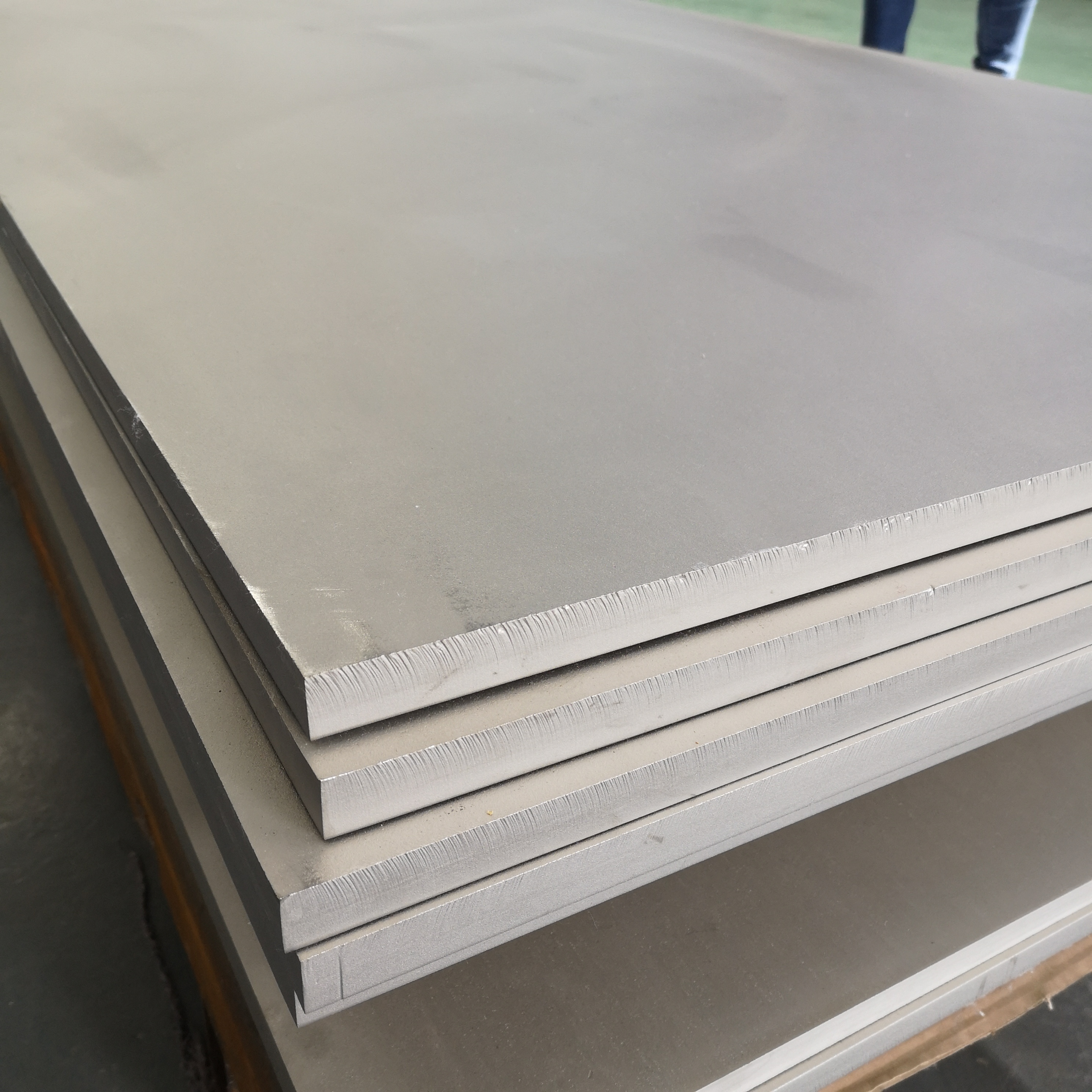

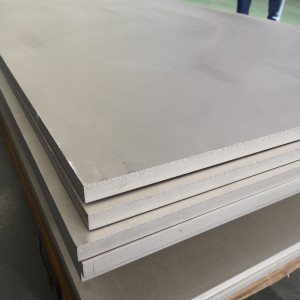

Titanium Sheet / Plate

Makin gama gari

Titanium Darasi na 1samfurin titanium mara ƙarfi ne mara ƙarfi wanda ke ɗauke da ƙarancin iskar oxygen tare da babban nau'i mai ƙarfi;Ana amfani da wannan darajar titanium a cikin firam ɗin iska, musayar zafi da raka'a na desalination.

