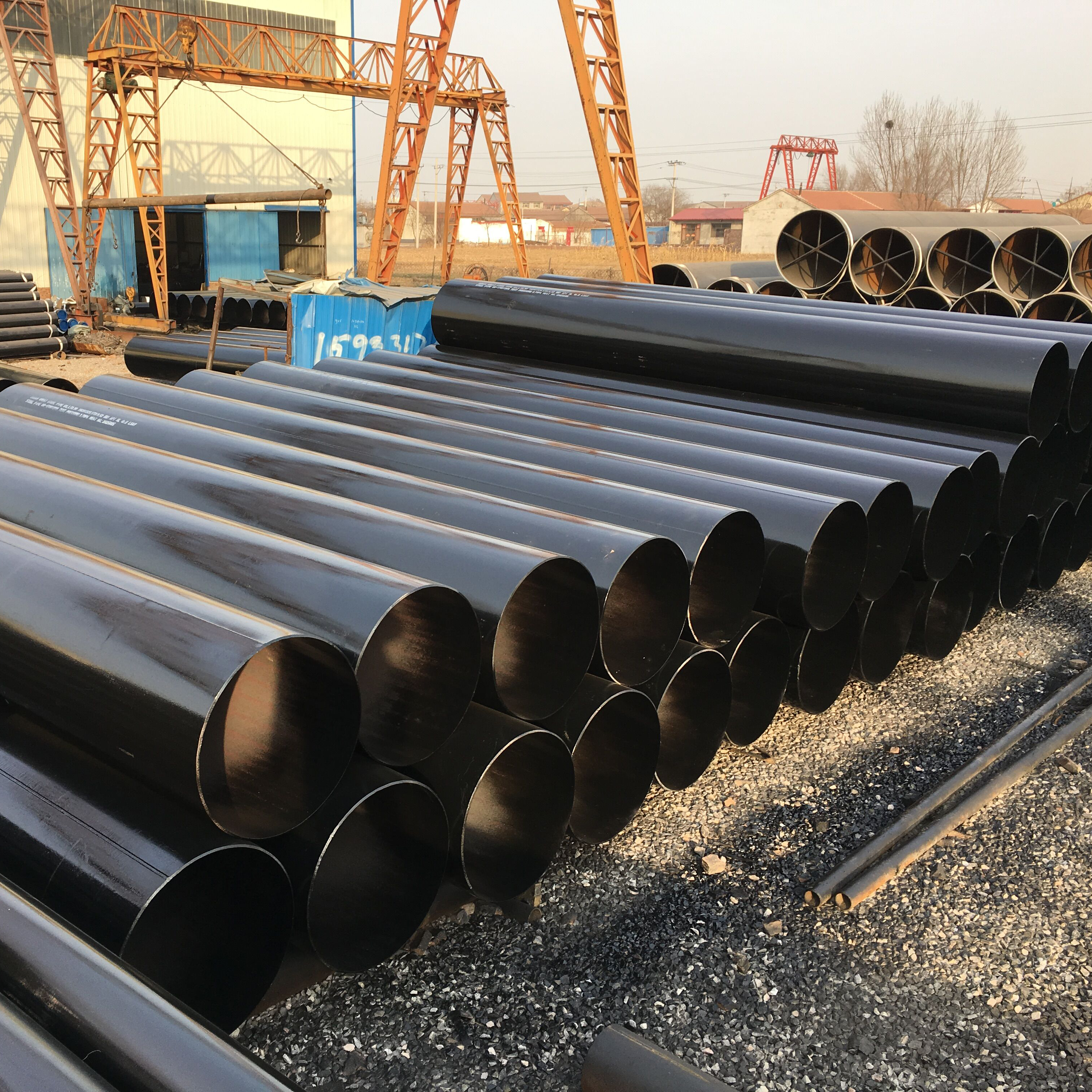

LSAW Steel Pipe

LSAW Steel Pipe (Longitudinale Seam Submerged Arc Welding Pipe)

UOE LSAW STEEL PIPES

De UOE-mûne hat de meast avansearre technology en proses, berikt hege produksje-effisjinsje, stabile produktkwaliteit en is foarsjoen fan folsleine ynspeksjeapparatuer.UOE mûne oannimt U & O foarmjen, de foarme pipen wurde laske binnen troch fiif ynterne welding stasjons mei trije triedden, en laske bûten troch fjouwer eksterne welding stasjons mei trije triedden.Yn oerienstimming mei ferskillende easken fan de klanten, de laske piip kin wurde útwreide itsij troch meganyske of hydrostatic útwreidzje te ferbetterjen dimensionale krektens, en elimineren oerbleaune stress.

