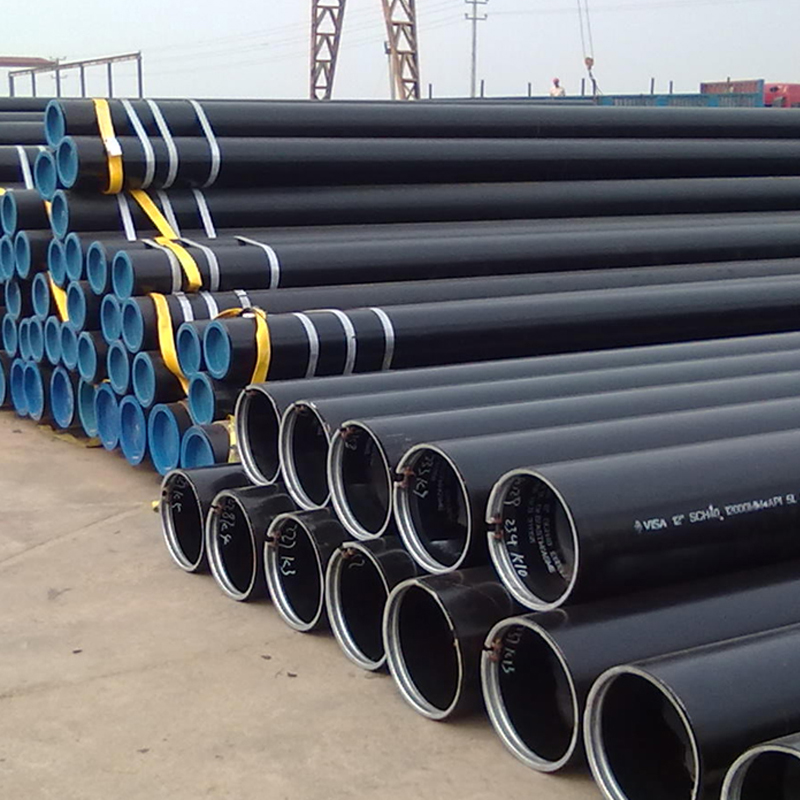

Line Pipe

Wurdt brûkt foar it ferfieren fan gas, wetter, en oalje yn sawol en ierdgas yndustry ensfh

Boarne: Boarring is in buis mei grutte diameter dy't tsjinnet as de strukturele behâld foar de muorren fan oalje- en gasputten, as putboring. om boarfluid te sirkulearjen en winning plakfine.Steel Casing Pipes hawwe glêde muorre & minimale opbringst sterkte fan 35.000 psi.

Tubing: Tubing is piip dy't brûkt wurdt foar it ferfier fan rûge oalje en ierdgas fan in oalje- as gaslaach nei it oerflak nei it boarjen is foltôge.It is makke om de druk te wjerstean dy't ûntstiet út it ekstraksjeproses.Tubing wurdt produsearre op deselde wize as casing, útsein dat in ekstra proses bekend as "upsetting" wurdt tapast om thicken de pipen.

Gemyske analyze (%):

| Standert | Soart pipe | Klasse | Klasse | C | Si | Mn | P | S | V | Nb | Ti |

| max | max | max | max | max | max | max | max | ||||

| API SPEC 5L | SMLS | PLS1 | L245 B L290 X42 L320 X46 L360 X52 L390 X56 L415 X60 L450 X65 L485 X70 L245N BN | 0.28 0.28 0.28 0.28 0.28 0.28 0.28 0.28 0.24 | 0.4 | 1,20 1,30 1,40 1,40 1,40 1,40 1,40 1,40 1,20 | 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,025 | 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,030 0,015 | ——— | ——— | 0.04 |

| PLS2 | L290N X42N | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | ||

| L320N X46N | 0.24 | 0.4 | 1.4 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | |||

| L360N X52N | 0.24 | 0,45 | 1.4 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | |||

| L390N X56N | 0.24 | 0,45 | 1.4 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | |||

| L415N X60N | 0.24 | 0,45 | 1.4 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | |||

| WELD | PLS1 | L245 B | 0.26 | - | 1.2 | - | 0.03 | 0.03 | - | - | |

| L290 X42 | 0.26 | - | 1.3 | - | 0.03 | 0.03 | - | - | |||

| L320 X46 | 0.26 | - | 1.4 | - | 0.03 | 0.03 | - | - | |||

| L360 X52 | 0.26 | - | 1.4 | - | 0.03 | 0.03 | - | - | |||

| L390 X56 | 0.26 | - | 1.4 | - | 0.03 | 0.03 | - | - | |||

| L415 X60 | 0.26 | - | 1.4 | - | 0.03 | 0.03 | - | - | |||

| L450 X65 | 0.26 | - | 1.45 | - | 0.03 | 0.03 | - | - | |||

| L485 X70 | 0.26 | - | 1.65 | - | 0.03 | 0.03 | - | - | |||

| PLS2 | L245M BM | 0.22 | 0,45 | 1.2 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | ||

