Ọkụ nwere oghere

Ọkpụkpọ ọkpọkọ nke nwere oghere na-eji nyocha mmanụ nwere ike igbochi 99% ájá, belata 80% nke mmanụ na-arụ ọrụ nke ọma, yana ịbawanye ike nke ọma mmanụ, ịdị n'otu na nkwụsi ike nke idebe ájá.Ka ọ dị ugbu a, teknụzụ mbepụ laser nwere ike ime ka oghere ahụ dị nro na nkenke.Nhazi nke ọkpọkọ casing slotted bụ ihe atụ, mana ọ na-arụ ọrụ nke ọma.

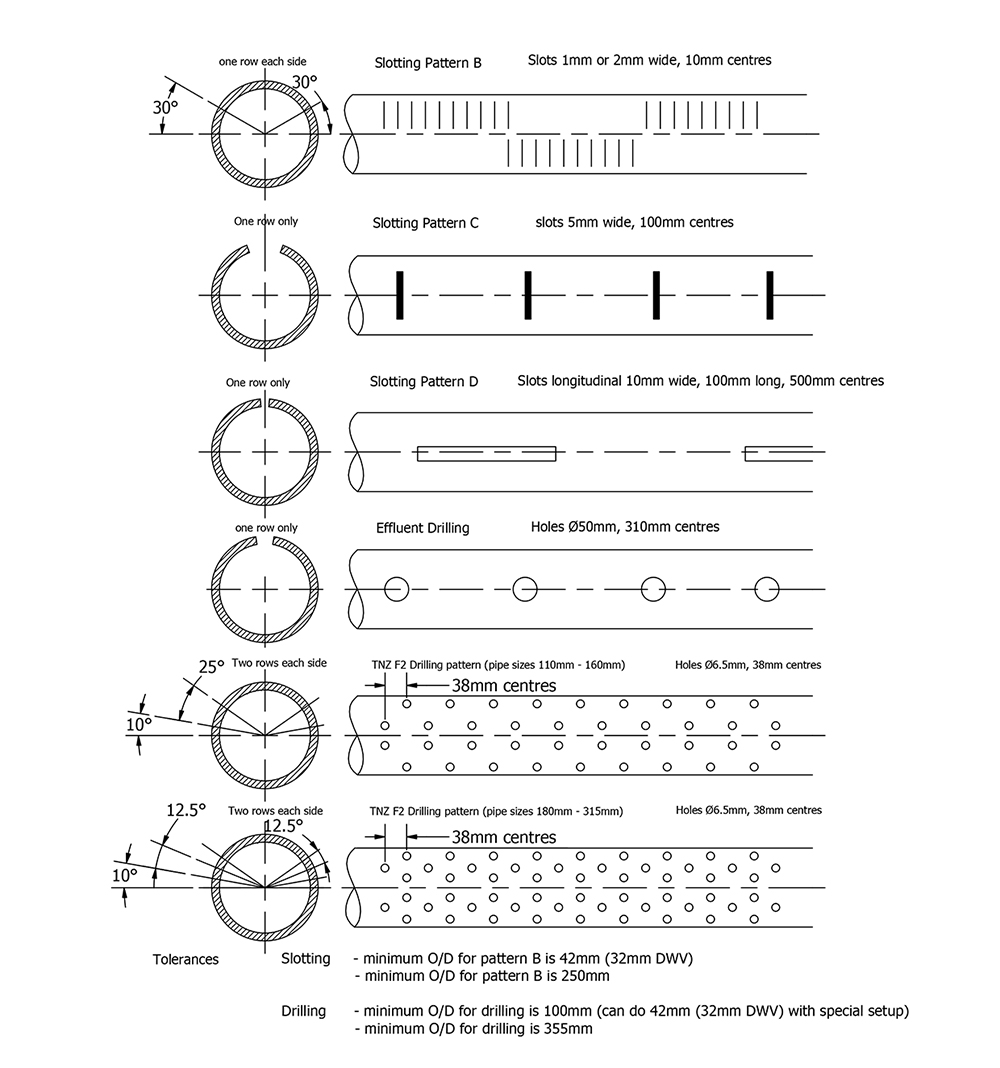

Slotted tube nhazi bụ na elu ike ígwè ahụ na oyi ma ọ bụ na-ekpo ọkụ na-arụ ọrụ ụzọ, igbupụ ọtụtụ narị puku longitudinal cracks, cracks ọtụtụ ji nkọwa maka: onuete obosara 0,15 3 mm, ọbụna ọzọ obosara, ọdịiche ogologo 50-200 mm.Cross ngalaba. ụdị bụ: akụkụ anọ, ubube ekara, kpọmkwem na dị iche iche, nwekwara a okirikiri uzo ihuenyo, oghere dayameta nkọwa nso 5-20 mm na mita.Slotted sieve tube oghere onuete ọnwụ mma tumadi dabere na nkenke nke onuete obosara, onu onuete cross- ngalaba udi idiocha ogo, na nsọtụ oghere onuete ire ụtọ na ogo corrosion eguzogide nke oghere onuete.

