Heavy Weight Drill Pipe

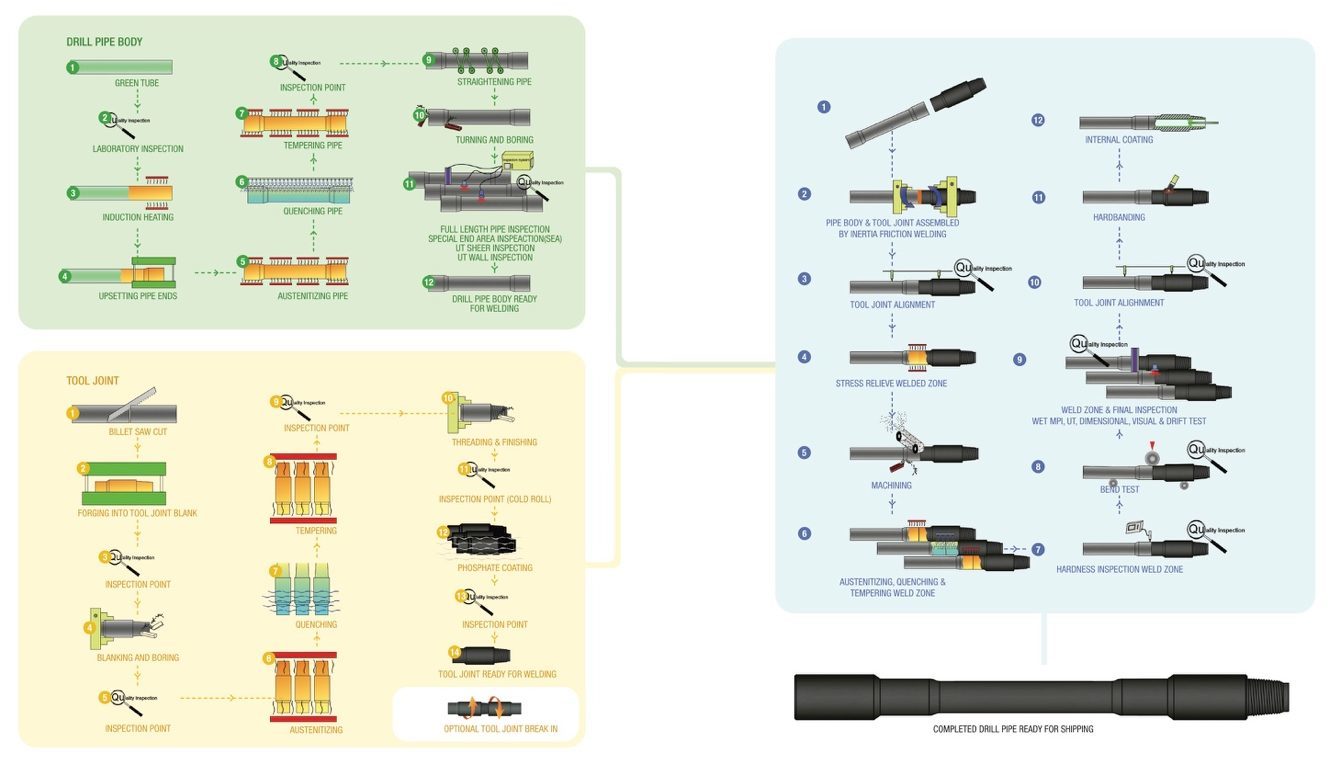

Yntegraal swier gewicht drill piip is de oergong sône tusken drill kraach en drill piip.It kin net allinnich ferminderjen stress-formaasje yn de ferbining fan drill kraach en drill piip, mar ek ferminderjen de wear op OD.

Yntegraal swier gewicht drill piip wurdt makke fan ien stik AISI 4145H bêst bar, folslein waarmte behannele, alle fysike eigenskippen oerien mei API spec7 lêste edysje.

