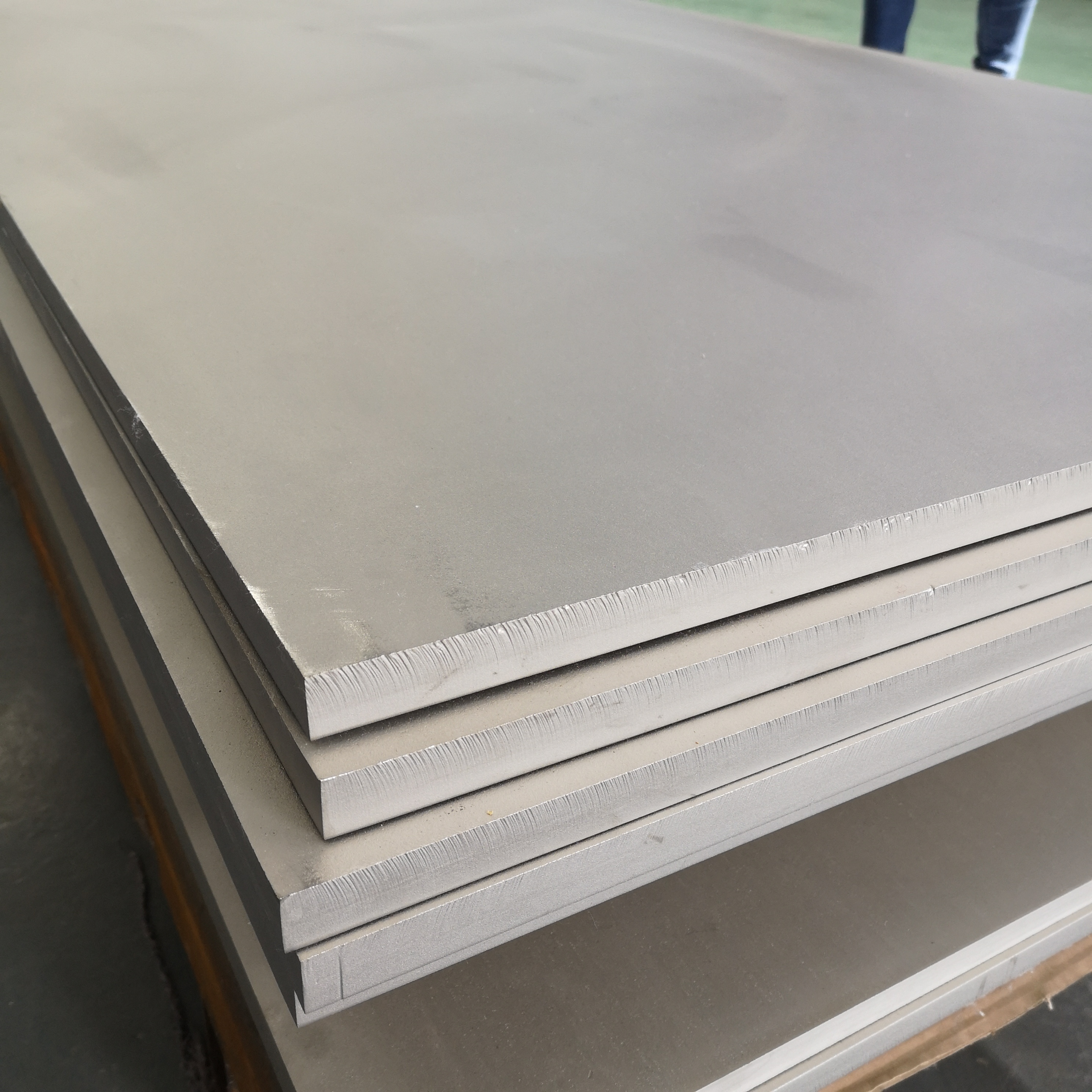

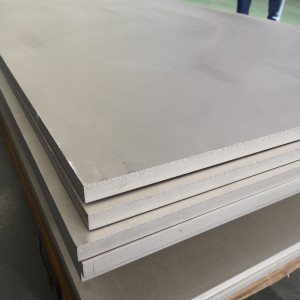

Titanium Sheet / Plaat

Common Grades

Titanium Grade 1is in unalloyed, lege sterkte titanium produkt befettet lege soerstof mei hege foarm fermogen;dizze titanium klasse wurdt brûkt yn lucht frames, waarmte útwikseling en desalination ienheden.

Titanium Grade 2is in unalloyed, medium sterkte titanium produkt.Dit titanium klasse wurdt brûkt yn lucht frames, fleanmasine motoren en marine dielen;goede weld fermogen en corrosie ferset binne syn ûnderskiedende skaaimerken.

Titanium Grade 3is in unalloyed, hege sterkte, titanium produkt providing poerbêst corrosie ferset en goede weld fermogen.Dizze titaniumklasse wurdt primêr brûkt yn loftframe en fleantúchmotordielen.

Titanium Grade 4is de heechste sterkte suver unalloyed titanium produkt.Dizze titaniumklasse wurdt hast allinich brûkt foar loftframe, fleanmasinemotordielen, marine, sjirurgyske ymplantaten, hydraulyske buizen.Goede foarmfeardigens en korrosjebestriding binne har skaaimerk.

