Umbhobho ovaliweyo

Imibhobho ye-oyile esotyiweyo esetyenziswa ekuphononongeni i-oyile inokuthintela i-99% yesanti, yehlise i-80% yequla le-oyile ugcino olunzima, ngokunjalo nokwandisa amandla omthombo we-oyile, imfezeko kunye nokuzinza kokugcina isanti.Okwangoku, i-laser incision tech inokwenza i-slot ibe mpuluswa kwaye ichaneke.Ubume bombhobho we-casing slotted yisampuli, kodwa isebenza kakuhle kakhulu.

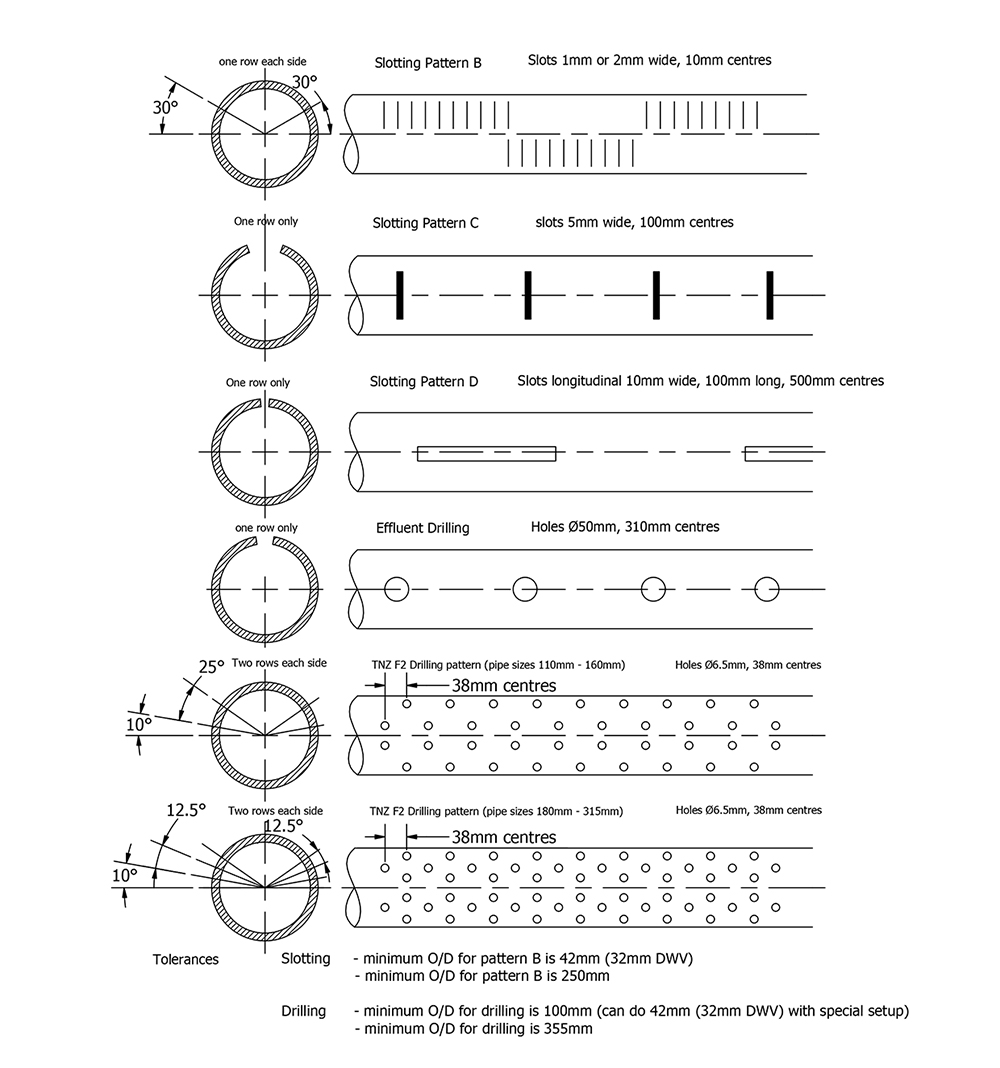

Ukusetyenzwa kwetyhubhu etyhidiweyo kumzimba oqinileyo wentsimbi kunye neendlela zokusebenza ezibandayo okanye ezishushu, ukusika amakhulu amawaka eentanda zexesha elide, iintanda ezisetyenziswa ngokuqhelekileyo: ububanzi be-seam 0.15 3 mm, ububanzi, ubude be-gap 50-200 mm.Cross section. iintlobo zezi: uxande, ileli emilisekileyo, ethile kunye nezahlukeneyo, nayo inescreen esisetyhula segroove, i-aperture diameter specitions ububanzi 5-20 mm kwiimitha icandelo imilo iqondo ecocekileyo, emphethweni umngxuma umthungo bugudileyo kunye neqondo lokumelana umhlwa umthungo umngxuma.

