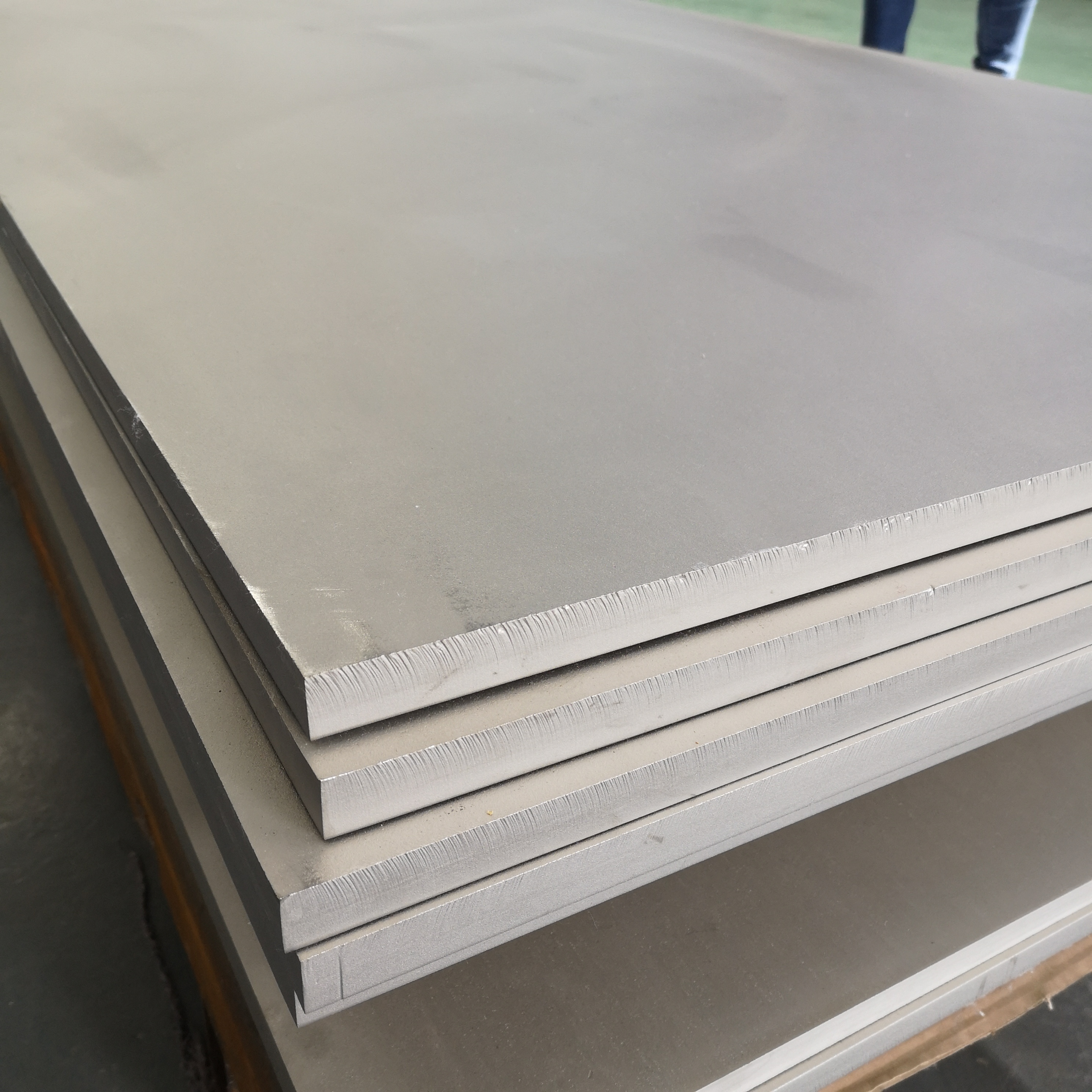

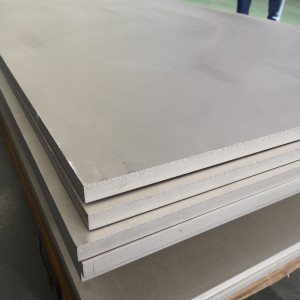

Titanium Sheet / Plate

Common Grades

Titanium Grade 1isiri yakasanganiswa, yakaderera simba titanium chigadzirwa chine yakaderera oxygen ine yakakwirira fomu kugona;iyi titanium giredhi inoshandiswa mumhepo mafuremu, kupisa kupisa uye desalination zvikamu.

