Peipi e koetsoeng

Liphaephe tse koetsoeng tse sebelisoang ha ho hlahlojoa oli li ka thibela lehlabathe la 99%, tsa fokotsa 80% ea tlhokomelo e boima ea seliba sa oli, hammoho le ho eketsa matla a seliba sa oli, botšepehi le botsitso ba ho boloka lehlabathe le le sieo.Ho sa le joalo, theknoloji ea laser incision e ka etsa hore slot e be boreleli le ho nepahala.Sebopeho sa pipe ea casing e slotted ke sampole, empa e sebetsa hantle haholo.

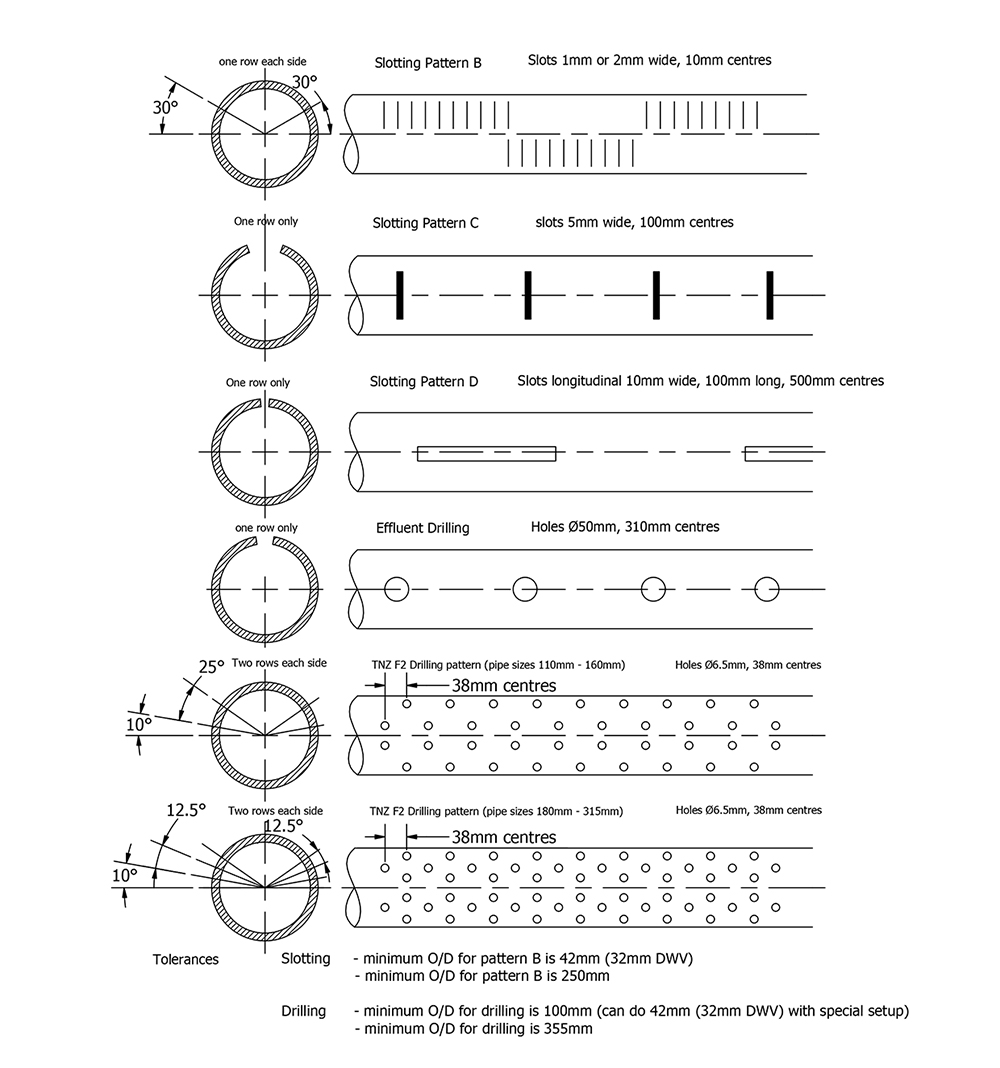

Slotted tube processing e holim'a 'mele oa tšepe o matla o nang le mekhoa e batang kapa e chesang ea ho sebetsa, ho khaola makholo a likete a mapetsong a longitudinal, mapetsong a tloaelehileng a sebelisoang bakeng sa: seam bophara 0.15 3 mm, le ho feta bophara, lekhalo bolelele 50-200 mm.Cross karolo. mefuta ke: khutlonnetsepa, lere e bōpehileng joaloka, itseng le tse fapa-fapaneng, e boetse e na le selikalikoe groove skrine, aperture bophara lintlha tse fapaneng 5-20 limilimithara ka limithara. karolo sebopeho makhethe tekanyo, moeling oa lesoba seam boreleli le tekanyo ea ho hanyetsa kutu ea lesoba seam.

