Square Pipe

Chimiro:

Hollow Chikamus: Square, Rectangular, Round, Triangular, Hexagonal, Eliptical Hollow zvikamu

Scaffolding

Kushandisa:

Hollow Sections:

Kuvaka: Chimiro cheHoro, Gungwa Trestle, Chimiro cheAirport, Kuvakwa kweChikepe, Kuchengetedza Door Frames, Garage Doors, Kusimbisa Liners eSimbi Doors neWindows, Indoor Partition Walls, Cable Bridge Structures uye Expressway Safety Guards, Balustrade, Kushongedza, Dzimba dzekugara, Ornamental Pipes.

Zvikamu zveMotokari:Mota Yekesi,Kugadzira Mota uye Bhazi, Mota

Zvekurima: Zvekurima

Indasitiri: Michina, Solar Stent, Offshore Oil Field, Mine Equipment, Electromechanical Hardware, , heavy engineering, Mining and Resources, Process Engineering, Materials Handling, Mechanical Parts

Traffic:Njanji dzekufamba, Roll-up Doors, Guardrail, Plaza Structure, Signage, Road Fenicha, Fencing

Logistics Storage: Supermarket Shelves, Containers, Transport Industries, Commercial Construction

Zvimwe: Zvishandiso zveMitambo, Zvishandiso zvekuvaraidza, Fenicha, Furnicha yeChikoro

Scaffolding Tube:

Material Storage Racks, Pallets, Hydraulic Platforms, Trusses, Columns, Purlins, Greenhouse Stands Towers

Quality Standard:

Hollow Sections:

GB/T 13793 Longitudinal magetsi kuramba welded simbi machubhu

GB/T 6728 Cold yakagadzira simbi isina simbi zvikamu zveyakajairwa chimiro-Dimensions, zvimiro, uremu uye zvinotenderwa kutsauka

ASTM A500 Cold Yakagadzirwa Welded uye isina Seamless Carbon Steel Structural Tubing muRound and Shapes

ASTM A 53 Yakajairwa Tsanangudzo yePipe, Simbi, Nhema uye Inopisa-Yakanyikwa, Zinc-Yakavharwa, Yakasungwa uye isina musono.

TS EN 10210 Kupisa kwakapedzwa kwezvimiro zvegomba zvikamu zveasiri-alloy uye zviyo zvakatsetseka zvimiro zvesimbi

TS EN 10219 Inotonhora yakagadzira yakakwenenzverwa makomba zvikamu zveasiri-alloy uye simbi dzezviyo.

JIS G 3466 Carbon simbi Square yezvakajairwa zvimiro zvinangwa

BS 1387 Simbi Machubhu ekushandisa Mvura, Gasi, Mhepo uye Chitsinga

BS 6323 CHIKAMU 5 MABHUBHU ESIMBA ASISINA MUSANIU UYE AKASIDEDWA EMOTA YEMACHHANICAL UYE JENERI Injiniya CHINANGWA.

IS : 1161 Simbi Machubhu Nezve Chimiro chinangwa uye Magetsi mapango.

IS: 3601 Simbi machubhu emakanika & general engineering zvinangwa.

IS: 3074 Simbi machubhu eMota chinangwa.

IS : 4923 Simbi machubhu eHollow zvikamu zvinoshandiswa muzvimiro

DIN 1626 WEDED CIRCULAR TUBES EZVISIMBA ZVAKASIYANA NAYE

ZVINHU ZVINHU ZVINOKOSHA

DIN 2394 WELDED UYE SIZED PRECISION SIMBA TUBES

Scaffolding Tube:

GB 15831 Simbi chubhu scaffold couplers

TS EN 39 Machubhu esimbi asina kusimba echubhu uye maviri mascaffolds

BS 1139 Metal scaffolding

Simbi Giredhi:

GB/T 13793, GB/T 6728, GB 15831:

Q195, Q215, Q235, Q275, Q295, Q345, 08F, 08, 08AL, 08F, 10F, 10, HG5, DF08

EN 10210, EN 10219, BS 1387: S185, S235, S235JR, S235 G2H, S275, S275JR, S355JRH, S355J2H, St12, St13, St14, St334, St34, 3ST7

ASTM A500, ASTM A 53: Gr.A, Gr B, Gr C, Gr.D, DC01, DC03, 1008, 1010

JIS G 3466: SS330, SS440, SS490, SPHD, SPHE

Maitiro: ERW uye isina musono

Saizi

Hollow Sections:

Sikweya: 10 mmx10mm - 500 mmx500mm

Retangular: 10mm x 20mm - 600mmx400mm

Kutenderera: 1/8" - 4"

Rusvingo Ukobvu: 0.5 - 20.0mm

Kureba: 0.3 mtr - 18 mtr sezvinodiwa nemutengi

Scaffolding Tube:

