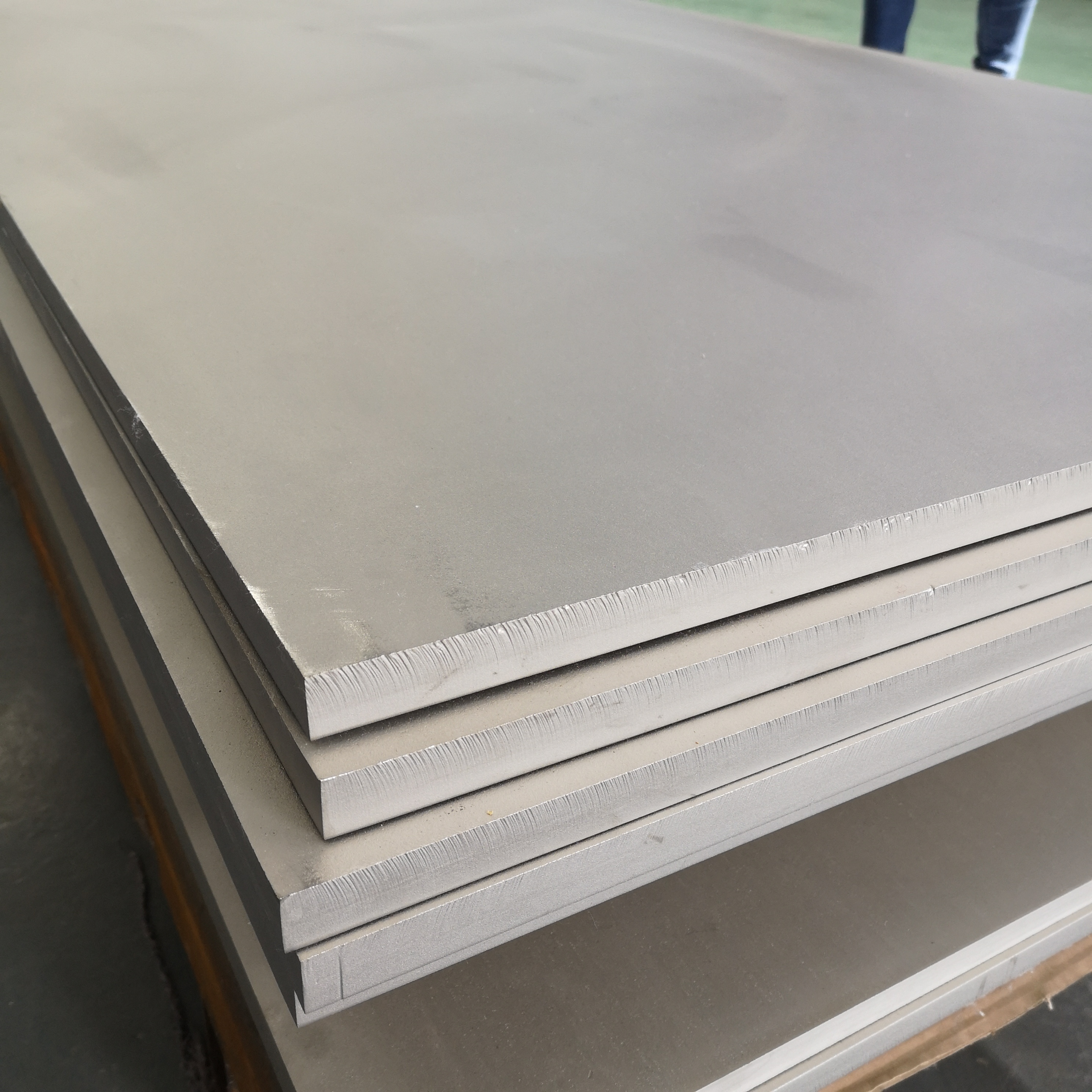

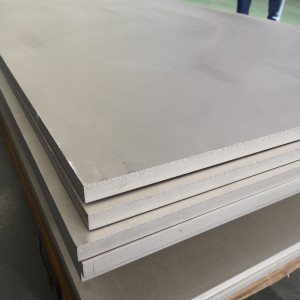

Titanium Sheet / Plate

Mga Karaniwang Marka

Titanium Baitang 1ay isang hindi pinaghalo, mababang lakas na titanium na produkto na naglalaman ng mababang oxygen na may mataas na kakayahan sa anyo;ang titanium grade na ito ay ginagamit sa mga air frame, heat exchange at desalination unit.

Titanium Baitang 2ay isang hindi pinaghalo, katamtamang lakas ng titanium na produkto.Ang titanium grade na ito ay ginagamit sa air frame, aircraft engine at marine parts;mahusay na kakayahan sa hinang at paglaban sa kaagnasan ang mga natatanging katangian nito.

Titanium Baitang 3ay isang hindi pinaghalo, mataas na lakas, produkto ng titanium na nagbibigay ng mahusay na paglaban sa kaagnasan at mahusay na kakayahan sa pagwelding.Ang titanium grade na ito ay pangunahing ginagamit sa air frame at aircraft engine parts.

Titanium Baitang 4ay ang pinakamataas na lakas purong unalloyed titanium na produkto.Ang titanium grade na ito ay ginagamit halos eksklusibo para sa air frame, aircraft engine parts, marine, surgical implants, hydraulic tubing.Ang mahusay na kakayahan sa anyo at paglaban sa kaagnasan ang tanda nito.

Titanium Grade 5 (6AL-4V)ay isang produktong alloyed titanium na naglalaman ng 6% Aluminum at 4% Vanadium;ay isang produkto ng katamtamang lakas.Ang titanium grade na ito ay kadalasang ginagamit sa airframe at turbine engine parts;at para gamitin sa surgical implants.Teknikal na Impormasyon Titanium 6AL–Ang 4V ELI ay isang alloyed titanium na produkto na naglalaman ng 6% Aluminum at 4% Vanadium, ELI (Extra Low Interstitial).

6AL–2Sn–4Zr–2Mo (6-2-4-2)ay isang alloyed titanium na produkto na naglalaman ng 6% Aluminum, 2% Tin, 4% Zirconium, 2% Molibdenum.

6AL–6V–2Sn (6-6-2)ay isang alloyed titanium na produkto na naglalaman ng 6% Aluminum, 6% Vanadium, 2% Tin.

5AL–2.5Sn at ELI (5-2.5)ay isang alloyed titanium na produkto na naglalaman ng 5% Aluminum at 2.5% Tin.Gayundin ang ELI (Extra Low Interstitial).

8AL–1V–1Mo (8-1-1)ay isang alloyed titanium na produkto na naglalaman ng 8% Aluminum, 1% Molibdenum at 1% Vanadium.

15V–3Cr–4AL–3Sn (15-3-4-3)ay isang alloyed titanium na produkto na naglalaman ng 15% Vanadium, 3% Chromium, 4% Aluminum, 3% Tin.