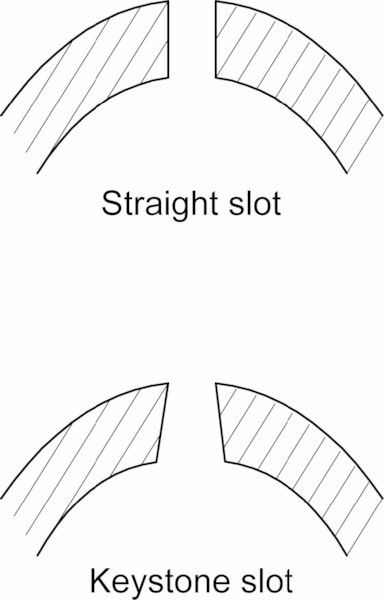

Oghere kwụ ọtọ-A na-egbutu oghere na nha nha nha site na mgbidi nke ọkpọkọ ma ID na OD.A kọwapụtara ebe nchikota ọka ájá dị na oghere ahụ adịghị mkpa, oghere kwụ ọtọ na-eguzogide ọgwụ karịa oghere isi okwute nwere akwa akwa ma dịkwa ọnụ ala iji mepụta.Ngwa a na-ahụkarị nke oghere ndị kwụ ọtọ bụ maka mmepụta oyi yana CBM olulu mmiri kwụ ọtọ na mgbakwunye na olulu mmiri injector SAGD.

Seamed Keystone oghere--a na-egweri obosara n'ime ọkpọkọ ma na-ehicha onwe ya iji nyere aka gbochie nkwụnye.Dị warara n'elu liner ma na-abawanye na obosara n'ime ime, ha na-ahapụ ájá nke na-abanye n'ime oghere na-enweghị nkwụnye.

| API casing ọkpọkọ | ID | Ogologo | Ogologo oghere | Oghere Mba. | Obosara oghere | oghere | Ihe nzacha bara uru | Oke. | ||

| Nkọwa mm | Ọkpụrụkpụ | Kwa Ibu | ||||||||

| 60.32 | 5 | 6.84 | 50.3 | 3 | 80 | 200 | 0.3 | ±50 | 48 | 512.54 |

| 73.02 | 5.5 | 9.15 | 62 | 240 | 57.6 | 688.55 | ||||

| 88.9 | 6.5 | 13.22 | 75.9 | 280 | 67.2 | 995.1 | ||||

| 101.6 | 6.5 | 15.22 | 88.6 | 300 | 72 | 1151.2 | ||||

| 114.3 | 7 | 18.47 | 100.3 | 10 | 320 | 76.8 | 1400.4 | |||

| 127 | 7.52 | 22.13 | 112 | 340 | 81.6 | 1673.8 | ||||

| 139.7 | 7.72 | 25.11 | 124.3 | 360 | 86.4 | 1900.2 | ||||

| 9.17 | 29.48 | 121.4 | 360 | 86.4 | 2232.4 | |||||

| 168.3 | 8.94 | 35.09 | 150.4 | 400 | 96 | 2672.95 | ||||

| 177.8 | 8.05 | 33.68 | 161.7 | 440 | 105.6 | 2559.2 | ||||

| 9.19 | 38.19 | 159.4 | 440 | 105.6 | 2940.7 | |||||

| Akụkụ anwụrụ ọkụ (n'ime) | OD (mm) | Ọkpụrụkpụ mgbidi (mm) | ID (mm) | Nọmba stitch nke okirikiri ọ bụla | Obosara oghere(mm) | Ogologo oghere (mm) | Ogologo(mm) |

| 2-3/8" | 60.3 | 4.83 | 50.64 | 12-18 | 0.2-0.8 | 45-100 | 1000-12000 |

| 2-7/8" | 73 | 5.51 | 61.98 | 20-24 | 45-100 | ||

| 3-1/2" | 88.9 | 6.45 | 76 | 24-28 | 45-100 | ||

| 4″ | 101.6 | 6.65 | 88.29 | 24-30 | 45-100 | ||

| 4-1/2 ″ | 114.3 | 5.69 | 102.92 | 24-30 | 45-100 | ||

| 6.35 | 101.6 | 45-100 | |||||

| 7.37 | 99.57 | 45-100 | |||||

| 8.56 | 97.18 | 45-100 | |||||

| 5″ | 127 | 5.59 | 115.82 | 28-36 | 0.25-0.8 | 45-100 | |

| 6.43 | 114.15 | 45-100 | |||||

| 7.52 | 111.96 | 45-100 | |||||

| 9.19 | 108.61 | 45-100 | |||||

| 5-1/2" | 139.7 | 6.2 | 127.3 | 30-38 | 45-100 | ||

| 6.99 | 125.73 | 45-100 | |||||

| 7.72 | 124.26 | 45-100 | |||||

| 9.17 | 121.36 | 45-100 | |||||

| 10.54 | 118.62 | 45-100 | |||||

| 7″ | 177.8 | 6.91 | 163.98 | 36-50 | 45-100 | ||

| 8.05 | 161.7 | 45-100 | |||||

| 9.19 | 159.41 | 45-100 | |||||

| 10.36 | 157.07 | 45-100 |

1. Anyị perforated ọkpọkọ na-eji J55/K55/N80 casing na tubings nke API ọkọlọtọ, na High n'ozuzu ike, adịghị mfe deformation.

