Titaan pyp/buis

Titaan naatlose buis word verwerk deur die afbreek van titanium ingot, ekstrudeer na titanium buis knuppel.Produseer dan titaanbuise tot toepaslike grootte met reeks prosesse soos meervoudige rol-, uitgloei-, beits- en maaltegnologie.

Titaan gelaste buis is deur die keuse van 'n geskikte dikte van die hoë kwaliteit koudgewalste titanium plaat, na die proses van plat, sny en was, dan opgerol titanium plaat in buis, sweis deur die hele outomatiese sweis toerusting.Ons gevorderde sweistoerusting het die kwaliteit van sweiswerk gewaarborg.Help uiteindelik om die titaniumbuis van uitstekende gehalte te produseer.

Titaan naatlose buis

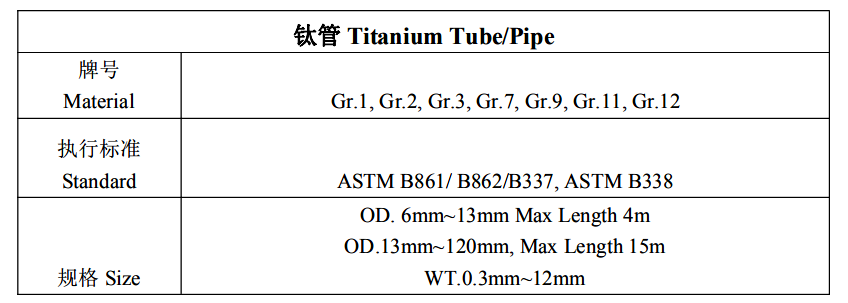

Graad: Gr1, Gr2, Gr7, Gr9, Gr11, Gr12, Gr16 ens

Buitendeursnee: 3~110mm

Muurdikte: 0,1 ~ 5,5 mm

Lengte: ≤19000mm

Titaan sweisbuis

Graad: Gr1, Gr2, Gr7, Gr9, Gr11, Gr12, Gr16 ens

Buitendeursnee: 10~1000mm

Muurdikte: 0,5 ~ 5,5 mm

Lengte: ≤19000mm

Gr5, Gr23 titanium legering naatlose buis

Buitendeursnee: 20 ~ 110 mm

Muurdikte: 1~50mm

Lengte: ≤3000mm

Vervaardigingsproses: Boor, Warmrol

| NAATLOOS TITANIUM PYP | ||||||||||

|

| S10 | S40 | S80 | |||||||

| Pyp grootte | OD | Muur | Binne Dia. | lbs / ft | Muur | Binne Dia. | lbs / ft | Muur | Binne Dia. | lbs / ft |

| 1/8 | .405 | .049 | .307 | .1072 | .068 | .269 | .1408 | .095 | .215 | .1810 |

| 1/4 | .540 | .065 | .410 | .1897 | .088 | .364 | .2442 | .119 | .302 | .3079 |

| 3/8 | .675 | .065 | .545 | .2437 | .091 | .493 | .3266 | .126 | .423 | .4251 |

| 1/2 | .840 | .083 | .674 | .3861 | .109 | .622 | .4896 | .147 | .546 | .6260 |

| 3/4 | 1,050 | .083 | .884 | .4932 | .113 | .824 | .6506 | .154 | .742 | .8479 |

| 1 | 1,315 | .109 | 1,097 | .8078 | .133 | 1,049 | .9660 | .179 | .957 | 1,2495 |

| 1-1/4 | 1,660 | .109 | 1,442 | 1,0389 | .140 | 1,380 | 1,3077 | .191 | 1,278 | 1,7242 |

| 1-1/2 | 1,900 | .109 | 1,681 | 1,1996 | .145 | 1,610 | 1,5637 | .200 | 1 500 | 2,0893 |

| 2 | 2,375 | .109 | 2,157 | 1,5178 | .154 | 2,067 | 2,1018 | .218 | 1,939 | 2,8895 |

| 2-1/2 | 2,875 | .120 | 2,635 | 2,0315 | .203 | 2,469 | 3,3331 | .276 | 2,323 | 4,4080 |

| 3 | 3 500 | .120 | 3,260 | 2,4924 | .216 | 3,068 | 4,3589 | .300 | 2,900 | 5,8992 |

| 3-1/2 | 4 000 | .120 | 3,760 | 2,8611 | .226 | 3,548 | 5,2412 | .318 | 3,364 | 7,1950 |

| 4 | 4 500 | .120 | 4,260 | 3,2298 | .237 | 4,026 | 6,2085 | .337 | 3,826 | 8,6210 |

| 5 | 5,563 | .134 | 5,295 | 4,4704 | .258 | 5,047 | 8,4106 | .375 | 4,813 | 11,9550 |

| 6 | 6,625 | .134 | 6,357 | 5,3449 | .280 | 6,065 | 10,917 | .432 | 5,761 | 16,440 |

| GELSTE TITANIUM PYP | |||||||

|

| S10 | S40 | |||||

| Pyp grootte | OD | Muur | Binne Dia. | lbs / ft | Muur | Binne Dia. | lbs / ft |

