Titanium Ring

Zvindori zvakakura zvetitanium zvinogadzirwa nemuchina wakakura wekukuya, zvindori zvidiki zvetitanium zvinogona kuwanikwa nemuchina wekugadzira.Sekambani ine makore anopfuura makumi maviri eruzivo rwekugadzira, isu tine nhevedzano yeakaomesesa forging process uye oparesheni bhuku, kusanganisira nhanho dzekudziya, nguva yekudziya uye nguva yekuchengetedza kupisa.Iyo 35MN uye 16MN yekukurumidza forging muchina yakavimbisa kuwanda kwefogi mune yakakodzera tembiricha renji, uye yakashandura chimiro chemukati chemukati chetitanium mhete.Yakavandudza zvakanyanya kunaka kwezvigadzirwa zvedu.

Pamusoro petitanium mhete, isu tinopawo kugadzirwa kwetitanium disc, titanium block nezvimwe.

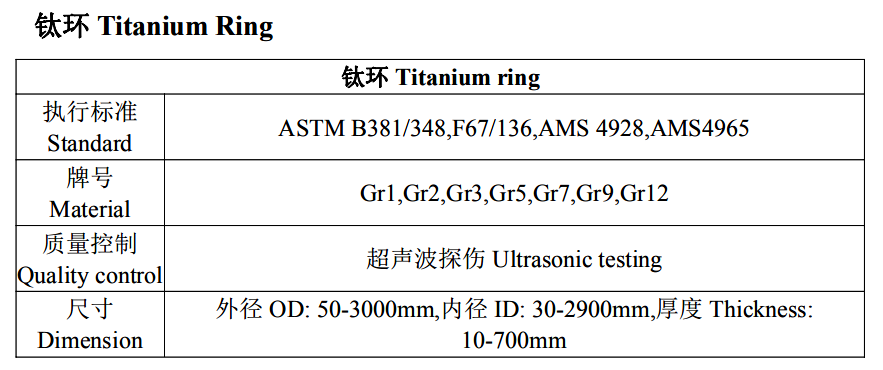

| zita rechigadzirwa | Titanium Ring |

| Size | OD (max3000mm)×ID (max2900mm)×kureba (kureba kwepamusoro 1000mm) |

| Giredhi | TA1/TA2/TA5/TA6/TA9/TA10/TA15/TA19/TC1/TC2/TC4/TC11/ GR1/GR2/GR5/GR7/GR9/GR12/GR23 |

| Mitemo | ASTM B381/348,F67/136,AMS4928,AMS4965,AMS,MIL,DIN,BS,JIS,GB / T,ISOetc |

| Density | 4.51g / cm3 Yakakwirira kuita maindasitiri ekugadzira, gr12 Titanium yakaumbwa inokunguruka mhete |

| Vadivelu Comedy Technology | Kugadzira, kukungurutsa, kukuya yakakwira kuita kwemaindasitiri kuforoma GR12 titanium yekuforoma inotenderedza mhete |

| Type | Iyo nzira yekutenderedza mhete isina musono inosanganisira kucheka gomba mune yakaumbwa zvinhu uye kuitenderedza kuita mhete nhete. Kuenzaniswa nekupfurwa kweplate kana butt welding, iyo yakakungurutswa mhete inopa kuvandudzwa kwemukati nemhete yakatsetseka. Mhete yepamusoro-soro yekushanda kwemaindasitiri yakagadzira GR12 titanium forged rolling ring |

| Application | 1. Electroplating;2.Kemikari uye petrochemical tekinoroji; 3.Chiremba chakanyanya kuita maindasitiri ekugadzira GR12 titanium forging rolling ring |

ASTM B381/348,F67/136,AMS4928,AMS4965

Kemikari yakagadzirwa

| Giredhi | Kemikari yakagadzirwa, uremu muzana (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Zvimwe Zvinhu Max.chimwe nechimwe | Zvimwe Zvinhu Max.zvachose | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5 -6.75 | 3.5 -4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12~0.25 | - | 0.12~0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5–3.5 | 2.0~3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12~0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04~0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5 -4.5 | - | - | - | - | 0.1 | 0.1 |

Zvinhu zvemuviri

| Giredhi | Zvinhu zvemuviri | |||||

| Kusimba simba Min | Goho simba Maminitsi (0.2%, offset) | Elongation mu4D Zvishoma (%) | Kuderedzwa kweNzvimbo Zvishoma (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |