Okpomọkụ Ex-mgbanwe

Kedu ihe bụ ndị na-agbanwe ọkụ?

A na-eji okwu ahụ bụ "onye na-ekpo ọkụ ọkụ" kọwaa ngwaọrụ na-eme ka ịnyefe ọkụ site n'otu mmiri gaa na nke ọzọ na-agwakọtaghị ha abụọ. Ọ nwere ọwa ma ọ bụ ụzọ abụọ dị iche iche, otu maka mmiri na-ekpo ọkụ na otu maka mmiri oyi, nke na-adị iche mgbe ọ na-agbanwe okpomọkụ. Ọrụ bụ isi nke igwe na-ekpo ọkụ bụ ịkwalite nrụpụta ike site na iji okpomọkụ mkpofu, ichekwa ihe onwunwe, na ibelata ụgwọ ọrụ.

Ụdị ndị na-agbanwe ọkụ ọkụ

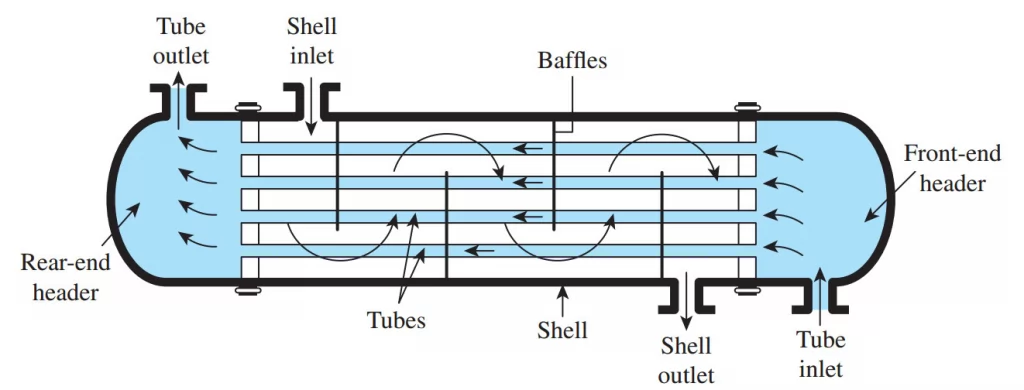

Shell na tube okpomọkụ mgbanwe:Ndị a bụ ụdị mgbanwe okpomọkụ a na-ejikarị eme ihe na sistemụ HVAC azụmahịa. Ha na-agụnye usoro tubes agbachiri na shei. Mmiri na-ekpo ọkụ na-esi na tubes mgbe mmiri oyi na-ekesa tubes n'ime shea ahụ, na-enye ohere maka mgbanwe okpomọkụ nke ọma.

Ndị na-agbanwe ọkụ efere efere:Ndị na-ekpo ọkụ efere efere na-eji nchịkọta nke efere ígwè nwere akụkụ ndị ọzọ ewelitere na ndị dara mbà n'obi. Mmiri na-ekpo ọkụ na oyi na-agba ọsọ site na ọwa dị iche iche nke e mere site na ọdịiche dị n'etiti efere ndị ahụ, na-eme ka okpomọkụ dịkwuo elu n'ihi nnukwu ebe dị elu.

Ndị na-agbanwe ọkụ ikuku na ikuku:A makwaara dị ka nkeji mgbake okpomọkụ, ndị na-ekpo ọkụ na-ekpo ọkụ na-ebufe okpomọkụ n'etiti mpụta na inye mmiri iyi. Ha na-ewepụ okpomọkụ site na ikuku siri ike ma nyefee ya na ikuku ọhụrụ, na-ebelata ike ike site na ịkwado ikuku na-abata.

Kedu ihe bụ ojiji nke Shell na Tube Heat Exchanger?

Eji ụlọ ọrụ mmepụta ihe nke shei na tube okpomọkụ, nke a na-eji kemịkalụ, nri, mmanụ na gas na ubi ndị ọzọ, bụ ebe niile. A na-arụkarị ha n'ọrụ na ụlọ ọrụ dị iche iche maka ịnyefe okpomọkụ n'etiti mmiri abụọ na-enweghị kọntaktị kpọmkwem. Ụfọdụ n'ime isi ụlọ ọrụ mmepụta ihe nke shei na tube okpomọkụ na-agbanwe ngwa gụnyere:

Usoro ikpo ọkụ na jụrụ oyi na osisi kemịkal

Condensing na evaporating ọrụ na refineries

Usoro mgbake ọkụ na ụlọ ọrụ mmepụta ike

Sistemụ HVAC na ụlọ azụmahịa na ebe obibi

Usoro refrigeration na osisi nhazi nri

Nlekọta okpomọkụ na ụlọ ọrụ mmepụta mmanụ na gas

N'ozuzu, shei na tube okpomọkụ na-arụ ọrụ dị oke mkpa n'ịkwalite arụmọrụ ọkụ yana idobe njikwa okpomọkụ n'ofe usoro mmepụta ihe dị iche iche.

Kedu ụdị nke Shell na Tube Heat Exchanger?

N'ikpeazụ, e nwere ụdị isi atọ nke shei na tube okpomọkụ nke a na-ejikarị eme ihe:

1. Mpempe akwụkwọ Tube edoziri (L, M, na N Ụdị nkụnye eji azụ azụ)

N'ime imewe a, a na-ejikọta mpempe akwụkwọ tube na shei ahụ, na-eme ka ọ dị mfe ma dị irè. Ọ bụ ezie na enwere ike ịsacha tubes ndị ahụ n'ụzọ ma ọ bụ kemịkalụ, ihe dị n'èzí nke tubes anaghị enweta ya ma e wezụga maka nhicha kemịkal. Mgbasa mgbasawanye nwere ike ịdị mkpa iji nabata nnukwu ọdịiche okpomọkụ dị n'etiti shea na ihe tube, ma ha nwere ike bụrụ isi iyi nke adịghị ike na ọdịda.

2. U-Tube Exchangers

Na onye na-agbanwe U-Tube, ụdị nkụnye eji isi mee n'ihu nwere ike ịdịgasị iche, na nkụnye eji azụ azụ bụ ụdị M-ụdị. U-tube na-enye ohere maka mgbasawanye ọkụ na-akparaghị ókè, enwere ike wepu ngwugwu tube maka ihicha. Otú ọ dị, n'ime ihicha nke tubes site n'ibu ụzọ siri ike, na-eme ka ụdị a adabara naanị maka ngwa ebe tube n'akụkụ mmiri dị ọcha.

3. Onye ngbanwe isi na-ese n'elu mmiri (P, S, T, na W Ụdị nkụnye eji azụ azụ)

N'ụdị mgbanwe a, tubesheet dị n'azụ nkụnye eji isi mee na-adịghị welded na shei ma kwere ka ịkwaga ma ọ bụ sere n'elu. Mpempe akwụkwọ tube dị n'ihu isi nkụnye eji isi mee bụ nke buru ibu karịa shei ahụ ma mechie ya n'otu aka ahụ na nhazi tubesheet edoziri.

Enwere ike ịnabata mgbasawanye thermal, enwere ike wepu ngwugwu tube maka ihicha. The S-Type Rear Head bụ nhọrọ kacha ewu ewu maka nkụnye eji isi mee azụ. Ndị na-agbanwe isi na-ese n'elu mmiri dabara adaba maka oke okpomọkụ na nrụgide mana ọ na-adịkarị ọnụ karịa ma e jiri ya tụnyere ndị na-agbanwe tubesheet edoziri.

Dịka ọkachamara na-ebubata ọkpọkọ, Hnssd.com nwere ike ịnye ndị na-agbanwe ọkụ ahaziri iche. Ọ bụrụ na ịchọrọ ozi ndị ọzọ gbasara ngwaahịa anyị, anyị na-arịọ gị ka ịkpọtụrụ anyị:sales@hnssd.com

Enwere ike imebi akụkụ nke shei na tube okpomọkụ n'ime akụkụ ndị a:

1. Shell

Shei bụ akụkụ mpụta nke okpomọkụ nke na-ejide ngwugwu tube. Ọ na-abụkarị akpa cylindrical nke ejiri ígwè ma ọ bụ ihe ndị ọzọ dabara adaba arụ ya

2. Ọkụ ma ọ bụ Tube Bundle

Nchịkọta tubes yiri ya na-agba ọsọ n'ogologo shei ahụ na-eme ka ngwugwu tube. Dabere na ojiji a kapịrị ọnụ, tubes nwere ike iji ihe dị iche iche mejupụtara, dị ka igwe anaghị agba nchara, ọla kọpa, ma ọ bụ titanium. The dayameta na ọkpụrụkpụ nke tubes dịkwa mkpa imewe parameters.