| 3/4 | .1.050 | .083 | .884 | .4932 | .113 | .824 | .6506 |

| 1 | 1,315 | .109 | 1,097 | .8078 | .133 | 1,049 | .9660 |

| 1-1/4 | 1,660 | .109 | 1,442 | 1,0389 | .140 | 1,380 | 1,3077 |

| 1-1/2 | 1,900 | .109 | 1,681 | 1,1996 | .145 | 1,610 | 1,5637 |

| 2 | 2,375 | .109 | 2,157 | 1,5178 | .154 | 2,067 | 2,1018 |

| 2-1/2 | 2,875 | .120 | 2,635 | 2,0315 | .203 | 2,469 | 3,3331 |

| 3 | 3 500 | .120 | 3,260 | 2,4924 | .216 | 3,068 | 4,3589 |

| 3-1/2 | 4 000 | .120 | 3,760 | 2,8611 | .226 | 3,548 | 5,2412 |

| 4 | 4 500 | .120 | 4,260 | 3,2298 | .237 | 4,026 | 6,2085 |

| 5 | 5,563 | .134 | 5,295 | 4,4704 | .258 | 5,047 | 8,4106 |

| 6 | 6,625 | .134 | 6,357 | 5,3449 | .280 | 6,065 | 10,917 |

| 8 | 8,625 | .148 | 8,329 | 7,7095 | .322 | 7,981 | 16,429 |

| 10 | 10,750 | .165 | 10,420 | 10,732 | .365 | 10,020 | 23,293 |

| 12 | 12,750 | .180 | 12,390 | 13,904 | .375 | 12 000 | 28,517 |

| 14 | 14 000 | .188 | 13,624 | 15,956 | .375 | 13,250 | 31,397 |

| 16 | 16 000 | .188 | 15,624 | 18,267 | .375 | 15,250 | 36,006 |

| 18 | 18 000 | .188 | 17,624 | 20,577 | .375 | 17,250 | 40,615 |

| 20 | 20 000 | .218 | 19,564 | 26 500 | .375 | 19,250 | 45,223 |

| 24 | 24 000 | .250 | 23,500 | 36,486 | .375 | 23,250 | 54,441 |

ASTM B338 – 10e1-standaardspesifikasie vir naatlose en gelaste titanium- en titaanlegeringsbuise vir kondensators en hitteruilers

ASTM B862 – 09 Standaardspesifikasie vir Titaan- en Titaanlegering-gesweisde pyp

ASTM B861 – 10 standaardspesifikasie vir naatlose pyp van titanium en titaniumlegering, ASTM B337

| Titaanbuis / pyp | Produk Naam | Graad | Spesifikasie (mm) | Standaard |

| Naatlose buis | Gr.1 Gr.2 Gr.7 Gr.9 Gr.12

| OD(3-114)×THK(0.5-10) ×≤ lengte 12000 | ASTM B337 ASTM B338 ASTM B 861 | |

| Sweispyp | Gr.1 Gr.2 Gr.7 Gr.12 | ≥OD133 | ASTM B862 | |

| Tube (Rusland) | BT1-0 | OD(3-114)×THK(0.5-10) ×≤ lengte 12000 | GOST22879 | |

Chemiese samestelling

| Graad | Chemiese samestelling, gewig persent (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Ander elemente Maks.elk | Ander elemente Maks.totaal | |

| Gr1 | 0,08 | 0,18 | 0,03 | 0,015 | 0,20 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr2 | 0,08 | 0,25 | 0,03 | 0,015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr4 | 0,08 | 0,25 | 0,03 | 0,015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 |

| Gr5 | 0,08 | 0,20 | 0,05 | 0,015 | 0,40 | 5,5–6,75 | 3,5–4,5 | — | — | — | — | 0.1 | 0.4 |

| Gr7 | 0,08 | 0,25 | 0,03 | 0,015 | 0.30 | — | — | 0,12–0,25 | — | 0,12–0,25 | — | 0.1 | 0.4 |

| Gr9 | 0,08 | 0,15 | 0,03 | 0,015 | 0,25 | 2,5–3,5 | 2.0–3.0 | — | — | — | — | 0.1 | 0.4 |

| Gr11 | 0,08 | 0,18 | 0,03 | 0,15 | 0.2 | — | — | 0,12–0,25 | — | — | — | 0.1 | 0.4 |

| Gr12 | 0,08 | 0,25 | 0,03 | 0,15 | 0.3 | — | — | — | — | 0,6–0,9 | 0,2–0,4 | 0.1 | 0.4 |

| Gr16 | 0,08 | 0,25 | 0,03 | 0,15 | 0.3 | — | — | 0,04–0,08 | — | — | — | 0.1 | 0.4 |

| Gr23 | 0,08 | 0,13 | 0,03 | 0,125 | 0,25 | 5,5–6,5 | 3,5–4,5 | — | — | — | — | 0.1 | 0.1 |

Fisiese eienskappe

| Graad | Fisiese eienskappe | ||||

| Trek sterkte Min | Lewer krag Min (0,2%, verrekening) | Verlenging in 2in of 50mm Min (%) | |||

| ksi | MPa | ksi | MPa | ||

| Gr1 | 35 | 240 | 20 | 138 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 20 |

| Gr5 | 130 | 895 | 120 | 828 | 10 |

| Gr7 | 50 | 345 | 40 | 275 | 20 |

| Gr9 | 90 | 620 | 70 | 483 | 15 |

| Gr11 | 35 | 240 | 20 | 138 | 24 |

| Gr12 | 70 | 483 | 50 | 345 | 18 |

| Gr16 | 50 | 345 | 40 | 275 | 20 |

| Gr23 | 120 | 828 | 110 | 759 | 10 |