Pombi yakatsvetwa

Mapombi akatsemurwa anoshandiswa mukutsvagisa oiri anogona kudzivirira 99% jecha, kuderedza 80% yeoiri tsime rinorema kugadzirisa, pamwe nekuwedzera kusimba kwechitsime chemafuta, kuperera uye kugadzikana kwekuchengeta jecha.Zvichakadaro, iyo laser incision tech inogona kuita kuti slot ive yakatsetseka uye nemazvo.Chimiro chepombi yakatsvuka casing sampuli, asi inoshanda zvakanyanya.

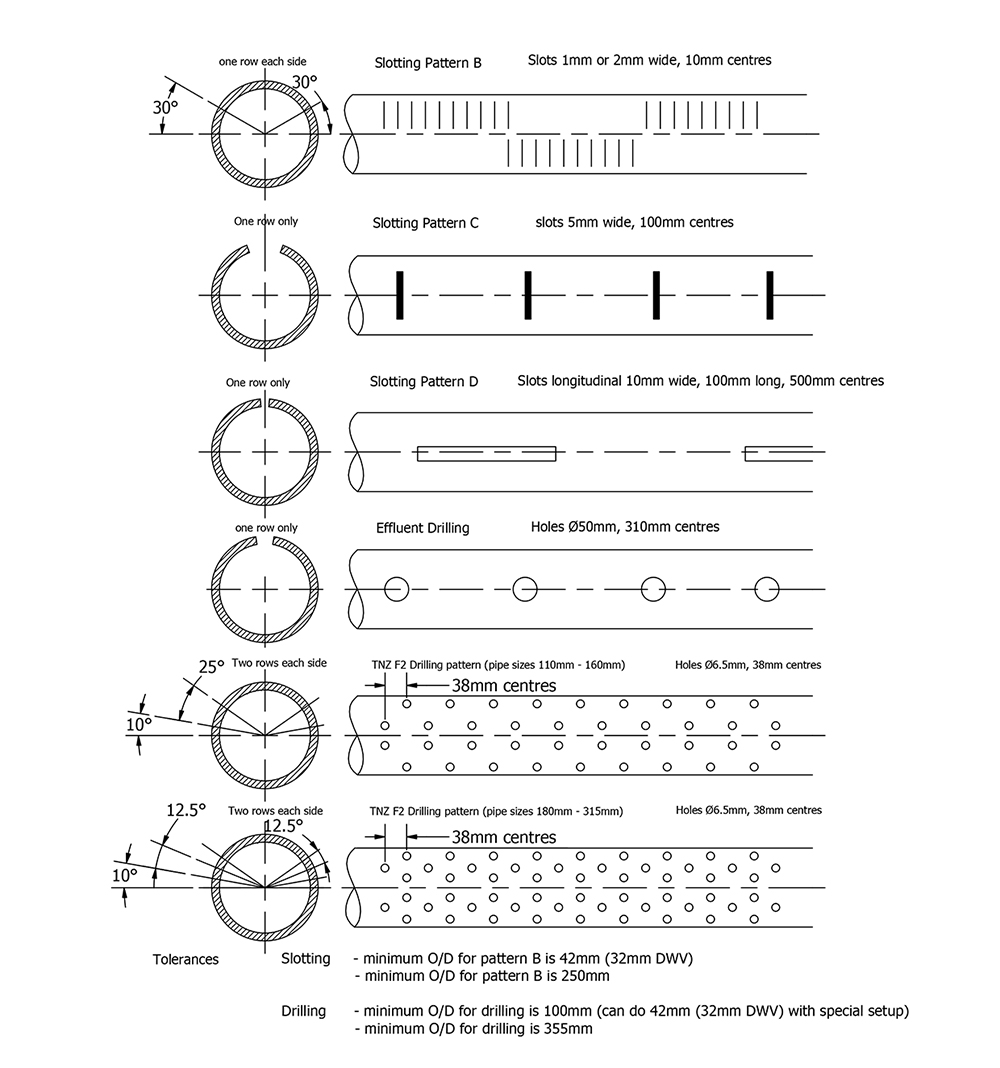

Slotted chubhu processing iri pamusoro simba simba simbi muviri pamwe kutonhora kana inopisa kushanda nzira, kucheka kunze mazana ezviuru longitudinal makatsemuka, makatsemuka anowanzoshandiswa tsanangudzo nokuti: musono upamhi 0.15 3 mm, kunyange zvakafara, gap kureba 50-200 mm.Cross chikamu. mhando ndeidzi: rectangular, manera akaumbwa, chaiwo uye akasiyana, anewo denderedzwa groove skrini, aperture dhayamita yakatarwa inosiyana 5-20 mm mumamita. chikamu chechimiro chakashambidzika dhigirii, pamucheto wegomba musono kutsvedzereka uye dhigirii rekupokana kwekupokana kwegomba seam.