Titanium Grade 2chinhu chisina kusanganiswa, chepakati simba titanium chigadzirwa.Iyi titanium giredhi inoshandiswa mumafuremu emhepo, injini dzendege uye zvikamu zvemugungwa;kunaka weld kugona uye kushora kuramba ndiwo maitiro ayo anosiyanisa.

Titanium Grade 3haina kurongeka, yakasimba simba, titanium chigadzirwa chinopa yakanakisa corrosion kuramba uye yakanaka weld kugona.Iyi titanium giredhi inonyanya kushandiswa mumhepo furemu uye ndege injini zvikamu.

Titanium Grade 4ndiyo yepamusoro simba yakachena unalloyed titanium chigadzirwa.Iri titanium giredhi rinoshandiswa rakangoita semhepo fremu, ndege injini zvikamu, zvemugungwa, ekuvhiya implants, hydraulic tubing.Yakanaka fomu kugona uye corrosion kuramba ndicho chiratidzo chayo.

Titanium Grade 5 (6AL-4V)is alloyed titanium chigadzirwa chine 6% Aluminium uye 4% Vanadium;chinhu chepakati simba chigadzirwa.Iyi titanium giredhi inonyanya kushandiswa muairframe uye turbine injini zvikamu;uye kuti ishandiswe mukuvhiya ma implants.Technical Info Titanium 6AL-4V ELI chigadzirwa chetitanium chakasanganiswa chine 6% Aluminium uye 4% Vanadium, ELI (Extra Low Interstitial).

6AL-2Sn-4Zr-2Mo (6-2-4-2)ndeye alloyed titanium chigadzirwa chine 6% Aluminium, 2% Tin, 4% Zirconium, 2% Molybdenum.

6AL-6V-2Sn (6-6-2)ndeye alloyed titanium chigadzirwa chine 6% Aluminium, 6% Vanadium, 2% Tin.

5AL-2.5Sn & ELI (5-2.5)ndeye alloyed titanium chigadzirwa chine 5% Aluminium uye 2.5% Tin.Uyewo ELI (Extra Low Interstitial).

8AL-1V-1Mo (8-1-1)ndeye alloyed titanium chigadzirwa chine 8% Aluminium, 1% Molybdenum uye 1% Vanadium.

15V-3Kr-4AL-3Sn (15-3-4-3)ndeye alloyed titanium chigadzirwa chine 15% Vanadium, 3% Chromium, 4% Aluminium, 3% Tin.