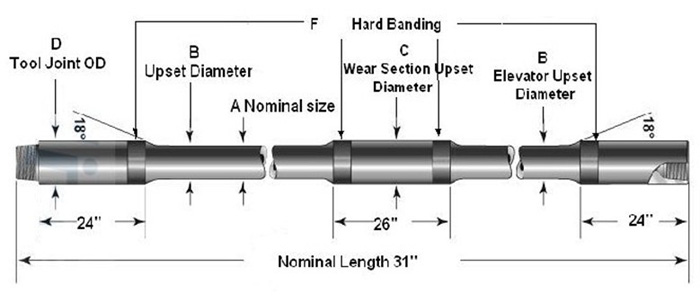

HWDP syn wear ferset hurde banding is standert op ark gewrichten ferbinings en sintrale upset.De soarten hurde banding omfetsje Arnco 100XT en 100XT.Alle triedden binne phosphated, koperisearre of kâld bewurke.Alle ferbinings binne foarsjoen fan yndrukt stielen tried protectors.Alle platen wurde ferwurke mei CNC-draaibanken - dûbele skuorren en spesjale triedden.

Technyske spesifikaasjes en parameters

| Grutte (yn) | OD (yn) | ID (yn) | Tool Joint OD (yn) | Tool Joint ID (yn) | Ferbining | Max. lift diameter (yn) | Sintrale oerstjoer dia.(yn) | Min.drift dia.size(in) |

| 3 1/2 | 3 1/2 | 2 1/4 | 4 3/4 | 2 1/4 | NC38 | 3 7/8 | 4 | 2 |

| 2 1/16 | 2 1/16 | 1 13/16 | ||||||

| 4 | 4 | 2 1/2 | 5 1/4 | 2 1/2 | NC40 | 4 3/16 | 4 1/2 | 2 1/4 |

| 2 9/16 | 2 9/16 | 2 5/16 | ||||||

| 4 1/2 | 4 1/2 | 2 11/16 | 6 1/4 | 2 11/16 | NC46 | 4 11/16 | 5 | 2 7/16 |

| 2 3/4 | 2 3/4 | 2 1/2 | ||||||

| 2 13/16 | 2 13/16 | 2 9/16 | ||||||

| 5 | 5 | 3 | 6 5/8 | 3 | NC50 | 5 1/8 | 5 1/2 | 2 3/4 |

| 5 1/2 | 5 1/2 | 3 1/4 | 7 | 3 1/4 | 5 1/2 FH | 5 11/16 | 6 | 3 |

| 3 3/8 | 3 3/8 | 3 1/8 | ||||||

| 3 7/8 | 3 7/8 | 3 5/8 | ||||||

| 4 | 4 | 3 3/4 | ||||||

| 6 5/8 | 6 5/8 | 4 | 8 | 4 | 6 5/8 FH | 6 15/16 | 7 1/8 | 3 3/4 |

| 4 1/2 | 4 1/2 | 4 1/4 | ||||||

| 5 | 5 | 4 3/4 |

| Spiraal swier gewicht drill pipe | ||||||||

| Spesifikaasje mm | Tube | Joint | ||||||

| ID mm | Lift upsetmm | lift groove / Slip bûten diametermm | Skroef yn diameter mm | Spiral groove djipte mm | Thread Type | OD mm | ID mm | |