Spesifikaasjes

Buitendiameter 508 mm - 1118 mm (20" - 44")

Muorre dikte: 6.0-25.4mm 1/4"-1"

Kwaliteitsnoarmen: API,DNV,ISO,DEP,EN,ASTM,DIN,BS,JIS,GB,CSA

Lingte: 9-12.3m (30'- 40')

Graden: API 5L A-X90, GB/T9711 L190-L625

JOCE LSAW PIPES (PRES BENDING)

Dit is grutte diameter longitudinaal ûnderdompele arc welded (LSAW) pipe produksje line yn Sina.De mûne oannimt foarútstribjende bûgen proses, featuring evenredich ferdield foarmjen stress, hege unifoarmens fan diminsje, ûneinige maten fariaasje & breed prouct berik, en hege fleksibiliteit, ensfh

Spesifikaasjes

Bûtendiameter:Φ406-1626 mm (16" - 64")

Dikte fan de muorre:6,0-75 mm (1/4" - 3")

Kwaliteit Standards:API,DNV,ISO,DEP,EN,ASTM,DIN,BS,JIS,GB,CSA

Lingte:3-12,5 m (10'- 41')

Graden:API 5L A-X100, GB / T9711 L190-L690

LSAW Steel Pipe Dimension

| Out Diameter | Muorre dikte (mm) | ||||||||||||||||

| Inch | mm | 6.4 | 7.1 | 7.9 | 9.53 | 12.7 | 14.3 | 15.9 | 19.1 | 22.2 | 25.4 | 28.6 | 31.8 | 34.9 | 38.1 | 41.3 | 44,5 |

| 16 | 406.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 18 | 457 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 20 | 508 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 22 | 559 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 24 | 610 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 26 | 660 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 28 | 711 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 30 | 762 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 32 | 813 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 34 | 864 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 36 | 914 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 38 | 965 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 40 | 1016 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 42 | 1067 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 44 | 1118 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 46 | 1168 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 48 | 1219 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 52 | 1321 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 56 | 1422 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 60 | 1524 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 64 | 1626 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Tolerânsje fan bûtendiameter en muorredikte

| Soarten | Standert | |||||

| SY/T5040-2000 | SY/T5037-2000 | SY/T9711.1-1977 | ASTM A252 | AWWA C200-97 | API 5L PSL1 | |

| Tube ein OD ôfwiking | ±0,5%D | ±0,5%D | -0.79 mm~+2.38mm | <±0.1%T | <±0.1%T | ± 1,6 mm |

| dikte fan de muorre | ±10,0%T | D<508mm, ±12,5%T | -8%T~+19,5%T | <-12,5%T | -8%T~+19,5%T | 5.0mm |

| D>508mm, ±10,0%T | T≥15.0mm, ±1.5mm | |||||

Gemyske gearstalling en meganyske eigenskippen

| Standert | Klasse | Gemyske gearstalling (max)% | Mechanyske eigenskippen (min) | |||||

| C | Mn | Si | S | P | Yield Strength (Mpa) | Treksterkte (Mpa) | ||

| GB/T700-2006 | A | 0.22 | 1.4 | 0,35 | 0.050 | 0.045 | 235 | 370 |

| B | 0.2 | 1.4 | 0,35 | 0.045 | 0.045 | 235 | 370 | |

| C | 0.17 | 1.4 | 0,35 | 0.040 | 0.040 | 235 | 370 | |

| D | 0.17 | 1.4 | 0,35 | 0.035 | 0.035 | 235 | 370 | |

| GB/T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| BS En10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 | |

| S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 | |

| DIN 17100 | ST37-2 | 0.2 | - | - | 0.050 | 0.050 | 225 | 340 |

| ST44-2 | 0.21 | - | - | 0.050 | 0.050 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0,55 | 0.040 | 0.040 | 345 | 490 | |

| JIS G3101 | SS400 | - | - | - | 0.050 | 0.050 | 235 | 400 |

| SS490 | - | - | - | 0.050 | 0.050 | 275 | 490 | |

| API 5L PSL1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 | |

| X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 | |

| X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 | |

| X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 | |

| X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 | |

Licht oalje, waarm dip galvanisearre, elektrogalvanisearre, swart, keal, lakcoating / anti-roest oalje, beskermjende coating