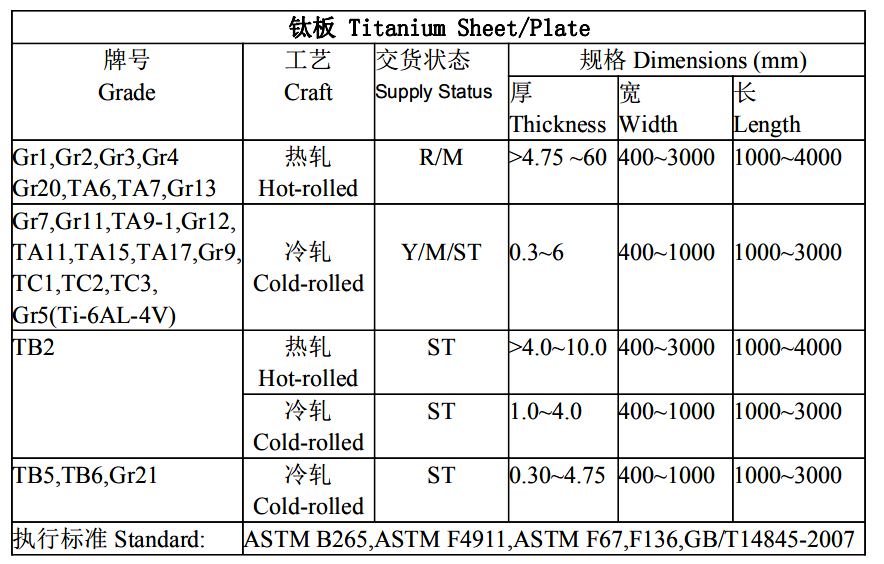

| Giredhi | Status | Tsanangudzo | ||

| Gr1,Gr2,Gr4,Gr5,Gr7,Gr9,Gr11, Gr12,Gr16,Gr23 | Kupisa kwakakungurutswa(R) Cold Rolled(Y) Yakapetwa(M) Solution kurapwa(ST) | Hukobvu(mm) | Upamhi(mm) | Kureba(mm) |

| 0.3 ~ 60 | ≥400 | ≤ 6000 | ||

| Titanium Sheet | |||

| Ukobvu | MaGrades | ||

| .016 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .020 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .025 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .032 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .040 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .050 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .063 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .071 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .080 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .090 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .100 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .125 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

Ongorora: Mamwe masaizi aripo, haasi ese ese anoratidzwa anowanikwa kubva kustock.Ndapota taura nesu kuti tione kuwanikwa.

| AMS:AMS 2631, AMS 4901, AMS 4907, AMS 4911ASTM: ASTM B265 Gr 23, ASTM B265 Gr 5, ASTM B265 Gr2, ASTM B265 Gr4, ASTM F136, ASTM F67MIL-T:MIL-T-9046, MIL-T-9046 CP1EN:EN 10204.3, SH 1-204:2005 3.1 NACE:NACE MR0175 ASME:ASME SB265 |

| Giredhi | AMS/MIL Zvikamu | Zviratidzo zveASTM |

| Grade 1 | AMS-T-9046B CP4 AMS 4940 MIL-T-9046J CP4 | ASTM B265 Gr1 Sheet/ndiro ASTM B337 Gr1 pombi ASTM B338 Gr1 chubhu ASTM B348 Gr1 bar ASTM F67 Gr1 Kuvhiya Kudyara |

| Grade 2 | Giredhi 2 AMS-T-9046B CP3 AMS 4902 MIL-T-9046J CP3 AMS 4941 AMS 4942 AMS 4951 Welding waya | ASTM B265 Gr2 Sheet/ndiro ASTM B337 Gr2 pombi ASTM B338 Gr2 chubhu ASTM B348 Gr2 bar ASTM F67 Gr2 Kuvhiya Kudyara |

| Grade 3 | AMS-T-9046B CP2 AMS 4900 MIL-T-9046J CP2 | ASTM B265 Gr3 Sheet/ndiro ASTM B337 Gr3 pombi ASTM B338 Gr3 chubhu ASTM B348 Gr3 bar ASTM F67 Gr3 Kuvhiya Kudyara |

| Grade 4 | AMS-T-9046B CP1 AMS-T-9047A CP70 AMS 4901 AMS 4921 MIL-T-9046J CP1 MIL-T-9047G CP70 | ASTM B265 Gr4 Sheet/ndiro ASTM B337 Gr4 pombi ASTM B338 Gr4 chubhu ASTM B348 Gr4 bar ASTM F67 Gr4 Kuvhiya Kudyara |

| Grade 7 | ASTM B265 Gr7 Sheet/ndiro ASTM B337 Gr7 pombi ASTM B338 Gr7 chubhu ASTM B348 Gr7 bar |

