Setsoe

Ts'ebetso ea ho Etsa Setsi sa Seamless (Ho Kobeha ha Mocheso le ho Kobeloa ha Mohatsela)

E 'ngoe ea mekhoa e atileng haholo ea ho etsa li-elbows ke ho sebelisa mandrel a chesang a kobang liphaephe tse otlolohileng tsa tšepe.Ka mor'a ho futhumatsa phala ea tšepe ka mocheso o phahameng, phala e sutumetsoa, e atolosoa, e kobehile ka lisebelisoa tsa ka hare tsa mandrel mohato ka mohato.Ho sebelisa ho kobeha ha mandrel e chesang ho ka etsa setsoe sa boholo bo se nang seam.Litšobotsi tsa mandrel kobang ba ka matla itšetlehile ka sebopeho intergrated le litekanyo tsa mandrel.Melemo ea tšebeliso ea litsoe tse chesang tse kobehang li kenyelletsa ho kheloha botenya bo nyane le radius e matla ea ho kobeha ho feta mofuta o mong oa ho kobeha.Ho sa le joalo, ho sebelisa ho kobeha ho e-na le ho kobeha tse entsoeng esale pele ho fokotsa haholo palo ea litšepe tse hlokahalang.Sena se fokotsa boholo ba mosebetsi o hlokahalang mme se eketsa boleng le ts'ebeliso ea lipeipi.Leha ho le joalo, ho kobeha ho batang ke mokhoa oa ho koba phala e otlolohileng ea tšepe ka mocheso o tloaelehileng mochining o kobehang.Ho kobeha ho batang ho loketse liphaephe tse nang le bophara bo ka ntle ba 17.0 ho isa ho 219.1 mm, le botenya ba lerako la 2.0 ho isa ho 28.0 mm.Sebaka se khothalelitsoeng sa ho kobeha ke 2.5 x Do.Ka tloaelo sebakeng se kobehang sa 40D.Ka ho sebelisa ho kobeha ho batang, re ka fumana likhau tse nyane tsa radius, empa re hloka ho paka tse kahare ka lehlabathe ho thibela ho sosobana.Ho kobeha ho batang ke mokhoa o potlakileng le o theko e tlaase oa ho kobeha.Ke khetho ea tlholisano ea ho etsa liphaephe le likarolo tsa mochini.

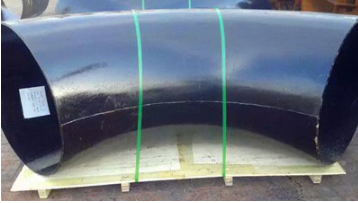

Ts'ebetso ea Tlhahiso ea Elbow e Welded (e Nyenyane le e Kholo)

Li-elbows tse cheselitsoeng li entsoe ka lipoleiti tsa tšepe, ka hona ha se litsoe tsa tšepe tse se nang seamless.Sebelisa hlobo 'me u hatelle poleiti ea tšepe ho sebopeho sa setsoe, ebe u cheselletsa seam hore e be setsoe sa tšepe.Ke mokhoa oa khale oa tlhahiso ea litsoe.Lilemong tsa morao tjena li-elbows tse nyane li batla li entsoe ka liphaephe tsa tšepe hona joale.Bakeng sa litsoe tsa boholo bo boholo, ho etsa mohlala, ho thata haholo ho hlahisa likhama tse fetang 36” OD ho tloha liphaepheng tsa tšepe.Kahoo hangata e entsoe ka lipoleiti tsa tšepe, e hatella poleiti ho ea sebopeho sa halofo ea setsoe, ebe e kopanya lihalofo tse peli hammoho.Kaha li-elbows li cheselitsoe 'meleng oa eona, ho hlahlojoa ha motsoako oa welding hoa hlokahala.Hangata re sebelisa tlhahlobo ea X-Ray joalo ka NDT.

| Boholo ba phala ka lebitso | Kantle Diameter | Bohareng ba ho Qetela | Center to Center | Khutlela ho Lifahleho | ||||||