Titanium Darasi na 2samfurin titanium ne mara ƙarfi, matsakaicin ƙarfi.Ana amfani da wannan darajar titanium a cikin firam ɗin iska, injunan jirgi da sassan ruwa;Kyakkyawan ikon walda da juriya na lalata sune halayensa na rarrabewa.

Titanium Darasi 3wani unalloyed ne, babban ƙarfi, titanium samfurin samar da kyakkyawan lalata juriya da kuma mai kyau weld ikon.Ana amfani da wannan darajar titanium da farko a cikin firam ɗin iska da sassan injin jirgin sama.

Babban darajar Titanium 4shine mafi girman ƙarfi tsantsa samfurin titanium mara kyau.Ana amfani da wannan darajar titanium kusan na musamman don firam ɗin iska, sassan injin jirgin sama, marine, injin tiyata, tubing na ruwa.Kyakkyawar ƙarfin siga da juriya na lalata su ne alamar sa.

Titanium Grade 5 (6AL-4V)wani alloyed titanium samfurin dauke da 6% Aluminum da 4% Vanadium;samfurin ƙarfin matsakaici ne.Ana amfani da wannan darajar titanium mafi yawa a cikin injin iska da injin turbine;da kuma yin amfani da su a cikin aikin tiyata.Bayanin Fasaha Titanium 6AL-4V ELI shine samfurin titanium alloyed wanda ya ƙunshi 6% Aluminum da 4% Vanadium, ELI (Extra Low Interstitial).

6 AL-2Sn-4Zr-2Mo (6-2-4-2)wani alloyed titanium samfurin dauke da 6% Aluminum, 2% Tin, 4% Zirconium, 2% Molybdenum.

6 AL-6V-2Sn (6-6-2)wani alloyed titanium samfurin dauke da 6% Aluminum, 6% Vanadium, 2% Tin.

5 AL-2.5Sn & ELI (5-2.5)wani alloyed titanium samfurin dauke da 5% Aluminum da 2.5% Tin.Hakanan ELI (Extra Low Interstitial).

8 AL-1V-1 wata (8-1-1)wani alloyed titanium samfurin dauke da 8% Aluminum, 1% molybdenum da 1% Vanadium.

15V-3Cr-4 AL-3Sn (15-3-4-3)wani alloyed titanium samfurin dauke da 15% Vanadium, 3% Chromium, 4% Aluminum, 3% Tin.

