Nikkel alloy pipe

| Materiaal | Monel / Inconel / Hastelloy / Duplex Steel / PH Steel / Nikkel Alloy |

| Foarm | Rûn, Forging, Ring, Coil, Flens, Disc, Folie, Sferysk, Lint, Fjouwerkant, Bar, Pipe, Sheet |

| Klasse | N02200, N02201, N04400, N06600, N06601, N06625, N06690, N08810, N08825, N08020, N08020, N08028, N0802801, N0802801, N0802801, N0802801 665, N06022, N06030, GH3030, GH3036 GH5188 Inconel706 Inconel600 InconelX-750 Inconel718 Inconel625 Inconel 617 Inconel601 Inconel690NS 1NS1NS3 NS112, Incoloy800H, NO8810 NS111 NS336 NS142 Incoloy825 NS355 Hastelloy C-4 Monel K500, N05500 |

| Spesifikaasje | Oaren: 253Ma, 254SMo, 654SMo, F50 (UNS S32100) F60, F61, F65, 1J22, N4, N6 ensfh |

| Legearing :lege 625, Alloy 20/28/31 | |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g; | |

| Hastelloy B / UNS N10001,Hastelloy B-2 / UNS N10665 / DIN W. Nr.2.4617,Hastelloy C,Hastelloy C-4 / UNS N06455 / DIN W. Nr.2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr.2.4602,Hastelloy C-276 / UNS N10276 / DIN W. Nr.2.4819,Hastelloy X / UNS N06002 / DIN W. Nr.2.4665 | |

| Haynes: Haynes 230/556/188; | |

| Inconel Searjes:Inconel 600/601/602CA/617/625/690/713/718/738/X-750,Timmerman 20; | |

| Inconel 718 / UNS N07718 /N04400/N06600/N08825/DIN W. Nr.2.4668,Inconel 601 / UNS N06601 / DIN W. Nr.2.4851, Inconel 625 / UNS N06625 / DIN W. Nr.2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr.2.4669,Inconel 600 / UNS N06600 / DIN W. Nr.2.4816 | |

| Inkoloy:Inkoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132, GH3030, GH3039, GH3128, GH4180, GH3044 | |

| Monel:Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60; | |

| Nimonic: Nimonic 75/80A/90/A263 ; | |

| Wire: 0.01-10mm Strip: 0.05 * 5.0-5.0 * 250mm Bar: φ4-50mm; Lengte 2000-5000mm Pipe: φ6-273mm;δ1-30mm; Lengte 1000-8000mm Blêd: δ 0.8-36mm; Breedte 650-2000mm; Lengte 800-4500mm | |

| Produkt Skaaimerken | 1. Neffens de tarieding proses kin wurde ferdield yn deformation superalloys, casting superalloys en poedermetallurgy superalloys. 2. Neffens de fersterking modus, der binne fêste oplossing fersterkjen type, delslach fersterkjen type, okside dispersion fersterkjen type en fiber fersterkjen type, ensfh |

| Standert | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Ynspeksje | ISO, SGS, BV, ensfh. |

| Oanfraach | Komponinten mei hege temperatueren lykas turbinebladen, geleidevaanen, turbineskiven, hege druk compressor skiven, machine manufacturing en ferbaarningskeamers brûkt by de fabrikaazje fan loftfeart, marine en yndustriële gasturbines |