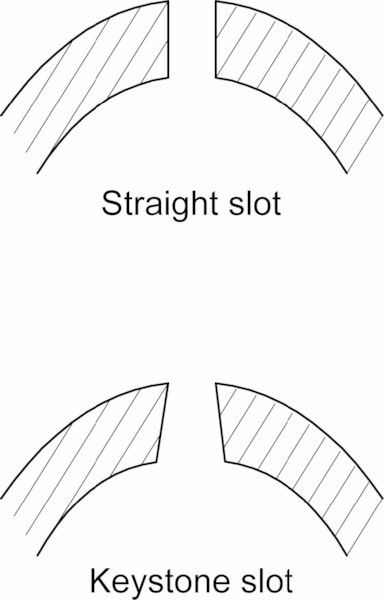

Straight Slots-Slots inochekwa nehupamhi hwakaenzana kuburikidza nemadziro epombi zvese ID neOD.Yakatsanangurwa uko jecha bhiriji rezviyo pane slot harina kukosha zvakanyanya, nzvimbo dzakatwasuka dzinoramba kupfeka pane dzakasimwa keystone slots uye dzinodhura kugadzira.Zvishandiso zvakajairika zveStraight cut slots ndezveCold Production uye CBM yakachinjika matsime kuwedzera kune SAGD injector matsime.

Semed Keystone Slots--anogayiwa yakafara pane pombi yemukati uye vari self kuchenesa kubatsira kudzivirira plugging.Yakatetepa pairi liner pamusoro uye ichiwedzera muhupamhi mukati, ivo vanorega jecha rinopinda richipfuura zviri nyore nepamitsetse pasina plugging.

| API Casing pombi | ID | Urefu | Slot Length | Slot Nha. | Slot width | Slot | Sefa Inoshanda | Max. | ||

| Spec mm | Ukobvu | Per Weight | ||||||||

| 60.32 | 5 | 6.84 | 50.3 | 3 | 80 | 200 | 0.3 | ±50 | 48 | 512.54 |

| 73.02 | 5.5 | 9.15 | 62 | 240 | 57.6 | 688.55 | ||||

| 88.9 | 6.5 | 13.22 | 75.9 | 280 | 67.2 | 995.1 | ||||

| 101.6 | 6.5 | 15.22 | 88.6 | 300 | 72 | 1151.2 | ||||

| 114.3 | 7 | 18.47 | 100.3 | 10 | 320 | 76.8 | 1400.4 | |||

| 127 | 7.52 | 22.13 | 112 | 340 | 81.6 | 1673.8 | ||||

| 139.7 | 7.72 | 25.11 | 124.3 | 360 | 86.4 | 1900.2 | ||||

| 9.17 | 29.48 | 121.4 | 360 | 86.4 | 2232.4 | |||||

| 168.3 | 8.94 | 35.09 | 150.4 | 400 | 96 | 2672.95 | ||||

| 177.8 | 8.05 | 33.68 | 161.7 | 440 | 105.6 | 2559.2 | ||||

| 9.19 | 38.19 | 159.4 | 440 | 105.6 | 2940.7 | |||||

| Sreen pombi dimension (mu) | OD(mm) | Kukora kwemadziro(mm) | ID (mm) | Sona nhamba yedenderedzwa rega rega | Slot wide (mm) | Hurefu hwenzvimbo (mm) | Kureba(mm) |

