Mga bahagi ng pamantayan ng titanium

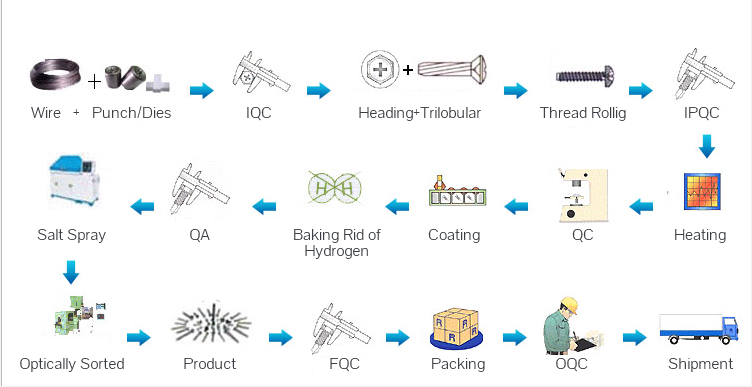

Produksyon ng DIN, ANSI/AMSE, ISO, JIS at iba pang mga pamantayan at hindi pamantayang high-strength titanium fasteners.Karaniwang kasama ang mga bolts, turnilyo, nuts, washers, retaining ring, at iba't ibang mga espesyal na hugis na piraso.Una, gagawin namin ang heat treatment, chemical composition testing, mechanical properties testing ng titanium bars, titanium plates at iba pang basic materials.Pagkatapos ng proseso ng straightening, leveling at polishing, gupitin sa naaangkop na laki.At pagkatapos ay magpatuloy sa pagliko, hot stamping, compression screw, heat treatment, polishing, paglilinis, inspeksyon, at isang serye ng mga pamamaraan, sa kalaunan ay makagawa ng mga de-kalidad na titanium fasteners.Mayroon kaming advanced na kagamitan sa produksyon na nagsisiguro sa aming mga produkto na makamit ang pinakamahusay sa bawat link ng produksyon.

Ang aming kumpanya ay may maraming imbentaryo ng titanium fasteners, na maaaring matugunan ang pandaigdigang maliit na halaga ng mga order at ang mga customer na may kagyat na pangangailangan sa paghahatid.Kasabay nito, nagbibigay din kami ng hindi karaniwang mga produkto ayon sa mga guhit na ibinigay ng mga customer.

Aplikasyon

Petroleum, metalurhiya, kemikal, elektroniko, parmasyutiko, Marine engineering, mga piyesa ng sasakyan, mga piyesa ng motorsiklo, mga piyesa ng bisikleta, mga aksesorya ng yate, mga suplay para sa kaligtasan ng buhay sa labas, mga gamit sa palakasan at iba pang larangan.

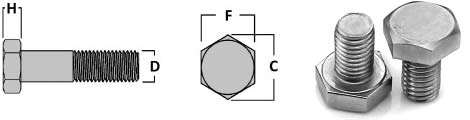

Bolt ng titanium

| produkto | Titanium at Titanium alloy bolt |

| Sukat | Diameter: M1.6-M30, Haba: 10mm-300mm (0.39″-11.8″) |

| materyal | Gr.1, Gr.2, Gr.5, Gr.7 atbp |

| Pamantayan | DIN912, DIN6912, DIN933, DIN931 atbp |

Titan hex nut

| produkto | Titanium at Titanium alloy nut |

| Sukat | M8-M 80 x 6 |

| materyal | Gr1, Gr2, Gr5, Gr7, Ti6Al4V ELI, atbp |

| Pamantayan | DIN, ISO, JIS, atbp. |

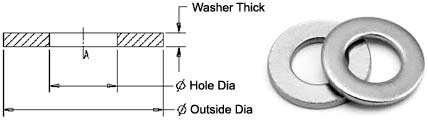

Titanium washer

| produkto | Titanium at Titanium alloy washer |

| Sukat | OD: 5mm-200mm (0.20″-7.87″), ID: 1mm-100mm (0.04″-3.94″), Kapal: 0.1mm-30mm (0.004″-1.18″) |

| materyal | Gr.2, Gr.5 atbp |

| Pamantayan | DIN125 atbp |

Titanium na tornilyo

| produkto | Titanium at Titanium alloy screw |

| Sukat | M1 hanggang M42, Haba: 10mm-300mm (0.39″-11.8″) |

| materyal | Gr1, Gr.2, Gr.5, Gr.7, Gr.12 atbp |

| Pamantayan | DIN912, DIN933, DIN84, DIN85, DIN963, DIN7991, DIN6912, DIN931, ISO7380, atbp. |

