Ring Titanium

Manyan zoben titanium ana kera su ta babban injin zobe na niƙa, ana iya samun ƙananan zoben titanium ta injin ƙirƙira.A matsayin kamfani da ke da fiye da shekaru 20 na ƙwarewar samarwa, muna da jerin tsauraran tsarin ƙirƙira da littafin aiki, gami da matakan dumama, lokacin dumama da lokacin adana zafi.Na'ura mai saurin ƙirƙira 35MN da 16MN sun ba da garantin ƙirƙira ƙirƙira da yawa a cikin kewayon zafin jiki mai dacewa, kuma sun canza tsarin jiki na ciki na zoben titanium.Ya inganta ingancin samfuran mu sosai.

Baya ga zoben titanium, muna kuma samar da samar da fayafai na titanium, toshe titanium da dai sauransu.

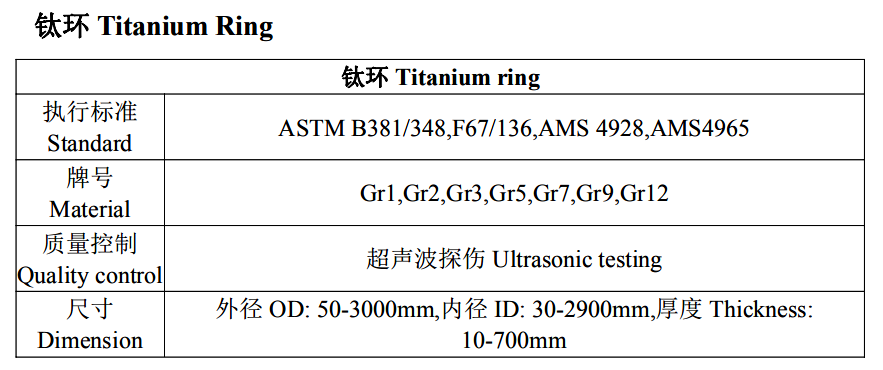

| sunan samfur | Ring Titanium |

| Girman | OD (max3000mm)×ID (max2900mm)×tsayi (mafi girman tsayi 1000mm) |

| Daraja | TA1/TA2/TA5/TA6/TA9/TA10/TA15/TA19/TC1/TC2/TC4/TC11/ GR1/GR2/GR5/GR7/GR9/GR12/GR23 |

| Matsayi | ASTM B381/348,F67/136,AMS4928,AMS4965,AMS,MIL,DIN,BS,JIS,GB/T,ISOda dai sauransu |

| Yawan yawa | 4.51g / cm3 Babban aikin ƙirƙira masana'antu, gr12 Titanium ƙirƙira zoben mirgina |

| Fasaha | Ƙirƙirar ƙirƙira, mirgina, niƙa babban aikin masana'antu ƙirƙira GR12 titanium ƙirƙira mirgina zobe |

| Nau'in | Tsarin jujjuyawar zobe mara kyau ya haɗa da yanke rami a cikin kayan ƙirƙira da jujjuya shi cikin zobe na bakin ciki. Idan aka kwatanta da harbin farantin karfe ko waldar gindi, zoben da aka yi birgima yana ba da ingantaccen haɓakawa tare da zobe mai santsi. Babban aikin zobe na ƙirƙira GR12 titanium ƙirƙira zoben mirgina |

| Aikace-aikace | 1. Electrolating;2.Fasahar sinadarai da petrochemical;3.Likita babban aikin masana'antu ƙirƙira GR12 titanium ƙirƙira mirgina zobe |

ASTM B381/348,F67/136,AMS4928,AMS4965

Abubuwan sinadaran

| Daraja | Abubuwan sinadaran, kashi dari (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Sauran Abubuwan Max.kowanne | Sauran Abubuwan Max.duka | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5 zuwa 6.75 | 3.5 zuwa 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 zuwa 0.25 | - | 0.12 zuwa 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 zuwa 3.5 | 2.0 zuwa 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 zuwa 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 zuwa 0.9 | 0.2 zuwa 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 zuwa 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 zuwa 6.5 | 3.5 zuwa 4.5 | - | - | - | - | 0.1 | 0.1 |

Kaddarorin jiki

| Daraja | Kaddarorin jiki | |||||

| Ƙarfin ƙarfi Min | Ƙarfin bayarwa Min (0.2%) | Tsawaitawa a cikin 4D Min (%) | Rage Yanki Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |