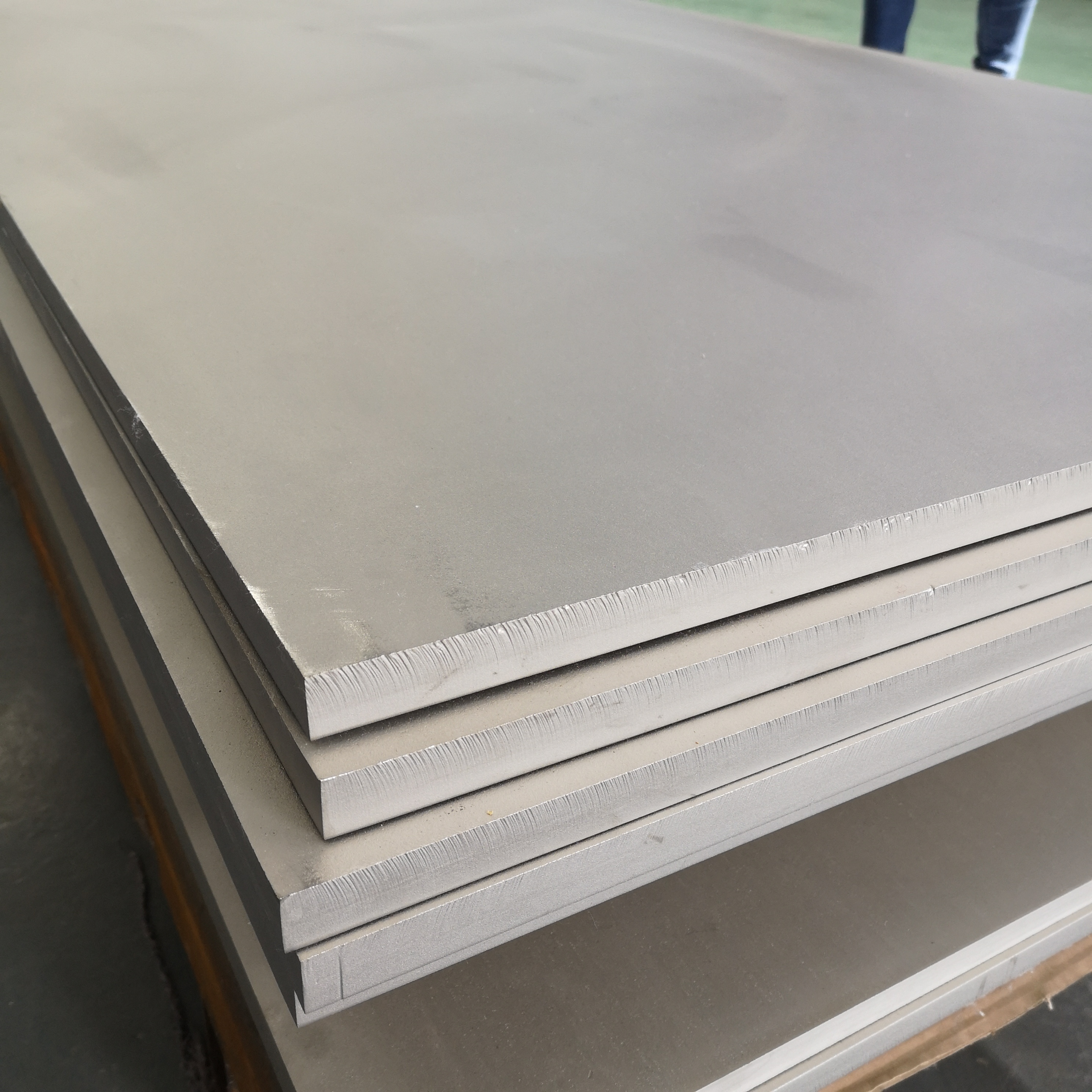

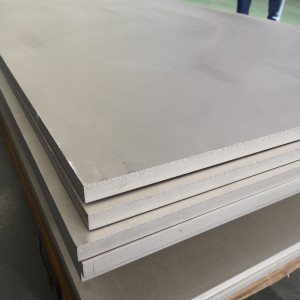

Folja tat-titanju / Pjanċa

Gradi Komuni

Titanju Grad 1huwa prodott tat-titanju mhux illigat, ta 'saħħa baxxa li fih ossiġnu baxx b'kapaċità ta' forma għolja;dan il-grad tat-titanju jintuża f'qafas ta 'l-arja, skambji tas-sħana u unitajiet ta' desalinizzazzjoni.

Titanju Grad 2huwa prodott tat-titanju ta 'saħħa medja mhux liga.Dan il-grad tat-titanju jintuża f'qafas tal-arja, magni tal-inġenji tal-ajru u partijiet tal-baħar;kapaċità tajba ta 'weldjatura u reżistenza għall-korrużjoni huma l-karatteristiċi distintivi tagħha.

Titanju Grad 3huwa prodott tat-titanju mhux liga, qawwa għolja, li jipprovdi reżistenza għall-korrużjoni eċċellenti u kapaċità tajba ta 'weldjatura.Dan il-grad tat-titanju jintuża primarjament fil-qafas tal-arja u l-partijiet tal-magni tal-inġenji tal-ajru.

Titanju Grad 4huwa l-ogħla qawwa pura mhux liga prodott tat-titanju.Dan il-grad tat-titanju jintuża kważi esklussivament għall-qafas tal-arja, partijiet tal-magni tal-inġenji tal-ajru, tal-baħar, impjanti kirurġiċi, tubi idrawliċi.L-abbiltà tal-forma tajba u r-reżistenza għall-korrużjoni huma l-karatteristika tagħha.

Titanju Grad 5 (6AL-4V)huwa prodott tat-titanju liga li fih 6% Aluminju u 4% Vanadju;huwa prodott ta 'saħħa medja.Dan il-grad tat-titanju jintuża b'mod predominanti fil-partijiet tal-qafas tal-airframe u tat-turbini;u għall-użu f'impjanti kirurġiċi.Informazzjoni Teknika Titanium 6AL–4V ELI huwa prodott tat-titanju illigat li fih 6% Aluminju u 4% Vanadju, ELI (Extra Low Interstitial).

6AL–2Sn–4Zr–2Mo (6-2-4-2)huwa prodott tat-titanju illigat li fih 6% Aluminju, 2% Landa, 4% Żirkonju, 2% Molibdenu.

6AL–6V–2Sn (6-6-2)huwa prodott tat-titanju illigat li fih 6% Aluminju, 6% Vanadju, 2% Tin.

5AL–2.5Sn & ELI (5-2.5)huwa prodott tat-titanju illigat li fih 5% Aluminju u 2.5% Tin.Ukoll ELI (Extra Low Interstizjali).

8AL–1V–1Mo (8-1-1)huwa prodott tat-titanju illigat li fih 8% Aluminju, 1% Molibdenu u 1% Vanadju.

15V–3Cr–4AL–3Sn (15-3-4-3)huwa prodott tat-titanju illigat li fih 15% Vanadju, 3% Kromju, 4% Aluminju, 3% Tin.

