I-Titanium Wire / iSilk

Sinokubonelela ngocingo lwe-tantalum lwe-vacuum electron beam yokunyibilika kunye neteknoloji ye-metallurgy yomgubo, injongo ngokubanzi yocingo lwe-tantalum lwaveliswa nge-vacuum electron beam yokunyibilikisa iteknoloji, inobunyulu obuphezulu.I-Capacitor grade tantalum wire idla ngokuveliswa yitekhnoloji yomgubo wesinyithi, iqulethe izinto ezikhethekileyo zetsimbi.Ucingo lweTantalum lwaveliswa ngokwesiseko se-tantalum bar.okokuqala, ukukhupha ubungakanani obufanelekileyo be-tantalum bar, ukucoca ibha ye-tantalum, ukususa imagazini yomhlaba kunye nongcoliseko lwe-oyile, ukucheba ibha ye-tantalum kwaye ucoceke kwakhona, emva koko ngokuzolula kunye ne-annealing amaxesha amaninzi, ekugqibeleni ufumane iinkcukacha zeemfuno zabathengi. , ngokucoca, ukulungelelanisa, ukujikeleza, sinokufumana ucingo oluchanekileyo okanye ikhoyili.Indlela ekhethekileyo ye-Metal ye-Metal yokuqengqeleka, inkqubo yokolula, ulawulo lomlinganiselo woxinzelelo, iqondo lobushushu le-annealing kunye nolawulo lwexesha le-annealing inokuqinisekisa ukuba ucingo lwe-tantalum luneempawu ezigqwesileyo zobuchwephesha, lwenza umphezulu ugudiswe, ucoceke, kungabikho oli, akukho zintanda kunye ne-burrs, akukho mdaka ujikeleze, kwaye iqwalaselwe phantsi kwamaxesha angama-25 yokukhulisa, ayinazibonda eziqhubekayo kunye nemikrwelo, inesakhiwo esihle sesinyithi, ukuze kuqinisekiswe umgangatho wocingo lwe-tantalum lungcono kunezinye iinkampani ezikushishino olufanayo.

Ukongeza ekuboneleleni ngocingo lwe-tantalum olusulungekileyo, inkampani yethu ikwabonelela ngocingo lwe-tantalum alloy.

Izinto:

I-Tantalum Niobium wire (TaNb3, TaNb20, TaNb40)

Ucingo lweTantalum Tungsten (Ta2.5W, Ta10W)

Ububanzi: 0.1 ~ 4mm

Umgangatho: ASTM B365

Ubume: Ngqo, Ikhoyili

Ubume: Inzima, inzima kancinci, iphakathi

Isicelo

I-Capacitor grade tantalum wire isetyenziselwa ukwenza i-tantalum electrolytic capacitor anode lead.I-tantalum wire yinto ephambili kwi-tantalum capacitor, i-tantalum capacitor iyona capacitor ingcono, malunga ne-65% ye-tantalum yehlabathi esetyenziswe kule ndawo.

Isetyenziselwa ukuvelisa i-tantalum mesh.

Isetyenziselwa ukuthunga ukubuyisela izicubu zomzimba, ukuthunga imithambo-luvo kunye neetendon, ukuveliswa kwemithambo yegazi, njl.

Isetyenziselwa ukuvelisa izixhobo zokufudumeza iziko lobushushu obuphezulu.

Isetyenziselwa i-vacuum electron etting cathode source, i-ion sputtering kunye nezinto zokugquma, njl.

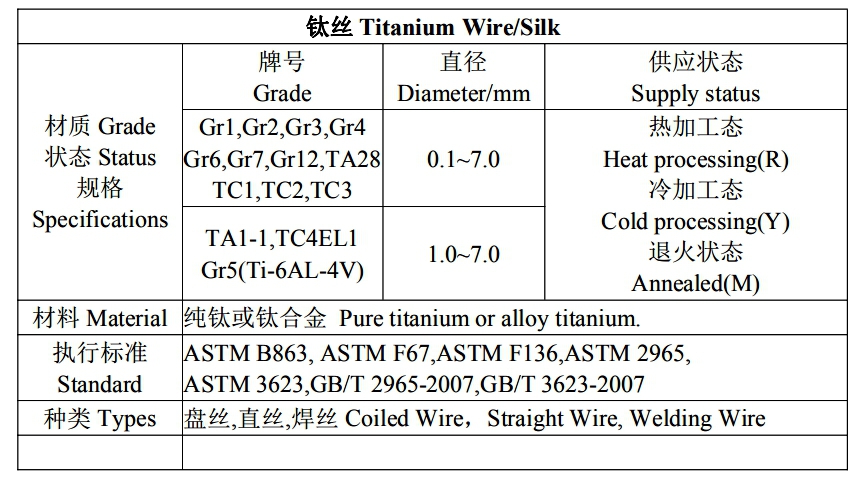

| I-Titanium Wire Diameters kunye neentlobo | ||||

| Ububanzi & Iintlobo | ||||

| Uluhlu lweDiameter | Iintlobo | |||

| mm | intshi | Ikhoyili | Spool | Ngqo |

| 0.05 ukuba 0.78 | 0.002 ukuba 0.031 | Y | Y | N |

| >0,78 ukuya ku-3.25 | >0.031 ukuba 0.128 | Y | Y | Y |

| > 3.25 ukuba 6.00 | > 0,128 ukuba 0,236 | Y | N | Y |

Ukunyamezela Ububanzi: +/-0.05mm (+/-0.002”) okanye bhetele.I-Spools: 100mm - 300mm (3.9" - 12").Ubude obuthe ngqo: 300mm – 3000mm (12” – 118”)

