Tubong haluang metal ng nikel

| materyal | Monel/Inconel/Hastelloy/Duplex Steel/PH Steel/Nickel Alloy |

| Hugis | Round, Forging, Ring, Coil, Flange, Disc, Foil, Spherical, Ribbon, Square, Bar, Pipe, Sheet |

| Grade | N02200,N02201,N04400,N06600,N06601,N06625,N06690,N08810,N08825,N08020,N18080,N180280 665、N06022、N06030、GH3030、GH3036 GH5188 Inconel706 Inconel600 InconelX-750 Inconel718 Inconel625 Inconel 617 Inconel601 Inconel 1NS311430 NS311430 NS3 NS112,Incoloy800H, NO8810 NS111 NS336 NS142 Incoloy825 NS355 Hastelloy C-4 Monel K500,N05500 |

| Pagtutukoy | Iba pa: 253Ma,254SMo,654SMo,F50(UNS S32100)F60,F61,F65,1J22,N4,N6 atbp |

| haluang metal :haluang metal 625,Alloy 20/28/31 | |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g; | |

| Hastelloy B / UNS N10001,Hastelloy B-2 / UNS N10665 / DIN W. Nr.2.4617, Hastelloy C, Hastelloy C-4 / UNS N06455 / DIN W. Nr.2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr.2.4602,Hastelloy C-276 / UNS N10276 / DIN W. Nr.2.4819,Hastelloy X / UNS N06002 / DIN W. Nr.2.4665 | |

| Haynes: Haynes 230/556/188; | |

| Inconel Series:Inconel 600/601/602CA/617/625/690/713/718/738/X-750,Karpintero 20; | |

| Inconel 718 / UNS N07718 /N04400/N06600/N08825/DIN W. Nr.2.4668,Inconel 601 / UNS N06601 / DIN W. Nr.2.4851, Inconel 625 / UNS N06625 / DIN W. Nr.2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr.2.4669,Inconel 600 / UNS N06600 / DIN W. Nr.2.4816 | |

| Incoloy:Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel:Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60; | |

| Nimonic: Nimonic 75/80A/90/A263 ; | |

| Kawad: 0.01-10mm Strip: 0.05*5.0-5.0*250mm Bar: φ4-50mm;Haba 2000-5000mm Pipe: φ6-273mm;δ1-30mm;Haba 1000-8000mm Sheet: δ 0.8-36mm; Lapad 650-2000mm; Haba 800-4500mm | |

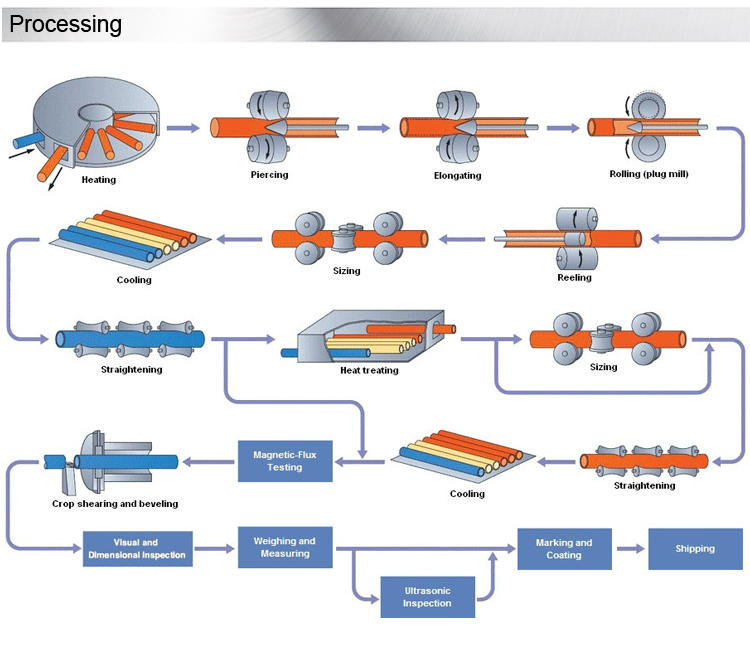

| produkto Mga katangian | 1. Ayon sa proseso ng paghahanda ay maaaring nahahati sa mga superalloy ng pagpapapangit, casting superalloys at powder metallurgy superalloys. 2. Ayon sa mode ng pagpapalakas, mayroong solidong uri ng pagpapalakas ng solusyon, pag-ulan uri ng pagpapalakas, uri ng pagpapalakas ng oxide dispersion at uri ng pagpapalakas ng hibla, atbp. |

