Hannun hannu

Tsarin Kera gwiwar gwiwar hannu mara sumul (lankwasawa da sanyin sanyi)

Ɗaya daga cikin hanyoyin da aka fi sani don kera gwiwar hannu shine ta amfani da mandrel mai zafi lankwasawa daga madaidaiciyar bututun ƙarfe.Bayan dumama bututun ƙarfe a yanayin zafi mai tsayi, ana tura bututun, faɗaɗa, lanƙwasa ta kayan aikin ciki na mandrel mataki-mataki.Aiwatar da lankwasawa mai zafi na iya ƙera babban girman kewayon gwiwar hannu mara kyau.Halayen lanƙwasawa mandrel sun dogara da ƙarfi akan sifar da aka haɗaka da girma na mandrel.Amfanin fa'idodin lankwasawa masu zafi sun haɗa da ƙaramin kauri da radius mai ƙarfi fiye da sauran nau'in hanyar lanƙwasawa.A halin yanzu, yin amfani da lanƙwasawa maimakon riga-kafi na lanƙwasa yana rage adadin walda da ake buƙata.Wannan yana rage yawan aikin da ake buƙata kuma yana ƙara inganci da amfani da bututu.Koyaya, lankwasawa sanyi shine tsari don lanƙwasa bututun ƙarfe madaidaiciya a yanayin yanayin al'ada a cikin injin lanƙwasawa.Cold lankwasawa ya dace da bututu tare da diamita na waje na 17.0 zuwa 219.1 mm, da kauri na bango 2.0 zuwa 28.0 mm.Shawarar lanƙwasawa radius shine 2.5 x Do.Yawanci a radius na lanƙwasawa na 40D.Ta amfani da lanƙwasawa mai sanyi, za mu iya samun ƙananan ƙwanƙwasa radius, amma muna buƙatar ɗaukar ciki da yashi don hana wrinkling.Lankwasawa sanyi hanya ce mai sauri kuma mara tsada.Zaɓin gasa ne don yin bututun mai da sassan injin.

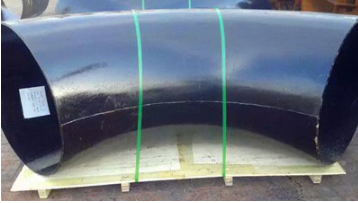

Tsarin Kera Hannun Hannun Welded (Ƙananan & Babba)

An yi maƙarƙashiyar gwiwar hannu ne daga faranti na ƙarfe, don haka ba ƙwanƙwaran ƙarfe ba ne.Yi amfani da mold kuma danna farantin karfe zuwa siffar gwiwar hannu, sa'an nan kuma weda kabu don zama ƙarshen gwiwar karfe.Ita ce tsohuwar hanyar samar da gwiwar hannu.Shekarun baya-bayan nan an kusan ƙera ƙananan gwiwar gwiwar hannu daga bututun ƙarfe a yanzu.Don girman girman gwiwar hannu, alal misali, yana da matukar wahala a samar da gwiwar hannu sama da 36 ”OD daga bututun ƙarfe.Don haka yawanci ana yin shi ne daga farantin karfe, ana danna farantin zuwa siffar rabin gwiwar hannu, da walƙiya rabi biyu tare.Tun da gwiwar hannu suna waldawa a jikinsa, duban haɗin gwiwar walda ya zama dole .Yawanci muna amfani da duban X-Ray azaman NDT.

| Girman bututu mara kyau | Waje Diamita | Cibiyar zuwa Ƙarshe | Cibiyar zuwa Cibiyar | Komawa Fuskoki | ||||||

