | 0,44–0,65 | - |

| P5 | K41545 | 0.15 max | 0.30–0.60 | 0.025 | 0.025 | 0.50 max | 4.00-6.00 | 0,45–0,65 | - |

| P9 | S50400 | 0.15 max | 0.30–0.60 | 0.025 | 0.025 | 0.25-1.00 | 8.00-10.00 | 0.90–1.10 | - |

| P11 | K11597 | 0,05–0,15 | 0.30–0.60 | 0.025 | 0.025 | 0.50-1.00 | 1.00-1.50 | 0,44–0,65 | - |

| P12 | K11562 | 0,05–0,15 | 0.30–0.61 | 0.025 | 0.025 | 0.50 max | 0,80–1,25 | 0,44–0,65 | - |

| P15 | K11578 | 0,05–0,15 | 0.30–0.60 | 0.025 | 0.025 | 1,15-1,65 | - | 0,44–0,65 | - |

| P21 | K31545 | 0,05–0,15 | 0.30–0.60 | 0.025 | 0.025 | 0.50 max | 2.65–3.35 | 0,80–1,06 | - |

| P22 | K21590 | 0,05–0,15 | 0.30–0.60 | 0.025 | 0.025 | 0.50 max | 1,90-2,60 | 0.87–1.13 | - |

| P23 | K41650 | 0,04–0,10 | 0,10–0,60 | 0.03 | 0.01 | 0.50 max | 1,90-2,60 | 0.05–0.30 | V 0,20-0,30 |

| Cb 0,02-0,08 | |||||||||

| B 0,0005–0,006 | |||||||||

| N 0.030 max | |||||||||

| Al 0.030 max | |||||||||

| W 1,45–1,75 | |||||||||

| P91 | K91560 | 0.08–0.12 | 0.30–0.60 | 0.02 | 0.01 | 0,20-0,50 | 8.00-9.50 | 0,85-1,05 | V 0,18–0,25 |

| N 0,030–0,070 | |||||||||

| Ni 0.40 max | |||||||||

| Al 0.04 max | |||||||||

| Cb 0,06-0,10 | |||||||||

| P92 | K92460 | 0,07–0,13 | 0.30–0.60 | 0.02 | 0.01 | 0.50 max | 8.50-9.50 | 0.30–0.60 | V 0,15-0,25 |

| N 0,03–0,07 | |||||||||

| Ni 0.40 max | |||||||||

| Al 0.04 max | |||||||||

| Cb 0,04-0,09 | |||||||||

| W 1,5-2,00 | |||||||||

| B 0,001–0,006 | |||||||||

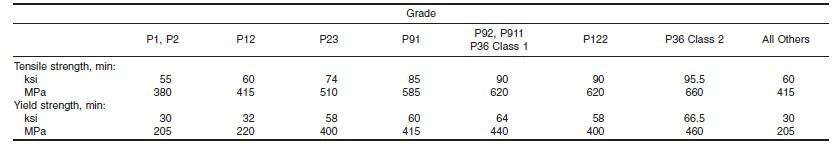

Meganyske eigenskippen:

Swarte coating, oalje / lak, FBE, 2PE, 3PE, galvanisearre ensfh Packaging Detail: Packing yn bondels as foar de eask fan de klant