Gongono

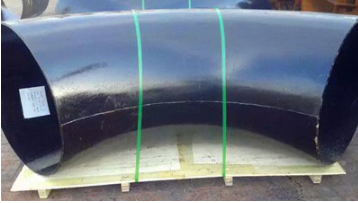

Njira Yopanga Zigongono Zopanda Msoko (Kupinda kwa Kutentha & Kupindika Kozizira)

Imodzi mwa njira zodziwika bwino zopangira zigongono ndikugwiritsa ntchito kupindika kwa mandrel otentha kuchokera ku mipope yachitsulo yowongoka.Pambuyo potenthetsa chitoliro chachitsulo pa kutentha kwakukulu, chitolirocho chimakankhidwa, kukulitsidwa, kupindika ndi zida zamkati za mandrel sitepe ndi sitepe.Kugwiritsa ntchito kupindika kwa mandrel otentha kumatha kupanga chigongono chosiyanasiyana.Makhalidwe a mandrel kupinda amadalira kwambiri mawonekedwe intergrated ndi miyeso ya mandrel.Ubwino wogwiritsa ntchito zigongono zotentha zimaphatikizira kupatuka kwa makulidwe ang'onoang'ono komanso utali wopindika wamphamvu kuposa mitundu ina yopindika.Pakadali pano, kugwiritsa ntchito kupindika m'malo mwa zopindika kale kumachepetsa kuchuluka kwa ma welds ofunikira.Izi zimachepetsa kuchuluka kwa ntchito yofunikira ndikuwonjezera ubwino ndi kugwiritsidwa ntchito kwa mapaipi.Komabe, kupindika kozizira ndi njira yopinda chitoliro chowongoka chachitsulo pamatenthedwe abwinobwino pamakina opindika.Kupinda kozizira ndikoyenera mapaipi okhala ndi mainchesi akunja a 17.0 mpaka 219.1 mm, ndi makulidwe a khoma 2.0 mpaka 28.0 mm.Malo opindika ovomerezeka ndi 2.5 x Do.Nthawi zambiri pamapindika opindika a 40D.Pogwiritsa ntchito kupindika kozizira, titha kupeza zigongono zazing'ono, koma tiyenera kunyamula zamkati ndi mchenga kuti tipewe makwinya.Kupinda kozizira ndi njira yachangu komanso yotsika mtengo yopinda.Ndi njira yampikisano yopangira mapaipi ndi zida zamakina.

Njira Yopangira Zigongono Zopangira (Zazing'ono & Zazikulu)

Zowotcherera elbows amapangidwa kuchokera mbale zitsulo, choncho si msoko zitsulo elbows.Gwiritsani ntchito nkhungu ndikusindikiza mbale yachitsulo kuti ikhale yofanana ndi chigongono, kenaka tenthetsani msoko kuti ukhale chitsulo chomaliza.Ndi njira yakale yopangira ma elbows.Zaka zaposachedwapa zazing'ono zazikulu elbows pafupifupi chopangidwa kuchokera zitsulo mapaipi tsopano.Kwa zigongono zazikuluzikulu, mwachitsanzo, ndizovuta kwambiri kupanga zigongono zopitilira 36" OD kuchokera ku mapaipi achitsulo.Choncho nthawi zambiri amapangidwa kuchokera ku mbale zachitsulo, kukanikiza mbaleyo kuti ikhale ngati theka la chigongono, ndikuwotcherera magawo awiriwo pamodzi.Popeza zigongono ndi welded mu thupi lake , kuyang'ana kwa kuwotcherera olowa m'pofunika .Nthawi zambiri timagwiritsa ntchito kuyesa kwa X-Ray ngati NDT.

| Kukula kwapaipi mwadzina | Kunja Diameter | Center mpaka Mapeto | Center mpaka Center | Bwererani ku Nkhope | ||||||

