Carbon Karfe Bututu maras kyau

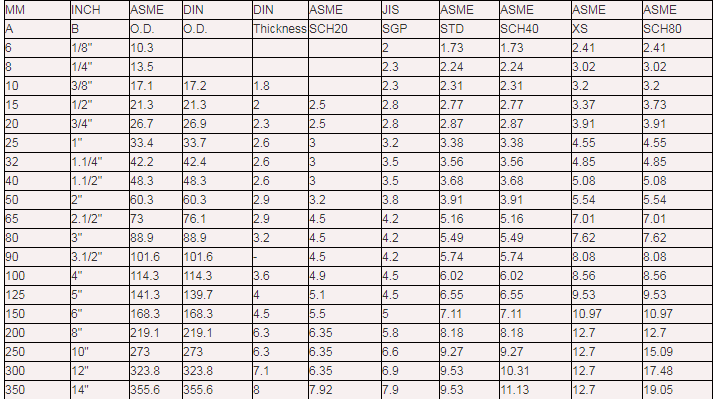

An yi bututun ƙarfe mara ƙarfi daga ƙarfe mai ƙarfi zagaye'billet'wanda ake zafi da turawa ko kuma a ja shi a kan wani nau'i har sai an siffata karfen zuwa bututu mai zurfi.Sannan an gama bututu maras sumul zuwa ƙayyadaddun kauri da kauri na bango a cikin girma daga 1/8 inch zuwa 32 inch OD.Carbon Karfe Sumul Bututu / tubes Karfe Karfe ne gami da ya ƙunshi baƙin ƙarfe da carbon.Yawan carbon a cikin karfe yana rinjayar taurin, ƙarfin elasticity da ductility na carbon karfe.An yi bututun ƙarfe na ƙarfe mara ƙarfi ko ingot ɗin ƙarfe mai ƙarfi daga bututun capillary ta cikin ramin, sannan ta birgima mai zafi, birgima ko sanyi ana yin kira.Sumul carbon karfe bututu a kasar Sin karfe masana'antu yana da wani muhimmin matsayi.Abun bututun ƙarfe mara ƙarfi shine bututu mai zagaye, bututun yankan bututu don wucewa ta hanyar yankan kusan mita 1 na tsayi mara kyau, kuma ana aika ta hanyar dumama bel ɗin isarwa.Ana ciyar da Billet a cikin tanderun dumama, zafin jiki yana kusan digiri 1200 ma'aunin Celsius.Fuel shine hydrogen ko acetylene.Kula da zafin wuta shine babban batun.Round tube ya fito don buga ta cikin injin ta hanyar iska.Gabaɗaya mafi na kowa naushi ne tapered yi perforation inji, da naushi high samar yadda ya dace, samfurin ingancin, babban diamita rami fadada, iya sa iri-iri na karfe.Perforation, bututu mai zagaye ya kasance akan jujjuyawar giciye mai birgima, mirgina ko extrusion.An matse daga bututu bayan girma.Girman ramukan jujjuyawar mazugi mai tsayi a cikin billet don samar da bututu.Diamita na bututu ta injin niƙa don tantance tsawon diamita na rawar soja.Bayan bututu ta hanyar ma'auni a cikin hasumiya mai sanyaya, sanyaya ta hanyar fesa ruwa, karfe bayan sanyaya, ya kamata a daidaita.Bayan bel ɗin karfe da aka aika ta hanyar daidaita injin gwajin ƙarfe (ko gwajin matsa lamba) don gwaji na ciki.Idan bututu na ciki ya tsage, za a gano kumfa da sauran matsalolin.Bayan bututu amma kuma ta hanyar zaɓen mai inganci mai inganci.Ƙarfe ingancin, amfani da fenti lambobin fenti, ƙayyadaddun bayanai, yawan adadin samarwa.By wani crane a cikin sito.

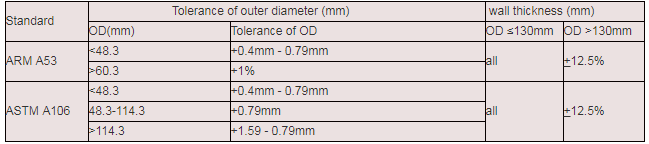

Kaurin bango na bututu mara nauyi

Hakuri na Diamita na waje da kaurin bango

| Daidaitawa | Bayani |

| Saukewa: ASTM A179/A179M | Sanyi mara kyau wanda aka zana ƙananan ƙarfe mai musanya zafi da bututun mai ɗaukar hoto. |

| API 5L | Bututun layi. |

| ASTM A53M | Black & Zinc Rufaffen Weld da Bututu Karfe mara sumul. |

| Saukewa: ASTM A106M | Bututun ƙarfe mara nauyi don sabis ɗin zafin jiki mai girma. |

| Saukewa: ASTM A105M | Carbon karfe forgings don bututu aikace-aikace. |

| Saukewa: ASTM A234M | Kayan aikin bututun ƙarfe na carbon da aka yi da ƙarfe na ƙarfe don matsakaici da sabis na zafin jiki. |

