Umbhobho ongenamthungo ongenaStainless

Ukuqina :

Iityhubhu zensimbi ezingenasici ziqhele ukusetyenziswa ukulinganisa ubulukhuni beBrinell, Rockwell kunye neVickers.Ubulukhuni beBrinell Phakathi kwemigangatho yepayipi yensimbi engenasici, ubulukhuni beBrinell busetyenziswa kakhulu, kwaye ubunzima bezinto eziphathekayo budla ngokubonakaliswa ngobubanzi be-indentation, obubonakalayo kwaye bulungele.Nangona kunjalo, ayifanelekanga kwimibhobho yensimbi yentsimbi enzima okanye encinci.

Ubunzima beRockwell:

Ityhubhu yensimbi engenasici yovavanyo lobulukhuni be-Rockwell iyafana novavanyo lobulukhuni beBrinell.Umahluko kukuba ilinganisa ubunzulu be-indent.Uvavanyo lobulukhuni be-Rockwell yindlela esetyenziswa ngokubanzi apho i-HRC isetyenziswa okwesibini kuphela kwi-Brinell ubulukhuni be-HB kwimigangatho yombhobho wentsimbi.Ukuqina kwe-Rockwell kungasetyenziswa ekumiselweni kwezixhobo zetsimbi ukusuka ekuthambileyo kakhulu ukuya kunzima kakhulu.Ibuyekeza indlela yeBrinell.Ilula kunendlela yeBrinell kwaye inokufunda ngokuthe ngqo ixabiso lobunzima ukusuka kwidayili yomatshini wobunzima.Nangona kunjalo, ngenxa ye-indentation yayo encinci, ixabiso lobunzima alichanekanga njengendlela yeBrinell.

Vickers ubulukhuni

Uvavanyo lobulukhuni lwetyhubhu ye-Vickers lukwayindlela yokuvavanya i-indentation yokulinganisa imathiriyeli yentsimbi ecekethekileyo kunye nokuqina komphezulu womgangatho.Ineenzuzo eziphambili zeBrinell kunye neendlela zeRockwell, kwaye inqoba iintsilelo zabo ezisisiseko, kodwa ayilula njengendlela ye-Rockwell.Indlela yeVickers ayifane isetyenziswe kwimigangatho yepayipi yensimbi.

Uvavanyo lokuqina

I-tube yensimbi engenasici ine-diameter yangaphakathi ye-6.0mm okanye ngaphezulu kunye ne-annealed steel stainless tube kunye nobukhulu bodonga lwe-13mm okanye ngaphantsi.Inokuba yi-W-B75 yovavanyo lobulukhuni lweVickers.Ikhawuleza kakhulu kwaye ilula ukuvavanya kwaye ifanelekile ukuhlolwa ngokukhawuleza kunye nokungonakalisi kweepayipi zensimbi ezingenasici.Iityhubhu zensimbi ezingenasici kunye nobubanzi bangaphakathi obungaphezulu kwe-30 mm kunye nobukhulu bodonga obungaphezulu kwe-1.2 mm buvavanywa nge-Rockwell hardness tester ukuvavanya ukuqina kwe-HRB kunye ne-HRC.Iityhubhu zensimbi ezingenasici kunye nobubanzi bangaphakathi obungaphezulu kwe-30 mm kunye nobukhulu bodonga obungaphantsi kwe-1.2 mm buvavanywa kunye ne-Rockwell hardness tester yokuvavanya ukuqina kwe-HRT okanye i-HRN.Kwimibhobho yensimbi engenasici kunye nobubanzi obungaphakathi obungaphantsi kwe-0 mm kunye nobukhulu kune-4.8 mm, ubunzima be-HR15T buvavanywa ngumhloli okhethekileyo we-Rockwell ukuqina kwemibhobho.Xa ububanzi bangaphakathi betyhubhu yensimbi engenasici bukhulu kune-26 mm, ubunzima bodonga lwangaphakathi lombhobho bunokuvavanywa yi-Ro.

