Nikkellegeringspyp

| Materiaal | Monel/Inconel/Hastelloy/Duplekstaal/PH-staal/Nikkellegering |

| Vorm | Rond, smee, ring, spoel, flens, skyf, foelie, sferies, lint, vierkantig, staaf, pyp, vel |

| Graad | N02200、N02201、N04400、N06600、N06601、N06625、N06690、N08810、N08825、N08020、N080801,N0802801,N0802801 665、N06022、N06030、GH3030、GH3036 GH5188 Inconel706 Inconel600 InconelX-750 Inconel718 Inconel625 Inconel 617 Inconel601 Inconel690NS 31NS3NS1NS NS112,Incoloy800H, NO8810 NS111 NS336 NS142 Incoloy825 NS355 Hastelloy C-4 Monel K500, N05500 |

| Spesifikasie | Ander: 253Ma,254SMo,654SMo,F50(UNS S32100)F60,F61,F65,1J22,N4,N6 ens |

| Allooi:legering 625,Allooi 20/28/31 | |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g; | |

| Hastelloy B / UNS N10001,Hastelloy B-2 / UNS N10665 / DIN W. Nr.2.4617,Hastelloy C,Hastelloy C-4 / UNS N06455 / DIN W. Nr.2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr.2.4602,Hastelloy C-276 / UNS N10276 / DIN W. Nr.2.4819,Hastelloy X / UNS N06002 / DIN W. Nr.2,4665 | |

| Haynes: Haynes 230/556/188; | |

| Inconel-reeks:Inconel 600/601/602CA/617/625/690/713/718/738/X-750,Trymwerker 20; | |

| Inconel 718 / UNS N07718 /N04400/N06600/N08825/DIN W. Nr.2.4668,Inconel 601 / UNS N06601 / DIN W. Nr.2,4851, Inconel 625 / UNS N06625 / DIN W. Nr.2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr.2.4669,Inconel 600 / UNS N06600 / DIN W. Nr.2,4816 | |

| Inkoloy:Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132, GH3030, GH3039, GH3128, GH4180, GH3044 | |

| Monel:Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60; | |

| Nimonic: Nimonic 75/80A/90/A263 ; | |

| Draad: 0,01-10 mm Strook: 0.05*5.0-5.0*250mm Staaf: φ4-50mm; Lengte 2000-5000mm Pyp: φ6-273mm;δ1-30mm; Lengte 1000-8000mm Blad: δ 0.8-36mm; Breedte 650-2000mm; Lengte 800-4500mm | |

| Produk Eienskappe | 1. Volgens die voorbereidingsproses kan verdeel word in vervorming superlegerings, gietsuperlegerings en poeiermetallurgie-superlegerings. 2. Volgens die versterking af, is daar soliede oplossing versterking tipe, neerslag versterkingstipe, oksieddispersie-versterkingstipe en veselversterkingstipe, ens. |

| Standaard | GB, AISI, ASTM, DIN, EN, SUS, UNS ens |

| Inspeksie | ISO, SGS, BV, ensovoorts. |

| Toepassing | Hoë-temperatuur komponente soos turbine lemme, geleide wieke, turbine skywe, hoë druk kompressorskywe, masjienvervaardiging en verbrandingskamers wat gebruik word in die vervaardiging van lugvaart-, vloot- en industriële gasturbines |

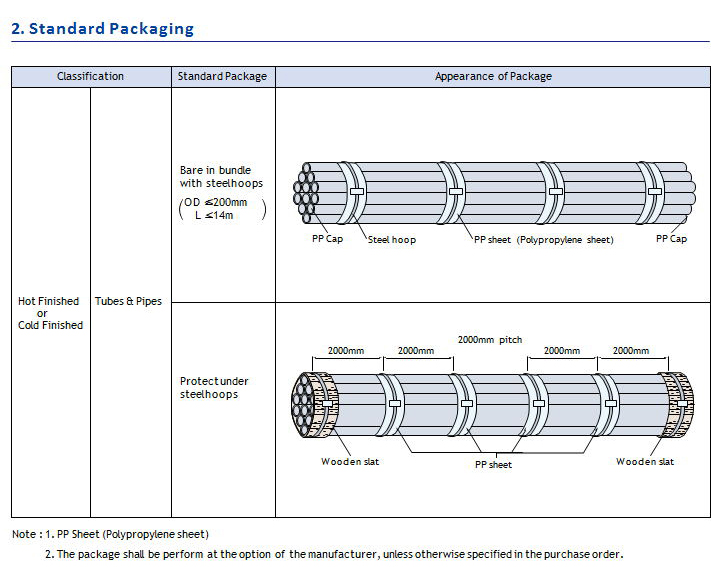

| Verpakking | 1. kiste verpak in houtkiste 2. papierverpakking 3. plastiekverpakking 4. skuim verpakking Verpakking volgens klantvereistes of produkte |

