Drill Kullari

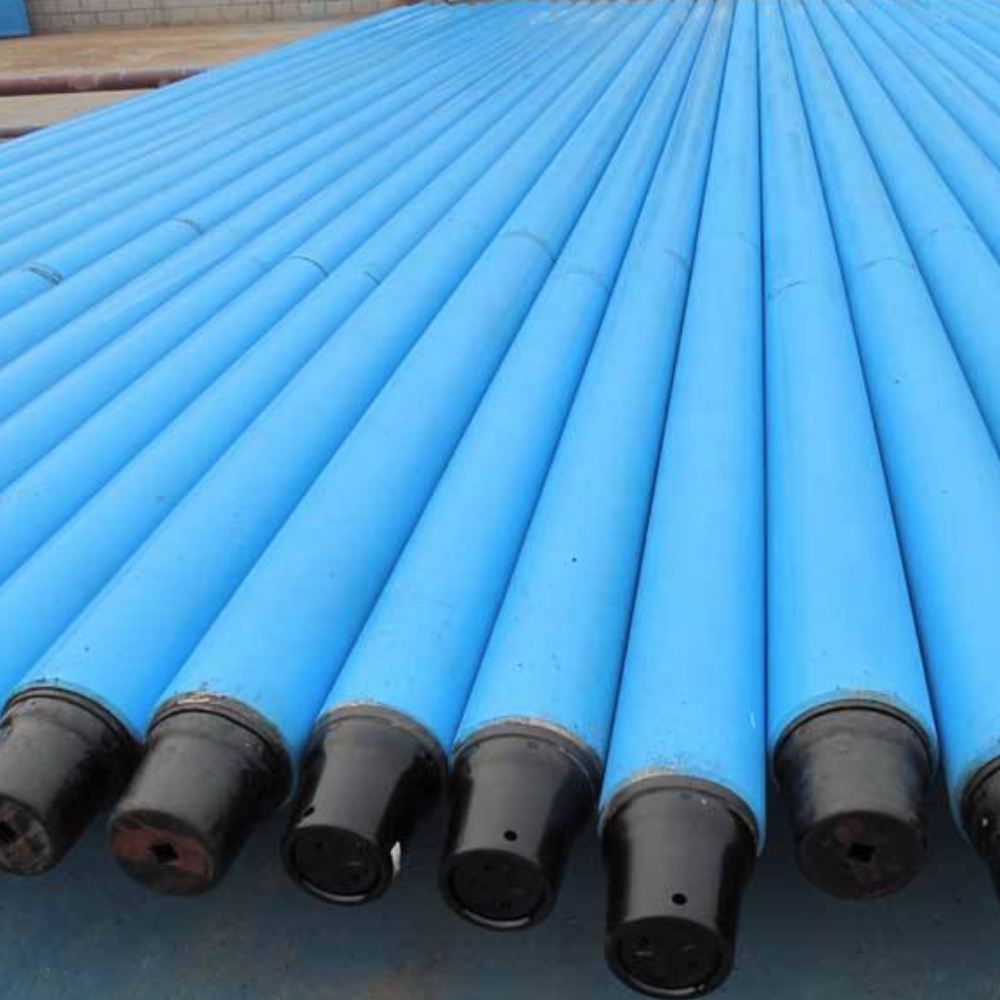

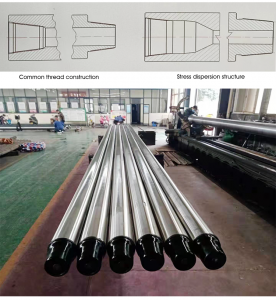

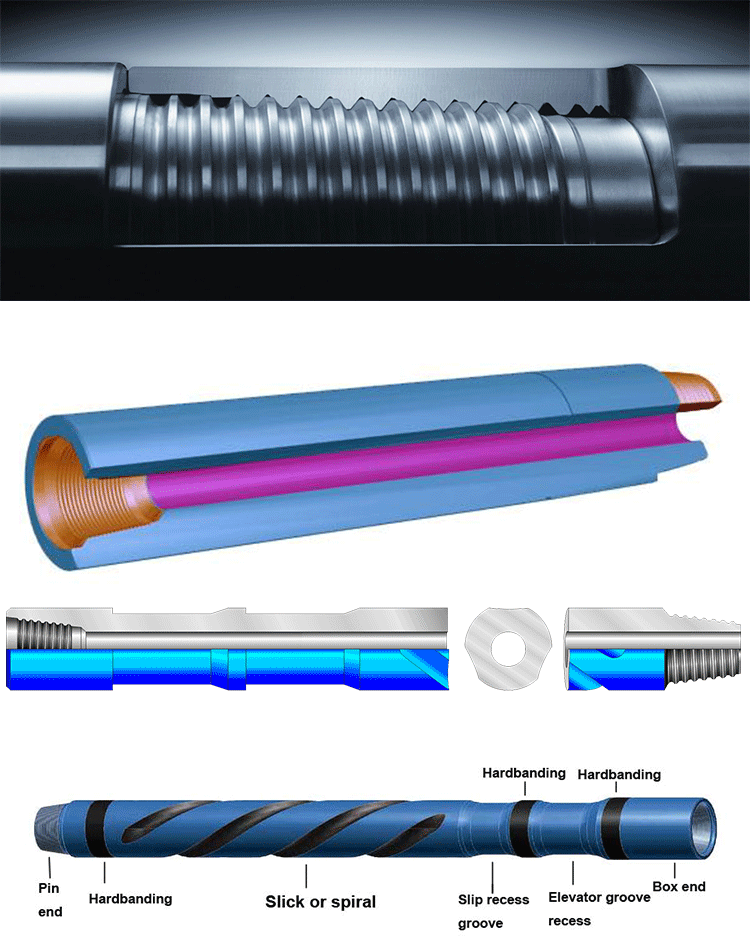

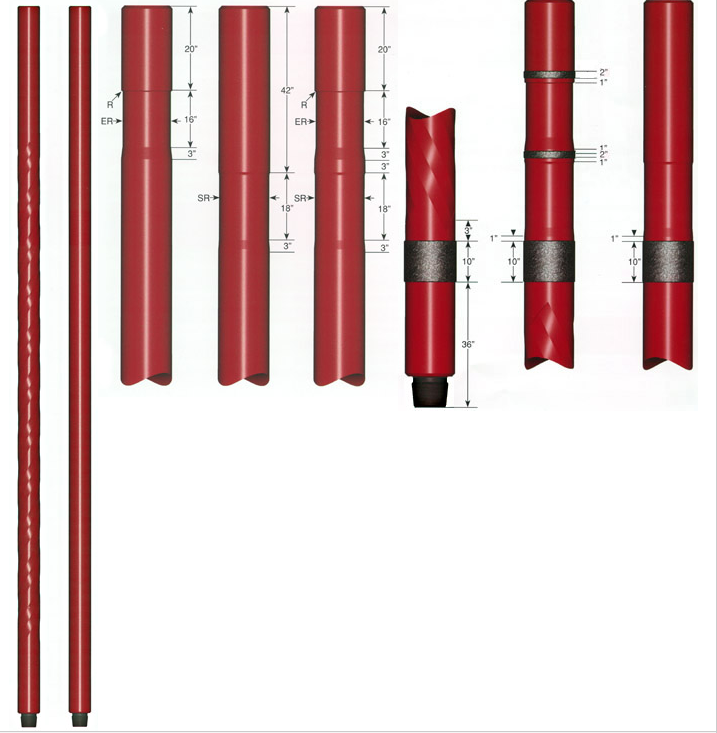

L-għonq tat-tħaffir bħala komponent wieħed ta 'sekwenza tat-trapan huwa estremament tubulari industrijali użati biex iħaffru fl-art biex jipprovdu piż fuq bit għat-tħaffir.Jintuża flimkien ma 'pajp tat-tħaffir.Hemm tipi roqgħa u spirali grooved prinċipalment.Il-proċess tal-manifattura tagħna huwa ċċertifikat għal API spec 7-1.L-għonq tat-drill huwa magħmul minn azzar illigat AISI 4145 H jew 4145 H Modifikat.It-toqob huma trepanned minn direzzjoni waħda mingħajr ebda nuqqas ta 'qbil.L-għenuq tat-trapan kollha huma ttrattati bis-sħana b'ebusija fi ħdan 285 sa 341 BHN, li huma garantiti pulzier taħt il-wiċċ tal-pajp.