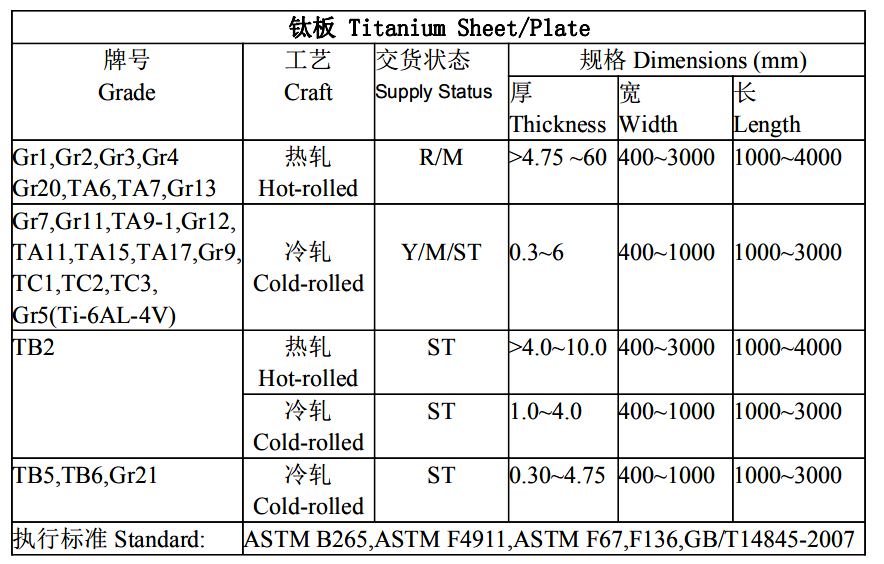

| Grad | Status | Speċifikazzjoni | ||

| Gr1,Gr2,Gr4,Gr5,Gr7,Gr9,Gr11, Gr12,Gr16,Gr23 | Irrumblat bis-sħana(R) Cold Rolled(Y) Ittemprat(M) Trattament tas-soluzzjoni (ST) | Ħxuna (mm) | Wisa' (mm) | Tul (mm) |

| 0.3~60 | ≥400 | ≤ 6000 | ||

| Folja tat-titanju | |||

| Ħxuna | Gradi | ||

| .016 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .020 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .025 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .032 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .040 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .050 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .063 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .071 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .080 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .090 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .100 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

| .125 | CP1, A70, 75A, CP3, A40, 55A, 6AL-4V ANN | ||

Nota: Daqsijiet addizzjonali disponibbli, mhux id-daqsijiet kollha murija huma disponibbli mill-istokk.Jekk jogħġbok ikkuntattjana biex tiċċekkja d-disponibbiltà.

| AMS:AMS 2631, AMS 4901, AMS 4907, AMS 4911ASTM: ASTM B265 Gr 23, ASTM B265 Gr 5, ASTM B265 Gr2, ASTM B265 Gr4, ASTM F136, ASTM F67MIL-T:MIL-T-9046, MIL-T-9046 CP1MT:EN 10204.3, EN 1-204:2005 3.1 NACE:NACE MR0175 ASME:ASME SB265 |

| Grad | Speċifikazzjonijiet AMS/MIL | Speċifikazzjonijiet ASTM |

| Grad 1 | AMS-T-9046B CP4 AMS 4940 MIL-T-9046J CP4 | ASTM B265 Gr1 Folja/pjanċa Pajp ASTM B337 Gr1 Tubu ASTM B338 Gr1 ASTM B348 Gr1 bar Impjant kirurġiku ASTM F67 Gr1 |

| Grad 2 | Grad 2 AMS-T-9046B CP3 AMS 4902 MIL-T-9046J CP3 AMS 4941 AMS 4942 AMS 4951 Wajer tal-welding | ASTM B265 Gr2 Folja/pjanċa Pajp ASTM B337 Gr2 Tubu ASTM B338 Gr2 ASTM B348 Gr2 bar Impjant kirurġiku ASTM F67 Gr2 |

| Grad 3 | AMS-T-9046B CP2 AMS 4900 MIL-T-9046J CP2 | ASTM B265 Gr3 Folja/pjanċa Pajp ASTM B337 Gr3 Tubu ASTM B338 Gr3 ASTM B348 Gr3 bar Impjant kirurġiku ASTM F67 Gr3 |

| Grad 4 | AMS-T-9046B CP1 AMS-T-9047A CP70 AMS 4901 AMS 4921 MIL-T-9046J CP1 MIL-T-9047G CP70 | ASTM B265 Gr4 Folja/pjanċa Pajp ASTM B337 Gr4 Tubu ASTM B338 Gr4 ASTM B348 Gr4 bar Impjant kirurġiku ASTM F67 Gr4 |

| Grad 7 | ASTM B265 Gr7 Folja/pjanċa Pajp ASTM B337 Gr7 Tubu ASTM B338 Gr7 ASTM B348 Gr7 bar |