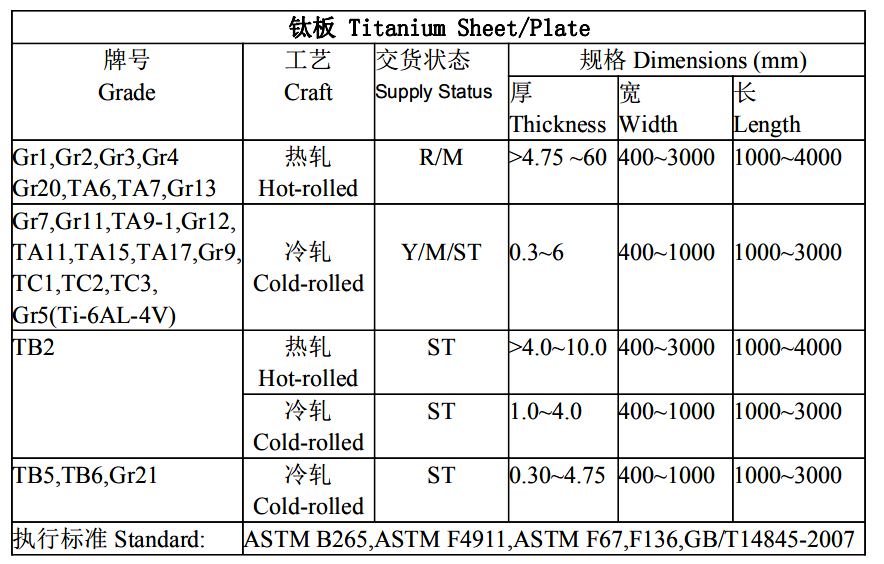

| Grade | Katayuan | Pagtutukoy | ||

| Gr1,Gr2,Gr4,Gr5,Gr7,Gr9,Gr11, Gr12,Gr16,Gr23 | Hot Rolled(R) Cold Rolled(Y) Annealed(M) Paggamot ng solusyon(ST) | Kapal (mm) | Lapad(mm) | Haba(mm) |

| 0.3~60 | ≥400 | ≤ 6000 | ||

| Titanium Sheet | |||

| kapal | Mga grado | ||

| .016 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .020 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .025 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .032 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .040 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .050 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .063 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .071 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .080 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .090 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .100 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .125 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

Tandaan: Available ang mga karagdagang laki, hindi lahat ng laki na ipinapakita ay available mula sa stock.Mangyaring makipag-ugnayan sa amin upang tingnan ang availability.

| AMS:AMS 2631, AMS 4901, AMS 4907, AMS 4911ASTM: ASTM B265 Gr 23, ASTM B265 Gr 5, ASTM B265 Gr2, ASTM B265 Gr4, ASTM F136, ASTM F67MIL-T:MIL-T-9046, MIL-T-9046 CP1EN:EN 10204.3, EN 1-204:2005 3.1 NACE:NACE MR0175 ASME:ASME SB265 |

| Grade | Mga Detalye ng AMS/MIL | Mga Detalye ng ASTM |

| Baitang 1 | AMS-T-9046B CP4 AMS 4940 MIL-T-9046J CP4 | ASTM B265 Gr1 Sheet/plate ASTM B337 Gr1 pipe ASTM B338 Gr1 tube ASTM B348 Gr1 bar ASTM F67 Gr1 Surgical Implant |

| Baitang 2 | Baitang 2 AMS-T-9046B CP3 AMS 4902 MIL-T-9046J CP3 AMS 4941 AMS 4942 AMS 4951 Welding wire | ASTM B265 Gr2 Sheet/plate ASTM B337 Gr2 pipe ASTM B338 Gr2 tube ASTM B348 Gr2 bar ASTM F67 Gr2 Surgical Implant |

| Baitang 3 | AMS-T-9046B CP2 AMS 4900 MIL-T-9046J CP2 | ASTM B265 Gr3 Sheet/plate ASTM B337 Gr3 pipe ASTM B338 Gr3 tube ASTM B348 Gr3 bar ASTM F67 Gr3 Surgical Implant |

| Baitang 4 | AMS-T-9046B CP1 AMS-T-9047A CP70 AMS 4901 AMS 4921 MIL-T-9046J CP1 MIL-T-9047G CP70 | ASTM B265 Gr4 Sheet/plate ASTM B337 Gr4 pipe ASTM B338 Gr4 tube ASTM B348 Gr4 bar ASTM F67 Gr4 Surgical Implant |

| Baitang 7 | ASTM B265 Gr7 Sheet/plate ASTM B337 Gr7 pipe ASTM B338 Gr7 tube ASTM B348 Gr7 bar |