Għenuq tat-drill mhux manjetiċi joffru saħħa u ebusija filwaqt li jipprevjenu interferenza manjetika li tista 'tfixkel l-eżattezza ta' stħarriġ manjetiku.Huwa manifatturat minn materjal ta 'l-azzar speċjali b'permeabilità baxxa, proprjetajiet mekkaniċi għoljin u reżistenza superjuri għall-qsim tal-korrużjoni.

Aħna nipprovdu għenuq ta 'drill roqgħa, għenuq ta' drill spirali u għenuq ta 'drill mhux manjetiku;id-daqsijiet tagħhom huma minn 3-1/8 sa 11-il pulzier.Minbarra l-għenuq tat-tħaffir fit-tabella hawn taħt, nistgħu nipprovdu kullari tat-tħaffir oħra fuq talba tal-klijenti.

| Oġġett | Isem | Spirali jew Roqgħa | OD | ID | Għodda konġunta | Dijametru taċ-ċanfrin pulzieri | Materjal | Tul totali | |

| in | in | Konnessjoni | ft | ||||||

| 1 | Drill kullar | Roqgħa jew Spirali | 3.1/8 | 1.1/4 | NC26 | 2.3/8″IF | 3 | 4145H | 30 jew 31 |

| 2 | Drill kullar | Roqgħa jew Spirali | 3.1/2 | 1.1/2 | NC26 | 2.3/8″IF | 4145H | 30 jew 31 | |

| 3 | Drill kullar | Roqgħa jew Spirali | 4.1/8 | 2 | NC31-41 | 2.7/8″IF | 3.61/64 | 4145H | 30 jew 31 |

