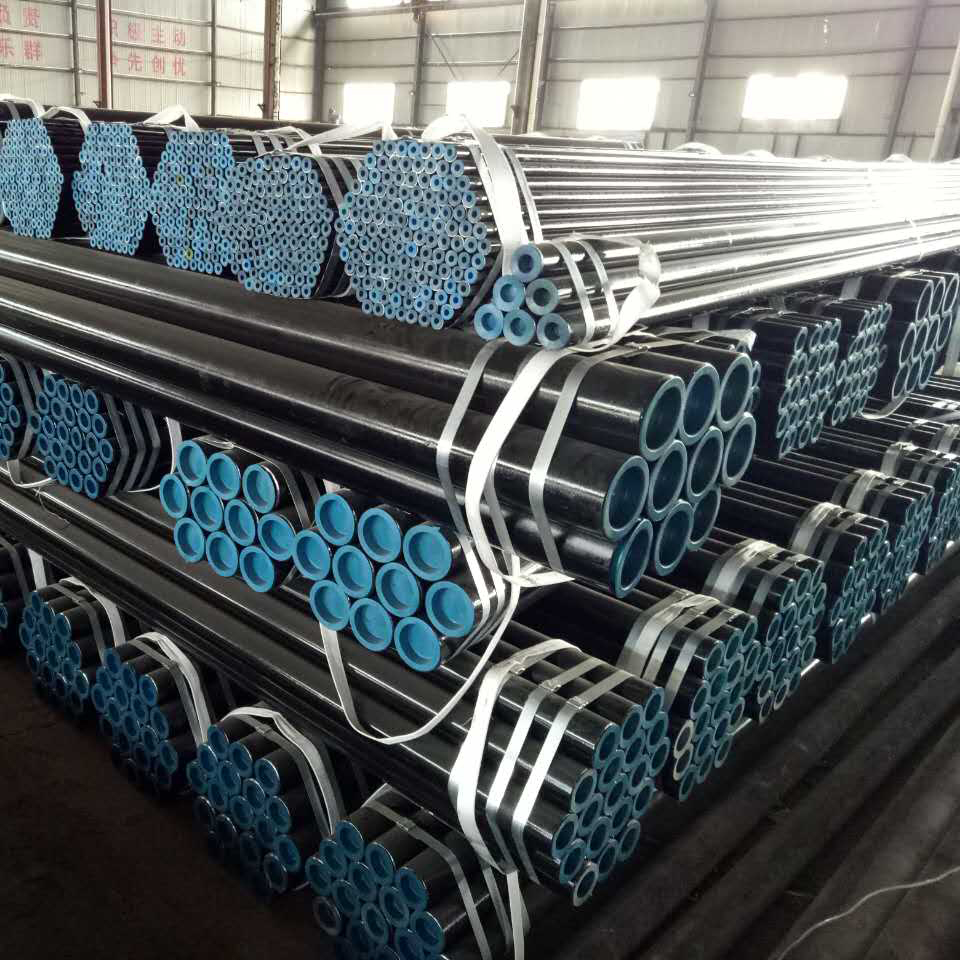

Pipe e Atolositsoeng e Atolositsoeng ea Seamless

Peipi ea tšepe e atolohang e chesang ke liphaephe tse chesang tse atolositsoeng tse se nang moroallo, tse batlang li le tlase haholo empa ho honyela ha phala e matla ea tšepe (peipi e se nang seam) ho ka bitsoa katoloso ea mocheso.Mokhoa oa ho roala skew kapa mokhoa oa ho taka ho holisa bophara ba phala.Tšepe phala thickening ka nako e khutšoanyane, ho ka hlahisa mefuta e sa tloaelehang le e khethehileng ea li-tubes tse se nang moeli tse nang le theko e tlaase le e phahameng ea tlhahiso ea tlhahiso, tsoelo-pele ea morao-rao ea machaba tšimong ea ho roala tube.

Pipe ea ho atolosa e chesang ke ka ho atolosa bophara ba phala ho qeta mekhoa - mokhoa oa ho atolosa mocheso oa tlhahiso ea phala ea tšepe.Peipi ea ho atolosa e chesang hangata e bitsoa liphaephe tse chesang tse atolositsoeng tse seamless.

Mekhahlelo ea Tekheniki ea Ho Atolosa Pipe ea Tšepe e Seamless:

| Boholo ba lebitso | Kantle | Botenya ba Lebota ka Lebitso (mm) | |||||||||||||

| DN | NPS | OD(MM) | SCH | SCH | SCH | STD | SCH | SCH | XS | SCH | SCH | SCH | SCH | SCH | XXS |

| 200 250 300 | 8 10 12 | 219.1 273.1 323.9 | 3.76 4.19 4.57 | 6.35 6.35 6.35 | 7.04 7.80 8.38 | 8.18 9.27 9.53 | 8.18 9.27 10.31 | 10.31 12.70 14.27 | 12.70 12.70 12.70 | 12.70 15.09 17.48 | 15.09 18.26 21.44 | 18.26 21.44 25.40 | 20.62 25.40 28.58 | 23.01 28.58 33.32 | 22.23 25.40 25.40 |

| 350 400 450 | 14 16 18 | 355.6 406.4 457.2 | 6.35 6.35 6.35 | 7.92 7.92 7.92 | 9.53 9.53 11.13 | 9.53 9.53 9.53 | 11.13 12.70 14.27 | 15.09 16.66 19.05 | 12.70 12.70 12.70 | 19.05 21.44 23.83 | 23.83 26.19 29.36 | 27.79 30.96 34.93 | 31.75 36.53 39.67 | 35.71 40.49 45.24 | -- |