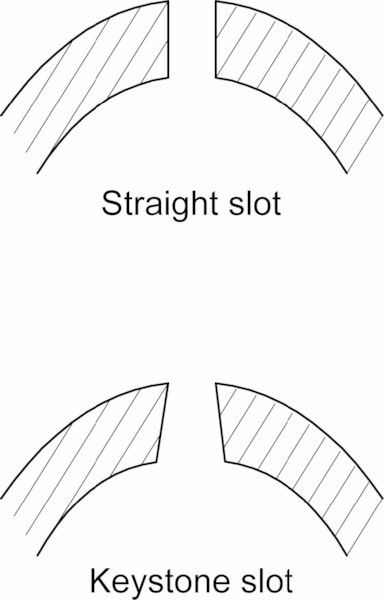

Slots Straight-I-Slots inqunywe ngobubanzi obulinganayo ngodonga lombhobho zombini i-ID kunye ne-OD.Ibaluliwe apho ibhulorho yeenkozo zesanti kwindawo yokubeka ingabalulekanga kakhulu, iindawo zokubeka ezithe tye ziyaxhathisa ukunxitywa kuneendawo zokubeka ilitye elingundoqo elithungelweyo kwaye azibizi mali ininzi ukuvelisa.Ukusetyenziswa okuqhelekileyo kweendawo zokubeka eziNgqongileyo zezoMveliso obandayo kunye ne-CBM ethe tyaba yamaqula ukongeza kwimithombo yokutofa ye-SAGD.

Izitshixo zelitye elingundoqo--zigaywe banzi kumbhobho wangaphakathi kwaye ziyazicoca ukuze zincede ukuthintela ukuplaga.Umxinwa kumphezulu we-liner kwaye ukhula ngobubanzi ngaphakathi, bavumela isanti engenayo ukuba idlule ngokulula kwiindawo zokubeka ngaphandle kokuplaga.

| Umbhobho we-API Casing | ID | Ubude | Slot Ubude | Indawo yesikhala | Slot ububanzi | Indawo yokubeka | Isihluzi esisebenzayo | Max. | ||

| Spec mm | Ukutyeba | Ngobunzima | ||||||||

| 60.32 | 5 | 6.84 | 50.3 | 3 | 80 | 200 | 0.3 | ±50 | 48 | 512.54 |

| 73.02 | 5.5 | 9.15 | 62 | 240 | 57.6 | 688.55 | ||||

| 88.9 | 6.5 | 13.22 | 75.9 | 280 | 67.2 | 995.1 | ||||

| 101.6 | 6.5 | 15.22 | 88.6 | 300 | 72 | 1151.2 | ||||

| 114.3 | 7 | 18.47 | 100.3 | 10 | 320 | 76.8 | 1400.4 | |||

| 127 | 7.52 | 22.13 | 112 | 340 | 81.6 | 1673.8 | ||||

| 139.7 | 7.72 | 25.11 | 124.3 | 360 | 86.4 | 1900.2 | ||||

| 9.17 | 29.48 | 121.4 | 360 | 86.4 | 2232.4 | |||||

| 168.3 | 8.94 | 35.09 | 150.4 | 400 | 96 | 2672.95 | ||||

| 177.8 | 8.05 | 33.68 | 161.7 | 440 | 105.6 | 2559.2 | ||||

| 9.19 | 38.19 | 159.4 | 440 | 105.6 | 2940.7 | |||||

| Ubungakanani bombhobho ococekileyo (ngaphakathi) | OD(mm) | Ubunzima bodonga(mm) | Isazisi (mm) | Inombolo yokuthunga yesangqa ngasinye | Ububanzi bendawo (mm) | Ubude bendawo (mm) | Ubude(mm) |