| 4 | Drill kullar | Roqgħa jew Spirali | 4.3/4 | 2 | NC35-47 | 4.33/64 | 4145H | 30 jew 31 | |

| 5 | Drill kullar | Roqgħa jew Spirali | 5 | 2.1/4 | NC38-50 | 3.1/2″IF | 4.49/64 | 4145H | 30 jew 31 |

| 6 | Drill kullar | Roqgħa jew Spirali | 6 | 2.1/4 | NC44-60 | 5.11/16 | 4145H | 30 jew 31 | |

| 7 | Drill kullar | Roqgħa jew Spirali | 6 | 2.13/16 | NC44-60 | 5.11/16 | 4145H | 30 jew 31 | |

| 8 | Drill kullar | Roqgħa jew Spirali | 6.1/4 | 2.1/4 | NC44-62 | 5.7/8 | 4145H | 30 jew 31 | |

| 9 | Drill kullar | Roqgħa jew Spirali | 6.1/4 | 2.13/16 | NC46-62 | 4″JEKK | 5.29/32 | 4145H | 30 jew 31 |

| 10 | Drill kullar | Roqgħa jew Spirali | 6.1/2 | 2.1/4 | NC46-65 | 4″JEKK | 6.3/32 | 4145H | 30 jew 31 |

| 11 | Drill kullar | Roqgħa jew Spirali | 6.1/2 | 2.13/16 | NC46-65 | 4″JEKK | 6.3/32 | 4145H | 30 jew 31 |

| 12 | Drill kullar | Roqgħa jew Spirali | 6.3/4 | 2.1/4 | NC46-67 | 4″JEKK | 6.9/32 | 4145H | 30 jew 31 |