| 45° Lintši | 90° Lintši | 180 ° Khutla | ||||||||

| H | F | P | K | |||||||

| DN | INCH | Letoto la A | Letoto la B | LR | LR | SR | LR | SR | LR | SR |

| 15 | 1/2 | 21.3 | 18 | 16 | 38 | - | 76 | - | 48 | - |

| 20 | 3/4 | 26.9 | 25 | 16 | 38 | - | 76 | - | 51 | - |

| 25 | 1 | 33.7 | 32 | 16 | 38 | 25 | 76 | 51 | 56 | 41 |

| 32 | 11/4 | 42.4 | 38 | 20 | 48 | 32 | 95 | 64 | 70 | 52 |

| 40 | 11/2 | 48.3 | 45 | 24 | 57 | 38 | 114 | 76 | 83 | 62 |

| 50 | 2 | 60.3 | 57 | 32 | 76 | 51 | 152 | 102 | 106 | 81 |

| 65 | 21/2 | 76.1(73) | 76 | 40 | 95 | 64 | 191 | 127 | 132 | 100 |

| 80 | 3 | 88.9 | 89 | 47 | 114 | 76 | 229 | 152 | 159 | 121 |

| 90 | 31/2 | 101.6 | - | 55 | 133 | 89 | 267 | 178 | 184 | 140 |

| 100 | 4 | 114.3 | 108 | 63 | 152 | 102 | 305 | 203 | 210 | 159 |

| 125 | 5 | 139.7 | 133 | 79 | 190 | 127 | 381 | 254 | 262 | 197 |

| 150 | 6 | 168.3 | 159 | 95 | 229 | 152 | 457 | 305 | 313 | 237 |

| 200 | 8 | 219.1 | 219 | 126 | 305 | 203 | 610 | 406 | 414 | 313 |

| 250 | 10 | 273.0 | 273 | 158 | 381 | 254 | 762 | 508 | 518 | 391 |

| 300 | 12 | 323.9 | 325 | 189 | 457 | 305 | 914 | 610 | 619 | 467 |

| 350 | 14 | 355.6 | 377 | 221 | 533 | 356 | 1067 | 711 | 711 | 533 |

| 400 | 16 | 406.4 | 426 | 253 | 610 | 406 | 1219 | 813 | 813 | 610 |

| 450 | 18 | 457.2 | 478 | 284 | 686 | 457 | 1372 | 914 | 914 | 686 |

| 500 | 20 | 508.0 | 529 | 316 | 762 | 508 | 1524 | 1016 | 1016 | 762 |

| 550 | 22 | 559 | - | 347 | 838 | 559 | Hlokomela: | |||

| 600 | 24 | 610 | 630 | 379 | 914 | 610 | ||||

| 650 | 26 | 660 | - | 410 | 991 | 660 | ||||

| 700 | 28 | 711 | 720 | 442 | 1067 | 711 | ||||

| 750 | 30 | 762 | - | 473 | 1143 | 762 | ||||

| 800 | 32 | 813 | 820 | 505 | 1219 | 813 | ||||

| 850 | 34 | 864 | - | 537 | 1295 | 864 | ||||

| 900 | 36 | 914 | 920 | 568 | 1372 | 914 | ||||

| 950 | 38 | 965 | - | 600 | 1448 | 965 | ||||

| 1000 | 40 | 1016 | 1020 | 631 | 1524 | 1016 | ||||

| 1050 | 42 | 1067 | - | 663 | 1600 | 1067 | ||||

| 1100 | 44 | 1118 | 1120 | 694 | 1676 | 1118 | ||||

| 1150 | 46 | 1168 | - | 726 | 1753 | 1168 | ||||

| 1200 | 48 | 1220 | 1220 | 758 | 1829 | 1219 | ||||

ASTM A234

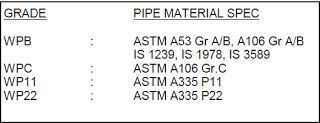

Tlhaloso ena e akaretsa lisebelisoa tsa tšepe tse entsoeng ka carbon le alloy tsa kaho e se nang seamless le e cheselitsoeng.Ntle le haeba kaho e se nang moroko kapa e cheselitsoeng e boletsoe ka tatellano, e ka fanoa ka khetho ea mofani oa thepa.Lisebelisoa tsohle tsa kaho tse cheselitsoeng ho latela maemo ana li fanoa ka 100% radiography.Tlas'a ASTM A234, limaraka tse 'maloa li fumaneha ho latela sebopeho sa lik'hemik'hale.Khetho e tla itšetleha ka thepa ea liphaephe e amanang le lisebelisoa tsena.

| Litlhoko tsa Tensile | WPB | WPC, WP11CL2 | WP11CL1 | WP11CL3 |

| Tensile Strength, min, ksi[MPa] | 60-85 | 70-95 | 60-85 | 75-100 |

| (0.2% offset kapa 0.5% katoloso-tlase-moroalo) | [415-585] | [485-655] | [415-585] | [520-690] |

| Kotulo e Matla, min, ksi[MPa] | 32 | 40 | 30 | 45 |

| [240] | [275] | [205] | [310] |

Tse ling tsa limaraka tse fumanehang tlas'a tlhaloso ena le litlhaloso tse tsamaellanang tsa liphaephe li thathamisitsoe ka tlase:

ASTM A403

Tlhaloso ena e akaretsa lihlopha tse peli tse akaretsang, WP & CR, ea lisebelisoa tse entsoeng ka tšepe e sa hloekang ea austenitic ea kaho e se nang moroallo le e cheselitsoeng.