| Grad | Speċifikazzjonijiet tal-Istati Uniti | Speċifikazzjonijiet ASTM |

| Grad 5 6Al-4V | AMS 4907 ELI AMS 4911 AMS 4928 AMS 4930 ELI AMS 4931 ELI Duplex ann AMS 4963 AMS 4965 AMS 4967 AMS 4985 AMS 4991 AMS 6931 AMS 6932 MIL-T-9046J AB-1 MIL-T-9046J AB-2 (ELI) MIL-T-9046H Tip 3 Comp C MIL-T-9046H Tip 3 Comp D AMS-T-9046B AB-1 AMS-T-9046B AB-2 (ELI) MIL-T-9047G 6Al-4v MIL-T-9047G 6Al-4v (ELI) AMS-T-9047A 6Al-4v AMS-T-9047A 6Al-4v (ELI) | ASTM B265 Gr5 Folja/pjanċa ASTM B348 Gr5 bar ASTM F136 Gr5 Implant Grad |

| Grad 9 3Al-2.5V | AMS 4943 AMS 4944 AMS 4945 AMS-T-9046B AB-5 AMS-T-9047A 3Al-2.5V MIL-T-9046J AB-5 MIL-T-9047 3Al-2.5V | ASTM B265 Gr6 Folja/pjanċa ASTM B348 Gr6 bar |

| Grad 23 6Al-4V ELI | AMS 4907 AMS 4930 AMS 6932 AMS-T-9046 AB-2 6AL-4V (ELI) AMS-T-9047 AB-2 6AL-4V (ELI) MIL-T-9046 AB-2 6AL-4V (ELI) MIL-T-9047 6AL-4V (ELI) | ASTM B265 Gr23 folja/pjanċa/strixxa ASTM B348 Gr23 bar/billet ASTM F136 Gr23 Implant Gra |

Kompożizzjoni kimika

| Grad | Kompożizzjoni kimika, fil-mija tal-piż (%) | ||||||||||||

| C ≤ | O ≤ | N ≤ | H ≤ | Fe ≤ | Al | V | Pd | Ru | Ni | Mo | Elementi Oħra Max.kull wieħed | Elementi Oħra Max.totali | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5~6.75 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | 0.12~0.25 | — | 0.12~0.25 | — | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | — | — | 0.12~0.25 | — | — | — | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | — | — | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | — | — | 0.04~0.08 | — | — | — | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5~6.5 | 3.5~4.5 | — | — | — | — | 0.1 | 0.1 |

Proprjetajiet fiżiċi

| Grad | Proprjetajiet fiżiċi | ||||||

| Saħħa tat-tensjoni Min | Saħħa ta 'rendiment (0.2%, ikkumpensat) | Titwil f'50mm Min (%) | |||||

| ksi | MPa | Min | Max | ||||

| ksi | MPa | ksi | MPa | ||||

| Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr4 | 80 | 550 | 70 | 483 | 95 | 655 | 15 |

| Gr5 | 130 | 895 | 120 | 828 | — | — | 10 |

| Gr7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr9 | 90 | 620 | 70 | 483 | — | — | 15 |

| Gr11 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

| Gr12 | 70 | 483 | 50 | 345 | — | — | 18 |

| Gr16 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | — | — | 10 |

Tolleranza (mm)

| Ħxuna | Tolleranza tal-wisa ' | ||

| 400 ~ 1000 | 1000 ~ 2000 | > 2000 | |

| 5.0~6.0 | ±0.35 | ±0.40 | ±0.60 |

| 6.0~8.0 | ±0.40 | ±0.60 | ±0.80 |

| 8.0~10.0 | ±0.50 | ±0.60 | ±0.80 |

| 10.0~15.0 | ±0.70 | ±0.80 | ±1.00 |

| 15.0~20.0 | ±0.70 | ±0.90 | ±1.10 |

| 20.0~30.0 | ±0.90 | ±1.00 | ±1.20 |

| 30.0~40.0 | ±1.10 | ±1.20 | ±1.50 |

| 40.0~50.0 | ±1.20 | ±1.50 | ±2.00 |

| 50.0~60.0 | ±1.60 | ±2.00 | ±2.50 |