| 13 | Drill kullar | Roqgħa jew Spirali | 7 | 2.1/4 | NC50-70 | 4.1/2″JEKK | 6.31/64 | 4145H | 30 jew 31 |

| 14 | Drill kullar | Roqgħa jew Spirali | 7 | 2.13/16 | NC50-70 | 4.1/2″JEKK | 6.31/64 | 4145H | 30 jew 31 |

| 15 | Drill kullar | Roqgħa jew Spirali | 7.1/4 | 2.13/16 | NC50-72 | 4.1/2″JEKK | 6.43/64 | 4145H | 30 jew 31 |

| 16 | Drill kullar | Roqgħa jew Spirali | 7.3/4 | 2.13/16 | NC56-77 | 7.19/64 | 4145H | 30 jew 31 | |

| 17 | Drill kullar | Roqgħa jew Spirali | 8 | 2.13/16 | NC56-80 | 7.31/64 | 4145H | 30 jew 31 | |

| 18 | Drill kullar | Roqgħa jew Spirali | 8.1/4 | 2.13/16 | 6.5/8″REG | 7.45/64 | 4145H | 30 jew 31 | |

| 19 | Drill kullar | Roqgħa jew Spirali | 9 | 2.13/16 | NC61-90 | 8.3/8 | 4145H | 30 jew 31 | |

| 20 | Drill kullar | Roqgħa jew Spirali | 9.1/2 | 3 | 7.5/8″REG | 8.13/16 | 4145H | 30 jew 31 | |

| 21 | Drill kullar | Roqgħa jew Spirali | 9.3/4 | 3 | NC70-97 | 9.5/32 | 4145H | 30 jew 31 | |

| 22 | Drill kullar | Roqgħa jew Spirali | 10 | 3 | NC70-100 | 9.11/32 | 4145H | 30 jew 31 | |

| 23 | Drill kullar | Roqgħa jew Spirali | 11 | 3 | 8.5/8″REG | 10.1/2 | 4145H | 30 jew 31 | |

| Nota: | Jekk il-klijent ikollu xi ħtieġa speċjali, pereżempju kompost, irrumblar fil-kesħa, għamla u tkissir, banding iebes (ARNCO 100XT ARNCO 300XT eċċ), kisi intern (TK34 TK34PTC2000, eċċ), Pinn ta’ ħelsien mill-istress, Kaxxa tad-dahar bored, Riċess tal-liftijiet, slip Recess jekk jogħġbok tħossok liberu li tikkuntattjana. | ||||||||

| Kullar Drill mhux Magetic | ||

| Grad | Qawwa Tensili Minima | |

| psi | Mpa | |

| 1 | 90000 | 621 |

| 2 | 9000 | 621 |

| 3 | 115000 | 793 |

| ** Kullar ta 'drill mhux magetic jista' jiġi personalizzat skond id-disinn tal-klijent.Id-daqs jekk jogħġbok irreferi għad-daqsijiet tal-għonq tat-trapan. | ||

| Spiral Drill Kullar | |||||||||

| OD (fi) | 4 3/4 | 6 1/4 | 6 3/4 | 7 1/4 | 7 1/2 | 8 | 9 1/2 | 10 | 11 |

| Fond tal-Qtugħ (in) | 7/32 ±1/32 | 9/32 ±1/16 | 5/16 ±1/16 | 11/32 ±1/16 | 11/32 ±1/16 | 3/8 ±1/16 | 13/32 ± 3/32 | 7/16 ± 3/32 | 15/32 ± 3/32 |

| Żift spirali (in) | 38 ±1 | 42 ±1 | 46 ±1 | 64 ±1 | 64 ±1 | 68 ±1 | 72 ±1 | 76 ±1 | 80 ±1 |

| ** L-għonq tat-tħaffir jista 'jiġi personalizzat skont id-disinn tal-klijent. | |||||||||