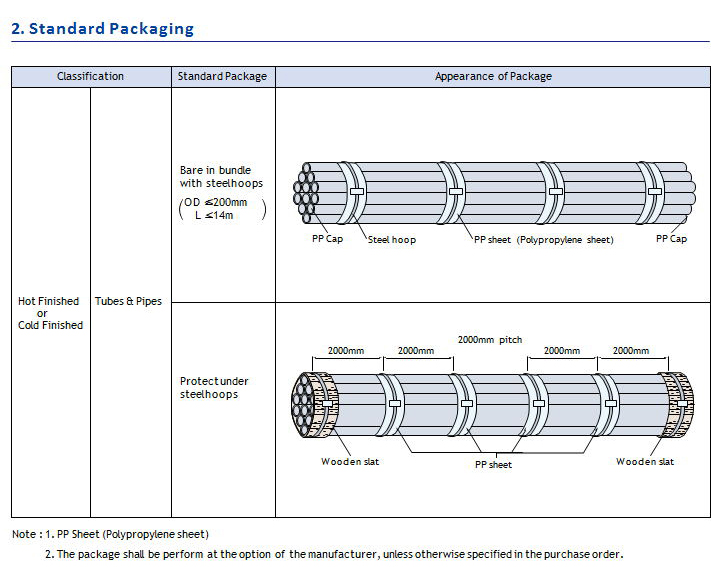

| Ferpakking | 1. gefallen ynpakt yn houten gefallen 2. papier ferpakking 3. plestik ferpakking 4. foam ferpakking Ferpakking neffens klant easken of produkten |

| Befalling | 7-25 dagen of neffens it produkt |

| Betelling | L / C, D / A, D / P, T / T, Western Union, MoneyGram, neffens klant easken betellingen foar offline oarders. |

| STOCKED SIZE | |||||||||||||

| GRUTTE | NIKKEL | LEGEARING | LEGEARING | LEGEARING | LEGEARING | LEGEARING | LEGEARING | LEGEARING | LEGEARING | LEGEARING | LEGEARING | GRUTTE | |

| 1/16" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 1,65 mm | |

| 0.010 | X | X | .25mm | ||||||||||

| 0.020 | X | .51mm | |||||||||||

| 1/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 3.18mm | |

| 0.010 | X | 0.25 | |||||||||||

| 0.012 | X | 3,05 mm | |||||||||||

| 0.016 | X | .31mm | |||||||||||

| 0.020 | X | X | X | .51mm | |||||||||

| 0.028 | X | X | X | X | .71mm | ||||||||

| 0.035 | X | X | X | X | .89mm | ||||||||

| 3/16" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 4.76mm | |

| 0.010 | X | .25mm | |||||||||||

| 0.016 | X | X | .31mm | ||||||||||

| 0.020 | X | .51mm | |||||||||||

| 0.028 | X | X | X | .71mm | |||||||||

| 0.035 | X | X | X | X | X | X | .89mm | ||||||

| 0.049 | X | X | X | 1,24 mm | |||||||||

| 1/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 6,35 mm | |

| 0.016 | X | .31mm | |||||||||||

| 0.020 | X | X | X | .51mm | |||||||||

| 0.028 | X | X | X | X | X | .71mm | |||||||

| 0.035 | X | X | X | X | X | X | X | X | .89mm | ||||

| 0.049 | X | X | X | X | X | X | X | X | 1,24 mm | ||||

| 0.065 | X | X | X | X | X | X | X | 1,65 mm | |||||

| 0.083 | X | 2,11 mm | |||||||||||

| 5/16" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 7.94mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | 1,24 mm | |||||||||||

| 0.065 | X | X | X | 1,65 mm | |||||||||

| 3/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 9,53 mm | |

| 0.020 | X | .51mm | |||||||||||

| 0.028 | X | X | X | X | .71mm | ||||||||

| 0.035 | X | X | X | X | X | X | X | X | .89mm | ||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0.065 | X | X | X | X | X | X | X | 1,65 mm | |||||

| 0.083 | X | X | 2,11 mm | ||||||||||

| 7/16" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 11,1 mm | |

| 0.035 | X | .89mm | |||||||||||

| 0.065 | X | 1,65 mm | |||||||||||

| 1/2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 12,7 mm | |

| 0.028 | X | X | X | X | .71mm | ||||||||

| 0.035 | X | X | X | X | X | X | X | X | X | .89mm | |||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0.058 | X | X | 1,47 mm | ||||||||||

| 0.065 | X | X | X | X | X | X | X | X | 1,65 mm | ||||

| 0.083 | X | X | X | 2,11 mm | |||||||||

| 0.095 | X | X | 2,41 mm | ||||||||||

| 0.109 | X | 2,77 mm | |||||||||||

| 0.120 | X | 3,05 mm | |||||||||||

| 9/16" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 14,3 mm | |

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | X | X | X | 1,24 mm | ||||||||