| 45° Gishiri | 90° Gishiri | 180° Komawa | ||||||||

| H | F | P | K | |||||||

| DN | INCH | Series A | Jerin B | LR | LR | SR | LR | SR | LR | SR |

| 15 | 1/2 | 21.3 | 18 | 16 | 38 | - | 76 | - | 48 | - |

| 20 | 3/4 | 26.9 | 25 | 16 | 38 | - | 76 | - | 51 | - |

| 25 | 1 | 33.7 | 32 | 16 | 38 | 25 | 76 | 51 | 56 | 41 |

| 32 | 11/4 | 42.4 | 38 | 20 | 48 | 32 | 95 | 64 | 70 | 52 |

| 40 | 11/2 | 48.3 | 45 | 24 | 57 | 38 | 114 | 76 | 83 | 62 |

| 50 | 2 | 60.3 | 57 | 32 | 76 | 51 | 152 | 102 | 106 | 81 |

| 65 | 21/2 | 76.1 (73) | 76 | 40 | 95 | 64 | 191 | 127 | 132 | 100 |

| 80 | 3 | 88.9 | 89 | 47 | 114 | 76 | 229 | 152 | 159 | 121 |

| 90 | 31/2 | 101.6 | - | 55 | 133 | 89 | 267 | 178 | 184 | 140 |

| 100 | 4 | 114.3 | 108 | 63 | 152 | 102 | 305 | 203 | 210 | 159 |

| 125 | 5 | 139.7 | 133 | 79 | 190 | 127 | 381 | 254 | 262 | 197 |

| 150 | 6 | 168.3 | 159 | 95 | 229 | 152 | 457 | 305 | 313 | 237 |

| 200 | 8 | 219.1 | 219 | 126 | 305 | 203 | 610 | 406 | 414 | 313 |

| 250 | 10 | 273.0 | 273 | 158 | 381 | 254 | 762 | 508 | 518 | 391 |

| 300 | 12 | 323.9 | 325 | 189 | 457 | 305 | 914 | 610 | 619 | 467 |

| 350 | 14 | 355.6 | 377 | 221 | 533 | 356 | 1067 | 711 | 711 | 533 |

| 400 | 16 | 406.4 | 426 | 253 | 610 | 406 | 1219 | 813 | 813 | 610 |

| 450 | 18 | 457.2 | 478 | 284 | 686 | 457 | 1372 | 914 | 914 | 686 |

| 500 | 20 | 508.0 | 529 | 316 | 762 | 508 | 1524 | 1016 | 1016 | 762 |

| 550 | 22 | 559 | - | 347 | 838 | 559 | Lura: | |||

| 600 | 24 | 610 | 630 | 379 | 914 | 610 | ||||

| 650 | 26 | 660 | - | 410 | 991 | 660 | ||||

| 700 | 28 | 711 | 720 | 442 | 1067 | 711 | ||||

| 750 | 30 | 762 | - | 473 | 1143 | 762 | ||||

| 800 | 32 | 813 | 820 | 505 | 1219 | 813 | ||||

| 850 | 34 | 864 | - | 537 | 1295 | 864 | ||||

| 900 | 36 | 914 | 920 | 568 | 1372 | 914 | ||||

| 950 | 38 | 965 | - | 600 | 1448 | 965 | ||||

| 1000 | 40 | 1016 | 1020 | 631 | 1524 | 1016 | ||||

| 1050 | 42 | 1067 | - | 663 | 1600 | 1067 | ||||

| 1100 | 44 | 1118 | 1120 | 694 | 1676 | 1118 | ||||

| 1150 | 46 | 1168 | - | 726 | 1753 | 1168 | ||||

| 1200 | 48 | 1220 | 1220 | 758 | 1829 | 1219 | ||||

ASTM A234

Wannan ƙayyadaddun ya haɗa da aikin ƙarfe na ƙarfe & gami da kayan aikin ƙarfe na ƙarfe mara nauyi da welded yi.Sai dai in an ƙayyadaddun ginin mara sumul ko welded cikin tsari, ko dai ana iya samar da shi a zaɓi na mai kaya.Duk kayan aikin ginin walda kamar wannan ma'auni ana kawo su tare da radiyo 100%.A ƙarƙashin ASTM A234, ana samun maki da yawa dangane da abun ciki na sinadarai.Zaɓin zai dogara ne akan kayan bututun da aka haɗa da waɗannan kayan aikin.

| Bukatun tensile | WPB | Saukewa: WP11CL2 | WP11CL1 | Saukewa: WP11CL3 |

| Ƙarfin Tensile, min, ksi[MPa] | 60-85 | 70-95 | 60-85 | 75-100 |

| (0.2% biya diyya ko 0.5% tsawo-ƙarƙashin kaya) | [415-585] | [485-655] | [415-585] | [520-690] |

| Ƙarfin Haɓaka, min, ksi [MPa] | 32 | 40 | 30 | 45 |

| [240] | [275] | [205] | [310] |

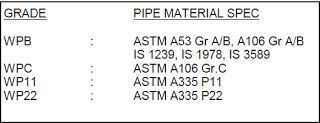

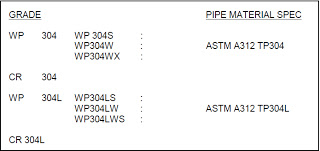

Wasu daga cikin maki da ake samu a ƙarƙashin wannan ƙayyadaddun bayanai da madaidaicin ƙayyadaddun kayan bututu an jera su a ƙasa:

Saukewa: ASTM A403

Wannan ƙayyadaddun ya ƙunshi azuzuwan gabaɗaya guda biyu, WP & CR, na kayan aikin bakin karfe na austenitic na kayan aiki mara nauyi da welded.