| Pamantayan | GB,AISI,ASTM,DIN,EN,SUS,UNS atbp |

| Inspeksyon | ISO, SGS, BV, at iba pa. |

| Aplikasyon | Mga sangkap na may mataas na temperatura tulad ng mga blades ng turbine, guide vane, mga turbine disk, mataas na presyon mga disk ng compressor, paggawa ng makina at mga combustion chamber na ginagamit sa paggawa ng aviation, naval at industrial gas turbines |

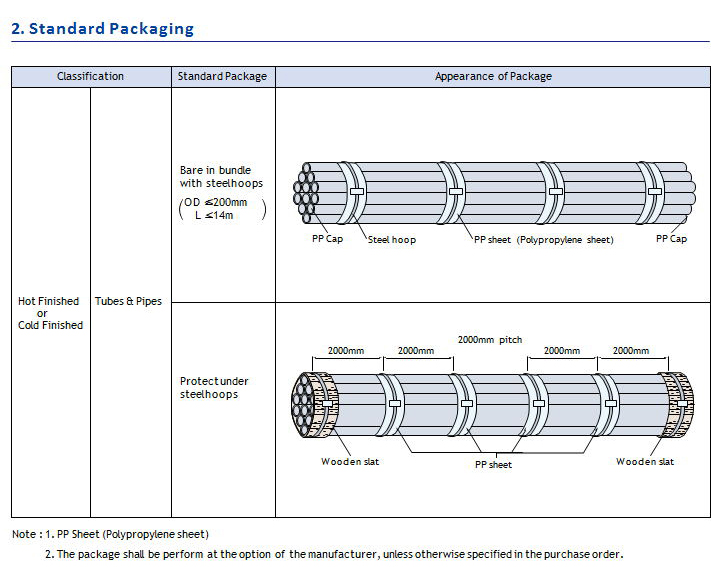

| Packaging | 1. mga kaso na nakaimpake sa mga kahon na gawa sa kahoy 2. packaging ng papel 3. plastic packing 4. packaging ng bula Pag-iimpake ayon sa mga kinakailangan o produkto ng customer |

| Paghahatid | 7-25days o ayon sa produkto |

| Pagbabayad | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Ayon sa mga pagbabayad na kinakailangan ng customer para sa mga offline na order. |

| STOCKED SIZE | |||||||||||||

| SIZE | NICKEL | HALOS | HALOS | HALOS | HALOS | HALOS | HALOS | HALOS | HALOS | HALOS | HALOS | SIZE | |

| 1/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 1.65mm | |

| 0.010 | X | X | .25mm | ||||||||||

| 0.020 | X | .51mm | |||||||||||

| 1/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 3.18mm | |

| 0.010 | X | 0.25 | |||||||||||

| 0.012 | X | 3.05mm | |||||||||||

| 0.016 | X | .31mm | |||||||||||

| 0.020 | X | X | X | .51mm | |||||||||

| 0.028 | X | X | X | X | .71mm | ||||||||

| 0.035 | X | X | X | X | .89mm | ||||||||

| 3/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 4.76mm | |

| 0.010 | X | .25mm | |||||||||||

| 0.016 | X | X | .31mm | ||||||||||

| 0.020 | X | .51mm | |||||||||||

| 0.028 | X | X | X | .71mm | |||||||||

| 0.035 | X | X | X | X | X | X | .89mm | ||||||

| 0.049 | X | X | X | 1.24mm | |||||||||

| 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 6.35mm | |

| 0.016 | X | .31mm | |||||||||||

| 0.020 | X | X | X | .51mm | |||||||||

| 0.028 | X | X | X | X | X | .71mm | |||||||

| 0.035 | X | X | X | X | X | X | X | X | .89mm | ||||

| 0.049 | X | X | X | X | X | X | X | X | 1.24mm | ||||

| 0.065 | X | X | X | X | X | X | X | 1.65mm | |||||

| 0.083 | X | 2.11mm | |||||||||||

| 5/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 7.94mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | 1.24mm | |||||||||||