| 0.065 | X | X | X | 1,65 mm | |||||||||

| 0.083 | X | 2,11 mm | |||||||||||

| 5/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 15.9mm | |

| 0.035 | X | X | X | X | X | .89mm | |||||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0.065 | X | X | X | X | X | X | 1,65 mm | ||||||

| 0.083 | X | X | 2,11 mm | ||||||||||

| 0.095 | X | X | 2,41 mm | ||||||||||

| 0.120 | X | 3,05 mm | |||||||||||

| 3/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 19,1 mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | X | X | X | X | X | .89mm | |||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0.065 | X | X | X | X | X | X | X | X | X | X | 1,65 mm | ||

| 0.083 | X | X | X | X | X | X | X | 2,11 mm | |||||

| 0.095 | X | X | 2,41 mm | ||||||||||

| 0.109 | X | X | X | X | 2,77 mm | ||||||||

| 0.120 | X | X | X | 3,05 mm | |||||||||

| 0.125 | X | X | 3.18 | ||||||||||

| 7/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 22,2 mm | |

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | X | X | 1,24 mm | |||||||||

| 0.065 | X | X | X | X | 1,65 mm | ||||||||

| 0.083 | X | X | 2,11 mm | ||||||||||

| 0.120 | X | 3,05 mm | |||||||||||

| 1" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 25,4 mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | X | X | X | X | .89mm | ||||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0.065 | X | X | X | X | X | X | X | X | 1,65 mm | ||||

| 0.083 | X | X | X | X | X | X | X | 2,11 mm | |||||

| 0.095 | X | X | 2,41 mm | ||||||||||

| 0.109 | X | X | X | X | 2,77 mm | ||||||||

| 0.120 | X | X | X | 3,05 mm | |||||||||

| 0.125 | X | 3.18 | |||||||||||

| 0.134 | X | X | |||||||||||

| 1 1/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 28.6mm | |

| 0.049 | X | ||||||||||||

| 1 1/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 31,8 mm | |

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | 1,24 mm | |||||||||||

| 0.065 | X | X | X | X | X | X | 1,65 mm | ||||||

| 0.083 | X | X | X | X | 2,11 mm | ||||||||

| 0.095 | X | 2,41 mm | |||||||||||

| 0.109 | X | 2,77 mm | |||||||||||

| 0.120 | X | X | 3,05 mm | ||||||||||

| 0.125 | X | 3.18 | |||||||||||

| 1 1/2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 38.1mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | .89mm | ||||||||||

| 0.049 | X | X | X | 1,24 mm | |||||||||

| 0.065 | X | X | X | X | X | X | 1,65 mm | ||||||

| 0.083 | X | X | X | 2,11 mm | |||||||||

| 0.095 | X | X | 2,41 mm | ||||||||||

| 0.109 | X | X | X | 2,77 mm | |||||||||

| 0.120 | X | X | X | 3,05 mm | |||||||||

| 0.125 | X | 3.18 | |||||||||||

| 1 5/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 41,3 mm | |

| 0.065 | X | 1,65 mm | |||||||||||

| 0.083 | X | 2,11 mm | |||||||||||

| 1 3/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 44,5 mm | |

| 0.065 | X | X | X | 1,65 mm | |||||||||

| 1 7/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 47.6mm | |

| 0.083 | X | 2,11 mm | |||||||||||

| 2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 50.8mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | .89mm | ||||||||||