| Giredhi | US Specs | Zviratidzo zveASTM |

| Grade 5 6Al-4V | AMS 4907 ELI AMS 4911 AMS 4928 AMS 4930 ELI AMS 4931 ELI Duplex ann AMS 4963 AMS 4965 AMS 4967 AMS 4985 AMS 4991 AMS 6931 AMS 6932 MIL-T-9046J AB-1 MIL-T-9046J AB-2 (ELI) MIL-T-9046H Rudzi rwe3 Comp C MIL-T-9046H Rudzi rwe3 Comp D AMS-T-9046B AB-1 AMS-T-9046B AB-2 (ELI) MIL-T-9047G 6Al-4v MIL-T-9047G 6Al-4v (ELI) AMS-T-9047A 6Al-4v AMS-T-9047A 6Al-4v (ELI) | ASTM B265 Gr5 Sheet/ndiro ASTM B348 Gr5 bar ASTM F136 Gr5 Kudyara Giredhi |

| Grade 9 3Al-2.5V | AMS 4943 AMS 4944 AMS 4945 AMS-T-9046B AB-5 AMS-T-9047A 3Al-2.5V MIL-T-9046J AB-5 MIL-T-9047 3Al-2.5V | ASTM B265 Gr6 Sheet/ndiro ASTM B348 Gr6 bar |

| Grade 23 6Al-4V ELI | AMS 4907 AMS 4930 AMS 6932 AMS-T-9046 AB-2 6AL-4V (ELI) AMS-T-9047 AB-2 6AL-4V (ELI) MIL-T-9046 AB-2 6AL-4V (ELI) MIL-T-9047 6AL-4V (ELI) | ASTM B265 Gr23 sheet/plate/strip ASTM B348 Gr23 bar/billet ASTM F136 Gr23 Kudyara Gra |

Kemikari yakagadzirwa

| Giredhi | Kemikari yakagadzirwa, uremu muzana (%) | ||||||||||||

| C ≤ | O ≤ | N ≤ | H ≤ | Fe ≤ | Al | V | Pd | Ru | Ni | Mo | Zvimwe Zvinhu Max.chimwe nechimwe | Zvimwe Zvinhu Max.zvachose | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5~6.75 | 3.5~4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12~0.25 | - | 0.12~0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12~0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04~0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5~4.5 | - | - | - | - | 0.1 | 0.1 |

Zvinhu zvemuviri

| Giredhi | Zvinhu zvemuviri | ||||||

| Tensile simba Min | Goho simba (0.2%, offset) | Elongation mu50mm Zvishoma (%) | |||||

| ksi | MPa | Min | Max | ||||

| ksi | MPa | ksi | MPa | ||||

| Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr4 | 80 | 550 | 70 | 483 | 95 | 655 | 15 |

| Gr5 | 130 | 895 | 120 | 828 | - | - | 10 |

| Gr7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr9 | 90 | 620 | 70 | 483 | - | - | 15 |

| Gr11 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr12 | 70 | 483 | 50 | 345 | - | - | 18 |

| Gr16 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | - | - | 10 |

Kushivirira (mm)

| Ukobvu | Width tolerance | ||

| 400 ~ 1000 | 1000 ~ 2000 | >2000 | |

| 5.0~6.0 | ±0.35 | ±0.40 | ±0.60 |

| 6.0~8.0 | ±0.40 | ±0.60 | ±0.80 |

| 8.0~10.0 | ±0.50 | ±0.60 | ±0.80 |

| 10.0~15.0 | ±0.70 | ±0.80 | ±1.00 |

| 15.0~20.0 | ±0.70 | ±0.90 | ±1.10 |

| 20.0~30.0 | ±0.90 | ±1.00 | ±1.20 |

| 30.0~40.0 | ±1.10 | ±1.20 | ±1.50 |

| 40.0~50.0 | ±1.20 | ±1.50 | ±2.00 |

| 50.0~60.0 | ±1.60 | ±2.00 | ±2.50 |