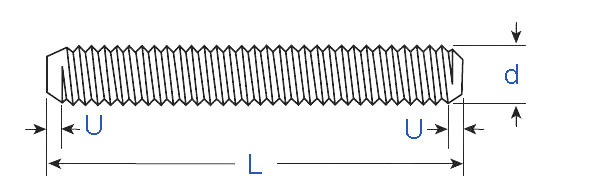

Titanium na sinulid na stud

| produkto | Titanium at Titanium alloy na may sinulid na stud |

| Sukat | Diameter: M1.6-M30, Haba: 10mm-300mm (0.39″-11.8″) |

| materyal | Gr.1, Gr.2, Gr.5, Gr.7, Gr.23 atbp |

| Pamantayan | DIN912, DIN933, DIN7991, DIN7984, DIN6921, ISO 7380, JIS, BS atbp. |

Mga Dimensyon ng Titanium Hex Bolts

| Heavy Hex Bolt Diameter | D | F | C | H | |||||

| Diameter ng Katawan | Lapad sa mga Flat | Lapad sa mga Sulok | taas | ||||||

| Max | Basic | Max | Min | Max | Min | Basic | Max | Min | |

| 1/2 | 0.515 | 7/8 | 0.875 | 0.850 | 1.010 | 0.969 | 11/32 | 0.364 | 0.302 |

| 5/8 | 0.642 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 27/64 | 0.444 | 0.378 |

| 3/4 | 0.768 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 1/2 | 0.524 | 0.455 |

| 7/8 | 0.895 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 37/64 | 0.604 | 0.531 |

| 1 | 1.022 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 43/64 | 0.700 | 0.591 |

| 1-1/8 | 1.149 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 3/4 | 0.780 | 0.658 |

| 1-1/4 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 27/32 | 0.876 | 0.749 |

| 1-3/8 | 1.404 | 2-3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 29/32 | 0.940 | 0.810 |

| 1-1/2 | 1.531 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1 | 1.036 | 0.902 |

| 1-3/4 | 1.785 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-5/32 | 1.196 | 1.054 |

| 2 | 2.039 | 3-1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1-11/32 | 1.388 | 1.175 |

| 2-1/4 | 2.305 | 3-1/2 | 3.500 | 3.388 | 4.041 | 3.862 | 1-1/2 | 1.548 | 1.327 |

| 2-1/2 | 2.559 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 1-21/32 | 1.708 | 1.479 |

Mga Dimensyon ng Hex Nuts

| ISO Titanium Hex Nut NB | Sa kabila ng mga Sulok | MAX Kapal | Kapal ng MIN | MAX Sa buong Flats | MIN Sa buong Flats |

