ASTM A335 Steel Pipe

| Product Name | Alloy Steel Pipe |

| Material | Alloy Steel |

| Pipe Length | Single Random Length uye kaviri Random Length.SRL:3M-5.8M DRL:10-11.8M kana Sezvinokumbirwa nevatengi kureba |

| Size | Saizi 1/4”ku24”Kunze Diameter 13.7 mm kusvika 609.6 mm |

| Kukora kwemadziro | SCH10, SCH20, SCH30, STD, SCH40, SCH60, SCH80, SCH100 SCH120, SCH160, XS, XXS |

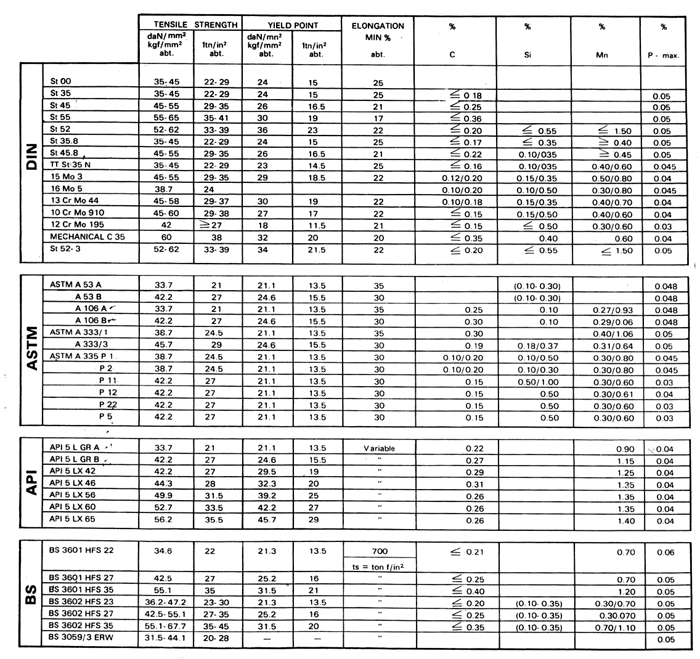

| Standard | ASTM A 335 Giredhi P1, P2, P5, P9, P9A, P11, P22.ASTM A213 T1B, T1, T2, T5, T9, T9A, T11, T12, T22.A199 T5, T9, T11, T22.BS 3604 Grade 621, 622, 625, 629-470, 629-590, 660, 762.DIN 17175 15 Mo 3, 13 Cr Mo 44, 10 Cr Mo 910, 14 Mo V 63, X 20 Cr 3 Cr. , 620-460, 622-490, 629-470, 629-590, 762. JISG3458/G3462/3467 uye DIN17175-79. |

| Applications | 1.Fluid pombi 2. Simba reSimba 3. Chimiro pombi 4. Yakakwirira uye yakaderera kudzvinyirira Boiler tube 5. Machubhu esimbi asina musono ekutsemuka peturu 6. Pombi pombi 7. Scaffolding pombi yemishonga uye kuvaka ngarava nezvimwe |

| Chitupa | ISO/PED/TUV/SGS/LR/BV |

| Main Market | Asia, Middle East, Europe, America, Africa, Australia, etc |

Kuumbwa Kwekemikari(%):

| Giredhi | UNS Designation | Kuumbwa,% | |||||||

| Carbon | Manganese | Phosphorus, | Sulfur | Silicon | Chromium | Molybdenum | Vamwe | ||

| max | max | ||||||||

| P1 | K11522 | 0.10–0.20 | 0.30–0.80 | 0.025 | 0.025 | 0.10–0.50 | - | 0.44–0.65 | - |

| P2 | K11547 | 0.10–0.20 | 0.30–0.61 | 0.025 | 0.025 | 0.10–0.30 | 0.50–0.81 | 0.44–0.65 | - |

| P5 | K41545 | 0.15 max | 0.30–0.60 | 0.025 | 0.025 | 0.50 max | 4.00–6.00 | 0.45–0.65 | - |

| P9 | S50400 | 0.15 max | 0.30–0.60 | 0.025 | 0.025 | 0.25–1.00 | 8.00–10.00 | 0.90–1.10 | - |

| P11 | K11597 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50–1.00 | 1.00–1.50 | 0.44–0.65 | - |

| P12 | K11562 | 0.05–0.15 | 0.30–0.61 | 0.025 | 0.025 | 0.50 max | 0.80–1.25 | 0.44–0.65 | - |

| P15 | K11578 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 1.15–1.65 | - | 0.44–0.65 | - |

| P21 | K31545 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50 max | 2.65–3.35 | 0.80–1.06 | - |

| P22 | K21590 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50 max | 1.90–2.60 | 0.87–1.13 | - |

| P23 | K41650 | 0.04–0.10 | 0.10–0.60 | 0.03 | 0.01 | 0.50 max | 1.90–2.60 | 0.05–0.30 | V 0.20–0.30 |

| Cb 0.02–0.08 | |||||||||

| B 0.0005–0.006 | |||||||||

| N 0.030 max | |||||||||

| Al 0.030 max | |||||||||

| W 1.45–1.75 | |||||||||

| P91 | K91560 | 0.08–0.12 | 0.30–0.60 | 0.02 | 0.01 | 0.20–0.50 | 8.00–9.50 | 0.85–1.05 | V 0.18–0.25 |

| N 0.030–0.070 | |||||||||

| Ndi 0.40 max | |||||||||

| Al 0.04 max | |||||||||

| Cb 0.06–0.10 | |||||||||

| P92 | K92460 | 0.07–0.13 | 0.30–0.60 | 0.02 | 0.01 | 0.50 max | 8.50–9.50 | 0.30–0.60 | V 0.15–0.25 |

| N 0.03–0.07 | |||||||||

| Ndi 0.40 max | |||||||||

| Al 0.04 max | |||||||||

| Cb 0.04–0.09 | |||||||||

| W 1.5–2.00 | |||||||||

| B 0.001–0.006 | |||||||||

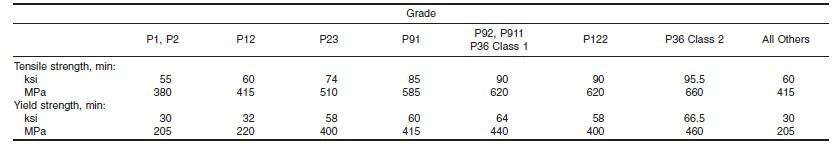

Mechanical Properties:

Kupfeka nhema, mafuta / varnish, FBE, 2PE, 3PE, galvanized etc Packaging Detail: Kurongedza mumasumbu kana kune zvinodiwa nemutengi.