| 88.9(3 1/2) | 54 | 92.1 | 88,9 | 101.6 | 9.5 | NC38 | 120,6 | 54 |

| 114.3(4 1/2) | 69.8 | 117,5 | 114.3 | 127 | 12.7 | NC46 | 158,8 | 69.8 |

| 127.0(5) | 76.2 | 130,2 | 127 | 139,7 | 12.7 | NC50 | 165.1 | 76.2 |

| Steel Mark | Gemyske gearstalling% | ||||||||

| C | Si | Mn | P | S | Cr | Mo | Cu | Al | |

| 4145H | 0.42~0.48 | 0.15~0,35 | 0,90~1.20 | ≤0,03 | ≤0,03 | 0,90~1.20 | 0.15~0.25 | ≤0.2 | 0.025~0.045 |

| Oare eleminten:N≤0.015,Ni≤0,5 | |||||||||

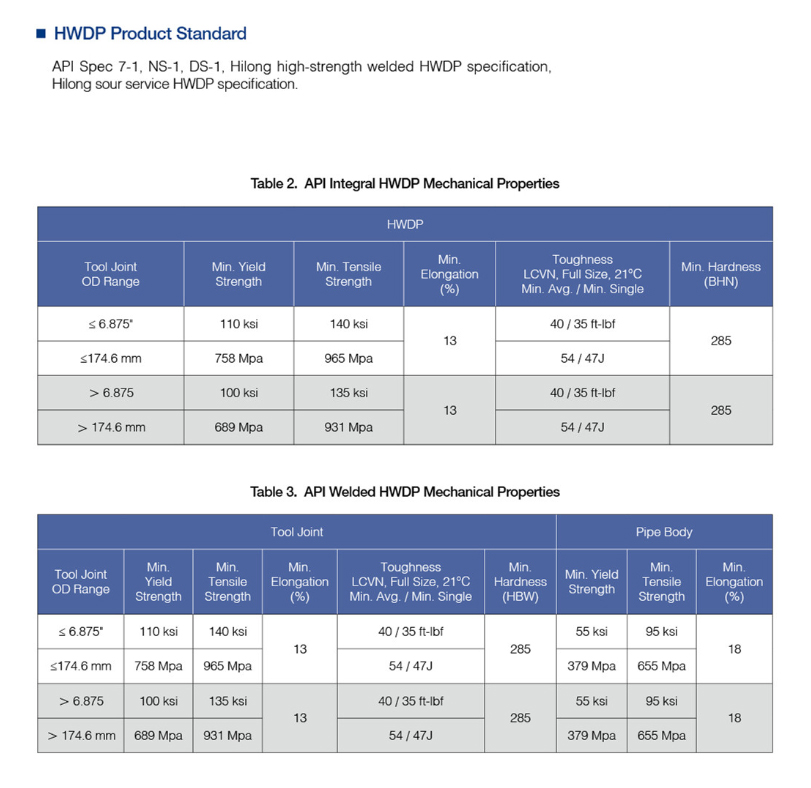

| Oanfraach | Materiaal | Grutte | Yield Strength (Min KSI) | Ultimate Strength (Min KSI) | Hardheid Brinell (HB) | Ferlinging (A%) | Min CHarpy (ft-lbs @+20 °C) |

| Yntegraal Standert | AISI 4145H wizige | Alle | 110 | 140 | 285 oant 340 | 13 | 40 |

| Welded Standert | AISI 1340 wizige | Alle | 65 | 95 | 235 (maksimaal) | 18 | 30 |

| Welded NS-1 | AISI 4140H wizige | Alle | 120 | 140 | 285 oant 340 | 13 | 40 |

| Welded Standert | AISI 4140H wizige | Boppe 7 1/4" | 120 | 140 | 285 oant 340 | 13 | 40 |

| Standert laske | AISI 4140H wizige | Oant 7 1/4" | 100 | 135 | 285 oant 340 | 13 | 40 |

| HWDP-110 HW MS | ASCOWELL C | Boppe 6 3/4" | 110 | 140 | 285 oant 340 | 13 | 0 |

| HWDP-110 HW MS | ASCOWELL C | Oant 6 3/4" | 100 | 135 | 285 oant 340 | 13 | 55 |

| HWDP-65 HW MS (tool joint) | ASCOWELL C | Boppe 6 3/4" | 110 | 140 | 285 oant 340 | 13 | 55 |

| HWDP-65 HW MS (tool joint) | ASCOWELL C | Oant 6 3/4" | 100 | 135 | 285 oant 340 | 13 | 55 |

| HWDP-65 HW MS | AISI 1340 wizige | Alle | 65 | 95 | 235 (maksimaal) | 18 | 30 |