| M 8 | 14.38 | 6.8 | 6.44 | 13 | 12.73 |

| M 10 | 17.77 | 8.4 | 8.04 | 16 | 15.73 |

| M 12 | 20.03 | 10.8 | 10.37 | 18 | 17.73 |

| M 14 | 23.35 | 12.8 | 12.1 | 21 | 20.67 |

| M 16 | 26.75 | 14.8 | 14.1 | 24 | 23.67 |

| M 18 | 29.56 | 15.8 | 15.1 | 27 | 26.16 |

| M 20 | 32.95 | 18 | 16.9 | 30 | 29.16 |

| M 22 | 37.29 | 19.4 | 18.1 | 34 | 33 |

| M 24 | 39.55 | 21.5 | 20.2 | 36 | 35 |

| M 27 | 45.2 | 23.8 | 22.5 | 41 | 40 |

| M 30 | 50.85 | 26.6 | 24.3 | 46 | 45 |

| M 33 | 55.37 | 28.7 | 27.4 | 50 | 49 |

| M 36 | 60.79 | 31 | 29.4 | 55 | 53.8 |

| M 39 | 66.44 | 33.4 | 31.8 | 60 | 58.8 |

| M 42 | 71.3 | 34 | 32.4 | 65 | 63.1 |

| M 45 | 76.95 | 36 | 34.4 | 70 | 68.1 |

| M 48 | 82.6 | 38 | 39.4 | 75 | 73.1 |

| M 52 | 88.25 | 42 | 40.4 | 80 | 78.1 |

| M 56 | 93.56 | 45 | 43.4 | 85 | 82.8 |

| M 60 | 99.21 | 48 | 46.4 | 90 | 87.8 |

| M 64 | 104.86 | 51 | 49.1 | 95 | 92.8 |

| M 68 | 110.51 | 54 | 52.1 | 100 | 97.8 |

| M 72 x 6 | 116.16 | 58 | 56.1 | 105 | 102.8 |

| M 76 x 6 | 121.81 | 61 | 59.1 | 110 | 107.8 |

| M 80 x 6 | 127.46 | 64 | 62.1 | 115 | 112.8 |

Mga Dimensyon ng Titanium Flat Washer

| Laki ng Ti Alloy Bolt | USS | SAE | ||||

| OD (in.) | ID (in.) | kapal | OD (in.) | ID (in.) | kapal | |

| 1/8 (#6) | - | - | - | 0.375 | 0.156 | .036/.065 |

| 5/32 (#8) | - | - | - | 0.438 | 0.188 | .036/.065 |

| 3/16 (#10) | 0.560 | 0.250 | .036/.065 | 0.500 | 0.220 | .036/.065 |

| 7/32 (#12) | - | - | - | 0.562 | 0.250 | .051/.080 |

| 1/4 (#14) | 0.734 | 0.312 | .051/.080 | 0.625 | 0.281 | .051/.080 |

| 5/16 | 0.875 | 0.375 | .064/.104 | 0.688 | 0.344 | .051/.080 |

| 3/8 | 1.000 | 0.438 | .064/.104 | 0.812 | 0.406 | .051/.080 |

| 7/16 | 1.250 | 0.500 | .064/.104 | 0.922 | 0.469 | .051/.080 |

| 1/2 | 1.375 | 0.562 | .086/.132 | 1.062 | 0.531 | .074/.121 |

| 9/16 | 1.469 | 0.625 | .086/.132 | 1.156 | 0.594 | .074/.121 |

| 5/8 | 1.750 | 0.688 | .108/.160 | 1.312 | 0.656 | .074/.121 |

| 3/4 | 2.000 | 0.812 | .122/.177 | 1.469 | 0.812 | .108/.160 |

| 7/8 | 2.250 | 0.938 | .136/.192 | 1.750 | 0.938 | .108/.160 |

| 1 | 2.500 | 1.062 | .136/.192 | 2.000 | 1.062 | .108/.160 |

| 1 1/8 | 2.750 | 1.250 | .136/.192 | 2.250 | 1.250 | .108/.160 |

| 1 1/4 | 3.000 | 1.375 | .136/.192 | 2.500 | 1.375 | .136/.192 |

| 1 3/8 | 3.250 | 1.500 | .153/.213 | 2.750 | 1.500 | .136/.213 |

| 1 1/2 | 3.500 | 1.625 | .153/.213 | 3.000 | 1.625 | .153/.213 |

| 1 5/8 | 3.750 | 1.750 | .153/.213 | - | - | - |

| 1 3/4 | 4.000 | 1.875 | .153/.213 | - | - | - |

| 1 7/8 | 4.250 | 2.000 | .153/.213 | - | - | - |

| 2 | 4.500 | 2.125 | .153/.213 | - | - | - |

| 2 1/4 | 4.750 | 2.375 | .193/.248 | - | - | - |

| 2 1/2 | 5.000 | 2.625 | .210/.280 | - | - | - |

| 2 3/4 | 5.250 | 2.875 | .228/.310 | - | - | - |

| 3 | 5.500 | 3.125 | .249/.327 | - | - | - |

Mga Dimensyon ng Tornilyo ng Socket Head Cap

| Ti Alloy Screw Nom.Sukat ng Thread Pitch | Katawan | Ulo | Ulo | Chamfer | Heksagono | Spline | Susi | Transisyon | |||