| 45 ° Zigono | 90 ° Zigono | 180 ° Kubwerera | ||||||||

| H | F | P | K | |||||||

| DN | INCH | Series A | Series B | LR | LR | SR | LR | SR | LR | SR |

| 15 | 1/2 | 21.3 | 18 | 16 | 38 | - | 76 | - | 48 | - |

| 20 | 3/4 | 26.9 | 25 | 16 | 38 | - | 76 | - | 51 | - |

| 25 | 1 | 33.7 | 32 | 16 | 38 | 25 | 76 | 51 | 56 | 41 |

| 32 | 11/4 | 42.4 | 38 | 20 | 48 | 32 | 95 | 64 | 70 | 52 |

| 40 | 11/2 | 48.3 | 45 | 24 | 57 | 38 | 114 | 76 | 83 | 62 |

| 50 | 2 | 60.3 | 57 | 32 | 76 | 51 | 152 | 102 | 106 | 81 |

| 65 | 21/2 | 76.1 (73) | 76 | 40 | 95 | 64 | 191 | 127 | 132 | 100 |

| 80 | 3 | 88.9 | 89 | 47 | 114 | 76 | 229 | 152 | 159 | 121 |

| 90 | 31/2 | 101.6 | - | 55 | 133 | 89 | 267 | 178 | 184 | 140 |

| 100 | 4 | 114.3 | 108 | 63 | 152 | 102 | 305 | 203 | 210 | 159 |

| 125 | 5 | 139.7 | 133 | 79 | 190 | 127 | 381 | 254 | 262 | 197 |

| 150 | 6 | 168.3 | 159 | 95 | 229 | 152 | 457 | 305 | 313 | 237 |

| 200 | 8 | 219.1 | 219 | 126 | 305 | 203 | 610 | 406 | 414 | 313 |

| 250 | 10 | 273.0 | 273 | 158 | 381 | 254 | 762 | 508 | 518 | 391 |

| 300 | 12 | 323.9 | 325 | 189 | 457 | 305 | 914 | 610 | 619 | 467 |

| 350 | 14 | 355.6 | 377 | 221 | 533 | 356 | 1067 | 711 | 711 | 533 |

| 400 | 16 | 406.4 | 426 | 253 | 610 | 406 | 1219 | 813 | 813 | 610 |

| 450 | 18 | 457.2 | 478 | 284 | 686 | 457 | 1372 | 914 | 914 | 686 |

| 500 | 20 | 508.0 | 529 | 316 | 762 | 508 | 1524 | 1016 | 1016 | 762 |

| 550 | 22 | 559 | - | 347 | 838 | 559 | Zindikirani: | |||

| 600 | 24 | 610 | 630 | 379 | 914 | 610 | ||||

| 650 | 26 | 660 | - | 410 | 991 | 660 | ||||

| 700 | 28 | 711 | 720 | 442 | 1067 | 711 | ||||

| 750 | 30 | 762 | - | 473 | 1143 | 762 | ||||

| 800 | 32 | 813 | 820 | 505 | 1219 | 813 | ||||

| 850 | 34 | 864 | - | 537 | 1295 | 864 | ||||

| 900 | 36 | 914 | 920 | 568 | 1372 | 914 | ||||

| 950 | 38 | 965 | - | 600 | 1448 | 965 | ||||

| 1000 | 40 | 1016 | 1020 | 631 | 1524 | 1016 | ||||

| 1050 | 42 | 1067 | - | 663 | 1600 | 1067 | ||||

| 1100 | 44 | 1118 | 1120 | 694 | 1676 | 1118 | ||||

| 1150 | 46 | 1168 | - | 726 | 1753 | 1168 | ||||

| 1200 | 48 | 1220 | 1220 | 758 | 1829 | 1219 | ||||

ASTM A234

Izi zimakwirira zitsulo zopangidwa ndi chitsulo cha carbon & alloy steel zomangira zopanda msoko ndi zowotcherera.Pokhapokha ngati nyumba yopanda msoko kapena yowotcherera yafotokozedwa mwadongosolo, mwina ikhoza kuperekedwa mwakufuna kwa wogulitsa.Zomangamanga zonse zowotcherera monga mwa muyezo uwu zimaperekedwa ndi 100% radiography.Pansi pa ASTM A234, magiredi angapo amapezeka kutengera kapangidwe kake.Kusankha kungadalire zinthu zapaipi zolumikizidwa ndi zolumikizira izi.

| Zofunikira za Tensile | WPB | Chithunzi cha WP11CL2 | Chithunzi cha WP11CL1 | Chithunzi cha WP11CL3 |

| Kulimbitsa Mphamvu, min, ksi[MPa] | 60-85 | 70-95 | 60-85 | 75-100 |

| (0.2% kuchepetsa kapena 0.5% yowonjezera-pansi-katundu) | [415-585] | [485-655] | [415-585] | [520-690] |

| Mphamvu Zokolola, min, ksi[MPa] | 32 | 40 | 30 | 45 |

| [240] | [275] | [205] | [310] |

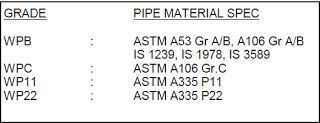

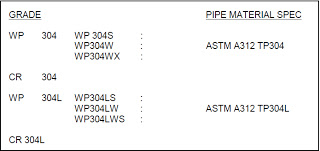

Ena mwa magiredi omwe akupezeka pansi pa izi komanso zinthu zolumikizidwa ndi mapaipi alembedwa pansipa:

Chithunzi cha ASTM A403

Izi zikuphatikiza magulu awiri wamba, WP & CR, a zitsulo zosapanga dzimbiri za austenitic zosapanga dzimbiri zomangira zopanda msoko komanso zowotcherera.

