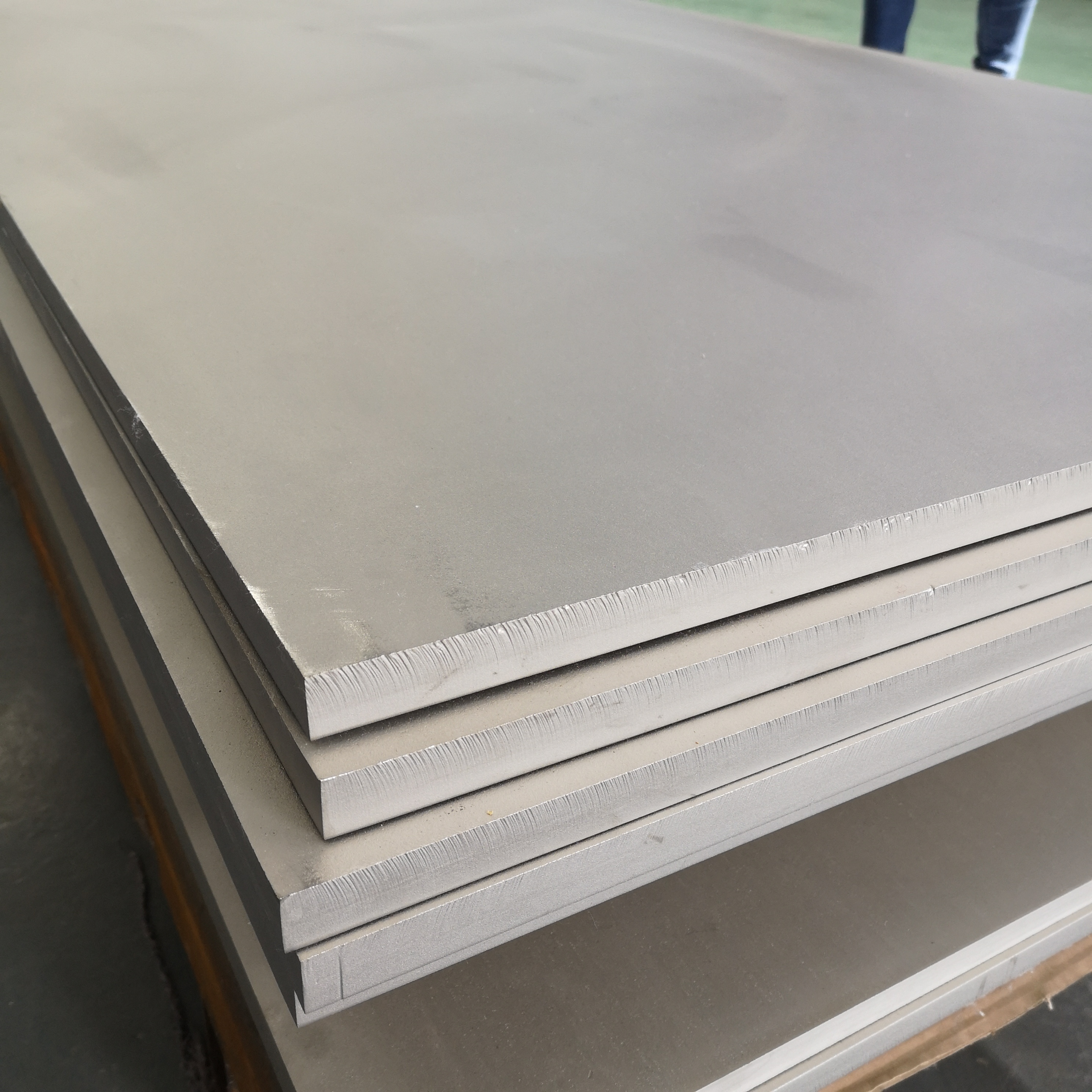

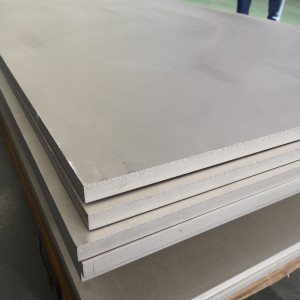

Letlapa la Titanium / Plate

Mephato e Tloaelehileng

Sehlopha sa 1 sa Titaniumke sehlahisoa sa titanium se sa tsitsang, se nang le matla a tlase se nang le oksijene e tlase e nang le bokhoni ba sebopeho se phahameng;sehlopha sena sa titanium se sebelisoa ka liforeimi tsa moea, phapanyetsano ea mocheso le likarolo tsa desalination.