Titanium Grade 5 (6AL-4V)is in alloyed titanium produkt befettet 6% Aluminium en 4% Vanadium;is in medium sterkte produkt.Dit titanium klasse wurdt foaral brûkt yn airframe en turbine motor dielen;en foar gebrûk yn sjirurgyske ymplantaten.Technyske ynformaasje Titanium 6AL-4V ELI is in alloyed titanium produkt befettet 6% aluminium en 4% Vanadium, ELI (Extra Low Interstitial).

6AL-2Sn-4 Zr-2 Mo (6-2-4-2)is in alloyed titanium produkt befettet 6% Aluminium, 2% Tin, 4% Zirconium, 2% Molybdenum.

6AL-6V-2Sn (6-6-2)is in alloyed titanium produkt befettet 6% Aluminium, 6% Vanadium, 2% Tin.

5AL-2.5Sn & ELI (5-2.5)is in alloyed titanium produkt befettet 5% Aluminium en 2,5% Tin.Ek ELI (Extra Low Interstitial).

8AL-1V-1 Mo (8-1-1)is in alloyed titanium produkt befettet 8% Aluminium, 1% Molybdenum en 1% Vanadium.

15V-3 Cr-4AL-3Sn (15-3-4-3)is in alloyed titanium produkt befettet 15% Vanadium, 3% Chromium, 4% Aluminium, 3% Tin.

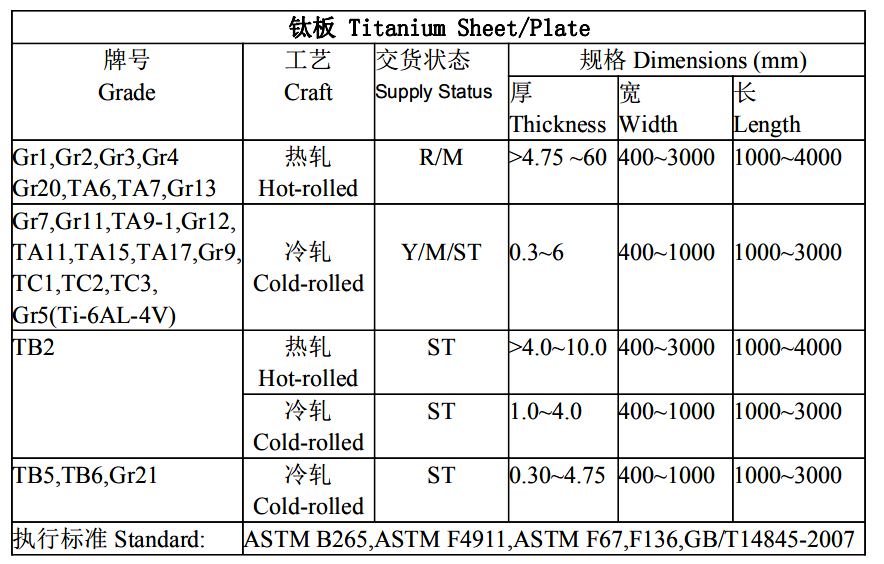

| Klasse | Status | Spesifikaasje | ||

| Gr1,Gr2,Gr4,Gr5,Gr7,Gr9,Gr11, Gr 12, Gr 16, Gr 23 | Hot Rolled (R) Kâld rôle (Y) Gegloeid (M) Solution behanneling (ST) | Dikte (mm) | Breedte (mm) | Lengte (mm) |

| 0,3-60 | ≥400 | ≤ 6000 | ||

| Titanium blêd | |||

| Dikte | Graden | ||

| .016 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .020 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .025 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .032 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .040 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .050 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .063 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .071 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .080 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .090 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .100 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .125 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

Opmerking: Oanfoljende maten beskikber, net alle werjûn maten binne beskikber út foarried.Nim dan kontakt mei ús op om de beskikberens te kontrolearjen.

| AMS:AMS 2631, AMS 4901, AMS 4907, AMS 4911ASTM: ASTM B265 Gr 23, ASTM B265 Gr 5, ASTM B265 Gr2, ASTM B265 Gr4, ASTM F136, ASTM F67MIL-T:MIL-T-9046, MIL-T-9046 CP1EN:EN 10204.3, EN 1-204:2005 3.1 NACE:NACE MR0175 LYKAS MY:ASME SB265 |

| Klasse | AMS/MIL-spesifikaasjes | ASTM spesifikaasjes |

| Klasse 1 | AMS-T-9046B CP4 AMS 4940 MIL-T-9046J CP4 | ASTM B265 Gr1 Blêd / plaat ASTM B337 Gr1 piip ASTM B338 Gr1 buis ASTM B348 Gr1 bar ASTM F67 Gr1 sjirurgysk ymplantaat |

| Klasse 2 | Grade 2 AMS-T-9046B CP3 AMS 4902 MIL-T-9046J CP3 AMS 4941 AMS 4942 AMS 4951 Welding wire | ASTM B265 Gr2 Blêd / plaat ASTM B337 Gr2 pipe ASTM B338 Gr2 buis ASTM B348 Gr2 bar ASTM F67 Gr2 sjirurgysk ymplantaat |