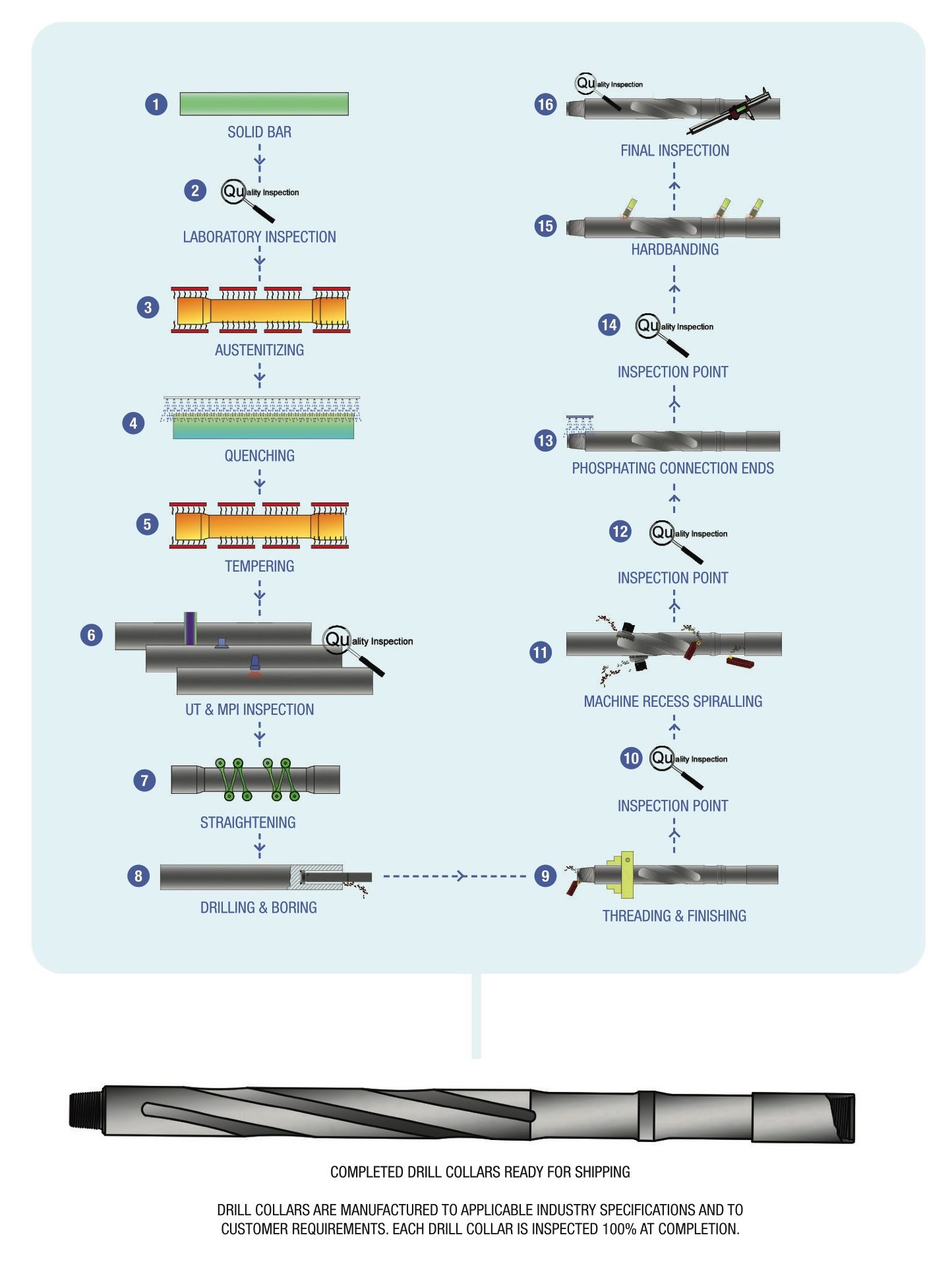

L-għenuq tat-tħaffir huma joint heavy duty integrali li huma mibnija minn bar solidu ta 'azzar liga modifikat AISI 4145H.?L-għenuq tat-drill standard tagħna huma fornuti b'kundizzjoni ta 'finitura tal-wiċċ "kif irrumblata".?Il-vireg standard kollha jirċievu trattament bis-sħana li jipprovdilhom il-proprjetajiet mekkaniċi meħtieġa.

