Structural Steel Pipe

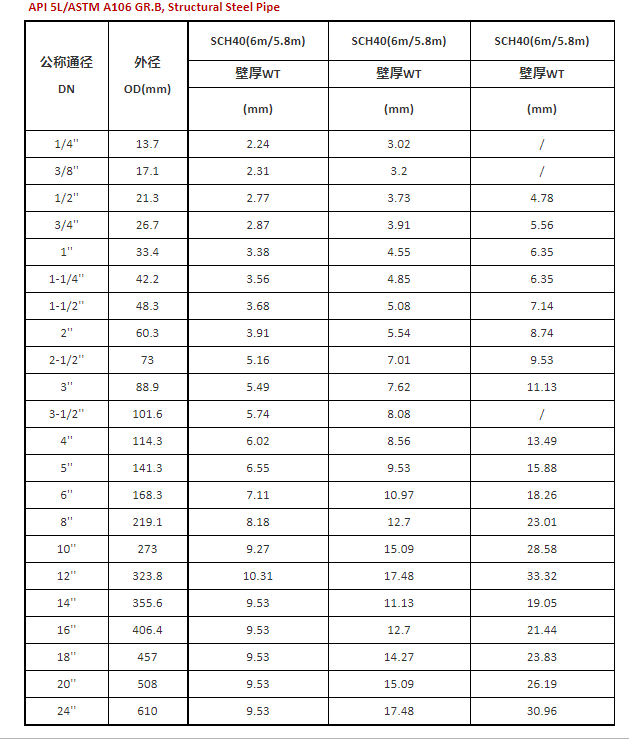

The Ọdịdị ígwè ọkpọkọ nwere na-ekpo ọkụ - akpọrepu enweghị nkebi ígwè tube na welded ígwè tube.The enweghị nkebi ígwè tube maka Ọdịdị na-ekewa abụọ ụdị dị ka ndokwa nke "enweghị nkebi ígwè tube maka Ọdịdị" (GB / t8162-2008): na-ekpo ọkụ Rolling ( extrusion, mgbasawanye) na ịbịaru oyi (na-atụgharị) .Mpụpụ dịpụrụ adịpụ nke ọkpọkọ na-ekpo ọkụ na-ekpo ọkụ bụ 32-630mm na mgbidi mgbidi bụ 2.5-75mm.Dayameta mpụta nke ọkpọkọ ígwè oyi na-adọkpụ bụ 5-200mm na ọkpụrụkpụ mgbidi bụ 2.5-12mm.A na-eji eriri ígwè ma ọ bụ eriri ígwè eme ihe na-eme ka ọ bụrụ ihe na-eme ka ọ dị mma ma na-akpụ, nke nwere ike kewaa n'ime ogologo welded steel pipe na spiral welded steel pipe. -12.7mm n'otu n'otu, nke ga-agbaso ndokwa nke GB / t3793-2008. The welded ígwè ọkpọkọ maka ala-nrụgide mmiri njem na-akpọ nkịtị welded ọkpọkọ, nke a na-akpọkarị clark pipe.Ekwuputara nkọwapụta ahụ na mm nke dayameta aha, nke kwesịrị ịgbaso usoro GB/t3091-2008 maka ụgbọ njem mmiri dị ala.