| IBanga | Iinkcukacha | ||

| AWS A5.16 | I-ASTM B863 | I-AMS | |

| I-Titanium ecocekileyo yoRhwebo | I-ERTi-1,2,3,4 | I-ASTM B863 Gr1,2,3,4 | I-AMS 4951 |

| I-ASTM F67 Gr1,2,3,4 | I-AMS 4921 | ||

| I-Ti 6Al-4V | I-ERTi-5 | I-ASTM B863 Gr5 | I-AMS 4954 |

| Ti 6Al-4V Eli | ERTi-5 Eli | I-ASTM B863 Gr23 | I-AMS 4956 |

| I-ASTM F136 Eli | |||

| ITi 0.2 Pd | I-ERTi-7 | I-ASTM B863 Gr7 | - |

| Ti 3Al-2.5V | I-ERTi-9 | I-ASTM B863 Gr9 | - |

| Ti 0.3Mo-0.8Ni | I-ERTi-12 | I-ASTM B863 Gr12 | - |

Ukuqulunqwa kweekhemikhali

| Ukuqamba (%) | |||||||||||||

| IBanga | Izinto eziphambili | Umxholo wokungcola (≤) | |||||||||||

| Ta | Nb | Fe | Si | Ni | W | Mo | Ti | Nb | O | C | H | N | |

| Ta1 | UBhal | - | 0.005 | 0.005 | 0.002 | 0.01 | 0.01 | 0.002 | 0.03 | 0.015 | 0.01 | 0.0015 | 0.005 |

| Ta2 | UBhal | - | 0.03 | 0.02 | 0.005 | 0.04 | 0.03 | 0.005 | 0.1 | 0.02 | 0.01 | 0.0015 | 0.005 |

| TaNb3 | UBhal | 1.5–3.5 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | - | 0.02 | 0.01 | 0.005 | 0.01 |

| TaNb20 | UBhal | 17.0-23.0 | 0.03 | 0.03 | 0.005 | 0.04 | 0.03 | 0.005 | - | 0.02 | 0.01 | 0.005 | 0.01 |

| TaNb40 | UBhal | 35.0-42.0 | 0.01 | 0.005 | 0.01 | 0.05 | 0.02 | 0.01 | - | 0.02 | 0.01 | 0.015 | 0.01 |

| Ta2.5W | UBhal | - | 0.01 | 0.005 | 0.01 | 2.0 ~ 3.5 | 0.01 | 0.002 | 0.1 | 0.01 | 0.01 | 0.0015 | 0.01 |

| Ta10W | UBhal | - | 0.01 | 0.005 | 0.01 | 9.0 ~ 11.0 | 0.01 | 0.002 | 0.1 | 0.015 | 0.01 | 0.0015 | 0. |

Iimpawu zoomatshini

| Ubume | Amandla okuqina (Mp) | Ubude (%) |

| Ubulali | 300-750 | 10 ~ 30 |

| Semi-nzima | 750-1250 | 1~6 |

| Kunzima | >1250 | 1~5 |

| I-TaNb3, TaNb20, iipropati zoomatshini ngokomzi-mveliso olinganisiweyo. | ||

Ukunyamezela (mm)

| Ububanzi | Ukunyamezelana |

| 0.1 ~ 0.2 | < 0.005 |

| 0.2 ~ 0.5 | < 0.007 |

| 0.5 ~ 0.7 | < 0.010 |

| 0.7-1.5 | < 0.015 |

| 1.5 ~ 2.0 | < 0.020 |

| 2.0-3.0 | < 0.030 |

| 3.0-4.0 | < 0.040 |

I-Antioxidant brittleness

| IBanga | Ububanzi (mm) | Ubuqhophololo beAntioxidant Inani lokugoba (≥) |

| Ta1 | 0.10-0.40 | 3 |

| >0.40 | 4 | |

| Ta2 | 0.10-0.40 | 4 |

| >0.40 | 6 |

Ucingo lwekhoyili: Emva komoya kunye nepasile ngomqhaphu weperile (ipolyethylene eyandiswayo), emva koko ipakishwe kwiimeko zokhuni.

Ucingo oluthe ngqo: Pakisha ucingo lwe-tantalum kwiingxowa zeplastiki kwaye ulufake kwibhere yeplastiki ethe tye, emva koko ipakishwe kwiibhokisi zomthi.