| Max | Min | Max | Min | Max | Min | Max | Nom. | Nom. | Min | Max | |

| M1.6 × 0.35 | 1.60 | 1.46 | 3.00 | 2.87 | 1.60 | 1.52 | 0.16 | 1.5 | 1.829 | 0.80 | 2.0 |

| M2 × 0.4 | 2.00 | 1.86 | 3.80 | 3.65 | 2.00 | 1.91 | 0.20 | 1.5 | 1.829 | 1.00 | 2.6 |

| M2.5 × 0.45 | 2.50 | 2.36 | 4.50 | 4.33 | 2.50 | 2.40 | 0.25 | 2.0 | 2.438 | 1.25 | 3.1 |

| M3 × 0.5 | 3.00 | 2.86 | 5.50 | 5.32 | 3.00 | 2.89 | 0.30 | 2.5 | 2.819 | 1.50 | 3.6 |

| M4 × 0.7 | 4.00 | 3.82 | 7.00 | 6.80 | 4.00 | 3.88 | 0.40 | 3.0 | 3.378 | 2.00 | 4.7 |

| M5 × 0.8 | 5.00 | 4.82 | 8.50 | 8.27 | 5.00 | 4.86 | 0.50 | 4.0 | 4.648 | 2.50 | 5.7 |

| M6 × 1 | 6.00 | 5.82 | 10.00 | 9.74 | 6.00 | 5.85 | 0.60 | 5.0 | 5.486 | 3.00 | 6.8 |

| M8 × 1.25 | 8.00 | 7.78 | 13.00 | 12.70 | 8.00 | 7.83 | 0.80 | 6.0 | 7.391 | 4.00 | 9.2 |

| M10 × 1.5 | 10.00 | 9.78 | 16.00 | 15.67 | 10.00 | 9.81 | 1.00 | 8.0 | … | 5.00 | 11.2 |

| M12 × 1.75 | 12.00 | 11.73 | 18.00 | 17.63 | 12.00 | 11.79 | 1.20 | 10.0 | … | 6.00 | 14.2 |

| M14 × 2b | 14.00 | 13.73 | 21.00 | 20.60 | 14.00 | 13.77 | 1.40 | 12.0 | … | 7.00 | 16.2 |

| M16 × 2 | 16.00 | 15.73 | 24.00 | 23.58 | 16.00 | 15.76 | 1.60 | 14.0 | … | 8.00 | 18.2 |

| M20 × 2.5 | 20.00 | 19.67 | 30.00 | 29.53 | 20.00 | 19.73 | 2.00 | 17.0 | … | 10.00 | 22.4 |

| M24 × 3 | 24.00 | 23.67 | 36.00 | 35.48 | 24.00 | 23.70 | 2.40 | 19.0 | … | 12.00 | 26.4 |

| M30 × 3.5 | 30.00 | 29.67 | 45.00 | 44.42 | 30.00 | 29.67 | 3.00 | 22.0 | … | 15.00 | 33.4 |

| M36 × 4 | 36.00 | 35.61 | 54.00 | 53.37 | 36.00 | 35.64 | 3.60 | 27.0 | … | 18.00 | 39.4 |

| M42 × 4.5 | 42.00 | 41.61 | 63.00 | 62.31 | 42.00 | 41.61 | 4.20 | 32.0 | … | 21.00 | 45.6 |

| M48 × 5 | 48.00 | 47.61 | 72.00 | 71.27 | 48.00 | 47.58 | 4.80 | 36.0 | … | 24.00 | |

Titanium na sinulid na stud

| ANSI /ASMEB 18.31.2 Threaded Rods-Unit:inch | ||||

| d | pitch | |||

| UNC | UNF | 8UN | ||

| 1/4 | 0.25 | 20 | 28 | / |

| 5/16 | 0.3125 | 18 | 24 | / |

| 3/8 | 0.375 | 18 | 24 | / |

| 7/16 | 0.4375 | 14 | 20 | / |

| 1/2 | 0.5 | 13 | 20 | / |

| 9/16 | 0.5625 | 12 | 18 | / |

| 5/8 | 0.625 | 11 | 18 | / |

| 3/4 | 0.75 | 10 | 16 | / |

| 7/8 | 0.875 | 9 | 14 | / |

| 1 | 1 | 8 | 12 | 8 |

| 1-1/8 | 1.125 | 7 | 12 | 8 |

| 1-1/4 | 1.25 | 7 | 12 | 8 |

| 1-3/8 | 1.375 | 6 | 12 | 8 |

| Yunit: pulgada | ||||

| d | pitch | |||

| UNC | UNF | 8UN | ||

| 1-1/2 | 1.5 | 6 | 12 | 8 |

| 1-5/8 | 1.625 | / | / | 8 |

| 1-3/7 | 1.75 | 5 | / | 8 |

| 1-7/8 | 1.875 | / | / | 8 |

| 2 | 2 | 4-1/2 | / | 8 |

| 2-1/4 | 2.25 | 4-1/2 | / | 8 |

| 2-1/2 | 2.5 | 4 | / | 8 |

| 2-3/4 | 2.75 | 4 | / | 8 |

| 3 | 3 | 4 | / | 8 |

| 3-1/4 | 3.25 | 4 | / | 8 |

| 3-1/2 | 3.5 | 4 | / | 8 |

| 3-3/4 | 3.75 | 4 | / | 8 |

| 4 | 4 | 4 | / | 8 |

| L | 1/2<L≤2-1/2 | 2-1/2<L≤4 | 4<L≤8 | 8<L≤16 | 16<L |

| Naka-fastened tolerance sa haba ng stud | ±0.04 | ±0.08 | ±0.10 | ±0.12 | ±0.18 |