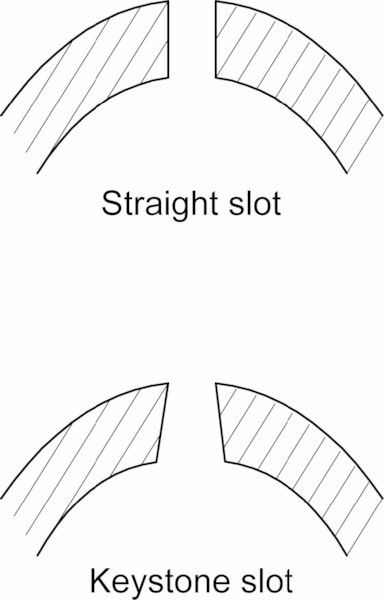

Slots e otlolohileng-Li-slots li khaotsoe ka bophara bo lekanang ka lebota la phala ID le OD.E hlalositsoe moo marokho a lehlabathe a sekotjana a seng bohlokoa bo boholo, li-slots tse otlolohileng ha li senyehe ho feta li-slots tsa lejoe la bohlokoa tse koahetsoeng 'me ha li bitse chelete e ngata ho li hlahisa.Lisebelisoa tse tloaelehileng tsa Straight cut slots ke tsa Cold Production le CBM tse tšekaletseng liliba ho kenyelletsa liliba tsa ente tsa SAGD.

Seamed Keystone Slots--Li siloa ka bophara ka hare ho phala 'me lia itlhoekisa ho thusa ho thibela ho phunya.E tšesaane karolong e ka holimo ea liner 'me e ntse e eketseha ka bophara ka hare, li lumella lehlabathe le kenang hore le fete habonolo ka har'a mekotla ntle le ho hokela.

| API Casing pipe | ID | Bolelele | Bolelele ba Slot | Setulo No. | Bophara ba slot | Sekotjana | Sefe e sebetsang | Max. | ||

| Spec mm | Botenya | Ka Boima ba 'mele | ||||||||

| 60.32 | 5 | 6.84 | 50.3 | 3 | 80 | 200 | 0.3 | ±50 | 48 | 512.54 |

| 73.02 | 5.5 | 9.15 | 62 | 240 | 57.6 | 688.55 | ||||

| 88.9 | 6.5 | 13.22 | 75.9 | 280 | 67.2 | 995.1 | ||||

| 101.6 | 6.5 | 15.22 | 88.6 | 300 | 72 | 1151.2 | ||||

| 114.3 | 7 | 18.47 | 100.3 | 10 | 320 | 76.8 | 1400.4 | |||

| 127 | 7.52 | 22.13 | 112 | 340 | 81.6 | 1673.8 | ||||

| 139.7 | 7.72 | 25.11 | 124.3 | 360 | 86.4 | 1900.2 | ||||

| 9.17 | 29.48 | 121.4 | 360 | 86.4 | 2232.4 | |||||

| 168.3 | 8.94 | 35.09 | 150.4 | 400 | 96 | 2672.95 | ||||

| 177.8 | 8.05 | 33.68 | 161.7 | 440 | 105.6 | 2559.2 | ||||

| 9.19 | 38.19 | 159.4 | 440 | 105.6 | 2940.7 | |||||

| Bophahamo ba pipe e bonojoana (ka hare) | OD(mm) | Botenya ba lebota(mm) | ID (mm) | Nomoro ea ho roka ea selikalikoe ka seng | Bophara ba slot(mm) | Bolelele ba slot (mm) | Bolelele(mm) |