| 500 550 600 | 20 22 24 | 508 559 610 | 6.35 6.35 6.35 | 9.53 9.53 9.53 | 12.70 12.70 14.27 | 9.53 9.53 9.53 | 15.09 - 17.48 | 20.62 22.23 24.61 | 12.70 | 26.19 28.58 30.96 | 32.54 34.93 38.89 | 38.10 41.28 46.02 | 44.45 47.63 52.37 | 50.01 53.98 59.54 | -- |

| 500 550 600 | 20 22 24 | 508 559 610 | 6.35 6.35 6.35 | 9.53 9.53 9.53 | 12.70 12.70 14.27 | 9.53 9.53 9.53 | 15.09 - 17.48 | 20.62 22.23 24.61 | 12.70 12.70 12.70 | 26.19 28.58 30.96 | 32.54 34.93 38.89 | 38.10 41.28 46.02 | 44.45 47.63 52.37 | 50.01 53.98 59.54 | -- |

| 660 700 750 | 26 28 30 | 660 711 762 | 7.92 7.92 7.92 | 12.70 12.70 12.70 | — 15.88 15.88 | 9.53 9.53 9.53 | -- | -- | 12.70 12.70 12.70 | -- | -- | -- | -- | -- | -- |

| 800 850 900 | 32 34 36 | 813 864 914 | 7.92 7.92 7.92 | 12.70 12.70 12.70 | 15.88 15.88 15.88 | 9.53 9.53 9.53 | 17.48 17.48 19.05 | -- | 12.70 12.70 12.70 | -- | -- | -- | -- | -- | -- |

| Bophara ba ka ntle (mm) / | SCH | SCH | SCH | STD | SCH | SCH | XS | SCH | SCH | SCH | SCH | SCH |

| 457 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.70 | 23.88 | 29.36 | 34.93 | 39.67 | 45.24 |

| 508 | 6.35 | 9.53 | 12.70 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 |

| 559 | 6.35 | 9.53 | 12.70 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | |

| 610 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.39 | 46.02 | 52.37 | 59.54 |

| 660 | 7.92 | 12.70 | 9.53 | 12.70 | ||||||||

| 711 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | |||||||

| 762 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | |||||||

| Tlhokomeliso: Litekanyetso le litlhaloso tse ka holimo ke tsa litšupiso feela, re ka boela ra hlahisa sehlahisoa se ikhethileng ho latela kopo ea moreki. | ||||||||||||

Phekolo ea holim'a phala ea tšepe:

E le ho ntlafatsa bophelo ba tšebeletso ea liphaephe tsa oli, phekolo ea holim'a metsi e atisa ho etsoa ho nolofalletsa motsoako o tiileng oa phala ea tšepe le ho thibela ho senya.

1 ho hloekisaGrese, lerōle, lubricant, lintho tse phelang tse khomaretsoeng holim'a phala ea tšepe, hangata li sebelisa solvent, emulsion ho hloekisa holim'a metsi. mekhoa ea phekolo e hlokahala.Tool rust removeSteel pipe surface oxide, rust, welding slag, ka sebelisa tšepe terata borashe ho hloekisa le ho bentsa holim' a treatment.Tool derusting ka aroloa ka bukana le matla, manual tool derusting ka fihla Sa

Boemo ba 2, ho senya sesebelisoa sa matla ho ka fihla boemong ba Sa3. Haeba bokaholimo ba phala ea tšepe bo khomaretsoe ka letlalo le matla haholo la oxide, ho ka 'na ha se ke ha khoneha ho tlosa mafome ka thuso ea lisebelisoa, kahoo re lokela ho fumana litsela tse ling.

3 pickling Mekhoa e tloaelehileng ea ho khetha e kenyelletsa k'hemistri le electrolysis.Empa ho sebelisoa feela lik'hemik'hale tsa ho khetha lik'hemik'hale bakeng sa tšireletso ea liphaephe.Ho khetha lik'hemik'hale ho ka finyella tekanyo e itseng ea bohloeki le ho ba mahlahahlaha holim'a phala ea tšepe, e loketseng melapo ea ankora e latelang. thunya (lehlabathe) ka mora ho ntlafala.

4 e thunya bakeng sa ho tlosa mafome Ka motlakase o matla o khanna li-blades tse pota-potileng ka lebelo le phahameng, grit ea tšepe, sethunya sa tšepe, karolo, liminerale le terata e 'ngoe e senyang tlas'a ts'ebetso ea matla a centrifugal holim'a peipi ea tšepe holim'a spray le ejection e ngata, tlosa mafome, li-oxide ka botlalo. le litšila ka lehlakoreng le leng, ka lehlakoreng le leng, tšepe phala tlas'a ketso ea abrasive tshusumetso e mabifi le matla a khohlano, ho finyella e hlokehang junifomo roughness.Har'a mekhoa e mene ea phekolo, thunya blasting le derusting ke mokhoa o loketseng oa phekolo bakeng sa phala derusting.Ka kakaretso, ho thunngoa le ho senya li sebelisoa haholo-holo bakeng sa phekolo ea ka hare ea holim'a phala ea tšepe, 'me ho thunya le ho senya li sebelisoa haholo-holo bakeng sa phekolo ea ka ntle ea phala ea tšepe.