| Klasse 3 | AMS-T-9046B CP2 AMS 4900 MIL-T-9046J CP2 | ASTM B265 Gr3 Blêd / plaat ASTM B337 Gr3 piip ASTM B338 Gr3 buis ASTM B348 Gr3 bar ASTM F67 Gr3 sjirurgysk ymplantaat |

| Klasse 4 | AMS-T-9046B CP1 AMS-T-9047A CP70 AMS 4901 AMS 4921 MIL-T-9046J CP1 MIL-T-9047G CP70 | ASTM B265 Gr4 Blêd / plaat ASTM B337 Gr4 piip ASTM B338 Gr4 buis ASTM B348 Gr4 bar ASTM F67 Gr4 sjirurgysk ymplantaat |

| Grade 7 | ASTM B265 Gr7 Blêd / plaat ASTM B337 Gr7 piip ASTM B338 Gr7 buis ASTM B348 Gr7 bar |

| Klasse | US Spesifikaasjes | ASTM spesifikaasjes |

| Grade 5 6Al-4V | AMS 4907 ELI AMS 4911 AMS 4928 AMS 4930 ELI AMS 4931 ELI Duplex ann AMS 4963 AMS 4965 AMS 4967 AMS 4985 AMS 4991 AMS 6931 AMS 6932 MIL-T-9046J AB-1 MIL-T-9046J AB-2 (ELI) MIL-T-9046H Type 3 Comp C MIL-T-9046H Type 3 Comp D AMS-T-9046B AB-1 AMS-T-9046B AB-2 (ELI) MIL-T-9047G 6Al-4v MIL-T-9047G 6Al-4v (ELI) AMS-T-9047A 6Al-4v AMS-T-9047A 6Al-4v (ELI) | ASTM B265 Gr5 Blêd / plaat ASTM B348 Gr5 bar ASTM F136 Gr5 Implant Grade |

| Grade 9 3Al-2.5V | AMS 4943 AMS 4944 AMS 4945 AMS-T-9046B AB-5 AMS-T-9047A 3Al-2.5V MIL-T-9046J AB-5 MIL-T-9047 3Al-2.5V | ASTM B265 Gr6 Blêd / plaat ASTM B348 Gr6 bar |

| Grade 23 6Al-4V ELI | AMS 4907 AMS 4930 AMS 6932 AMS-T-9046 AB-2 6AL-4V (ELI) AMS-T-9047 AB-2 6AL-4V (ELI) MIL-T-9046 AB-2 6AL-4V (ELI) MIL-T-9047 6AL-4V (ELI) | ASTM B265 Gr23 blêd / plaat / strip ASTM B348 Gr23 bar/billet ASTM F136 Gr23 Implant Gra |

Gemyske gearstalling

| Klasse | Gemyske gearstalling, gewicht persintaazje (%) | ||||||||||||

| C ≤ | O ≤ | N ≤ | H ≤ | Fe ≤ | Al | V | Pd | Ru | Ni | Mo | Oare eleminten Max.elk | Oare eleminten Max.totaal | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5~6.75 | 3.5~4.5 | - | - | - | - | 0.1 | 0.4 |

| gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12~0.25 | - | 0.12~0.25 | - | 0.1 | 0.4 |

| gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12~0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04~0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5~4.5 | - | - | - | - | 0.1 | 0.1 |

Fysike eigenskippen

| Klasse | Fysike eigenskippen | ||||||

| Treksterkte Min | Yield sterkte (0.2%, offset) | Verlenging in 50 mm Min (%) | |||||

| ksi | MPa | Min | Max | ||||

| ksi | MPa | ksi | MPa | ||||

| Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr4 | 80 | 550 | 70 | 483 | 95 | 655 | 15 |

| Gr5 | 130 | 895 | 120 | 828 | - | - | 10 |

| gr7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| gr9 | 90 | 620 | 70 | 483 | - | - | 15 |

| Gr11 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr12 | 70 | 483 | 50 | 345 | - | - | 18 |

| Gr16 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | - | - | 10 |

Tolerânsje (mm)

| Dikte | Breedte tolerânsje | ||

| 400~1000 | 1000~2000 | >2000 | |

| 5.0-6.0 | ±0.35 | ±0.40 | ±0.60 |

| 6.0-8.0 | ±0.40 | ±0.60 | ±0,80 |

| 8.0-10.0 | ±0,50 | ±0.60 | ±0,80 |

| 10.0-15.0 | ±0,70 | ±0,80 | ±1.00 |

| 15.0-20.0 | ±0,70 | ±0,90 | ±1.10 |

| 20.0-30.0 | ±0,90 | ±1.00 | ±1,20 |

| 30.0-40.0 | ±1.10 | ±1,20 | ±1,50 |

| 40.0 ~ 50.0 | ±1,20 | ±1,50 | ±2.00 |

| 50.0 ~ 60.0 | ±1,60 | ±2.00 | ±2,50 |