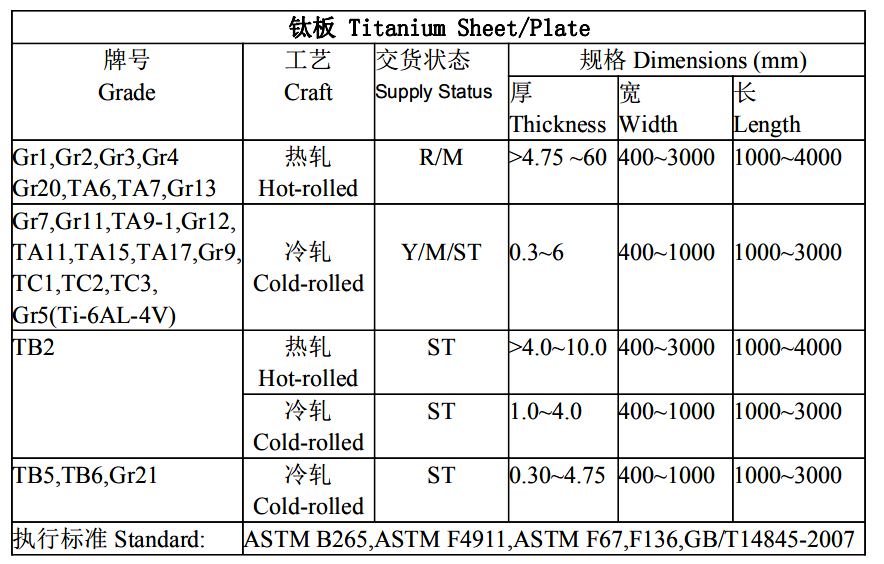

| Daraja | Matsayi | Ƙayyadaddun bayanai | ||

| Gr1,Gr2,Gr4,Gr5,Gr7,Gr9,Gr11, Gr12,Gr16,Gr23 | Hot Rolled(R) Cold Rolled(Y) Annealed(M) Maganin Magani (ST) | Kauri (mm) | Nisa (mm) | Tsawon (mm) |

| 0.3 zuwa 60 | ≥400 | ≤ 6000 | ||

| Titanium Sheet | |||

| Kauri | Maki | ||

| .016 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .020 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .025 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .032 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .040 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .050 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .063 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .071 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .080 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .090 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .100 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .125 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

Lura: Akwai ƙarin girma dabam, ba duk girman da aka nuna ana samun su daga hannun jari ba.Da fatan za a tuntuɓe mu don bincika samuwa.

| AMS:AMS 2631, AMS 4901, AMS 4907, AMS 4911ASTM: ASTM B265 Gr 23, ASTM B265 Gr 5, ASTM B265 Gr2, ASTM B265 Gr4, ASTM F136, ASTM F67MIL-T:MIL-T-9046, MIL-T-9046 CP1EN:EN 10204.3, EN 1-204: 2005 3.1 NACE:NACE MR0175 ASME:Saukewa: ASME SB265 |

| Daraja | Bayanan Bayani na AMS/MIL | Bayanan Bayani na ASTM |

| Darasi na 1 | Saukewa: AMS-T-9046B Saukewa: AMS4940MIL-T-9046J | ASTM B265 Gr1 Sheet/Plate ASTM B337 Gr1 bututu ASTM B338 Gr1 tube ASTM B348 Gr1 mashaya ASTM F67 Gr1 Injin Tiyata |

| Darasi na 2 | Babban darajar AMS-T-9046B CP3 Saukewa: AMS4902MIL-T-9046J Farashin 4941 Farashin 4942 AMS 4951 Welding waya | ASTM B265 Gr2 takarda / farantin ASTM B337 Gr2 bututu ASTM B338 Gr2 tube ASTM B348 Gr2 mashaya ASTM F67 Gr2 Injin Tiyata |

| Darasi na 3 | Saukewa: AMS-T-9046B Farashin 4900 MIL-T-9046J CP2 | ASTM B265 Gr3 Sheet/Plate ASTM B337 Gr3 bututu ASTM B338 Gr3 tube ASTM B348 Gr3 mashaya ASTM F67 Gr3 Injin tiyata |

| Darasi na 4 | Saukewa: AMS-T-9046B Saukewa: AMS-T-9047ACP70 Farashin 4901 Saukewa: AMS4921MIL-T-9046J MIL-T-9047G CP70 | Takardar bayanai:ASTM B265Gr4 ASTM B337 Gr4 bututu ASTM B338 Gr4 tube ASTM B348 Gr4 ASTM F67 Gr4 Injin tiyata |

| Darasi na 7 | ASTM B265 Gr7 Sheet/Plate ASTM B337 Gr7 bututu ASTM B338 Gr7 tube ASTM B348 Gr7 mashaya |