2. Ọnụ nke oghere ahụ kwụ ọtọ, dị nro, na-enweghị burrs, oghere ahụ bụkwa otu.

3. Ọkpụkpọ a na-eme ka ọ dị mma maka olulu mmiri aja, nke dayameta nke ájá karịrị 0.3mm.

4. Oghere ahụ nwere ike ịbụ ogologo ogologo na ntụgharị, akụkụ nke oghere nwere ike ịdị n'otu na ụdị trapezoidal, nke nwere oghere sara mbara.

5. Slotted ihuenyo ọkpọkọ nwere nnukwu n'ime dayameta.

API Spec 5CT-Nkọwapụta 5CT/ISO 11960 nkọwapụta maka casing na tubing, mbipụta nke asatọ, mmanụ ala na gas ụlọ ọrụ - ọkpọkọ ígwè maka ojiji dị ka casing ma ọ bụ tubing maka olulu mmiri.

| Ọkọlọtọ | Ọkwa | Ngwakọta kemịkalụ () | |||||||||

| API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34 ~ 0.39 | 0.20 ~ 0.35 | 1.25 ~ 1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34 ~ 0.38 | 0.20 ~ 0.35 | 1.45 ruo 1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11 ~ 0.16 | |

| L80 | 0.15 ~ 0.22 | ≤1.00 | 0.25 ~ 1.00 | ≤0.020 | ≤0.010 | 12.0 ~ 14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26 ~ 0.395 | 0.17 ~ 0.37 | 0.40 ~ 0.70 | ≤0.020 | ≤0.010 | 0.80 ~ 1.10 | ≤0.20 | ≤0.20 | 0.15 ~ 0.25 | ≤0.08 | |

Ihe eji arụ ọrụ

| Ọkwa | Ụdị | Mkpokọta elongation n'okpuru ibu (%) | Ike mpụta (nkeji) | Ike mpụta (kacha) | Ike tensile min Mpa | Oke siri ike (HRC) | Oke ike ike (HBW) |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | - | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | - | 0.5 | 655 | 758 | 724 | - | - |

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 | - | - |

| Q125 | Ha niile | 0.65 | 862 | 1034 | 931 | - | - |

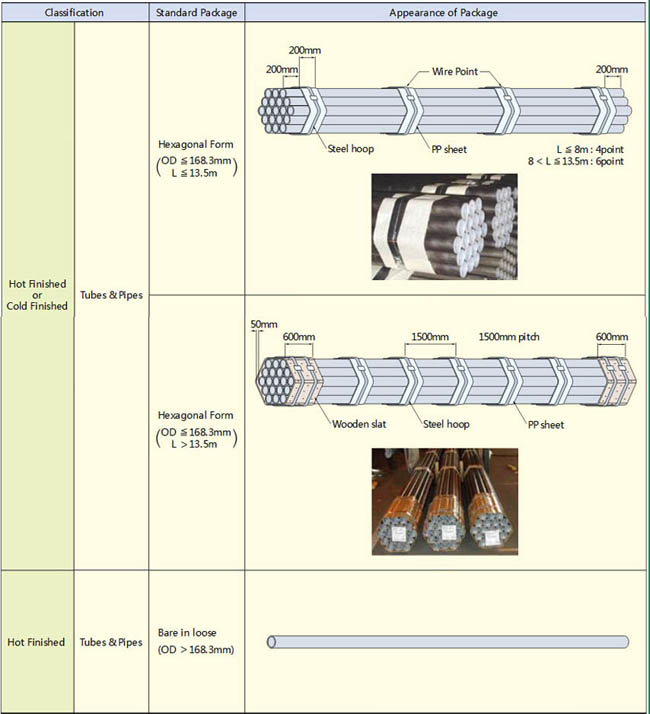

Single na afụ akpa na mgbe ahụ na osisi ikpe (fumigation akwụkwọ).Akara nke ọ bụla n'ụzọ doro anya na:

1. Aha & akara njirimara nke emeputa-HuaDong Brand

2. Ogbe nọmba

3. Ụbọchị nke emeputa

4. Ihe

5. Nchekwa kpo oku & ngwa okpomọkụ