| 0.065 | X | X | X | 1.65mm | |||||||||

| 3/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 9.53mm | |

| 0.020 | X | .51mm | |||||||||||

| 0.028 | X | X | X | X | .71mm | ||||||||

| 0.035 | X | X | X | X | X | X | X | X | .89mm | ||||

| 0.049 | X | X | X | X | X | X | X | 1.24mm | |||||

| 0.065 | X | X | X | X | X | X | X | 1.65mm | |||||

| 0.083 | X | X | 2.11mm | ||||||||||

| 7/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 11.1mm | |

| 0.035 | X | .89mm | |||||||||||

| 0.065 | X | 1.65mm | |||||||||||

| 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 12.7mm | |

| 0.028 | X | X | X | X | .71mm | ||||||||

| 0.035 | X | X | X | X | X | X | X | X | X | .89mm | |||

| 0.049 | X | X | X | X | X | X | X | 1.24mm | |||||

| 0.058 | X | X | 1.47mm | ||||||||||

| 0.065 | X | X | X | X | X | X | X | X | 1.65mm | ||||

| 0.083 | X | X | X | 2.11mm | |||||||||

| 0.095 | X | X | 2.41mm | ||||||||||

| 0.109 | X | 2.77mm | |||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 9/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 14.3mm | |

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | X | X | X | 1.24mm | ||||||||

| 0.065 | X | X | X | 1.65mm | |||||||||

| 0.083 | X | 2.11mm | |||||||||||

| 5/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 15.9mm | |

| 0.035 | X | X | X | X | X | .89mm | |||||||

| 0.049 | X | X | X | X | X | X | X | 1.24mm | |||||

| 0.065 | X | X | X | X | X | X | 1.65mm | ||||||

| 0.083 | X | X | 2.11mm | ||||||||||

| 0.095 | X | X | 2.41mm | ||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 3/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 19.1mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | X | X | X | X | X | .89mm | |||||

| 0.049 | X | X | X | X | X | X | X | 1.24mm | |||||

| 0.065 | X | X | X | X | X | X | X | X | X | X | 1.65mm | ||

| 0.083 | X | X | X | X | X | X | X | 2.11mm | |||||

| 0.095 | X | X | 2.41mm | ||||||||||

| 0.109 | X | X | X | X | 2.77mm | ||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | X | 3.18 | ||||||||||

| 7/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 22.2mm | |

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | X | X | 1.24mm | |||||||||

| 0.065 | X | X | X | X | 1.65mm | ||||||||

| 0.083 | X | X | 2.11mm | ||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 1″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 25.4mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | X | X | X | X | .89mm | ||||||

| 0.049 | X | X | X | X | X | X | X | 1.24mm | |||||

| 0.065 | X | X | X | X | X | X | X | X | 1.65mm | ||||

| 0.083 | X | X | X | X | X | X | X | 2.11mm | |||||

| 0.095 | X | X | 2.41mm | ||||||||||

| 0.109 | X | X | X | X | 2.77mm | ||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | 3.18 | |||||||||||

| 0.134 | X | X | |||||||||||

| 1 1/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 28.6mm | |

| 0.049 | X | ||||||||||||

| 1 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 31.8mm | |

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | 1.24mm | |||||||||||

| 0.065 | X | X | X | X | X | X | 1.65mm | ||||||

| 0.083 | X | X | X | X | 2.11mm | ||||||||

| 0.095 | X | 2.41mm | |||||||||||

| 0.109 | X | 2.77mm | |||||||||||

| 0.120 | X | X | 3.05mm | ||||||||||

| 0.125 | X | 3.18 | |||||||||||

| 1 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 38.1mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | .89mm | ||||||||||

| 0.049 | X | X | X | 1.24mm | |||||||||

| 0.065 | X | X | X | X | X | X | 1.65mm | ||||||

| 0.083 | X | X | X | 2.11mm | |||||||||

| 0.095 | X | X | 2.41mm | ||||||||||

| 0.109 | X | X | X | 2.77mm | |||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | 3.18 | |||||||||||

| 1 5/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 41.3mm | |

| 0.065 | X | 1.65mm | |||||||||||

| 0.083 | X | 2.11mm | |||||||||||

| 1 3/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 44.5mm | |

| 0.065 | X | X | X | 1.65mm | |||||||||

| 1 7/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 47.6mm | |

| 0.083 | X | 2.11mm | |||||||||||

| 2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 50.8mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | .89mm | ||||||||||