| 2-3/8″ | 60.3 | 4.83 | 50.64 | 12~18 | 0.2~0.8 | 45~100 | 1000 ~ 12000 |

| 2-7/8″ | 73 | 5.51 | 61.98 | 20~24 | 45~100 | ||

| 3-1/2″ | 88.9 | 6.45 | 76 | 24~28 | 45~100 | ||

| 4″ | 101.6 | 6.65 | 88.29 | 24~30 | 45~100 | ||

| 4-1/2″ | 114.3 | 5.69 | 102.92 | 24~30 | 45~100 | ||

| 6.35 | 101.6 | 45~100 | |||||

| 7.37 | 99.57 | 45~100 | |||||

| 8.56 | 97.18 | 45~100 | |||||

| 5″ | 127 | 5.59 | 115.82 | 28~36 | 0.25~0.8 | 45~100 | |

| 6.43 | 114.15 | 45~100 | |||||

| 7.52 | 111.96 | 45~100 | |||||

| 9.19 | 108.61 | 45~100 | |||||

| 5-1/2″ | 139.7 | 6.2 | 127.3 | 30~38 | 45~100 | ||

| 6.99 | 125.73 | 45~100 | |||||

| 7.72 | 124.26 | 45~100 | |||||

| 9.17 | 121.36 | 45~100 | |||||

| 10.54 | 118.62 | 45~100 | |||||

| 7″ | 177.8 | 6.91 | 163.98 | 36~50 | 45~100 | ||

| 8.05 | 161.7 | 45~100 | |||||

| 9.19 | 159.41 | 45~100 | |||||

| 10.36 | 157.07 | 45~100 |

1. Yedu perforated pombi inoshandisa J55/K55/N80 casing uye tubings eAPI chiyero, ine Yakakwirira simba rose, kwete nyore kuti deformation.

2. Mucheto we slot wakamira, wakatsetseka, usina burrs, uye slot yakaenzana.

3. Iyo perforated pombi yakakodzera kune jecha tsime, iyo dhayamita yejecha yakakura kupfuura 0.3mm.

4. Iyo slot inogona kunge yakareba uye yakachinjika, chikamu cheiyo slot inogona kufanana uye trapezoidal marudzi, ine nzvimbo yakazaruka.

5. Slotted sikirini pombi ine dhayamita hombe yomukati.

API Spec 5CT-Tsanangudzo 5CT/ISO 11960, Tsanangudzo yeCasing uye Tubing, Eighth Edition, Petroleum uye magasi echisikigo maindasitiri-Simbi mapaipi ekushandisa secasing kana tubing kumatsime.

| Standard | Giredhi | Kemikari zvinyorwa (()) | |||||||||

| API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34~0.39 | 0.20~0.35 | 1.25 ~ 1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34~0.38 | 0.20~0.35 | 1.45 ~1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11 ~ 0.16 | |

| L80 | 0.15~0.22 | ≤1.00 | 0.25 ~1.00 | ≤0.020 | ≤0.010 | 12.0~14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26~0.395 | 0.17 ~ 0.37 | 0.40 ~ 0.70 | ≤0.020 | ≤0.010 | 0.80~1.10 | ≤0.20 | ≤0.20 | 0.15~0.25 | ≤0.08 | |

Mechanical Properties

| Giredhi | Type | Kurebesa kwese kuri pasi pemutoro (%) | Goho simba (min) | Goho simba (max) | Tensile simba min Mpa | Hardness Max (HRC) | Hurema Max(HBW) |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Kr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Kr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | - | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | - | 0.5 | 655 | 758 | 724 | - | - |

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 | - | - |

| Q125 | Zvose | 0.65 | 862 | 1034 | 931 | - | - |

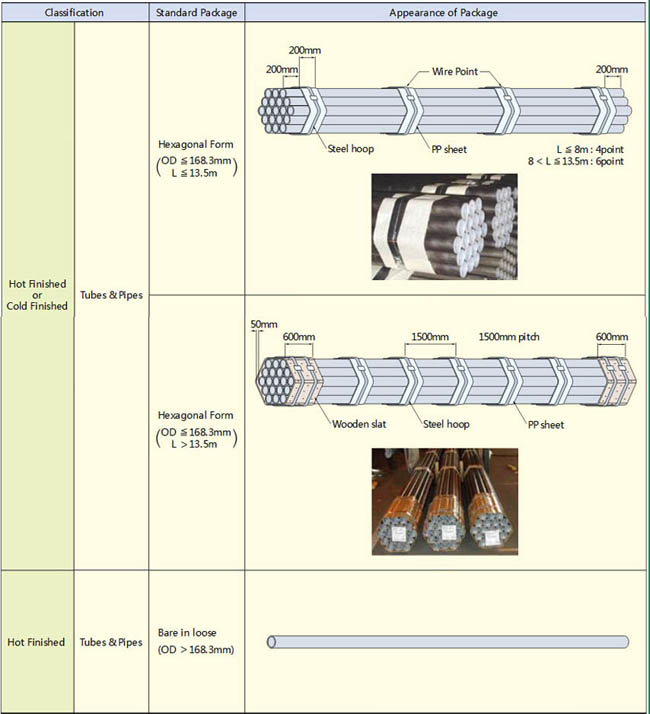

Single ine bubble bag uyezve mune yemapuranga kesi (fumigation certificate).Mhosva imwe neimwe yakanyorwa zvakajeka nei:

1. Zita & chiziviso chiratidzo chemugadziri-HuaDong Brand

2. Batch nhamba

3. Zuva remugadziri

4. Zvinhu

5. Kupisa kwakachengeteka & kupisa kwekushandisa