| Farashin ASTM3799 | Kayan aikin bututun ƙarfe, screwd da socket weldability don masana'antar mai. |

| Farashin AS1163 | Tsarin karfe m sassan |

| Farashin AS1074 | Bututun ƙarfe da tubulars don sabis na yau da kullun |

| Saukewa: BS13872 | Bututun ƙarfe da bututun ƙarfe da soket |

| Daidaitawa | Nau'in bututu | Class | Daraja |

| API SPEC 5L ISO 3183 | SMLS | PLS1 | L245B, L290 X42, L320 X46 , L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| PLS2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q, L485Q X70Q

| ||

| PLS2 Muhalli mai tsami | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS

| ||

| WELD | PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| PLS2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, | ||

| Daidaitawa | Daraja |

| ASTM A53M | A, B |

| ASTM A106M | A, B, C |

| Farashin G3454 | STPG 370, STPG 410 |

| Farashin G3455 | Saukewa: STPG370,STPG410 |

| Farashin G3456 | Saukewa: STPG370,STPG410 |

Daraja: Haɗin Sinadari (%):

| Daidaitawa | Daraja | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTMA 53M | A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | - | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| ASTM A106M | A | ≤0.25 | ≥0.10 | 0.27-0.93 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| Farashin G3454 | Farashin STPG370 | ≤0.25 | ≤0.35 | 0.30-0.90 | ≤0.040 | ≤0.040 | - | - | - | - | - |

| Saukewa: STPG410 | ≤0.30 | ≤0.35 | 0.30-1.00 | ≤0.040 | ≤0.040 | - | - | - | - | - | |

| Farashin G3455 | Farashin STS370 | ≤0.25 | 0.10-0.35 | 0.30-1.10 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| Saukewa: STS410 | ≤0.30 | 0.10-0.35 | 0.30-1.40 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| Saukewa: STS480 | ≤0.33 | 0.10-0.35 | 0.30-1.50 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| Farashin G3456 | STPT 370 | ≤0.25 | 0.10-0.35 | 0.30-0.90 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STPT 410 | ≤0.30 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STPT 480 | ≤0.33 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - |

Surface jiyya na karfe bututu: Domin inganta rayuwar sabis na mai bututun, surface jiyya yawanci za'ayi don sauƙaƙe m hade da karfe bututu da anticorrosive coating.Common aiki hanyoyin ne: tsaftacewa, kayan aiki derusting, pickling, harbi ayukan iska mai ƙarfi derusting. nau'i hudu.1 CleaningGrease, ƙura, mai mai, kwayoyin kwayoyin halitta a kan saman bututun ƙarfe, yawanci ta yin amfani da sauran ƙarfi, emulsion don tsaftace farfajiyar. Duk da haka, tsatsa, fata oxide da walƙiya slag a saman bututun karfe ba za a iya cirewa ba, don haka sauran magani hanyoyin ake bukata.Tool tsatsa RemoveSteel bututu surface oxide, tsatsa, waldi slag, iya amfani da karfe waya goga don tsaftacewa da goge da surface treatment.Tool derusting za a iya raba zuwa manual da iko, manual kayan aiki derusting iya isa Sa 2 matakin, iko. derusting kayan aiki zai iya kaiwa matakin Sa3. Idan an haɗa saman bututun ƙarfe tare da fata mai ƙarfi na musamman mai ƙarfi, yana iya zama ba zai yuwu a cire tsatsa ba tare da taimakon kayan aiki, don haka muna buƙatar nemo wasu hanyoyi.3 pickling Common pickling hanyoyin sun hada da chemistry da electrolysis.Amma kawai sinadaran pickling da ake amfani da shi don kare lalata bututun.Chemical pickling zai iya cimma wani mataki na tsabta da roughness a saman saman karfe bututu, wanda ya dace da na gaba anka Lines.Yawanci a matsayin harbi (yashi) bayan sake sarrafawa.4 harbi iska mai ƙarfi don cire tsatsa ta hanyar babban motar motsa jiki mai saurin jujjuya ruwan wukake, grit karfe, harbin karfe, sashi, ma'adanai da sauran waya mai abrasive a ƙarƙashin aikin ƙarfin centrifugal akan fesa bututun ƙarfe da fitar da taro, cire tsatsa sosai, oxides. da datti a daya hannun, a daya hannun, karfe bututu karkashin mataki na abrasive tashin hankali tasiri da gogayya karfi, don cimma da ake bukata uniform roughness.A cikin hudu jiyya hanyoyin, harbi ayukan iska mai ƙarfi da derusting ne manufa magani Hanyar for bututu derusting.Gabaɗaya, harbin iska mai ƙarfi da ɓarkewa ana amfani da su ne don jiyya da bututun ƙarfe na ciki, kuma harbin iska mai ƙarfi da derusting galibi ana amfani da su don maganin bututun ƙarfe na waje.

Fenti fenti

Fenti fenti

Marufi mai hana ruwa