Kunze Diameter: 38mm, 42mm, 48.3mm-48.6mm

Ukobvu hwemadziro: 2.0mm, 2.5mm, 2.75mm, 3.0mm, 3.25mm, 3.85mm, 4.0mm

Kureba: 0.3mtr -18 mtr

Maitiro:

Seamless: Kupisa kwakatenderedzwa, Kupisa Kuongororwa

Welded: ERW, HFW

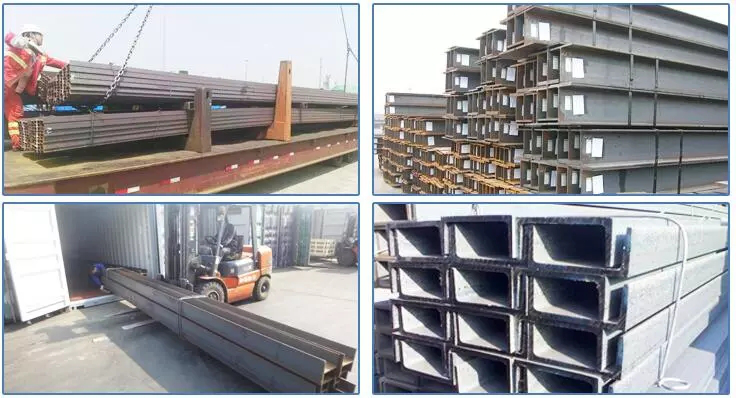

Kupfekedza: Kupisa-kukanyiwa Galvanised, Magetsi Yakagadzirwa

Raw Material:

Seamless: Pipe Billet (Hot Rolled, kana Con-casting), Amai Pipe

Welded: Hot Rolled Steel Coil (HRC), Cold Rolled Steel Coil (CRC), Pre-pained Galvanized Steel Strip

Kupera: Square cut, Burr yakabviswa

Pamusoro: Yakazorwa mafuta zvishoma, Dip inopisa yakabatiswa, Electro galvanized, Dema

Kurapa Kupisa: Yakajeka Yakanatswa, Yakasviba Yakashongedzwa

Packing: Plastic plugs mumagumo ese ari maviri, Hexagonal bundles of max.2,000kg ine tambo dzesimbi dzinoverengeka, Ma tag maviri pachisumbu chimwe nechimwe, Yakaputirwa nebepa risingapindi mvura, PVC sleeve, uye masaga ane simbi akati wandei.

Muedzo: Chemical Component Analysis, Mechanical Properties (Ultimate tensile simba, Goho

simba, Elongation), Tekinoroji Zvivakwa (Flattening Test, Flaring Test, Bending Test, Hardness Test, Blow Test, Impact Test etc), Exterior Size Inspection.