| 2-3/8″ | 60.3 | 4.83 | 50.64 | 12-18 | 0.2~0.8 | 45 ~ 100 | 1000 ~ 12000 |

| 2-7/8″ | 73 | 5.51 | 61.98 | 20-24 | 45 ~ 100 | ||

| 3-1/2″ | 88.9 | 6.45 | 76 | 24-28 | 45 ~ 100 | ||

| 4″ | 101.6 | 6.65 | 88.29 | 24-30 | 45 ~ 100 | ||

| 4-1/2″ | 114.3 | 5.69 | 102.92 | 24-30 | 45 ~ 100 | ||

| 6.35 | 101.6 | 45 ~ 100 | |||||

| 7.37 | 99.57 | 45 ~ 100 | |||||

| 8.56 | 97.18 | 45 ~ 100 | |||||

| 5″ | 127 | 5.59 | 115.82 | 28-36 | 0.25~0,8 | 45 ~ 100 | |

| 6.43 | 114.15 | 45 ~ 100 | |||||

| 7.52 | 111.96 | 45 ~ 100 | |||||

| 9.19 | 108.61 | 45 ~ 100 | |||||

| 5-1/2″ | 139.7 | 6.2 | 127.3 | 30-38 | 45 ~ 100 | ||

| 6.99 | 125.73 | 45 ~ 100 | |||||

| 7.72 | 124.26 | 45 ~ 100 | |||||

| 9.17 | 121.36 | 45 ~ 100 | |||||

| 10.54 | 118.62 | 45 ~ 100 | |||||

| 7″ | 177.8 | 6.91 | 163.98 | 36-50 | 45 ~ 100 | ||

| 8.05 | 161.7 | 45 ~ 100 | |||||

| 9.19 | 159.41 | 45 ~ 100 | |||||

| 10.36 | 157.07 | 45 ~ 100 |

1. Peipi ea rona e nang le perforated e sebelisa J55 / K55 / N80 casing le li-tubing tsa API standard, e nang le matla a Phahameng ka kakaretso, ha ho bonolo ho e fetola.

2. Moeli oa slot o otlolohile, o boreleli, o se na li-burrs, 'me slot e tšoana.

3. Pipe e nang le perforated e loketse seliba sa lehlabathe, leo bophara ba lehlabathe bo fetang 0.3mm.

4. Slot e ka ba longitudinal le transverse, karolo ea slot e ka ba mefuta e tšoanang le ea trapezoidal, e nang le sebaka se pharaletseng se bulehileng.

5. Peipi ea skrine e kentsoeng e na le bophara bo boholo bo ka hare.

Tlhaloso ea API 5CT-Tlhaloso ea 5CT/ISO 11960, Tlhaloso ea Casing le Tubing, Khatiso ea Borobeli, Indasteri ea peterole le khase ea tlhaho-Lipeipi tsa tšepe bakeng sa ho sebelisoa e le casing kapa tubing bakeng sa liliba.

| Standard | Kereiti | Metsoako ea lik'hemik'hale (()) | |||||||||

| API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34–0.39 | 0.20–0.35 | 1.25–1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34–0.38 | 0.20–0.35 | 1.45–1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11–0.16 | |

| L80 | 0.15–0.22 | ≤1.00 | 0.25–1.00 | ≤0.020 | ≤0.010 | 12.0–14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26 ~ 0.395 | 0.17–0.37 | 0.40 ~ 0.70 | ≤0.020 | ≤0.010 | 0.80–1.10 | ≤0.20 | ≤0.20 | 0.15–0.25 | ≤0.08 | |

Thepa ea Mechini

| Kereiti | Mofuta | Kakaretso ea bolelele bo tlas'a mojaro (%) | Matla a tlhahiso (min) | Matla a tlhahiso (max) | Tensile matla min Mpa | Hardness Max (HRC) | Hardness Max(HBW) |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Kr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Kr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | - | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | - | 0.5 | 655 | 758 | 724 | - | - |

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 | - | - |

| Q125 | Tsohle | 0.65 | 862 | 1034 | 931 | - | - |

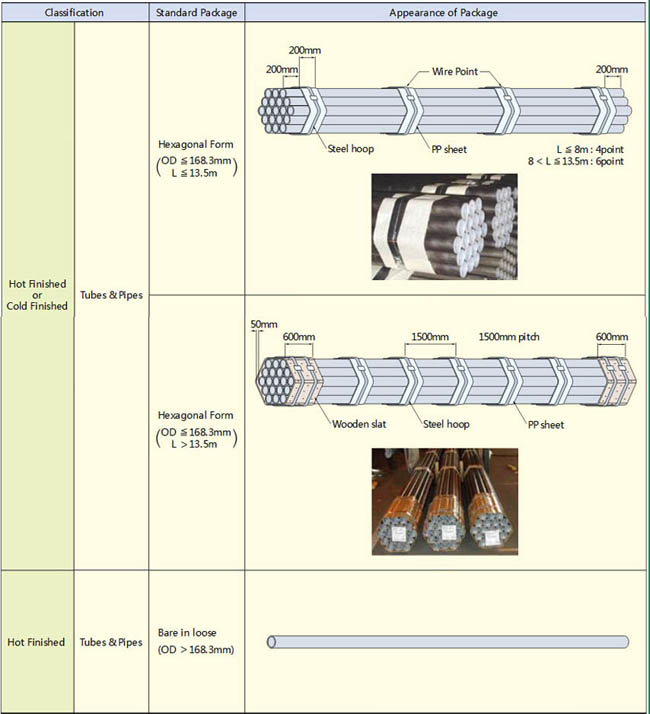

E le 'ngoe e nang le mokotla oa bubble ebe e le joalo ka lehong (setifikeiti sa fumigation).Taba ka 'ngoe e tšoailoe ka ho hlaka ka:

1. Lebitso le letšoao la boitsebiso la moetsi-HuaDong Brand

2. Nomoro ea sehlopha

3. Letsatsi la moetsi

4. Boitsebiso

5. Ho futhumatsa ho bolokehileng & mocheso oa kopo