Ukuqulunqwa kwemichiza

| Amabanga | C max | Mn max | P max | S max | Simax max | Cr | Ni | Mo |

| 304 | 0.08 | 2.00 | 0.04 | 0.03 | 0.075 | 18.00-20.00 | 8.00-11.00 | / |

| 304L | 0.035 | 2.00 | 0.04 | 0.03 | 0.075 | 18.00-20.00 | 8.00-13.00 | / |

| 316 | 0.08 | 2.00 | 0.04 | 0.03 | 0.075 | 16.00-18.00 | 11.00-14.00 | 2.00-3.00 |

| 316L | 0.035 | 2.00 | 0.04 | 0.03 | 0.075 | 16.00-18.00 | 10.00-15.00 | 2.00-3.00 |

Iipropati zoomatshini

| Amabanga | I-Itemper | Tensile Psi | Isivuno Psi | Elong % | Ubunzima beRockwell |

| 304 | I-Anealed | 85000-105000 | 35000-75000 | 20-55 | 80-95 |

| 304L | I-Anealed I1/8 Nzima | 80000-105000 | 30000-75000 | 20-55 | 75-95 |

| 316 | I-Anealed | 85000 imiz | 35000 min | 50 imiz | 80 imiz |

| I-Anealed | 80000 imiz | 30000 min | 50 imiz | 75 imiz |

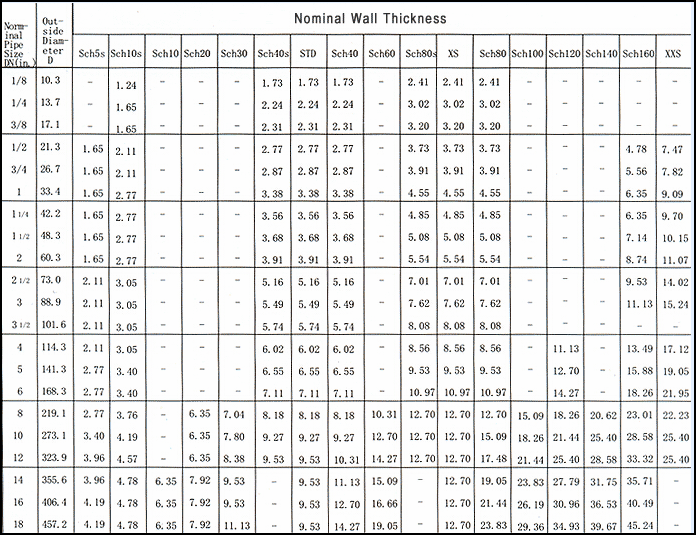

Ubungakanani bombhobho weNtsimbi engatyiwa

I-Annealed & pickled, i-annealing eqaqambileyo, ikhazimlisiwe

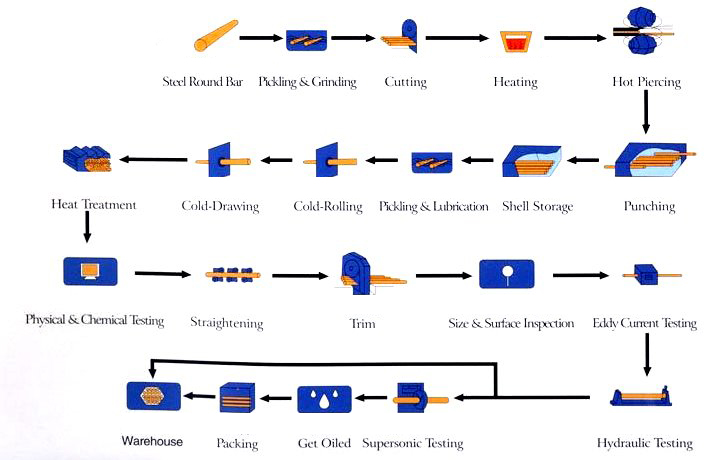

Inkqubo