3. Mpempe akwụkwọ tube

Ibé akwụkwọ tube bụ mpempe akwụkwọ siri ike nke na-arụ ọrụ dị ka ihe mgbochi n'etiti ngwugwu tube na shei. A na-eji ígwè arụkarị ha ma jikọta ya na shei ahụ iji hụ na mmechi siri ike na enweghị mgbaka. A na-etinye tubes ndị ahụ site na oghere na mpempe tube ma gbasaa ma ọ bụ welded n'ọnọdụ.

4. Ọgba aghara

Baffles bụ efere ma ọ bụ mkpanaka ndị a na-etinye n'ime shei ahụ iji chịkwaa mmegharị nke mmiri na gburugburu ngwugwu tube. Ndị a nwere ike ịbụ ogologo ogologo ma ọ bụ transverse na nghazi na e bu n'obi kwalite ịdị irè nke nnyefe ọkụ.

5. Nozzles ntinye na ntinye

Oghere ụzọ mbata na mpụta na-eje ozi dị ka ebe ntinye na ọpụpụ maka mmiri dị na igwe na-ekpo ọkụ. A na-etinyekarị njikọ ndị a na nsọtụ nke shei ahụ ma na-etinye ya na tubes na shei ahụ site na iji flanges ma ọ bụ ụdị ihe ndị ọzọ.

6. Mgbasawanye nkwonkwo

Njikọ mgbasawanye bụ njikọ na-agbanwe agbanwe nke na-anabata mgbasawanye na mkpirisi okpomọkụ nke ngwugwu tube. A na-adịkarị na ntinye na ntinye nke onye na-ekpo ọkụ ọkụ, a na-arụ nkwonkwo ndị a site na iji mgbanaka ígwè ma ọ bụ ihe ndị ọzọ na-agbanwe agbanwe.

7. Usoro nkwado

Ụlọ nkwado na-ejide ndị na-ekpo ọkụ ọkụ n'ọnọdụ, na-eme ka ntọala siri ike. Ụlọ nkwado nwere ike ịdịru nwa oge ma ọ bụ na-adịgide adịgide ma nwee ike iji ígwè ma ọ bụ ihe ndị ọzọ mee ya.

Shell na tube geometric okwu

| 1 | Isi ọdụ ọdụ (N'ihu)—Ọwa | 20 | Flange na-akwado ndabere |

| 2 | Isi ọdụ ọdụ (N'ihu)—Bonnet | 21 | Uwe Tubesheet na-ese n'elu mmiri |

| 3 | Flange isi ọdụ ọdụ (n'ihu). | 22 | Uwe Tubesheet na-ese n'elu mmiri |

| 4 | Mkpuchi ọwa | 23 | Nkwakọ ngwaahịa igbe Flange |

| 5 | Isi Nozzles na-eguzo | 24 | Nkwakọ ngwaahịa |

| 6 | Tubesheet na-akwụsị | 25 | Mgbanaka ndị na-esochi mbukota |

| 7 | Ọkpụkpụ | 26 | Mgbanaka Lantern |

| 8 | Shell | 27 | Tie Rods na Spacers |

| 9 | Mkpuchi Shell | 28 | Baffles ntụgharị ma ọ bụ efere nkwado |

| 10 | Shell Flange — Ọgwụgwụ isi ọdụ | 29 | Mgbochi ihe mgbochi ma ọ bụ efere |

| 11 | Shell Flange—Nkwụsị Isi azụ | 30 | Ogologo ogologo oge |

| 12 | Shell Nozzle | 31 | Nyefee nkebi |

| 13 | Shell mkpuchi flange | 32 | Njikọ ikuku |

| 14 | Njikọ Mgbasawanye | 33 | Njikọ igbapu |

| 15 | Tubesheet na-ese n'elu mmiri | 34 | Ngwa Njikọ |

| 16 | Ihe mkpuchi isi na-ese n'elu mmiri | 35 | Nkwado Saddle |

| 17 | Isi Flange na-ese n'elu mmiri | 36 | Na-ebuli Lug |

| 18 | Ngwaọrụ na-akwado isi n'elu mmiri | 37 | Nkwado nkwado |

| 19 | Mgbanaka Shear gbawara |

Tube dayameta okirikiri nhọrọ ukwuu na pitch

Tubes nwere ike ịdị na dayameta site na 12.7 mm (0.5 in) ruo 50.8 mm (2 in), mana 19.05 mm (0.75 in) na 25.4 mm (1 in) bụ nha a na-ahụkarị. A na-edobe tubes ahụ n'ụdị triangular ma ọ bụ square na mpempe akwụkwọ tube.