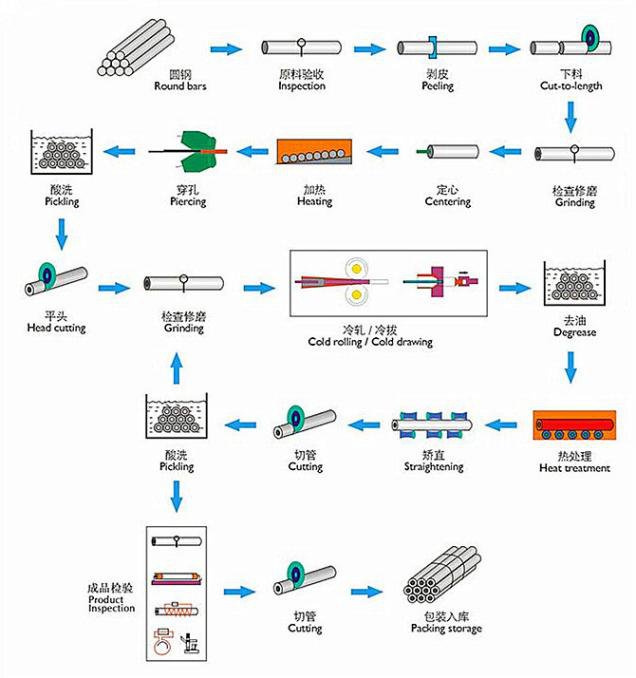

Usoro nrụpụta

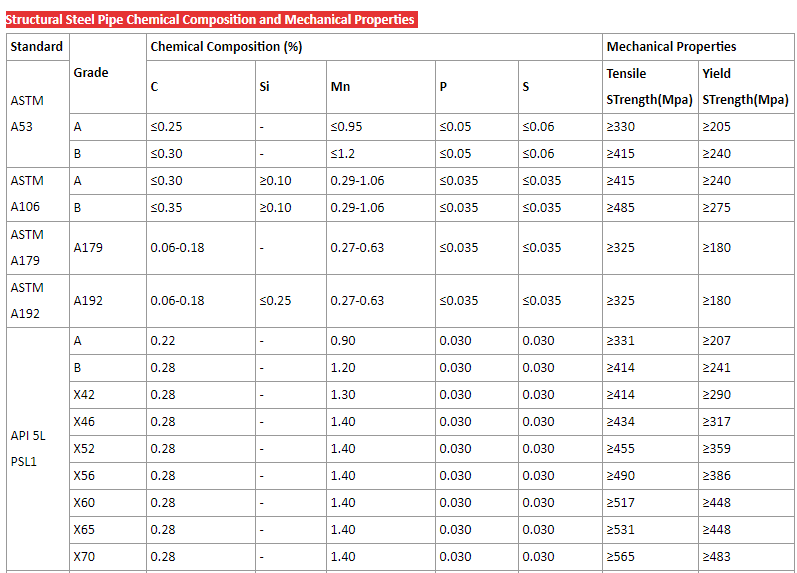

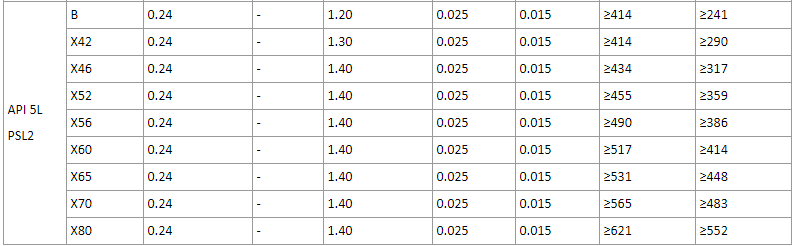

Ngwakọta kemịkalụ

| Ọkwa | C | Mn | P | S | Si | Cr | Mo |

| 1010 | 0.08-0.13 | 0.30-0.60 | ≤0.04 | ≤0.05 | - | - | - |

| 1020 | 0.08-0.23 | 0.30-0.60 | ≤0.04 | ≤0.05 | - | - | - |

| 1045 | 0.43-0.50 | 0.60-0.90 | ≤0.04 | ≤0.05 | - | - | - |

| 4130 | 0.28-0.33 | 0.40-0.60 | ≤0.04 | ≤0.05 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.75-1.00 | ≤0.04 | ≤0.05 | 0.15-0.35 | 0.80-1.10 | 0.15-0.25 |

Ihe eji arụ ọrụ

| Ọkwa | Ọnọdụ | Ike tensile Mpa(min) | Mpụta ike Mpa(min) | Mgbatị %(min) |

| 1020 | CW | 414 | 483 | 5 |

| SR | 345 | 448 | 10 | |

| A | 193 | 331 | 30 | |

| N | 234 | 379 | 22 | |

| 1025 | CW | 448 | 517 | 5 |

| SR | 379 | 483 | 8 | |

| A | 207 | 365 | 25 | |

| N | 248 | 379 | 22 | |

| 4130 | SR | 586 | 724 | 10 |

| A | 379 | 517 | 30 | |

| N | 414 | 621 | 20 | |

| 4140 | SR | 689 | 855 | 10 |

| A | 414 | 552 | 25 | |

| N | 621 | 855 | 20 |

Annealed, ahaziri nke ọma, ewepụla nchekasị, oyi gwụchara, emenyụọ na iwe