Sehlopha sa 2 sa Titaniumke sehlahisoa sa titanium se sa tsitsang, se nang le matla a mahareng.Sehlopha sena sa titanium se sebelisoa liforeiming tsa moea, lienjineng tsa lifofane le likarolong tsa leoatle;bokhoni bo botle ba weld le ho hanyetsa kutu ke litšobotsi tsa eona tse khethollang.

Sehlopha sa 3 sa Titaniumke sehlahisoa se sa tsitsang, se matla haholo, sehlahisoa sa titanium se fanang ka khanyetso e ntle ea kutu le bokhoni bo botle ba weld.Sehlopha sena sa titanium se sebelisoa haholo-holo ho foreimi ea moea le likarolo tsa enjene ea sefofane.

Titanium Grade 4ke matla phahameng ka ho fetisisa a hloekileng unalloyed titanium sehlahisoa.Sehlopha sena sa titanium se sebelisoa hoo e batlang e le bakeng sa foreimi ea moea, likarolo tsa enjene ea sefofane, tsa metsing, li-implants tsa ho buoa, li-tubing tsa hydraulic.Bokhoni bo botle ba sebopeho le ho hanyetsa kutu ke letšoao la eona.

Titanium Grade 5 (6AL-4V)ke sehlahisoa sa alloyed titanium se nang le 6% Aluminium le 4% Vanadium;ke sehlahisoa sa matla a mahareng.Sehlopha sena sa titanium se sebelisoa haholo ho li-airframe le likarolo tsa enjene ea turbine;le bakeng sa tšebeliso ea ho kenya li-implants tsa ho buoa.Lintlha tsa Teknoloji Titanium 6AL-4V ELI ke sehlahisoa sa titanium se kopantsoeng se nang le 6% Aluminium le 4% Vanadium, ELI (Extra Low Interstitial).

6AL-2Sn-4Tsr-2Mo (6-2-4-2)ke sehlahisoa sa alloyed titanium se nang le 6% Aluminium, 2% Tin, 4% Zirconium, 2% Molybdenum.

6AL-6V-2Sn (6-6-2)ke sehlahisoa se kopantsoeng sa titanium se nang le 6% Aluminium, 6% Vanadium, 2% Tin.

5AL-2.5Sn & ELI (5-2.5)ke sehlahisoa sa alloyed titanium se nang le 5% Aluminium le 2.5% Tin.Hape ELI (Extra Low Interstitial).

8AL-1V-1Mo (8-1-1)ke sehlahisoa se kopantsoeng sa titanium se nang le 8% Aluminium, 1% Molybdenum le 1% Vanadium.

15V-3Kr-4AL-3Sn (15-3-4-3)ke sehlahisoa se kopantsoeng sa titanium se nang le 15% Vanadium, 3% Chromium, 4% Aluminium, 3% Tin.