The square layouts na-achọrọ ebe ọ dị mkpa iji nweta na tube elu maka n'ibu ihicha. Nhazi triangular na-enye ohere ka ọtụtụ tubes na oghere enyere. Ọkpụkpọ ọkpọkọ bụ ebe etiti ruo etiti kacha nso n'etiti tubes. A na-enye oghere tube site na tube pitch / tube dayameta, nke na-abụkarị 1.25 ma ọ bụ 1.33. Ebe ọ bụ na a na-eji okirikiri nhọrọ ukwuu maka ihicha ihe, a na-ahapụ oghere kacha nta nke 6.35 mm (0.25 in) n'etiti tubes.

Ụdị mgbagwoju anya

A na-etinye baffles n'akụkụ shea iji nye ọkụ ọkụ na-ebufe elu n'ihi ụba ọgbaghara na ịkwado tubes si otú ahụ na-ebelata ohere nke mmebi n'ihi ịma jijiji. E nwere ọtụtụ ụdị baffle dị iche iche, nke na-akwado tubes ma na-akwalite ịgbasa n'ofe tubes.

Otu ngalaba (nke a bụ nke a na-ahụkarị),

Nkeji abụọ (a na-eji nke a iji nweta ọsọ ọsọ n'akụkụ shei dị ala na ọdịda nrụgide),

Disc na Donut.

A na-akpọ ebe etiti na etiti dị n'etiti baffles baffle-pitch na nke a nwere ike gbanwee ka ọ gbanwee ọsọ ọsọ gafere. N'omume, ụda mgbanaka anaghị adịkarị ka anya ruru dayameta nke shei ma ọ bụ nso karịa ebe dị ka otu ụzọ n'ụzọ ise nke dayameta ma ọ bụ 50.8 mm (2 na) nke ọ bụla ka ukwuu. Iji mee ka mmiri ahụ na-asọghachi azụ na n'ihu gafee tubes, a na-ebipụ akụkụ nke baffle ahụ. A na-akpọ ịdị elu nke akụkụ a dị ka ihe a na-egbutu ma na-atụ ya dị ka pasentị nke dayameta shei, dịka ọmụmaatụ, 25 pacenti akpụ akpụ. Ọ dị mkpa ka a tụleba nha nha nke mkpụbelata-mkpụcha (ma ọ bụ windo baffle) yana pitch baffle. Ọ bụ ihe kwesịrị ekwesị ịha nha ụda mgbanaka na ihe gbagwojuru anya ka ha nhata ọsọ ọsọ site na windo na n'ofe gafere, n'otu n'otu.

The n'ibu imewe nke a shei na tube okpomọkụ Exchanger na-enye ozi na ihe ndị dị ka shei ọkpụrụkpụ, flange ọkpụrụkpụ, wdg Ndị a na-gbakọọ iji a mgbali arịa imewe koodu dị ka ji esi mmiri ọkụ na Pressure Vessel koodu si ASME (American Society of Mechanical Engineers). na British Master Pressure Vessel Standard, BS 5500. ASME bụ koodu a na-ejikarị eme ihe maka ndị na-agbanwe ọkụ ma dị na ngalaba 11. Nkebi nke Asatọ (Ụgbọ mmiri Nrụgide) nke koodu ahụ bụ nke kacha emetụta maka ndị na-agbanwe ọkụ mana akụkụ nke Abụọ—Ihe onwunwe na Nkebi V—Nnwale na-adịghị emebi emebi dịkwa mkpa.

Ma ASME na BS5500 ka a na-eji ma nabata ya n'ụwa niile mana ụfọdụ mba na-ekwusi ike na ejiri koodu obodo nke ha. Iji nwaa ma mee ka nke a dị mfe, International Standards Organisation na-anwa ugbu a imepụta koodu ọhụrụ amatara na mba ụwa mana ọ ga-abụ obere oge tupu anabata nke a.