Litaba tsa Lihlahisoa

-

Litšitiso tse nang le galvanized (galvanizing) tse chesang

Litšitiso tse nang le masela a chesang a chesang: ho tima, ho ingoaea, ho fetisoa ha plaque, matlapa a zinki, lehlakore le teteaneng, matšoao a thipa ea moea, mengoallo ea thipa ea moea, tšepe e pepeneneng, li-inclusions, tšenyo ea mochini, ts'ebetso e mpe ea tšepe ea tšepe, moeli oa wave, ho putlama. , boholo bo sa tloaheleheng, ho khabisa, lesela la zinki le teteaneng...Bala haholoanyane -

Likarolo tsa Precision Tubes

Likarolo tsa Precision Tubes Precision steel tubes ke mofuta oa phala ea tšepe e se nang seam. Li-tubes tse nepahetseng li na le likarolo: 1. Mamello a tšepe a batang a pota-potiloeng le ho nepahala ho phahameng, taolo e nepahetseng ea sehlahisoa ± 5mm, qetello ea lerako la ka ntle, lera la oxide e ka holimo. 2. The batang-phuthoa ho nepahetseng tšepe comprehen...Bala haholoanyane -

JIS G3445 Li-tubes tsa tšepe tsa carbon bakeng sa merero ea meralo ea mochini

JIS G3445 Li-tubes tsa tšepe tsa Carbon bakeng sa merero ea meralo ea mochini Tekanyetso ena ea Indasteri ea Japane e totobatsa li-tubes tsa carbon steel, tseo hamorao li tla bitsoa "li-tubes", tse sebelisetsoang mechini, likoloi, libaesekele, thepa ea ka tlung, lisebelisoa le likarolo tse ling tsa mochini. Li-tubes li tla ba manufac ...Bala haholoanyane -

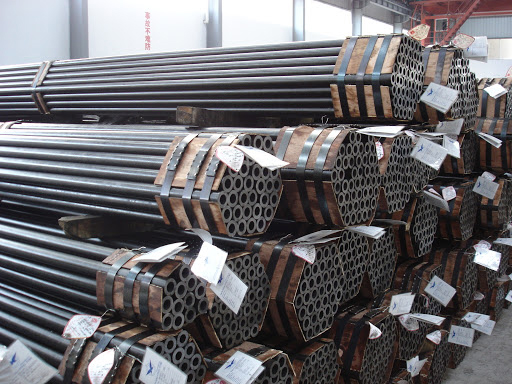

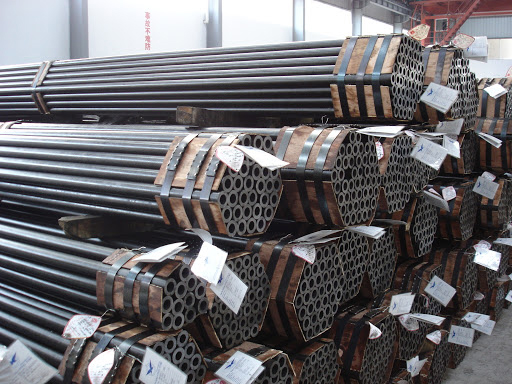

Pipe ea tšepe e chesitsoeng e chesang

Pipe ea tšepe e chesitsoeng e chesang e sebelisoa ha ho etsoa ts'ebetso e chesang ea extrusion ho etsa li-tubes tsa tšepe tse se nang moeli. Hot extrusion e sebelisoa haholo tlhahiso ea aluminium, koporo le liphaephe tse ling tsa tšepe tse nonferrous le profiles. Hot extrusion ea tšepe bakeng sa tlhahiso ea bobeli liphaephe khethehileng le pr...Bala haholoanyane -

Lintlha tsa mefokolo ea weld

Lintlha tse bakang bofokoli ba ho chesella (1) Lintho tse bonahalang: Ntho e bitsoang material factor e bolela litšepe tsa welding le lintho tse sebelisoang, tse kang lithapo, lithupa, flux le khase e sireletsang le tse ling tse joalo. Lisebelisoa tsena kaofela li ameha ka ho toba puddle ea welding kapa physico-chemical reaction ea ...Bala haholoanyane -

Kaho le polokelo ea tšepe e thibelang ho bola

Ho hahoa le ho boloka tšepe e khahlanong le kutu: (1) Pele ho penta ts'ebetso ea tšepe holim'a tšepe Sa2.5 sethaleng, mohaho o thibetsoe ka ho feletseng ka metsing, lerōleng, oli le brushing e le ho netefatsa boleng. (2) Karo-karolelano ea ho roala: Lintlha tsa sehlopha sa A (motheo), Karolo ea B (hardener) = pente ea 9kg: 1kg hardener (o...Bala haholoanyane