| Aflewering | 7-25 dae of volgens die produk |

| Betaling | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Betalings volgens klantvereistes vir vanlyn bestellings. |

| VOORRAAD GROOTTES | |||||||||||||

| GROOTTE | NIKKEL | LEGERING | LEGERING | LEGERING | LEGERING | LEGERING | LEGERING | LEGERING | LEGERING | LEGERING | LEGERING | GROOTTE | |

| 1/16 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 1,65 mm | |

| 0,010 | X | X | .25 mm | ||||||||||

| 0,020 | X | .51 mm | |||||||||||

| 1/8 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 3,18 mm | |

| 0,010 | X | 0,25 | |||||||||||

| 0,012 | X | 3,05 mm | |||||||||||

| 0,016 | X | .31mm | |||||||||||

| 0,020 | X | X | X | .51 mm | |||||||||

| 0,028 | X | X | X | X | .71mm | ||||||||

| 0,035 | X | X | X | X | .89 mm | ||||||||

| 3/16 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 4,76 mm | |

| 0,010 | X | .25 mm | |||||||||||

| 0,016 | X | X | .31mm | ||||||||||

| 0,020 | X | .51 mm | |||||||||||

| 0,028 | X | X | X | .71mm | |||||||||

| 0,035 | X | X | X | X | X | X | .89 mm | ||||||

| 0,049 | X | X | X | 1,24 mm | |||||||||

| 1/4 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 6,35 mm | |

| 0,016 | X | .31mm | |||||||||||

| 0,020 | X | X | X | .51 mm | |||||||||

| 0,028 | X | X | X | X | X | .71mm | |||||||

| 0,035 | X | X | X | X | X | X | X | X | .89 mm | ||||

| 0,049 | X | X | X | X | X | X | X | X | 1,24 mm | ||||

| 0,065 | X | X | X | X | X | X | X | 1,65 mm | |||||

| 0,083 | X | 2,11 mm | |||||||||||

| 5/16 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 7,94 mm | |

| 0,028 | X | .71mm | |||||||||||

| 0,035 | X | X | X | .89 mm | |||||||||

| 0,049 | X | 1,24 mm | |||||||||||

| 0,065 | X | X | X | 1,65 mm | |||||||||

| 3/8 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 9,53 mm | |

| 0,020 | X | .51 mm | |||||||||||

| 0,028 | X | X | X | X | .71mm | ||||||||

| 0,035 | X | X | X | X | X | X | X | X | .89 mm | ||||

| 0,049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | X | 1,65 mm | |||||

| 0,083 | X | X | 2,11 mm | ||||||||||

| 7/16 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 11,1 mm | |

| 0,035 | X | .89 mm | |||||||||||

| 0,065 | X | 1,65 mm | |||||||||||

| 1/2 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 12,7 mm | |

| 0,028 | X | X | X | X | .71mm | ||||||||

| 0,035 | X | X | X | X | X | X | X | X | X | .89 mm | |||

| 0,049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,058 | X | X | 1,47 mm | ||||||||||