Zopangira za WP Class zimapangidwa motsatira zofunikira za ASME B16.9 & ASME B16.28 ndipo zimagawidwa m'magulu atatu motere:

- WP - Yopangidwa kuchokera kuzinthu zopanda msoko ndi njira yopangira yopanda msoko.

- WP - W Zopangira izi zimakhala ndi ma welds ndi ma welds onse opangidwa ndi wopanga oyenerera kuphatikiza kuyambitsa chitoliro chowotcherera ngati chitolirocho chidawotcherera ndikuwonjezera zinthu zodzaza ndi radiographed.Komabe palibe radiography yomwe imachitidwa poyambira chitoliro chowotcherera ngati chitolirocho chidawotchedwa popanda kuwonjezera zinthu zodzaza.

- WP-WX Zopangira izi zimakhala ndi ma welds ndi zowotcherera zonse kaya zopangidwa ndi wopanga zoyenerera kapena wopanga zinthu zoyambira zimajambulidwa ndi radiograph.

Zopangira za Class CR zimapangidwa motsatira zofunikira za MSS-SP-43 ndipo sizifunikira kuyesedwa kopanda kuwonongeka.

Pansi pa ASTM A403 magiredi angapo amapezeka kutengera kapangidwe kake.Kusankha kungadalire zinthu zapaipi zolumikizidwa ndi zolumikizira izi.Ena mwa magiredi omwe akupezeka pansi pa izi komanso zinthu zolumikizidwa ndi mapaipi alembedwa pansipa:

Chithunzi cha ASTM A420

Izi zimakwirira zitsulo zopangidwa ndi chitsulo cha carbon ndi alloy zitsulo zomanga zopanda msoko & zowotcherera zomwe zimagwiritsidwa ntchito potentha kwambiri.Imakhala ndi magiredi anayi WPL6, WPL9, WPL3 & WPL8 kutengera kapangidwe kake.Zoyikira WPL6 zimayesedwa pa kutentha - 50° C, WPL9 pa -75° C, WPL3 pa -100° C ndi WPL8 pa -195° C kutentha.

Kukakamiza kovomerezeka kwa zotengera zitha kuwerengedwa ngati chitoliro chowongoka chopanda msoko molingana ndi malamulo okhazikitsidwa ndi gawo loyenera la ASME B31.3.

Makulidwe a khoma la chitoliro ndi mtundu wa zinthu zizikhala zomwe zidalamulidwa kuti zigwiritsidwe ntchito, zomwe zimadziwika pazigawozo zimakhala m'malo mwazolemba zamphamvu.

| Chitsulo No. | Mtundu | Chemical zikuchokera | ||||||||||||

| C | Si | S | P | Mn | Cr | Ni | Mo | Zina | ob | os | δ5 ndi | HB | ||

| WPL6 | 0.3 | 0.15-0.3 | 0.04 | 0.035 | 0.6-1.35 | 0.3 | 0.4 | 0.12 | Cb:0.02;V:0.08 | 415-585 | 240 | 22 | ||

| WPL9 | 0.2 | 0.03 | 0.03 | 0.4-1.06 | 1.6-2.24 | 435-610 | 315 | 20 | ||||||

| WPL3 | 0.2 | 0.13-0.37 | 0.05 | 0.05 | 0.31-0.64 | 3.2-3.8 | 450-620 | 240 | 22 | |||||

| WPL8 | 0.13 | 0.13-0.37 | 0.03 | 0.03 | 0.9 | 8.4-9.6 | 690-865 | 515 | 16 | |||||

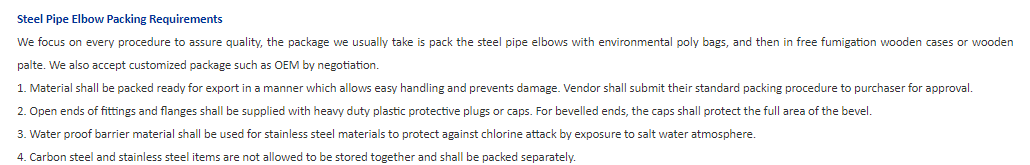

Kupaka Mafuta Opepuka, Kupaka Kwakuda, Kupaka galvanizing, PE / 3PE Anti-corrosion Coating

Odzaza mu Wood Cabins / Wood Tray