Carbon Steel Seamless Pipe

Seamless Steel Pipe amapangidwa kuchokera kuchitsulo chozungulira cholimba'billet'chomwe chimatenthedwa ndi kukankhira kapena kukoka pamtundu wina mpaka chitsulocho chipangidwe kukhala chubu lopanda kanthu.Chitoliro chopanda msoko chimatsirizidwa kuti chikhale chofanana ndi makulidwe a khoma kuchokera pa 1/8 inchi mpaka 32 inchi OD.Carbon Steel Seamless Pipes / Tubes Carbon steel ndi aloyi wopangidwa ndi chitsulo ndi kaboni.Gawo la mpweya muzitsulo limakhudza kuuma, mphamvu ya elasticity ndi ductility ya carbon steel.Chitoliro chachitsulo chosasunthika cha carbon steel kapena ingot yolimba yachitsulo imapangidwa ndi chubu cha capillary kudzera mu dzenje, kenako kudzera pa kuyimba kotentha, kozizira kapena kozizira kumapangidwa.Msokonezo mpweya zitsulo chitoliro mu makampani zitsulo China ali ndi udindo wofunika.Seamless carbon steel chitoliro ndi chubu chozungulira, mapaipi odulira makina opangira ma dzira kuti adutse pafupifupi 1 m kutalika opanda kanthu, ndikutumizidwa ndi kutentha kwa ng'anjo ya conveyor lamba.Billet amadyetsedwa mu ng'anjo yotentha, kutentha kumakhala pafupifupi madigiri 1200 Celsius.Mafuta ndi hydrogen kapena acetylene.Kuwongolera kutentha kwa ng'anjo ndiyo nkhani yaikulu.Chubu lozungulira linatuluka kuti liwombetse makinawo kudzera mumphamvu ya mpweya.Nthawi zambiri nkhonya wamba ndi tapered mpukutu perforation makina, nkhonya mkulu kupanga dzuwa, mankhwala khalidwe, lalikulu m'mimba mwake kukula dzenje, akhoza kuvala zosiyanasiyana zitsulo.Perforation, chubu chozungulira chakhala chikugubuduza mtanda wa mipukutu itatu, kugudubuza kapena kutulutsa.Chofinyidwa pa chubu pambuyo kukula.Kukula pobowola mothamanga kwambiri ma rotary cone mu billet kupanga chubu.Chitoliro cha m'mimba mwa mphero kuti mudziwe kutalika kwa kubowola awiri.Pambuyo chitoliro mwa sizing mu kuzirala nsanja, kuzirala ndi kutsitsi madzi, zitsulo pambuyo kuzirala, ayenera kuwongola.Pambuyo pa lamba wachitsulo wotumizidwa ndi kuwongola makina oyesera zitsulo (kapena kuyesa kukakamiza) kuyesa mkati.Ngati chitoliro mkati ming'alu, thovu ndi mavuto ena adzakhala wapezeka.Pambuyo chitoliro komanso kudzera okhwima khalidwe ulamuliro Buku kusankha.Ubwino wachitsulo, kugwiritsa ntchito manambala a utoto wopopera, mawonekedwe, nambala yopangira zambiri.Ndi crane kulowa m'nkhokwe.

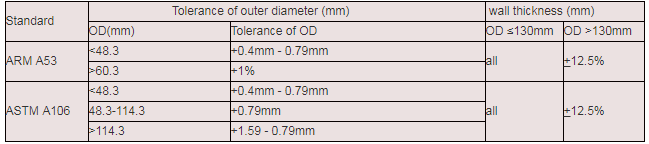

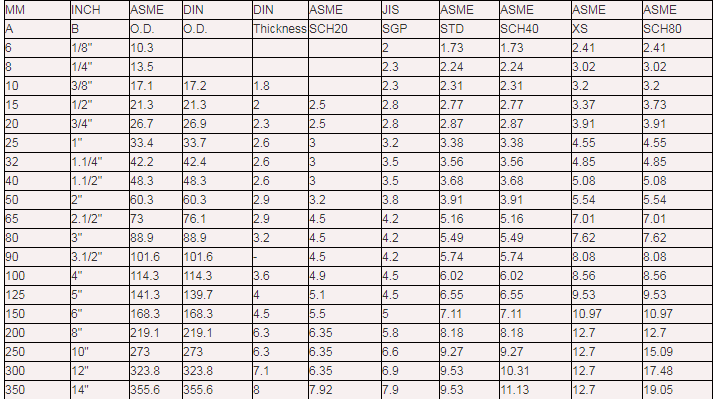

Makulidwe a khoma la chitoliro chopanda msoko

Kulekerera kwa Diameter Yakunja ndi makulidwe a Khoma

| Standard | Kufotokozera |

| ASTM A179/A179M | Kutentha kosasunthika kosasunthika komwe kumakokedwa ndi chitsulo chotsika cha aloyi ndi machubu a condenser. |

| API 5L | Chitoliro cha mzere. |

| Chithunzi cha ASTM A53M | Chitoliro Chachitsulo Chakuda & Zinc Chokutidwa ndi Chowotcherera komanso Chopanda Msokonezo. |

| Chithunzi cha ASTM A106M | Chitoliro chosasunthika cha chitsulo cha carbon pa ntchito yotentha kwambiri. |

| Chithunzi cha ASTM A105M | Zopangira zitsulo za kaboni zopangira mapaipi. |

| ASTM A234M | Kuyika kwa mapaipi achitsulo chopangidwa ndi kaboni ndi chitsulo cha aloyi kwa ntchito yotentha komanso yotentha kwambiri. |

