Bakin Karfe Bututu

Tauri:

Ana amfani da bututun bakin karfe don auna taurin Brinell, Rockwell da Vickers.Brinell taurin Daga cikin bakin karfe bututu matsayin, Brinell taurin ne mafi yadu amfani, da kuma taurin na abu ne sau da yawa bayyana da indentation diamita, wanda yake duka da ilhama da kuma dace.Duk da haka, bai dace da bututun ƙarfe na ƙarfe mai wuya ko bakin ciki ba.

Rockwell taurin:

Gwajin taurin bakin karfe na Rockwell daidai yake da gwajin taurin Brinell.Bambanci shine yana auna zurfin ciki.Gwajin taurin Rockwell hanya ce da ake amfani da ita sosai wacce ake amfani da HRC ta biyu kawai zuwa Brinell hardness HB a daidaitattun bututun ƙarfe.Ana iya amfani da taurin Rockwell don tantance kayan ƙarfe daga matuƙar taushi zuwa wuya sosai.Yana rama hanyar Brinell.Yana da sauƙi fiye da hanyar Brinell kuma yana iya karanta ƙimar taurin kai tsaye daga bugun kiran na'urar taurin.Koyaya, saboda ƙaramar shigarta, ƙimar taurin ba daidai bane kamar hanyar Brinell.

Vickers taurin

Bakin karfe tube Vickers gwajin taurin kuma hanya ce ta gwaji don auna kayan ƙarfe na bakin ciki da taurin saman.Yana da babban fa'idodin hanyoyin Brinell da Rockwell, kuma yana shawo kan gazawar su na asali, amma ba ta da sauƙi kamar hanyar Rockwell.Hanyar Vickers ba a cika yin amfani da shi ba a daidaitattun bututun ƙarfe.

Gwajin taurin

Bututun bakin karfe yana da diamita na ciki na 6.0mm ko sama da haka da bututun bakin karfe da aka rufe da kaurin bango na 13mm ko kasa da haka.Yana iya zama nau'in W-B75 Vickers hardness tester.Yana da sauri da sauƙi don gwadawa kuma ya dace da sauri kuma mara lalacewa na bututun ƙarfe.An gwada bututun bakin karfe mai diamita na ciki fiye da mm 30 da kaurin bango sama da 1.2 mm tare da ma'aunin taurin Rockwell don gwada taurin HRB da HRC.An gwada bututun bakin karfe mai diamita na ciki fiye da mm 30 da kaurin bangon da bai wuce 1.2 mm ba tare da gwajin taurin dutsen Rockwell don gwada taurin HRT ko HRN.Don bututun bakin karfe tare da diamita na ciki na kasa da 0 mm kuma sama da 4.8 mm, ana gwada taurin HR15T ta wani na musamman na Rockwell hardness tester don bututu.Lokacin da diamita na ciki na bakin karfe bututu ya fi girma fiye da 26 mm, taurin bangon ciki na bututu kuma ana iya gwada shi ta hanyar Ro.

Haɗin Sinadari

| Maki | C max | Mn max | P max | S max | Si max | Cr | Ni | Mo |

| 304 | 0.08 | 2.00 | 0.04 | 0.03 | 0.075 | 18.00-20.00 | 8.00-11.00 | / |

| 304l | 0.035 | 2.00 | 0.04 | 0.03 | 0.075 | 18.00-20.00 | 8.00-13.00 | / |

| 316 | 0.08 | 2.00 | 0.04 | 0.03 | 0.075 | 16.00-18.00 | 11.00-14.00 | 2.00-3.00 |

| 316l | 0.035 | 2.00 | 0.04 | 0.03 | 0.075 | 16.00-18.00 | 10.00-15.00 | 2.00-3.00 |

Kayayyakin Injini

| Maki | Abu | Tsuntsaye Psi | Haɓaka Psi | Yawan % | Rockwell Hardness |

| 304 | Annealed | 85000-105000 | 35000-75000 | 20-55 | 80-95 |

| 304l | Annealed I1/8 Hard | 80000-105000 | 30000-75000 | 20-55 | 75-95 |

| 316 | Annealed | 85000 min | 35000 min | 50 min | 80 min |

| Annealed | 80000 min | 30000 min | 50 min | 75 min |

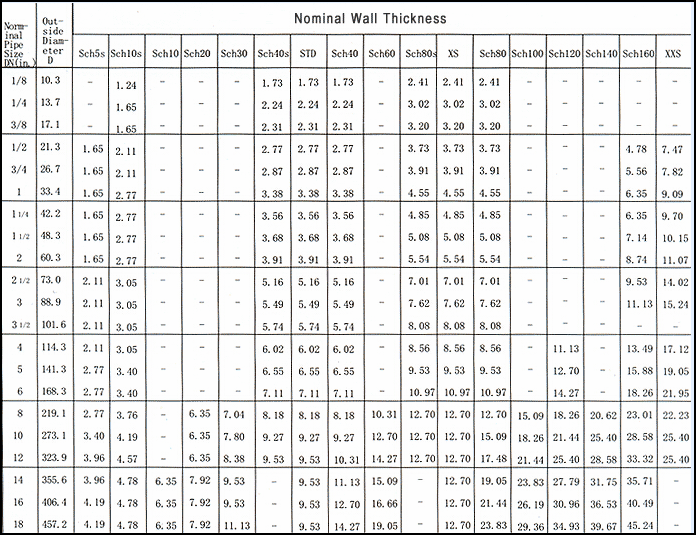

Girman Bututu Bakin Karfe

Annealed & pickled, annealing mai haske, goge

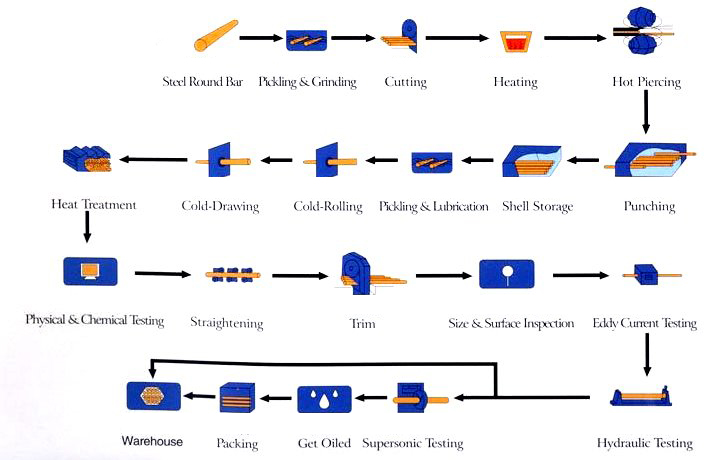

Tsari