Mill Test Certificate: EN 10204/3.1B

Square chubhu saizi

| Saizi (mm) | Ukobvu hwemadziro (mm) | Saizi (mm) | Ukobvu hwemadziro (mm) |

| 20*20 | 1.2 | 70*70 60*80 100*40 | 1.8 |

| 1.3 | 2 | ||

| 1.4-1.5 | 2.2 | ||

| 1.7 | 2.3 | ||

| 1.8 | 2.5-4.0 | ||

| 2 | 4.5-5.0 | ||

| 2.2 | 5.5-5.75 | ||

| 2.3 | 75*75 60*90 100*50 | 1.8 | |

| 2.5-2.75 | 2 | ||

| 25*25 20*30 | 1.2 | 2.2 | |

| 1.3 | 2.3 | ||

| 1.5 | 2.5-4.0 | ||

| 1.7 | 4.5-5.0 | ||

| 1.8 | 5.5-5.75 | ||

| 2 | 80*80 100*60 100*80 120*60 | 2 | |

| 2.3-2.3 | 2.2 | ||

| 2.5-3.0 | 2.3 | ||

| 30*30 30*40 25*40 20*40 | 1 | 2.5-4.0 | |

| 1.2 | 4.5-5.0 | ||

| 1.3 | 5.5-5.75 | ||

| 1.5 | 7.5-7.75 | ||

| 1.7 | 100*100 120*80 | 2 | |

| 1.8 | 2.2 | ||

| 2 | 2.3 | ||

| 2.2 | 2.5-5.0 | ||

| 2.3 | 5.5-5.75 | ||

| 2.5*2.75 | 7.5-7.75 | ||

| 3 | 120*120 140*80 150*100 160*80 | 2.5 | |

| 40*40 30*50 25*50 | 1.2 | 2.75 | |

| 1.3 | 3 | ||

| 1.4-1.5 | 3.25-5.0 | ||

| 1.7 | 5.5-7.0 | ||

| 1.8 | 7.5-7.75 | ||

| 2 | 140*140 150*150 200*100 | 3.5-4.0 | |

| 2.2-2.3 | 4.5-5.0 | ||

| 2.5-4.0 | 5.25-7.0 | ||

| 50*50 60*40 30*60 40*50 | 1.5 | 7.5-7.75 | |

| 1.7 | 160*160 180*180

| 3 | |

| 1.8 | 3.5 | ||

| 2 | 3.75 | ||

| 2.2 | 4.0-5.0 | ||

| 2.3 | 5.25-5.75 | ||

| 2.5 * -4.0 | 7.5-7.75 | ||

| 4.25-5.0 | 60*60 40*80 75*75 50*70 50*80 | 2.3 | |

| 60*60 40*80 75*45 50*70 50*80 | 1.5 | 2.5-4.0 | |

| 1.7 | 4.25-5.0 | ||

| 1.8 | 5.5-5.75 | ||

| 2 | / | ||

| 2.2-2.3 | / |

Available Quality Standards

ASTM A500 Cold Yakagadzirwa Welded uye isina Seamless Carbon Steel Structural Tubing muRound and Shapes

TS EN 10210 Kupisa kwakapedzwa kwezvimiro zvegomba zvikamu zveasiri-alloy uye zviyo zvakatsetseka zvimiro zvesimbi

TS EN 10219 Inotonhora yakagadzira yakakwenenzverwa makomba zvikamu zveasiri-alloy uye simbi dzezviyo.

ASTM A53 inoshandiswa sesimbi yezvimiro kana yepasi-kumanikidza pombi

Standard Corner Radius(Structural Sizes:)

Max.3 x Nominal Wall Ukobvu

| Mechanical Sizes | Structural Sizes | ||

| Yakakura Nominal Kunze Dimension | Kunze Kushivirira kumativi ese pamakona | Yakakura Nominal Kunze Dimension | Kunze Kushivirira kumativi ese pamakona |

| 3/16 kusvika 5/8 | ± 0.004 | 2 1/2 uye pasi | ± 0.020 |

| pamusoro pe5/8 kusvika 1 1/8 | ± 0.005 | pamusoro pe2 1/2 kusvika 3 1/2 | ± 0.020 |

| pamusoro pe1 1/8 kusvika 1 1/2 | ± 0.006 | pamusoro pe3 1/2 kusvika 5 1/2 | ± 0.030 |

| pamusoro pe1 1/2 kusvika ku2 | ± 0.008 | pamusoro pe5 1/2 | ± 1% |

| pamusoro 2 ku3 | ± 0.010 | ||

| pamusoro 3 ku4 | ± 0.020 | ||

| pamusoro 4 ku6 | ± 0.020 | ||

| pamusoro 6 ku8 | ± 0.025 | ||

Kururama

Mechanical Size: Max.1/16 ″ mu3 tsoka

Zvimiro Saizi: Max.1/8″ x Nhamba yemafiti ehurefu hwakaganhurwa ne5

Kukora Kwemadziro

Mechanical & Structural Sizes: ± 10% yeNominal Wall Ukobvu

Squareness of Sides

Mechanical Size: Max: ± b = cx 0.006″

b = Kushivirira kwekunze-kwe-square

c = Yakakura yekunze dimension pamafurati

Zvimiro Saizi: Mativi ari pedyo anogona kutsauka kubva pa90 ° ne ± 2 °.

Maximum Twist (Mechanical & Structural sizes)

| Yakakura Dimension, inches | Max.Twist*, inches |

| pamusoro pe1/2 kusvika 1 1/2 | 0.050 |

| pamusoro pe1 1/2 kusvika 2 1/2 | 0.062 |

| pamusoro pe2 1/2 kusvika ku4 | 0.075 |

| pamusoro 4 ku6 | 0.087 |

| pamusoro 4 ku8 | 0.100 |

Convexity & Concavity (Mechanical & Structural Sizes)

| Yakakura Nominal OD, Inches | Kushivirira ± masendimita |

| 2 1/2 uye pasi | ± 0.010 |

| pamusoro pe2 1/2 kusvika ku4 | ± 0.015 |

| pamusoro 4 ku8 | ± 0.025 |

Structural Tubing A 500 Zvinodiwa

| MaGrades | Chemical | Zvenyama | ||||||

| C Max.% | Mn Max.% | P Max.% | S Max.% | Ku Max.% | Kusimba simba, min.psi | Goho simba, min.psi | Elongation mu2 mukati. | |

| Giredhi B | 0.26 | / | 0.04 | 0.05 | 0.20 | 58,000 | 46,000 | 23 |

| Giredhi C | 0.23 | 1.35 | 0.04 | 0.05 | 0.20 | 62,000 | 50,000 | 21 |

Bright Annealed, Black Annealed

Plastic plugs mumativi ese maviri, Hexagonal masumbu e max.2,000kg ine tambo dzesimbi dzinoverengeka, Ma tag maviri pachisumbu chimwe nechimwe, Yakaputirwa nebepa risingapindi mvura, PVC sleeve, uye masaga ane simbi akati wandei.

Kuongorora: Chemical Component Analysis, Mechanical Properties