| Mtengo wa ASTM 3799 | Zoyikira mapaipi achitsulo, zopindika komanso kuwotcherera kwa socket kwamakampani amafuta. |

| Chithunzi cha AS 1163 | Zomangamanga zitsulo dzenje zigawo |

| Chithunzi cha AS 1074 | Machubu achitsulo ndi ma tubular a ntchito wamba |

| Mtengo wa BS13872 | Chubu chachitsulo chokulungidwa komanso chokhazikika komanso ma tubulars |

| Standard | Mtundu wa chitoliro | Kalasi | Gulu |

| API SPEC 5L ISO 3183 | SMLS | Chithunzi cha PLS1 | L245B, L290 X42, L320 X46, L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| Chithunzi cha PLS2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q , L485Q X70Q

| ||

| PLS2 Chilengedwe Chowawa | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS

| ||

| WELD | Chithunzi cha PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| Chithunzi cha PLS2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, | ||

| Standard | Gulu |

| ASTM A 53M | A, B |

| Chithunzi cha ASTM A106M | A, B, C |

| Chithunzi cha JIS G3454 | STPG 370, STPG 410 |

| Chithunzi cha JIS G3455 | STPG370, STPG410, STPG480 |

| Chithunzi cha JIS G3456 | STPG370, STPG410, STPG480 |

Gulu: Mapangidwe a Chemical (%):

| Standard | Gulu | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTMA 53m | A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | - | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| Chithunzi cha ASTM A106M | A | ≤0.25 | ≥0.10 | 0.27-0.93 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| Chithunzi cha JIS G3454 | Mtengo wa 370 | ≤0.25 | ≤0.35 | 0.30-0.90 | ≤0.040 | ≤0.040 | - | - | - | - | - |

| Mtengo wa 410 | ≤0.30 | ≤0.35 | 0.30-1.00 | ≤0.040 | ≤0.040 | - | - | - | - | - | |

| Chithunzi cha JIS G3455 | Mtengo wa 370 | ≤0.25 | 0.10-0.35 | 0.30-1.10 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| Mtengo wa 410 | ≤0.30 | 0.10-0.35 | 0.30-1.40 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| Mtengo wa 480 | ≤0.33 | 0.10-0.35 | 0.30-1.50 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| Chithunzi cha JIS G3456 | Chithunzi cha 370 | ≤0.25 | 0.10-0.35 | 0.30-0.90 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| Mtengo wa 410 | ≤0.30 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| Mtengo wa 480 | ≤0.33 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - |

Pamwamba mankhwala a zitsulo chitoliro: Pofuna kusintha moyo utumiki wa payipi mafuta, mankhwala pamwamba nthawi zambiri ikuchitika kuti atsogolere olimba kuphatikiza zitsulo chitoliro ndi anticorrosive ❖ kuyanika.Common processing njira ndi: kuyeretsa, chida derusting, pickling, kuwombera kuphulika derusting. magulu anayi.1 kuyeretsa mafuta, fumbi, lubricant, organic nkhani amamatira pamwamba pa chitoliro zitsulo, kawirikawiri ntchito zosungunulira, emulsion kuyeretsa pamwamba. mankhwala njira zofunika.Chida dzimbiri kuchotsaSteel chitoliro padziko okusayidi, dzimbiri, kuwotcherera slag, angagwiritse ntchito zitsulo waya burashi kuyeretsa ndi kupukuta pamwamba treatment.Tool derusting akhoza kugawidwa mu Buku ndi mphamvu, Buku chida derusting angafikire Sa 2 mlingo, mphamvu chida derusting akhoza kufika Sa3 mlingo.Ngati pamwamba zitsulo chitoliro Ufumuyo ndi makamaka amphamvu okusayidi khungu, zingakhale zosatheka kuchotsa dzimbiri mothandizidwa ndi zida, choncho tiyenera kupeza njira zina.3 pickling Njira yodziwika bwino ya pickling imaphatikizapo chemistry ndi electrolysis. Koma pickling yokha ya mankhwala imagwiritsidwa ntchito poteteza payipi ya dzimbiri. Kusakaniza kwa mankhwala kungathe kukwaniritsa ukhondo ndi kuuma pamwamba pa chitoliro chachitsulo, chomwe chimakhala chosavuta kwa mizere ya nangula yotsatira. kuwombera (mchenga) pambuyo pokonzanso.Kuwombera kwa 4 kuti muchotse dzimbiri Pogwiritsa ntchito injini yamphamvu yoyendetsa makina othamanga kwambiri, grit yachitsulo, kuwombera zitsulo, gawo, mchere ndi waya wonyezimira pogwiritsira ntchito mphamvu ya centrifugal pazitsulo zachitsulo pamwamba pazitsulo ndi kutulutsa kwakukulu, kuchotsani dzimbiri, ma oxides. ndi dothi pa dzanja limodzi, Komano, zitsulo chitoliro pansi zochita za abrasive chiwawa mphamvu ndi mikangano mphamvu, kukwaniritsa chofunika yunifolomu roughness.Mwa njira zinayi mankhwala, kuwombera kuphulika ndi derusting ndi njira yabwino mankhwala kwa chitoliro derusting.Nthawi zambiri, kuwombera kabotolo ndi derusting makamaka ntchito mkati padziko mankhwala a zitsulo chitoliro, ndi kuwombera kabotolo ndi derusting zimagwiritsa ntchito kunja mankhwala pamwamba zitsulo chitoliro.

Utsi utoto

Utsi utoto

Kuyika kwamadzi