An kera kayan aikin WP na Class zuwa buƙatun ASME B16.9 & ASME B16.28 kuma an raba su zuwa ƙananan aji uku kamar haka:

- WP - An ƙera shi daga samfurin da ba shi da kyau ta hanyar ƙira mara kyau.

- WP - W Wadannan kayan aikin sun ƙunshi welds da duk welds da masana'anta masu dacewa suka yi ciki har da farawar bututu idan an haɗa bututun tare da ƙari na kayan filler ana yin rediyo.Duk da haka ba a yin aikin rediyo don walƙiyar bututun farawa idan an haɗa bututun ba tare da ƙarin kayan filler ba.

- WP-WX Waɗannan kayan aikin sun ƙunshi walda da duk wani walda ko na masana'anta masu dacewa ko na masu ƙirƙira kayan farawa ana yin radiyo.

An ƙera kayan aikin aji na CR zuwa buƙatun MSS-SP-43 kuma baya buƙatar jarrabawa mara lalacewa.

A ƙarƙashin ASTM A403 akwai maki da yawa dangane da abun ciki na sinadarai.Zaɓin zai dogara ne akan kayan bututun da aka haɗa da waɗannan kayan aikin.Wasu daga cikin maki da ake samu a ƙarƙashin wannan ƙayyadaddun bayanai da madaidaicin ƙayyadaddun kayan bututu an jera su a ƙasa:

ASTM A420

Wannan ƙayyadaddun ya haɗa da aikin ƙarfe na carbon da kayan haɗin gwal na kayan aiki maras sumul & welded ginin da aka yi nufin amfani da shi a ƙananan yanayin zafi.Ya ƙunshi maki huɗu WPL6, WPL9, WPL3 & WPL8 dangane da abubuwan sinadaran.Fittings WPL6 ana gwada tasirin tasiri a yanayin zafi - 50 ° C, WPL9 a -75 ° C, WPL3 a -100 ° C da WPL8 a -195 ° C zazzabi.

Za a iya ƙididdige ƙimar matsi da aka yarda don kayan aiki a matsayin madaidaiciyar bututu mara nauyi daidai da ƙa'idodin da aka kafa a cikin sashin da ya dace na ASME B31.3.

Kaurin bangon bututu da nau'in kayan ya zama abin da aka ba da umarnin yin amfani da kayan aiki, ainihin su akan kayan aikin a maimakon alamar ƙimar matsin lamba.

| Karfe No. | Nau'in | Abubuwan sinadaran | ||||||||||||

| C | Si | S | P | Mn | Cr | Ni | Mo | Sauran | ib | yas | δ5 | HB | ||

| Farashin WPL6 | 0.3 | 0.15-0.3 | 0.04 | 0.035 | 0.6-1.35 | 0.3 | 0.4 | 0.12 | Cb:0.02;V:0.08 | 415-585 | 240 | 22 | ||

| Farashin 9 | 0.2 | 0.03 | 0.03 | 0.4-1.06 | 1.6-2.24 | 435-610 | 315 | 20 | ||||||

| Farashin WPL3 | 0.2 | 0.13-0.37 | 0.05 | 0.05 | 0.31-0.64 | 3.2-3.8 | 450-620 | 240 | 22 | |||||

| Farashin 8 | 0.13 | 0.13-0.37 | 0.03 | 0.03 | 0.9 | 8.4-9.6 | 690-865 | 515 | 16 | |||||

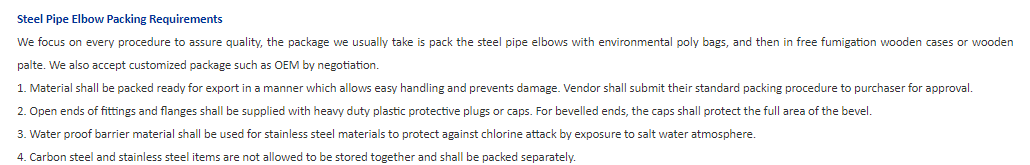

Mai Haske, Zanen Baƙar fata, Galvanizing, PE / 3PE Rufin Lalacewa

Kunshe a cikin katako na katako / tire na katako