| 0.049 | X | X | 1,24 mm | ||||||||||

| 0.065 | X | X | X | X | X | 1,65 mm | |||||||

| 0.083 | X | X | X | X | 2,11 mm | ||||||||

| 0.095 | X | 2,41 mm | |||||||||||

| 0.109 | X | X | 2,77 mm | ||||||||||

| 0.120 | X | X | X | 3,05 mm | |||||||||

| 0.125 | X | X | 3.18 | ||||||||||

| 2 1/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 57,2 mm | |

| 0.035 | X | .89mm | |||||||||||

| 0.049 | X | 1,24 mm | |||||||||||

| 0.120 | X | 3,05 mm | |||||||||||

| 2 1/2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 63,5 mm | |

| 0.065 | X | X | X | X | 1,65 mm | ||||||||

| 0.083 | X | X | 2,11 mm | ||||||||||

| 0.109 | X | 2,77 mm | |||||||||||

| 0.120 | X | X | 3,05 mm | ||||||||||

| 3" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 76,2 mm | |

| 0.065 | X | X | X | X | 1,65 mm | ||||||||

| 0.083 | X | X | X | 2,11 mm | |||||||||

| 0.120 | X | X | 3,05 mm | ||||||||||

| 0.125 | X | 3.18 | |||||||||||

| 0.250 | X | 6.35 | |||||||||||

| 3 1/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 82.6mm | |

| 0.125 | X | 3.18 | |||||||||||

| 3 1/2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 88.9mm | |

| 0.375 | 9,53 mm | ||||||||||||

| Standert | – ASTM A270,ASTM A249,ASTM A511,ASTM A778,ASTM A312,ASTM A358,ASTM A409,ASTM A213,ASTM A790,ASTM A268,ASTM A269,ASTM A554,ASTM B338,ASTM B673,ASTM B673,ASTM B673 B675, ASTM B676, ASTM B690, ASTM A928, ASME B36.19, ASME B36.10– EN10216-5, EN10217-7, DIN 17456, DIN 17458 – JIS G3463, JIS G3119, JIS G3446, JIS G3218, JIS G3258, JIS G3448, JIS H4631 – DEP 31, DEP 40, DEP 20, DEP 32, DNV-OS-F101 |

| Grutte Range | OD:NPS 1/8 -80, BN 6 – 2000, 10,3 – 2030, Alao kapilaryWT:Sch5s-Sch160s, SchXXH, STD, XS, XXSLingte:Oanpassing |

| Klasse | S32750, 00Cr25Ni7Mo4N, 022Cr25Ni7Mo4N, 1.441, 1.4307/1.4301/304L/3, S30408/S30403, 0Cr18Ni9DQ, 0Cr18Ni9DQ, 3.494, S30408/S30403 , 1.4948, 06Cr23Ni13, S30908, SUS309S, SUS310S, 1.4845, S31008, S31008S, 06Cr25Ni20, 0Cr25Ni20, 1.4401/1.4404/316/31, S31635, SUS316Ti, 1.4571, 1.4571/316Ti, S31703, 022Cr19Ni13Mo3, 00Cr17Ni12Mo2, S317.70, S317.70, S317. SUS410S, 1.4, 06Cr13, S11306, 0Cr13, S42000, SUS420J1, 1.4021, SUS420J2, 1.4028. 07, 304/304L, 304DQ , 304H, 309S, 310S, 316/316L, 316Ti, 317L, 410S, 420J1, 420J2, 430F, 254Smo, 1.4529, HC276, 800, 602, 800, 600, 800, 601, 801 0, 630, XM19, C4, S30815 , S31254, 174PH, F51, F60, F53, S32760, 253MA, HC2000, 800H, 926, GH2132, GH4169, GH3030, GH3039, GH4151, N8Br600, N54300 N08810 |

| ASTM B111 / ASME SB111 | Standert spesifikaasje foar koperen en koperlegering naadleaze kondensorbuizen en ferrule | |

| ASTM B161 / ASME SB161 | Standert spesifikaasje foar Nikkel Seamless Pipe en Tube | |

| ASTM B163 / ASME SB163 | Standert spesifikaasje foar seamless nikkel en nikkel Alloy Condenser en Heat-Exchanger Tubes | |

| ASTM B165 / ASME SB165 | Standert spesifikaasje foar nikkel-koperlegering (UNS N04400) * Naadleaze buis en buis | |

| ASTM B167 / ASME SB167 | Standert spesifikaasje foar nikkel-chroom-izerlegeringen, nikkel-chroom-kobalt-molybdeenlegering (UNS N06617), en nikkel-izer-chroom-wolframlegering (UNS N06674) Naadleaze buis en buis | |

