I-Titanium Ring

Amakhonkco amakhulu e-titanium enziwa ngumatshini omkhulu wokusila, amakhonkco amancinci e-titanium anokufezekiswa ngomatshini wokubumba.Njengenkampani engaphezulu kweminyaka engama-20 yamava emveliso, sinothotho lwenkqubo yokubumba engqongqo kunye nencwadana yokusebenza, kubandakanya amanyathelo okufudumeza, ixesha lokufudumeza kunye nexesha lokugcinwa kobushushu.I-35MN kunye ne-16MN umatshini wokugaya ngokukhawuleza waqinisekisa ukubunjwa okuphindaphindiweyo kwinqanaba lobushushu obufanelekileyo, kwaye utshintshe isakhiwo sangaphakathi somzimba we-titanium rings.Kuphuculwe kakhulu umgangatho weemveliso zethu.

Ukongeza kwindandatho ye-titanium, sikwabonelela ngokuveliswa kwediski ye-titanium, ibhloko ye-titanium njl.

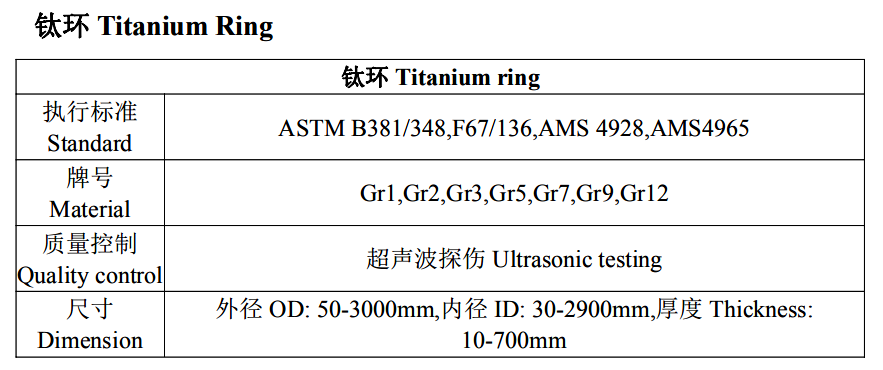

| Igama lemveliso | I-Titanium Ring |

| Ubungakanani | OD (max3000mm)×Isazisi (max2900mm)×ubude (obona bude bubuninzi 1000mm) |

| IBanga | TA1/TA2/TA5/TA6/TA9/TA10/TA15/TA19/TC1/TC2/TC4/TC11/ GR1/GR2/GR5/GR7/GR9/GR12/GR23 |

| Imigangatho | ASTM B381/348,F67/136,AMS4928,AMS4965,I-AMS,MIL,I-DIN,BS,I-JIS,GB / T,ISOnjl |

| Ukuxinana | I-4.51g / cm3 Ukusebenza okuphezulu kwimizi-mveliso, i-gr12 ye-Titanium eyenziwe ngomsesane wokuqengqeleka |

| Iteknoloji | Ukubumba, ukuqengqeleka, ukugaya ukusebenza okuphezulu kwimizi-mveliso yokubumba i-GR12 ye-titanium yokubumba iringi |

| Uhlobo | Inkqubo ye-ringless ring rolling ibandakanya ukusika umngxuma kwizinto ezibunjiweyo kunye nokuqengqeleka kwindandatho encinci. Xa kuthelekiswa nokudubula kwepleyiti okanye i-butt welding, i-ring forged forged ring ibonelela ngophuculo olugxile kumsesane ogudileyo womphezulu. Umsesane osebenza kakhulu owenziwe kwimizi-mveliso i-GR12 titanium eyenziwe ngomjikelo weringi |

| Isicelo | 1. Electroplating;2.Itekhnoloji yekhemikhali kunye nepetrochemical;3.Ukusebenza kwezonyango kuphezulu kwimizi-mveliso yokubumba i-GR12 titanium yokubumba iringi |

ASTM B381/348,F67/136,AMS4928,AMS4965

Ukuqulunqwa kweekhemikhali

| IBanga | Ukwakheka kweekhemikhali, ubunzima bepesenti (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Ezinye izinto Max.nganye | Ezinye izinto Max.iyonke | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5-6.75 | 3.5-4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12-0.25 | - | 0.12-0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5–3.5 | 2.0-3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12-0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6-0.9 | 0.2 ~ 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 ~ 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5-6.5 | 3.5-4.5 | - | - | - | - | 0.1 | 0.1 |

Iimpawu ezibonakalayo

| IBanga | Iimpawu ezibonakalayo | |||||

| Tensile strength Min | Unikeze Amandla Umz (0.2%, i-offset) | Ukwandiswa kwi-4D Ubuncinci (%) | Ukuncitshiswa kweNdawo Ubuncinci (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |