I-Titanium Disc / Ithagethi

| Igama | Ubungakanani(MM) | IBanga | Inkcazo |

| Idiski yeTitanium | φ50-1000 Ubude: 35-110 | TA1,TA2, TA3,TA4, TC4, TC11, TC15 njl | GB/T,GJB, I-ASTM, A |

| Imveliso | Ubungakanani(mm) | IBakala No | Inkcazo | |

| Ububanzi | Ubude beCandelo | |||

| Iidiski zeTitanium kunye neTitanium Alloy | Φ(150~300) | 20-600 | TA1,TA2,TA3, TA4,TA9,TA10, TA15,TC4 | GB/T,ASTM, ASME, AMS, ISO,JIS,MIL |

| Φ(300~500) | 20-600 | |||

| Φ(500~1100) | 35-600 | |||

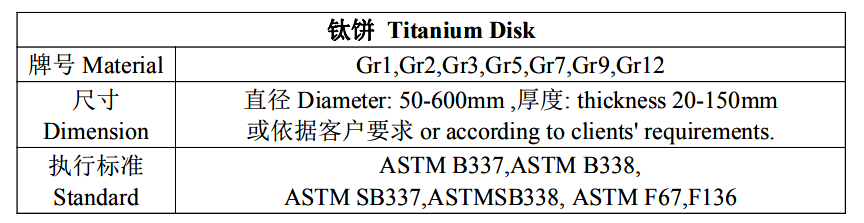

Inombolo ye-UNS.

| Inombolo ye-UNS. | Inombolo ye-UNS. | ||||

| Gr1 | I-UNS R50250 | CP-Ti | Gr11 | I-UNS R52250 | ITi-0.15Pd |

| Gr2 | I-UNS R50400 | CP-Ti | Gr12 | I-UNS R53400 | Ti-0.3Mo-0.8Ni |

| Gr4 | I-UNS R50700 | CP-Ti | Gr16 | I-UNS R52402 | I-Ti-0.05Pd |

| Gr7 | I-UNS R52400 | ITi-0.20Pd | Gr23 | I-UNS R56407 | Ti-6Al-4V ELI |

| Gr9 | I-UNS R56320 | I-Ti-3Al-2.5V | |||

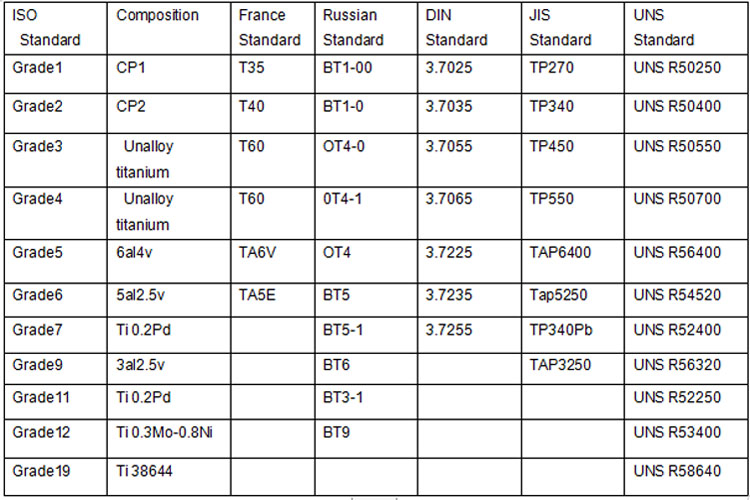

Ukuqulunqwa kweekhemikhali

| IBanga | Ukwakheka kweekhemikhali, ubunzima bepesenti (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Ezinye izinto Max.nganye | Ezinye izinto Max.iyonke | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5-6.75 | 3.5-4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12-0.25 | - | 0.12-0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5–3.5 | 2.0-3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12-0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6-0.9 | 0.2 ~ 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 ~ 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5-6.5 | 3.5-4.5 | - | - | - | - | 0.1 | 0.1 |

Iimpawu ezibonakalayo

| IBanga | Iimpawu ezibonakalayo | |||||

| Tensile strength Min | Unikeze Amandla Umz (0.2%, i-offset) | Ukwandiswa kwi-4D Ubuncinci (%) | Ukuncitshiswa kweNdawo Ubuncinci (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

Ukupakishwa kweemveliso ezincinci: Iphepha / iPlastiki kunye neCarton

Ukupakishwa kweemveliso ezininzi: Iphepha / ugwebu ngaphakathi, ipalethi yomthi ngaphandle.