| Pamantayan | Paglalarawan | Pamantayan | Paglalarawan |

| DIN 84 | Mga slotted cheese head screws | DIN 439 | Jam nuts |

| DIN 125 | Mga flat washer | DIN 963 | Mga naka-slot na countersunk flat head screws |

| DIN 127 | Mga panlaba ng spring lock | DIN 965 | Phillips flat head machine screws |

| DIN 912 | Hex socket head cap screws | DIN 985 | Lock nuts (na may non-metallic insert) |

| DIN913/DIN 914/DIN915/DIN916 | Itakda ang mga turnilyo | DIN 1665/DIN 6921 | Hex bolts na may flange |

| DIN 931 | Hex head cap screws (part thread) | DIN 6912/DIN 7984 | Hexagon socket thin head cap screws |

| DIN 933 | Hex head cap screws (buong thread) | DIN 7991 | Flat head countersunk socket cap screws |

| DIN 934 | Hex nuts | DIN 9021 | Flat washer |

Mga Katumbas na Materyal na Grado Para sa Mga Pangkabit ng Titanium

| STANDARD | WERKSTOFF NR. | UNS |

| Titanium Baitang2 | 3.7035 | R50400 |

| Titanium Grade5 | 3.7165 | R56400 |

Mga Mekanikal na Katangian Ng Titanium Fasteners

| Grade | Lakas ng Tensile (min) | Lakas ng Yield 0.2% Offset | Pagpahaba sa 2 pulgada o 50mm % (min) | ||

| KSI | MPa | KSI | MPa | ||

| Gr.1 | 35 | 240 | 20 – 45 | 138 – 310 | 24 |

| Gr.2 | 50 | 345 | 40 – 65 | 275 – 450 | 20 |

| Gr.3 | 65 | 450 | 55 – 80 | 380 – 550 | 18 |

| Gr.4 | 80 | 550 | ≥70 | ≥483 | 15 |

| Gr.5 | 138 | 950 | ≥128 | ≥880 | 14 |

| Gr.7 | 50 | 345 | ≥40 | ≥275 | 24 |

| Gr.9 | 125 | 860 | ≥105 | ≥725 | 10 |

| Gr.12 | 70 | 483 | ≥50 | ≥345 | 18 |

| Gr.23 | 125 | 860 | ≥115 | ≥790 | 15 |

| Elemento | Densidad | Temperatura ng pagkatunaw | Lakas ng makunat | Lakas ng Yield (0.2% Offset) | Pagpahaba |

| Titan Gr.2 | 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900 , MPa – 344 | Psi – 39900 , MPa – 275 | 20% |

| Titan Gr.5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000 , MPa – 950 | Psi – 128000 , MPa – 880 | 14 % |

Komposisyon ng Materyal na Kemikal Ng Mga Pangkabit ng Titanium

| Grade | Fe% | C% | N% | H% | O% | Al% | V% | Mo% | Ni% | Pd% | Ti |

| Gr1 | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 | — | — | — | — | — | BAL. |

| Gr2 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | — | — | — | — | — | BAL. |

| Gr3 | 0.3 | 0.08 | 0.05 | 0.015 | 0.35 | — | — | — | — | — | BAL. |

| Gr4 | 0.3 | 0.08 | 0.05 | 0.015 | 0.40 | — | — | — | — | — | BAL |

| Gr5 | 0.25 | 0.08 | 0.03 | 0.015 | 0.02 | 5.5 – 6.75 | 3.5 – 4.5 | — | — | — | BAL |

| Gr7 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | — | — | — | — | 0.12 – 0.25 | BAL. |

| Gr9 | 0.25 | 0.08 | 0.03 | 0.015 | 0.15 | 2.5 – 3.3 | 2.0 – 3.0 | — | — | — | BAL. |

| Gr12 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | — | — | 0.2 – 0.4 | 0.6 – 0.9 | — | BAL. |

| Gr23 | 0.3 | 0.08 | 0.03 | 0.015 | 0.13 | 5.5 – 6.75 | — | — | — | — | B |