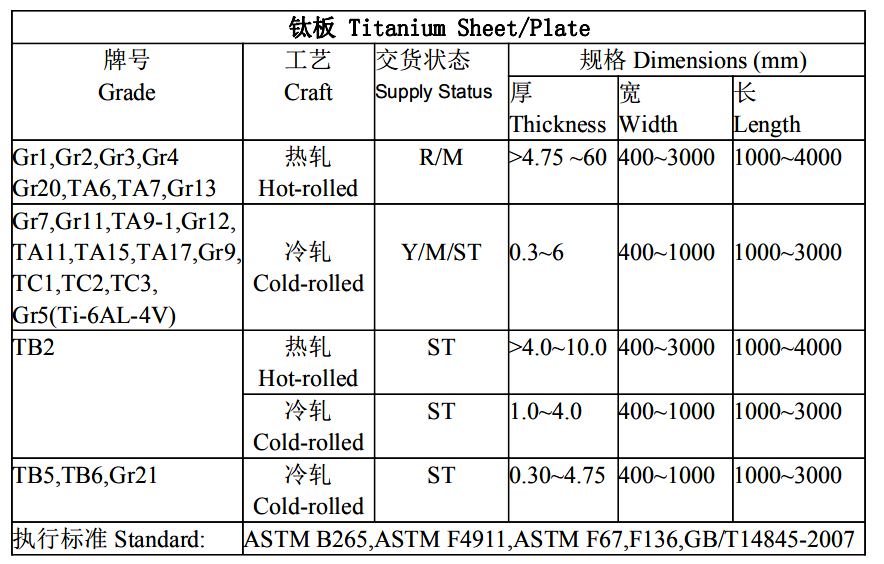

| Kereiti | Boemo | Tlhaloso | ||

| Gr1,Gr2,Gr4,Gr5,Gr7,Gr9,Gr11, Gr12,Gr16,Gr23 | Ho Qhaseha (R) Cold Rolled(Y) Annealed(M) Phekolo ea tharollo(ST) | Botenya(mm) | Bophara(mm) | Bolelele(mm) |

| 0.3 ho isa ho 60 | ≥400 | ≤ 6000 | ||

| Letlapa la Titanium | |||

| Botenya | Mephato | ||

| .016 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .020 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .025 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .032 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .040 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .050 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .063 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .071 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .080 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .090 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .100 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .125 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

Tlhokomeliso: Lisaese tsa tlatsetso li teng, ha se boholo bo bonts'itsoeng bo fumanehang ho tsoa stock.Ka kopo ikopanye le rona ho bona hore na e teng.

| AMS:AMS 2631, AMS 4901, AMS 4907, AMS 4911ASTM: ASTM B265 Gr 23, ASTM B265 Gr 5, ASTM B265 Gr2, ASTM B265 Gr4, ASTM F136, ASTM F67MIL-T:MIL-T-9046, MIL-T-9046 CP1EN:EN 10204.3, EN 1-204:2005 3.1 NACE:NACE MR0175 ASME:ASME SB265 |

| Kereiti | Litlhaloso tsa AMS/MIL | Litlhaloso tsa ASTM |

| Sehlopha sa 1 | AMS-T-9046B CP4 AMS 4940 MIL-T-9046J CP4 | ASTM B265 Gr1 Leqephe/plate ASTM B337 Gr1 pipe ASTM B338 Gr1 tube ASTM B348 Gr1 bar ASTM F67 Gr1 Implant ea ho Buoa |

| Sehlopha sa 2 | Sehlopha sa 2 AMS-T-9046B CP3 AMS 4902 MIL-T-9046J CP3 AMS 4941 AMS 4942 AMS 4951 Wilding terata | ASTM B265 Gr2 Leqephe/plate ASTM B337 Gr2 phala ASTM B338 Gr2 tube ASTM B348 Gr2 bar ASTM F67 Gr2 Implant ea ho Buoa |

| Sehlopha sa 3 | AMS-T-9046B CP2 AMS 4900 MIL-T-9046J CP2 | ASTM B265 Gr3 Leqephe/plate ASTM B337 Gr3 phala ASTM B338 Gr3 tube ASTM B348 Gr3 bar Ho kengoa ka ASTM F67 Gr3 ho Buoa |

| Sehlopha sa 4 | Setšoantšo sa AMS-T-9046B CP1 AMS-T-9047A CP70 AMS 4901 AMS 4921 MIL-T-9046J CP1 MIL-T-9047G CP70 | ASTM B265 Gr4 Leqephe/plate ASTM B337 Gr4 phala ASTM B338 Gr4 tube ASTM B348 Gr4 bar ASTM F67 Gr4 Implant ea ho Buoa |

| Sehlopha sa 7 | ASTM B265 Gr7 Leqephe/plate ASTM B337 Gr7 phala ASTM B338 Gr7 tube ASTM B348 Gr7 bar |