Il-vireg huma mbagħad trepanned u drifted.?L-għenuq tat-trapan kollha tagħna huma manifatturati fihom

skond API spec 7, Q1 u prattika rakkomandata 7G, kif applikabbli.

Daqsijiet Standard, Bores, u Konnessjonijiet

| Drill Kullar Konnessjoni Daqs u Tip | Min. OD | Bore | Tul | Qawwa tal-liwi Proporzjon*** | Drill Kullar Wt. |

| (in.) | (in.) | (ft.) | (LB.) | ||

| NC 26 (2-3/8 IF) | 3-1/2 | 1-1/2 | 30 | 2.42:1 | 801 |

| NC 31 (2-7/8 IF) | 4-1/8 | 2 | 30 | 2.43:1 | 1041 |

| NC 38 (3-1/2 IF) | 4-3/4 | 2-1/4 | 31 | 1.85:1 | 1451 |

| NC 38 (3-1/2 IF) | 5 | 2-1/4 | 31 | 2.38:1 | 1652 |

| NC 44 | 6 | 2-1/4 | 31 | 2.49:1 | 2561 |

| NC 44 | 6 | 2-13/16 | 31 | 2.84:1 | 2353 |

| NC 44 | 6-1/4 | 2-1/4 | 31 | 2.91:1 | 2806 |

| NC 46 (4 IF) | 6-1/4 | 2-13/16 | 31 | 2.63:1 | 2598 |

| NC 46 (4 IF) | 6-1/2 | 2-1/4 | 31 | 2.76:1 | 3085 |

| NC 46 (4 IF) | 6-1/2 | 2-13/16 | 31 | 3.05:1 | 2877 |

| NC 46 (4 IF) | 6-3/4 | 2-1/4 | 31 | 3.18:1 | 3364 |

| NC 50 (4-1/2 IF) | 7 | 2-1/4 | 31 | 2.54:1 | 3643 |

| NC 50 (4-1/2 IF) | 7 | 2-13/16 | 31 | 2.73:1 | 3434 |

| NC 50 (4-1/2 IF) | 7-1/4 | 2-13/16 | 31 | 3.12:1 | 3714 |

| NC 56 | 8 | 2-13/16 | 31 | 3.02:1 | 4675 |

| 6-5/8 REG. | 8 | 2-13/16 | 31 | 2.60:1 | 4675 |

| 6-5/8 REG. | 8-1/4 | 2-13/16 | 31 | 2.93:1 | 5016 |

| 7-5/8 REG. | 9-1/2 | 3 | 31 | 2.81:1 | 6727 |

| 7-5/8 REG.** | 9-3/4 | 3 | 31 | 3.09:1 | 7130 |

| 8-5/8 REG.** | 11 | 3 | 30 | 2.78:1 | 8970 |

| ** Wiċċ ta 'torque baxx *** Proporzjon tal-kaxxa għall-modulu tas-sezzjoni tal-pin - Ara l-API RP7G għad-dettalji Nota: Daqsijiet u konnessjonijiet oħra huma disponibbli kif ukoll kwalunkwe karatteristika fakultattiva oħra elenkati | |||||

| Proprjetà Mekkanika | ||||||

| TTT | Qawwa tar-rendiment 0.2Mpa | Saħħa tat-tensjoni b Mpa | Titwil 4% | Ebusija (Brinell) | VALUR TAL-IMPATT(CHAPPY-V) | |

| mm | fil-pulzier | |||||

| 79.4-171.4 | 3 1/8-6 3/4 | ≥ 758 | ≥ 965 | ≥ 13 | 285-341 | ≥ 54 |

| 177.8-279.4 | 7-11 | ≥ 689 | ||||