| 2-3/8″ | 60.3 | 4.83 | 50.64 | 12-18 | 0.2~0.8 | 45-100 | 1000~12000 |

| 2-7/8″ | 73 | 5.51 | 61.98 | 20–24 | 45-100 | ||

| 3-1/2″ | 88.9 | 6.45 | 76 | 24–28 | 45-100 | ||

| 4″ | 101.6 | 6.65 | 88.29 | 24~30 | 45-100 | ||

| 4-1/2″ | 114.3 | 5.69 | 102.92 | 24~30 | 45-100 | ||

| 6.35 | 101.6 | 45-100 | |||||

| 7.37 | 99.57 | 45-100 | |||||

| 8.56 | 97.18 | 45-100 | |||||

| 5″ | 127 | 5.59 | 115.82 | 28–36 | 0.25~0.8 | 45-100 | |

| 6.43 | 114.15 | 45-100 | |||||

| 7.52 | 111.96 | 45-100 | |||||

| 9.19 | 108.61 | 45-100 | |||||

| 5-1/2″ | 139.7 | 6.2 | 127.3 | 30–38 | 45-100 | ||

| 6.99 | 125.73 | 45-100 | |||||

| 7.72 | 124.26 | 45-100 | |||||

| 9.17 | 121.36 | 45-100 | |||||

| 10.54 | 118.62 | 45-100 | |||||

| 7″ | 177.8 | 6.91 | 163.98 | 36~50 | 45-100 | ||

| 8.05 | 161.7 | 45-100 | |||||

| 9.19 | 159.41 | 45-100 | |||||

| 10.36 | 157.07 | 45-100 |

1. Ipayipi yethu ene-perforated isebenzisa i-J55 / K55 / N80 i-casing kunye ne-tubings ye-API esemgangathweni, kunye namandla aphezulu aphezulu, akulula kakhulu ukuguqulwa.

2. Umda we-slot umi nkqo, ugudileyo, ngaphandle kwe-burrs, kwaye i-slot iyafana.

3. Umbhobho we-perforated ufanelekile kwisanti kakuhle, apho ububanzi besanti bukhulu kune-0.3mm.

4. I-slot ingaba yi-longitudinal kunye ne-transverse, icandelo le-slot liyakwazi ukuhambelana kunye neentlobo ze-trapezoidal, kunye nommandla ovulekileyo obanzi.

5. Umbhobho wesikrini osikiweyo unobukhulu bangaphakathi obukhulu.

I-API Spec 5CT-Ukucaciswa kwe-5CT/ISO 11960, Ukucaciswa kweCasing kunye neTubing, uHlelo lweSibhozo, iPetroleum kunye negesi yendalo-Imibhobho yentsimbi esetyenziswa njengecasing okanye iityhubhu yamaqula

| Umgangatho | IBanga | Ukuqulunqwa kweekhemikhali (()) | |||||||||

| I-API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34-0.39 | 0.20-0.35 | 1.25–1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34-0.38 | 0.20-0.35 | 1.45-1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11-0.16 | |

| L80 | 0.15-0.22 | ≤1.00 | 0.25 ~1.00 | ≤0.020 | ≤0.010 | 12.0-14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26-0.395 | 0.17-0.37 | 0.40-0.70 | ≤0.020 | ≤0.010 | 0.80-1.10 | ≤0.20 | ≤0.20 | 0.15 ~ 0.25 | ≤0.08 | |

Iipropati zoomatshini

| IBanga | Uhlobo | Ubude obupheleleyo phantsi komthwalo (%) | Amandla esivuno (min) | Amandla esivuno (ubuninzi) | Amandla okuqina min Mpa | Ubunzima obukhulu (HRC) | Ubunzima obukhulu (HBW) |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Kr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Kr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | - | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | - | 0.5 | 655 | 758 | 724 | - | - |

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 | - | - |

| Q125 | Konke | 0.65 | 862 | 1034 | 931 | - | - |

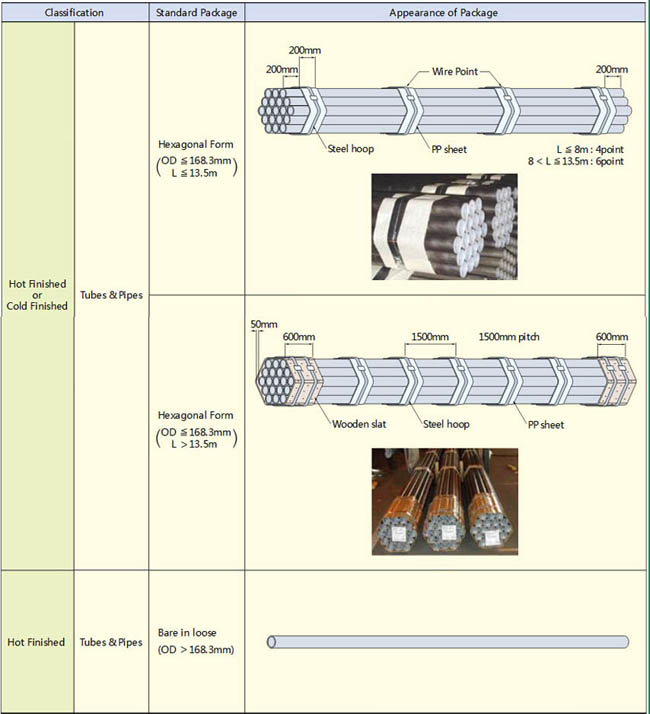

I-Single kunye nebhegi ye-bubble kwaye emva koko kwimeko yeplanga (isiqinisekiso sokutshisa).Imeko nganye iphawulwe ngokucacileyo ngolu hlobo:

1. Igama kunye nophawu lokuchonga lomenzi-HuaDong Brand

2. Inombolo yebhetshi

3. Umhla womenzi

4. Izinto eziphathekayo

5. Ukufudumala okukhuselekileyo kunye nobushushu besicelo