| ASTM B395 / ASME SB395 | Standert spesifikaasje foar U-Bend seamless koper en koperlegering waarmtewikseler en kondensorbuizen | |

| ASTM B407 | Standert spesifikaasje foar Nikkel-Iron-Chromium Alloy Seamless Pipe en Tube | |

| ASTM B423 / ASME SB423 | Standert spesifikaasje foar nikkel-chroom-molybdeen-kolumbium-legeringen (UNS N06625 en UNS N06852) en nikkel-chroom-molybdeen-silicium-legeringen (UNS N06219) Pipe en buis | |

| ASTM B444 / ASME SB444 | Standert spesifikaasje foar nikkel-chroom-molybdeen-kolumbium-legeringen (UNS N06625 en UNS N06852) en nikkel-chroom-molybdeen-silicium-legeringen (UNS N06219) Pipe en buis | |

| ASTM B622 / ASME SB622 | Standert spesifikaasje foar seamless nikkel en nikkel-kobalt alloy Pipe en Tube | |

| ASTM B668 / ASME SB668 | Standert spesifikaasje foar UNS N08028 en N08029 Seamless Pipe en Tube | |

| ASTM B677 / ASME SB677 | Standert spesifikaasje foar UNS N08925, UNS N08354, en UNS N08926 Seamless Pipe and Tube | |

| ASME SB690 / ASME SB690 | Standert spesifikaasje foar izer-nikkel-chroom-molybdeen-legeringen (UNS N08366 en UNS N08367) Naadleaze piip en buis | |

| ASTM B705 / ASME SB705 | Standert spesifikaasje foar nikkellegering (UNS N06625, N06219 en N08825) Welded Pipe | |

| ASTM B729 / ASME SB729 | Standert spesifikaasje foar naadleaze UNS N08020, UNS N08026, en UNS N08024 nikkel alloy piip en buis | |

| ASTM B829 / ASME SB829 | Standert spesifikaasje foar Algemiene easken foar nikkel en nikkel Alloys Seamless Pipe en Tube |

Gemyske gearstalling:

| Klasse | Gemyske gearstalling | ||||||||

| C | Si max | Mn max | P | S | Ni | Cr | Mo | Ti | |

| 200 | 0.15 | 0,35 | 0,35 | 0.010 | 99 min | ||||

| 201 | 0.02 | 0,35 | 0,35 | 0.010 | 99 min | ||||

| 400 | 0.30 | 0,50 | 2.00 | 0.024 | 63 min | ||||

| 600 | 0.15 | 0,50 | 1.00 | 0.015 | 72 min | 14 – 17 | |||

| 601 | 0.10 | 0,50 | 1.00 | 0.015 | 58 – 63 | 21 – 25 | |||

| 625 | 0.10 | 0,50 | 0,50 | 0.015 | 0.015 | 58 min | 20 – 23 | 8 – 10 | 0.40 max |

| 800 | 0.10 | 1.00 | 1,50 | 0.03 | 0.015 | 30 – 35 | 19 – 23 | 0.15 0.60 | |

| 800H | 0.05 0.10 | 1.00 | 1,50 | 0.015 | 30 – 35 | 19 – 23 | 0.15 0.60 | ||

| 825 | 0.05 | 0,50 | 1.00 | 0.03 | 38 – 46 | 19,5 23,5 | 2,5 3,5 | 0.6 1.2 | |

| 904L | 0.02 | 1.00 | 2.00 | 0.030 | 0.015 | 24 – 26 | 19 23 | 4 5 | |

Nikkel Alloy Fysike Eigenskippen

| LEGEARING | NIKKEL ALLOY DENSITY | WARMTEGELIEDING | THERMAL LINEAR, EXPANSION COEFF., (20-95 °C) | ELEKTRISCH WEERSTAND, BY 20 °C |

| G/CM³ | W/MK | 10-6/K | ΜΩ-CM | |

| NI 200/201 | 8.89 | 70,20 | 13.3 | 9 |

| NI 205/205 LC | 8.89 | 75,00 | 13.3 | 8.9 |