| Grade | Mga Detalye ng US | Mga Detalye ng ASTM |

| Baitang 5 6Al-4V | AMS 4907 ELI AMS 4911 AMS 4928 AMS 4930 ELI AMS 4931 ELI Duplex ann AMS 4963 AMS 4965 AMS 4967 AMS 4985 AMS 4991 AMS 6931 AMS 6932 MIL-T-9046J AB-1 MIL-T-9046J AB-2 (ELI) MIL-T-9046H Type 3 Comp C MIL-T-9046H Type 3 Comp D AMS-T-9046B AB-1 AMS-T-9046B AB-2 (ELI) MIL-T-9047G 6Al-4v MIL-T-9047G 6Al-4v (ELI) AMS-T-9047A 6Al-4v AMS-T-9047A 6Al-4v (ELI) | ASTM B265 Gr5 Sheet/plate ASTM B348 Gr5 bar ASTM F136 Gr5 Implant Grade |

| Baitang 9 3Al-2.5V | AMS 4943 AMS 4944 AMS 4945 AMS-T-9046B AB-5 AMS-T-9047A 3Al-2.5V MIL-T-9046J AB-5 MIL-T-9047 3Al-2.5V | ASTM B265 Gr6 Sheet/plate ASTM B348 Gr6 bar |

| Baitang 23 6Al-4V ELI | AMS 4907 AMS 4930 AMS 6932 AMS-T-9046 AB-2 6AL-4V (ELI) AMS-T-9047 AB-2 6AL-4V (ELI) MIL-T-9046 AB-2 6AL-4V (ELI) MIL-T-9047 6AL-4V (ELI) | ASTM B265 Gr23 sheet/plate/strip ASTM B348 Gr23 bar/billet ASTM F136 Gr23 Implant Gra |

Komposisyong kemikal

| Grade | Komposisyon ng kemikal, porsyento ng timbang (%) | ||||||||||||

| C ≤ | O ≤ | N ≤ | H ≤ | Fe ≤ | Al | V | Pd | Ru | Ni | Mo | Iba pang Elemento Max.bawat isa | Iba pang Elemento Max.kabuuan | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5~6.75 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | 0.12~0.25 | — | 0.12~0.25 | — | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | — | — | 0.12~0.25 | — | — | — | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | — | — | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | 0.04~0.08 | — | — | — | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5~4.5 | — | — | — | — | 0.1 | 0.1 |

Mga katangiang pisikal

| Grade | Mga katangiang pisikal | ||||||

| lakas ng makunat Min | lakas ng ani (0.2%, offset) | Pagpahaba sa 50mm Min (%) | |||||

| ksi | MPa | Min | Max | ||||

| ksi | MPa | ksi | MPa | ||||

| Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr4 | 80 | 550 | 70 | 483 | 95 | 655 | 15 |

| Gr5 | 130 | 895 | 120 | 828 | — | — | 10 |

| Gr7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr9 | 90 | 620 | 70 | 483 | — | — | 15 |

| Gr11 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr12 | 70 | 483 | 50 | 345 | — | — | 18 |

| Gr16 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | — | — | 10 |

Pagpapahintulot (mm)

| kapal | Pagpaparaya sa lapad | ||

| 400~1000 | 1000~2000 | >2000 | |

| 5.0~6.0 | ±0.35 | ±0.40 | ±0.60 |

| 6.0~8.0 | ±0.40 | ±0.60 | ±0.80 |

| 8.0~10.0 | ±0.50 | ±0.60 | ±0.80 |

| 10.0~15.0 | ±0.70 | ±0.80 | ±1.00 |

| 15.0~20.0 | ±0.70 | ±0.90 | ±1.10 |

| 20.0~30.0 | ±0.90 | ±1.00 | ±1.20 |

| 30.0~40.0 | ±1.10 | ±1.20 | ±1.50 |

| 40.0~50.0 | ±1.20 | ±1.50 | ±2.00 |

| 50.0~60.0 | ±1.60 | ±2.00 | ±2.50 |