| Daraja | Bayanan Amurka | Bayanan Bayani na ASTM |

| Darasi na 5 6 Al-4V | Saukewa: AMS4907 Farashin 4911 Farashin 4928 Saukewa: AMS4930 AMS 4931 ELI Duplex ann Farashin 4963 Farashin 4965 Farashin 4967 Farashin 4985 Farashin 4991 Farashin 6931 Farashin 6932 MIL-T-9046J AB-1 MIL-T-9046J AB-2 (ELI) MIL-T-9046H Nau'in 3 Comp C MIL-T-9046H Nau'in 3 Comp D AMS-T-9046B-1 AMS-T-9046B AB-2 (ELI) MIL-T-9047G 6Al-4v MIL-T-9047G 6Al-4v (ELI) AMS-T-9047A 6Al-4v AMS-T-9047A 6Al-4v (ELI) | ASTM B265 Gr5 takarda / farantin ASTM B348 Gr5 mashaya ASTM F136 Gr5 Matsayin Shigarwa |

| Darasi na 9 3 Al-2.5V | Farashin 4943 Farashin 4944 Farashin 4945 AMS-T-9046B-5 AMS-T-9047A 3Al-2.5V MIL-T-9046J AB-5 MIL-T-9047 3Al-2.5V | ASTM B265 Gr6 Sheet/Plate ASTM B348 Gr6 mashaya |

| Darasi na 23 6 Al-4V ELI | Farashin 4907 Farashin 4930 Farashin 6932 AMS-T-9046 AB-2 6AL-4V (ELI) AMS-T-9047 AB-2 6AL-4V (ELI) MIL-T-9046 AB-2 6AL-4V (ELI) MIL-T-9047 6AL-4V (ELI) | ASTM B265 Gr23 takarda / farantin / tsiri ASTM B348 Gr23 mashaya/billet ASTM F136 Gr23 Implant Gra |

Abubuwan sinadaran

| Daraja | Abubuwan sinadaran, kashi dari (%) | ||||||||||||

| C ≤ | O ≤ | N ≤ | H ≤ | Fe ≤ | Al | V | Pd | Ru | Ni | Mo | Sauran Abubuwan Max.kowanne | Sauran Abubuwan Max.duka | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5~6.75 | 3.5~4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12~0.25 | - | 0.12~0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12~0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04~0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5~4.5 | - | - | - | - | 0.1 | 0.1 |

Kaddarorin jiki

| Daraja | Kaddarorin jiki | ||||||

| Ƙarfin ƙarfi Min | Ƙarfin bayarwa (0.2%) | Girma a cikin 50mm Min (%) | |||||

| ksi | MPa | Min | Max | ||||

| ksi | MPa | ksi | MPa | ||||

| Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr4 | 80 | 550 | 70 | 483 | 95 | 655 | 15 |

| Gr5 | 130 | 895 | 120 | 828 | - | - | 10 |

| Gr7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr9 | 90 | 620 | 70 | 483 | - | - | 15 |

| Gr11 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr12 | 70 | 483 | 50 | 345 | - | - | 18 |

| Gr16 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | - | - | 10 |

Haƙuri (mm)

| Kauri | Haƙuri mai faɗi | ||

| 400-1000 | 1000-2000 | :2000 | |

| 5.0 ~ 6.0 | ± 0.35 | ± 0.40 | ± 0.60 |

| 6.0 zuwa 8.0 | ± 0.40 | ± 0.60 | ± 0.80 |

| 8.0 ~ 10.0 | ± 0.50 | ± 0.60 | ± 0.80 |

| 10.0 ~ 15.0 | ± 0.70 | ± 0.80 | ± 1.00 |

| 15.0 ~ 20.0 | ± 0.70 | ± 0.90 | ± 1.10 |

| 20.0 ~ 30.0 | ± 0.90 | ± 1.00 | ± 1.20 |

| 30.0 ~ 40.0 | ± 1.10 | ± 1.20 | ± 1.50 |

| 40.0 ~ 50.0 | ± 1.20 | ± 1.50 | ± 2.00 |

| 50.0 ~ 60.0 | ± 1.60 | ± 2.00 | ± 2.50 |