Alloy Seamless Pipe

OD: 6-720MM

WT: 0,5-120 mm

Lingte: 3-16M

Applikaasje: Petroleum, Chemical Engineering, Elektrisiteit, Boiler

Standert: ASTM A335/A335M, ASTM A213/213M, DIN17175-79, JIS3467-88, GB5310-95

Materiaal: P5, T5, P11, P12, STFA22, P22, T91, T9, WB36

Alloy piip is in soarte fan naadleaze stielen piip, syn prestaasjes is folle heger as dy fan algemiene naadleaze stielen piip, omdat dit soarte fan stielen piip befettet mear Cr, syn hege temperatuer ferset, lege temperatuer ferset, corrosie ferset prestaasjes is folle better as oare Steel piip, sadat de alloy piip wurdt in soad brûkt yn petroleum, Aerospace, gemyske, elektryske krêft, boiler, militêre en oare yndustry.

| Produkt | SEAMLESS / ERW / SAW ALLOY STEEL PIPE |

| Diminsje | 6 mm - 1080 mm |

| Dikte | 1mm - 135 mm |

| Lingte | 3 m - 12 m of neffens de easken fan kliïnten |

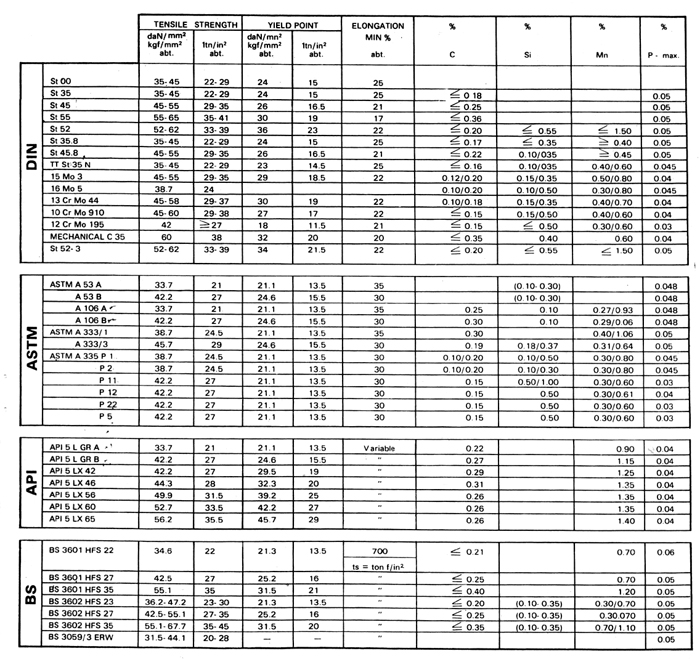

| Standert | ASTM GB DIN |

| Steel grade | A106/53/179/214/192/210 A/B/CST37.2/35.4/35.8/52/52.3/52.4/42/4510# 20# 45#P2, P12, P11, P22, P5, P9, P91T , T11, T5, T9, T22, 4140, 12CrMo, 15CrMo, 12Cr2Mo, 1Cr5Mo, 2CrMo4, 1Cr9Mo, 10CrMo910, ensfh. |

| Hannelsbetingsten | FOB/CIF/CFR |

| Betellingsbetingsten | T/T, L/C |

| Levering haven | Tianjin, Sina |

| Levertiid | 10 of neffens de echte kwantiteit fan 'e buizen |

| Oerflak behanneling | Swarte skilderijLakskilderij3PEWarmgalvanisearre of oare coating neffens jo easkenBare buis |

| Ein fan buizen | Beveled, gewoane, tried, plestik doppen |

| Ynspeksje | Ultrasone ûndersyk, eddy-ynspeksje, hydrostyske testen ensfh. |

| Pakket | Bundels, losmeitsje of neffens jo easken |

| Sertifikaat | API 5L/5CT, ISO, PED ensfh. |

Gemyske gearstalling

| C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % |

| 0,05-0,15 | 0,30-0,60 | 0.025 max | 0.025 max | 0,50-1,00 | 1.00-1.50 | 0,44-0,65 |