| 0.049 | X | X | 1.24mm | ||||||||||

| 0.065 | X | X | X | X | X | 1.65mm | |||||||

| 0.083 | X | X | X | X | 2.11mm | ||||||||

| 0.095 | X | 2.41mm | |||||||||||

| 0.109 | X | X | 2.77mm | ||||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | X | 3.18 | ||||||||||

| 2 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 57.2mm | |

| 0.035 | X | .89mm | |||||||||||

| 0.049 | X | 1.24mm | |||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 2 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 63.5mm | |

| 0.065 | X | X | X | X | 1.65mm | ||||||||

| 0.083 | X | X | 2.11mm | ||||||||||

| 0.109 | X | 2.77mm | |||||||||||

| 0.120 | X | X | 3.05mm | ||||||||||

| 3″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 76.2mm | |

| 0.065 | X | X | X | X | 1.65mm | ||||||||

| 0.083 | X | X | X | 2.11mm | |||||||||

| 0.120 | X | X | 3.05mm | ||||||||||

| 0.125 | X | 3.18 | |||||||||||

| 0.250 | X | 6.35 | |||||||||||

| 3 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 82.6mm | |

| 0.125 | X | 3.18 | |||||||||||

| 3 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 88.9mm | |

| 0.375 | 9.53mm | ||||||||||||

| Pamantayan | – ASTM A270,ASTM A249,ASTM A511,ASTM A778 ,ASTM A312,ASTM A358,ASTM A409,ASTM A213,ASTM A790,ASTM A268,ASTM A269,ASTM A554,ASTM B333,4ASTM767,ASTM77 B675, ASTM B676, ASTM B690, ASTM A928, ASME B36.19, ASME B36.10– EN10216-5, EN10217-7, DIN 17456, DIN 17458 – JIS G3463,JIS G3119,JIS G3446,JIS G3218,JIS G3258,JIS G3448,JIS H4631– DEP 31,DEP 40,DEP 20,DEP 32,DNV-OS-F101 |

| Laki ng saklaw | OD:NPS 1/8 -80, BN 6 – 2000, 10.3 – 2030 , Alao capillaryWT:Sch5s-Sch160s, SchXXH, STD,XS,XXSHaba:Pagpapasadya |

| Grade | S32750, 00Cr25Ni7Mo4N, 022Cr25Ni7Mo4N, 1.441, 1.4307/1.4301/304L/3, S30408/S30403, 0Cr18Ni9DQ, 1.4948/3048 4948, 06Cr23Ni13, S30908, SUS309S, SUS310S, 1.4845, S31008, S31008S, 06Cr25Ni20, 0Cr25Ni20, 1.4401/1.4404/316/31, S31635, SUS316Ti, 1.4571, 1.4571/316Ti, S31703, 022Cr19Ni13Mo3, 00Cr17Ni12Mo2, S31703, SUS. 410S, 1.4, 06Cr13, S11306, 0Cr13, S42000, SUS420J1, 1.4021, SUS420J2, 1.4028, S43020, 430F, SUS430F, 1.4104, , 301, 302, 303, 305, 309, 310, 316, 317, 321, 347, 403, 41, 42,403 07, 304/304L, 304DQ . 0, 630, XM19, C4, S30815 , S31254, 174PH, F51, F60, F53, S32760, 253MA, HC2000, 800H, 926, GH2132, GH4169, GH3030, GH3039, GH4150, N0434, NCMo 08810 |

| ASTM B111 / ASME SB111 | Karaniwang Pagtutukoy para sa Copper at Copper-Alloy Seamless Condenser Tubes at Ferrule Stock | |

| ASTM B161 / ASME SB161 | Karaniwang Pagtutukoy para sa Nickel Seamless Pipe at Tube | |

| ASTM B163 / ASME SB163 | Karaniwang Pagtutukoy para sa Seamless Nickel at Nickel Alloy Condenser at Heat-Exchanger Tubes | |

| ASTM B165 / ASME SB165 | Karaniwang Pagtutukoy para sa Nickel-Copper Alloy (UNS N04400)* Seamless Pipe at Tube | |

| ASTM B167 / ASME SB167 | Karaniwang Pagtutukoy para sa Nickel-Chromium-Iron Alloys, Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617), at Nickel-Iron-Chromium-Tungsten Alloy (UNS N06674) Seamless Pipe at Tube | |