| L290M X42M | 0.22 | 0,45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | |||

| L320M X46M | 0.22 | 0,45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | |||

| L360M X52M | 0.22 | 0,45 | 1.4 | 0.025 | 0.015 | - | - | - | |||

| L390M X56M | 0.22 | 0,45 | 1.4 | 0.025 | 0.015 | - | - | - | |||

| L415M X60M | 0.12 | 0,45 | 1.6 | 0.025 | 0.015 | - | - | - | |||

| L450M X65M | 0.12 | 0,45 | 1.6 | 0.025 | 0.015 | - | - | - | |||

| L485M X70M | 0.12 | 0,45 | 1.7 | 0.025 | 0.015 | - | - | - | |||

| L555M X80M | 0.12 | 0,45 | 1.85 | 0.025 | 0.015 | - | - | - |

Mechanyske eigenskippen:

| Standert | Klasse | Klasse | Opbringststerkte net minder dan (MPa) | Treksterkte (MPa) | Ferlinging (%) | YS/TS | |

| API SPEC 5L ISO 3183 | PLS1 | L245B | min | 245 | 415 | b | - |

| L290X42 | min | 290 | 415 | b | - | ||

| L320X46 | min | 320 | 435 | b | - | ||

| L360X52 | min | 360 | 460 | b | - | ||

| L390X56 | min | 390 | 490 | b | - | ||

| L415X60 | min | 415 | 520 | b | - | ||

| L450X60 | min | 450 | 535 | b | - | ||

| L485X70 | min | 485 | 570 | b | - | ||

| PLS2 | L245N BN | min | 245 | 415 | b | - | |

| L245M BM | max | 450 | 760 | b | 0.93 | ||

| L290NX42N | min | 290 | 415 | b | - | ||

| L290MX42M | max | 495 | 760 | b | 0.93 | ||

| L320NX46N | min | 320 | 435 | b | - | ||

| L320MX46M | max | 525 | 760 | b | 0.93 | ||

| L360NX52N | min | 360 | 460 | b | - | ||

| L360MX52M | max | 530 | 760 | b | 0.93 | ||

| L390NX56N | min | 390 | 490 | b | - | ||

| L390MX56M | max | 545 | 760 | b | 0.93 | ||

| L415NX60N | min | 415 | 520 | b | - | ||

| L415MX60M | max | 565 | 760 | b | 0.93 | ||

| L450MX65M | min | 450 | 535 | b | - | ||

| max | 600 | 760 | b | 0.93 | |||

| L485MX70M | min | 485 | 570 | b | - | ||

| max | 635 | 760 | b | 0.93 | |||

| L555MX80M | min | 555 | 625 | b | - | ||

| max | 705 | 825 | b | 0.93 |

Toughness:

| Standert | Klasse | Dwars minimale ynfloed fan Pipe lichem | Dwars minimale ynfloed fan weld (J) | |||||

| (J) | ||||||||

| D=508 | 508 mm | 762 mm | 914mm | 1219 mm | D<1422 mm | D = 1422 mm | ||

| API SPEC 5L | =L415×60 | 27 (20) | 27 (20) | 40 (30) | 40 (30) | 40 (30) | 27 (20) | 40 (30) |

| >L415×60 | 27 (20) | 27 (20) | 40 (30) | 40 (30) | 54 (40) | 27 (20) | 40 (30) | |

| =L450×65 | ||||||||

| >L450×65 | 27 (20) | 27 (20) | 40 (30) | 40 (30) | 54 (40) | 27 (20) | 40 (30) | |

| =L485×70 | ||||||||

| >L485×70 | 40 (30) | 40 (30) | 40 (30) | 40 (30) | 54 (40) | 27 (20) | 40 (30) | |

| =L555×80 | ||||||||

Opmerking: (1) De wearden yn 'e tabel binne geskikt foar de standertmonster yn folsleine grutte.

(2) De wearden binnen beugel is de minimale inkele wearde, bûten beugel is de gemiddelde wearde.

(3) Test Temperatuer: 0 ° C.

Anti-corrosie Water Based Paint