Meganyske eigenskippen

| Treksterkte, MPa | Yield Strength, MPa | Ferlinging, % |

| 415 min | 205 min | 30 min |

Outside Diameter & Tolerânsje

| ASTM A450 | Hot rôle | Buitendiameter, mm | Tolerânsje, mm |

| OD≤101.6 | +0,4/-0,8 | ||

| 101.6<OD≤190,5 | +0,4/-1,2 | ||

| 190,5<OD≤228,6 | +0,4/-1,6 | ||

| Kâld Drawn | Buitendiameter, mm | Tolerânsje, mm | |

| OD<25.4 | ±0.10 | ||

| 25.4≤OD≤38.1 | ±0.15 | ||

| 38.1<OD<50.8 | ±0.20 | ||

| 50.8≤OD<63,5 | ±0.25 | ||

| 63,5≤OD<76.2 | ±0.30 | ||

| 76.2≤OD≤101.6 | ±0.38 | ||

| 101.6<OD≤190,5 | +0,38/-0,64 | ||

| 190,5<OD≤228,6 | +0,38/-1,14 | ||

| ASTM A530 en ASTM A335 | NPS | Buitendiameter, inch | Tolerânsje, mm |

| 1/8≤OD≤1-1/2 | ±0.40 | ||

| 1-1/2<OD≤4 | ±0.79 | ||

| 4<OD≤8 | +1,59/-0,79 | ||

| 8<OD≤12 | +2,38/-0,79 | ||

| OD>12 | ±1% |

Muorre dikte & Tolerânsje

| ASTM A450 | Hot rôle | Buitendiameter, mm | Tolerânsje, % |

| OD≤101.6, WT≤2.4 | +40/-0 | ||

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD≤101,6, 3,8<WT≤4.6 | +33/-0 | ||

| OD≤101.6, WT>4.6 | +28/-0 | ||

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD>101,6, 3,8<WT≤4.6 | +33/-0 | ||

| OD>101.6, WT>4.6 | +28/-0 | ||

| Kâld Drawn | Buitendiameter, mm | Tolerânsje, % | |

| OD≤38.1 | +20/-0 | ||

| OD>38.1 | +22/-0 | ||

| ASTM A530 | NPS | Buitendiameter, inch | Tolerânsje, % |

| 1/8≤OD≤2-1/2 | +20,0/-12,5 | ||

| 3≤OD≤18, WT/OD≤5% | +22,5/-12,5 | ||

| 3≤OD≤18, WT/OD>5% | +15,0/-12,5 | ||

| OD≥20, WT/OD≤5% | +22,5/-12,5 | ||

| OD≥20, WT/OD>5% | +15,0/-12,5 |

ASTM A335-foar naadleaze ferrityske alloy-stalen buis foar hege temperatuertsjinst

ASTM A519 - foar naadleaze meganyske buizen fan koalstof en alloy stiel

ASTM A213 - foar naadleaze ferrityske en austenityske alloy-stalen ketel, superheater, en waarmtewikselbuizen

ASTM ASME (S)A-335/(S)A-335M Grade en gemyske gearstalling

| Klasse | UNS | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

| P1 | K11522 | 0.10~0.20 | 0.30~0.80 | 0.025 | 0.025 | 0.10~0.50 | - | 0.44~0.65 |

| P2 | K11547 | 0.10~0.20 | 0.30~0.61 | 0.025 | 0.025 | 0.10~0.30 | 0.50~0.81 | 0.44~0.65 |

| P5 | K41545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0,50 | 4.00~6.00 | 0.44~0.65 |

| P5b | K51545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.00~2.00 | 4.00~6.00 | 0.44~0.65 |

| P5c | K41245 | 0.12 | 0.30~0.60 | 0.025 | 0.025 | 0,50 | 4.00~6.00 | 0.44~0.65 |

| P9 | S50400 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50~1.00 | 8.00~10.00 | 0.44~0.65 |

| P11 | K11597 | 0.05~0.15 | 0.30~0.61 | 0.025 | 0.025 | 0.50~1.00 | 1.00~1.50 | 0.44~0.65 |

| P12 | K11562 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0,50 | 0.80~1.25 | 0.44~0.65 |

| P15 | K11578 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.15~1.65 | - | 0.44~0.65 |

| P21 | K31545 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0,50 | 2.65~3.35 | 0.80~1.60 |

| P22 | K21590 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0,50 | 1.90~2.60 | 0.87~1.13 |

| P91 | K91560 | 0.08~0.12 | 0.30~0.60 | 0.020 | 0.010 | 0.20~0.50 | 8.00~9.50 | 0.85~1.05 |

| P92 | K92460 | 0.07~0.13 | 0.30~0.60 | 0.020 | 0.010 | 0,50 | 8.50~9.50 | 0.30~0.60 |

Opmerking: (S)A335 P91 oare gemyske gearstalling binne: V 0.18~0.25;N 0.030~0.070;Ni≤0,40;Al≤0.04 ;Nb 0.06~0.10

(S)A335 P92 oare gemyske gearstalling binne: V 0,15 ~ 0,25;N 0.030~0.070;Ni≤0,40;Al≤0.04 ;Nb 0.04~0.09;W 1.5~2.00 ;B 0,001~0,006

Swarte coating, oalje / lak, FBE, 2PE, 3PE, galvanisearre ensfh Packaging Detail: Packing yn bondels as foar de eask fan de klant