Lisebelisoa tsa Sehlopha sa WP li entsoe ho latela litlhoko tsa ASME B16.9 & ASME B16.28 'me li arotsoe ka lihlopha tse tharo ka tsela e latelang:

- WP - E entsoe ka sehlahisoa se se nang seamless ka mokhoa o se nang moeli oa tlhahiso.

- WP - W Lisebelisoa tsena li na le li-welds le li-welds tsohle tse entsoeng ke moetsi ea loketseng ho kenyelletsa le ho qala pipe weld haeba phala e ne e cheselitsoe ka ho eketsoa ha thepa ea ho tlatsa e entsoe ka radiographed.Leha ho le joalo ha ho radiography e etsoang bakeng sa ho qala phala tjheseletsa haeba phala e ne e cheselitsoe ntle le ho eketsoa ha thepa ea ho tlatsa.

- WP-WX Lisebelisoa tsena li na le li-welds le li-welds tsohle hore na li entsoe ke moetsi ea loketseng kapa ke moetsi oa thepa ea qalang li entsoe ka radiographed.

Lisebelisoa tsa Sehlopha sa CR li entsoe ho latela litlhoko tsa MSS-SP-43 'me ha li hloke tlhahlobo e sa senyeheng.

Tlas'a ASTM A403 limaraka tse 'maloa li fumaneha ho latela sebopeho sa lik'hemik'hale.Khetho e tla itšetleha ka thepa ea liphaephe e amanang le lisebelisoa tsena.Tse ling tsa limaraka tse fumanehang tlas'a tlhaloso ena le litlhaloso tse tsamaellanang tsa liphaephe li thathamisitsoe ka tlase:

ASTM A420

Tlhaloso ena e akaretsa lisebelisoa tsa tšepe tse entsoeng ka carbon le alloy steel ea kaho e se nang seam & welded e reretsoeng ho sebelisoa ka mocheso o tlase.E akaretsa lihlopha tse 'nè tsa WPL6, WPL9, WPL3 & WPL8 ho itšetlehile ka sebopeho sa lik'hemik'hale.Lisebelisoa tsa WPL6 li lekoa ka mocheso - 50° C, WPL9 ho -75° C, WPL3 ho -100° C le WPL8 ho -195° C.

Litekanyetso tse lumelletsoeng tsa khatello ea li-fittings li ka baloa joalo ka peipi e otlolohileng e seamless ho latela melao e thehiloeng karolong e sebetsang ea ASME B31.3.

Botenya ba lerako la pipe le mofuta oa thepa e tla ba tseo lisebelisoa li laetsoeng hore li sebelisoe ka tsona, boitsebiso ba bona ho li-fittings bo sebakeng sa matšoao a khatello ea khatello.

| Nomoro ea tšepe. | Mofuta | Sebopeho sa lik'hemik'hale | ||||||||||||

| C | Si | S | P | Mn | Cr | Ni | Mo | Tse ding | ób | ós | δ5 | HB | ||

| WPL6 | 0.3 | 0.15-0.3 | 0.04 | 0.035 | 0.6-1,35 | 0.3 | 0.4 | 0.12 | Cb:0.02;V:0.08 | 415-585 | 240 | 22 | ||

| WPL9 | 0.2 | 0.03 | 0.03 | 0.4-1.06 | 1.6-2.24 | 435-610 | 315 | 20 | ||||||

| WPL3 | 0.2 | 0.13-0.37 | 0.05 | 0.05 | 0.31-0.64 | 3.2-3.8 | 450-620 | 240 | 22 | |||||

| WPL8 | 0.13 | 0.13-0.37 | 0.03 | 0.03 | 0.9 | 8.4-9.6 | 690-865 | 515 | 16 | |||||

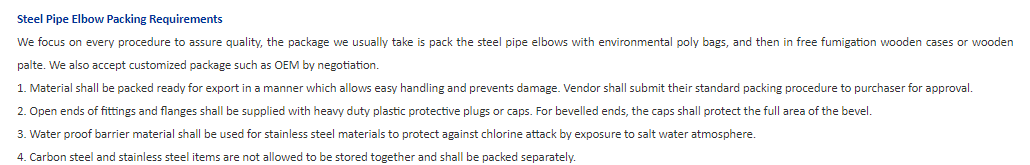

Ho tlotsa oli e khanyang, ho penta ho ntsho, ho roala masela, PE /3PE Anti-corrosion Coating

E pakiloe ka Likamoreng tsa Wood / Wood Tray