| ASTM B395 / ASME SB395 | Karaniwang Pagtutukoy para sa U-Bend Seamless Copper at Copper Alloy Heat Exchanger at Condenser Tubes | |

| ASTM B407 | Karaniwang Pagtutukoy para sa Nickel-Iron-Chromium Alloy Seamless Pipe at Tube | |

| ASTM B423 / ASME SB423 | Standard Specification para sa Nickel-Chromium-Molybdenum-Columbium Alloys (UNS N06625 at UNS N06852) at Nickel-Chromium-Molybdenum-Silicon Alloy (UNS N06219) Pipe at Tube | |

| ASTM B444 / ASME SB444 | Standard Specification para sa Nickel-Chromium-Molybdenum-Columbium Alloys (UNS N06625 at UNS N06852) at Nickel-Chromium-Molybdenum-Silicon Alloy (UNS N06219) Pipe at Tube | |

| ASTM B622 / ASME SB622 | Karaniwang Pagtutukoy para sa Seamless Nickel at Nickel-Cobalt Alloy Pipe at Tube | |

| ASTM B668 / ASME SB668 | Standard Specification para sa UNS N08028 at N08029 Seamless Pipe and Tube | |

| ASTM B677 / ASME SB677 | Standard Specification para sa UNS N08925, UNS N08354, at UNS N08926 Seamless Pipe and Tube | |

| ASME SB690 / ASME SB690 | Karaniwang Pagtutukoy para sa Iron-Nickel-Chromium-Molybdenum Alloys (UNS N08366 at UNS N08367) Seamless Pipe at Tube | |

| ASTM B705 / ASME SB705 | Karaniwang Pagtutukoy para sa Nickel-Alloy (UNS N06625, N06219 at N08825) Welded Pipe | |

| ASTM B729 / ASME SB729 | Standard na Pagtutukoy para sa tuluy-tuloy na UNS N08020, UNS N08026, at UNS N08024 nickel alloy pipe at Tube | |

| ASTM B829 / ASME SB829 | Karaniwang Pagtutukoy para sa Pangkalahatang Pangangailangan para sa Nickel and Nickel Alloys Seamless Pipe and Tube |

Komposisyong kemikal:

| Grade | Komposisyong kemikal | ||||||||

| C | Si max | Mn max | P | S | Ni | Cr | Mo | Ti | |

| 200 | 0.15 | 0.35 | 0.35 | 0.010 | 99 min | ||||

| 201 | 0.02 | 0.35 | 0.35 | 0.010 | 99 min | ||||

| 400 | 0.30 | 0.50 | 2.00 | 0.024 | 63 min | ||||

| 600 | 0.15 | 0.50 | 1.00 | 0.015 | 72 min | 14 – 17 | |||

| 601 | 0.10 | 0.50 | 1.00 | 0.015 | 58 – 63 | 21 – 25 | |||

| 625 | 0.10 | 0.50 | 0.50 | 0.015 | 0.015 | 58 min | 20 – 23 | 8 – 10 | 0.40 max |

| 800 | 0.10 | 1.00 | 1.50 | 0.03 | 0.015 | 30 – 35 | 19 – 23 | 0.15 0.60 | |

| 800H | 0.05 0.10 | 1.00 | 1.50 | 0.015 | 30 – 35 | 19 – 23 | 0.15 0.60 | ||

| 825 | 0.05 | 0.50 | 1.00 | 0.03 | 38 – 46 | 19.5 23.5 | 2.5 3.5 | 0.6 1.2 | |

| 904L | 0.02 | 1.00 | 2.00 | 0.030 | 0.015 | 24 – 26 | 19 23 | 4 5 | |

Mga Pisikal na Katangian ng Nickel Alloy

| HALOS | NICKEL ALLOY DENSITY | THERMAL , CONDUCTIVITY | THERMAL LINEAR , EXPANSION COEFF., (20-95 °C) | ELECTRICAL RESISTIVITY , SA 20°C |

| G/CM³ | W/MK | 10-6/K | ΜΩ-CM | |

| NI 200/201 | 8.89 | 70.20 | 13.3 | 9 |

| NI 205/205 LC | 8.89 | 75.00 | 13.3 | 8.9 |