| Kereiti | Lintlha tsa US | Litlhaloso tsa ASTM |

| Sehlopha sa 5 6Al-4V | AMS 4907 ELI AMS 4911 AMS 4928 AMS 4930 ELI AMS 4931 ELI Duplex ann AMS 4963 AMS 4965 AMS 4967 AMS 4985 AMS 4991 AMS 6931 AMS 6932 MIL-T-9046J AB-1 MIL-T-9046J AB-2 (ELI) Mofuta oa 3 oa MIL-T-9046H oa Comp C Mofuta oa 3 oa MIL-T-9046H AMS-T-9046B AB-1 AMS-T-9046B AB-2 (ELI) MIL-T-9047G 6Al-4v MIL-T-9047G 6Al-4v (ELI) AMS-T-9047A 6Al-4v AMS-T-9047A 6Al-4v (ELI) | ASTM B265 Gr5 Leqephe/plate ASTM B348 Gr5 bar ASTM F136 Gr5 Implant Kereiti |

| Sehlopha sa 9 3Al-2.5V | AMS 4943 AMS 4944 AMS 4945 AMS-T-9046B AB-5 AMS-T-9047A 3Al-2.5V MIL-T-9046J AB-5 MIL-T-9047 3Al-2.5V | ASTM B265 Gr6 Leqephe/plate ASTM B348 Gr6 bar |

| Sehlopha sa 23 6Al-4V ELI | AMS 4907 AMS 4930 AMS 6932 AMS-T-9046 AB-2 6AL-4V (ELI) AMS-T-9047 AB-2 6AL-4V (ELI) MIL-T-9046 AB-2 6AL-4V (ELI) MIL-T-9047 6AL-4V (ELI) | ASTM B265 Gr23 sheet/plate/strip ASTM B348 Gr23 bar/billet ASTM F136 Gr23 Implant Gra |

Sebopeho sa lik'hemik'hale

| Kereiti | Sebopeho sa lik'hemik'hale, peresente ea boima ba 'mele (%) | ||||||||||||

| C ≤ | O ≤ | N ≤ | H ≤ | Fe ≤ | Al | V | Pd | Ru | Ni | Mo | Lintlha Tse Ling Max.enngwe le enngwe | Lintlha Tse Ling Max.kakaretso | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5~6.75 | 3.5~4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12~0.25 | - | 0.12~0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12~0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04~0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5~4.5 | - | - | - | - | 0.1 | 0.1 |

Lintho tsa 'mele

| Kereiti | Lintho tsa 'mele | ||||||

| Matla a tsitsipano Min | Ho hlahisa matla (0.2%, offset) | Elongation ka 50mm Min (%) | |||||

| ksi | MPa | Min | Max | ||||

| ksi | MPa | ksi | MPa | ||||

| Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr4 | 80 | 550 | 70 | 483 | 95 | 655 | 15 |

| Gr5 | 130 | 895 | 120 | 828 | - | - | 10 |

| Gr7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr9 | 90 | 620 | 70 | 483 | - | - | 15 |

| Gr11 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr12 | 70 | 483 | 50 | 345 | - | - | 18 |

| Gr16 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | - | - | 10 |

Mamello (mm)

| Botenya | Ho mamellana ka bophara | ||

| 400 ~ 1000 | 1000 ~ 2000 | >2000 | |

| 5.0–6.0 | ±0.35 | ±0.40 | ±0.60 |

| 6.0–8.0 | ±0.40 | ±0.60 | ±0.80 |

| 8.0–10.0 | ±0.50 | ±0.60 | ±0.80 |

| 10.0–15.0 | ±0.70 | ±0.80 | ±1.00 |

| 15.0–20.0 | ±0.70 | ±0.90 | ±1.10 |

| 20.0–30.0 | ±0.90 | ±1.00 | ±1.20 |

| 30.0–40.0 | ±1.10 | ±1.20 | ±1.50 |

| 40.0–50.0 | ±1.20 | ±1.50 | ±2.00 |

| 50.0–60.0 | ± 1.60 | ±2.00 | ± 2.50 |