| 0,065 | X | X | X | X | X | X | X | X | 1,65 mm | ||||

| 0,083 | X | X | X | 2,11 mm | |||||||||

| 0,095 | X | X | 2,41 mm | ||||||||||

| 0,109 | X | 2,77 mm | |||||||||||

| 0,120 | X | 3,05 mm | |||||||||||

| 9/16 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 14,3 mm | |

| 0,035 | X | X | X | .89 mm | |||||||||

| 0,049 | X | X | X | X | 1,24 mm | ||||||||

| 0,065 | X | X | X | 1,65 mm | |||||||||

| 0,083 | X | 2,11 mm | |||||||||||

| 5/8 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 15,9 mm | |

| 0,035 | X | X | X | X | X | .89 mm | |||||||

| 0,049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | 1,65 mm | ||||||

| 0,083 | X | X | 2,11 mm | ||||||||||

| 0,095 | X | X | 2,41 mm | ||||||||||

| 0,120 | X | 3,05 mm | |||||||||||

| 3/4 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 19,1 mm | |

| 0,028 | X | .71mm | |||||||||||

| 0,035 | X | X | X | X | X | X | X | .89 mm | |||||

| 0,049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | X | X | X | X | 1,65 mm | ||

| 0,083 | X | X | X | X | X | X | X | 2,11 mm | |||||

| 0,095 | X | X | 2,41 mm | ||||||||||

| 0,109 | X | X | X | X | 2,77 mm | ||||||||

| 0,120 | X | X | X | 3,05 mm | |||||||||

| 0,125 | X | X | 3.18 | ||||||||||

| 7/8 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 22,2 mm | |

| 0,035 | X | X | X | .89 mm | |||||||||

| 0,049 | X | X | X | 1,24 mm | |||||||||

| 0,065 | X | X | X | X | 1,65 mm | ||||||||

| 0,083 | X | X | 2,11 mm | ||||||||||

| 0,120 | X | 3,05 mm | |||||||||||

| 1 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 25,4 mm | |

| 0,028 | X | .71mm | |||||||||||

| 0,035 | X | X | X | X | X | X | .89 mm | ||||||

| 0,049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | X | X | 1,65 mm | ||||

| 0,083 | X | X | X | X | X | X | X | 2,11 mm | |||||

| 0,095 | X | X | 2,41 mm | ||||||||||

| 0,109 | X | X | X | X | 2,77 mm | ||||||||

| 0,120 | X | X | X | 3,05 mm | |||||||||

| 0,125 | X | 3.18 | |||||||||||

| 0,134 | X | X | |||||||||||

| 1 1/8 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 28,6 mm | |

| 0,049 | X | ||||||||||||

| 1 1/4 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 31,8 mm | |

| 0,035 | X | X | X | .89 mm | |||||||||

| 0,049 | X | 1,24 mm | |||||||||||

| 0,065 | X | X | X | X | X | X | 1,65 mm | ||||||

| 0,083 | X | X | X | X | 2,11 mm | ||||||||

| 0,095 | X | 2,41 mm | |||||||||||

| 0,109 | X | 2,77 mm | |||||||||||

| 0,120 | X | X | 3,05 mm | ||||||||||

| 0,125 | X | 3.18 | |||||||||||

| 1 1/2 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 38,1 mm | |

| 0,028 | X | .71mm | |||||||||||

| 0,035 | X | X | .89 mm | ||||||||||

| 0,049 | X | X | X | 1,24 mm | |||||||||

| 0,065 | X | X | X | X | X | X | 1,65 mm | ||||||

| 0,083 | X | X | X | 2,11 mm | |||||||||

| 0,095 | X | X | 2,41 mm | ||||||||||

| 0,109 | X | X | X | 2,77 mm | |||||||||

| 0,120 | X | X | X | 3,05 mm | |||||||||

| 0,125 | X | 3.18 | |||||||||||

| 1 5/8 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 41,3 mm | |

| 0,065 | X | 1,65 mm | |||||||||||

| 0,083 | X | 2,11 mm | |||||||||||

| 1 3/4 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 44,5 mm | |

| 0,065 | X | X | X | 1,65 mm | |||||||||

| 1 7/8 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 47,6 mm | |

| 0,083 | X | 2,11 mm | |||||||||||

| 2 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 50,8 mm | |

| 0,028 | X | .71mm | |||||||||||

| 0,035 | X | X | .89 mm | ||||||||||

| 0,049 | X | X | 1,24 mm | ||||||||||

| 0,065 | X | X | X | X | X | 1,65 mm | |||||||

| 0,083 | X | X | X | X | 2,11 mm | ||||||||

| 0,095 | X | 2,41 mm | |||||||||||

| 0,109 | X | X | 2,77 mm | ||||||||||

| 0,120 | X | X | X | 3,05 mm | |||||||||

| 0,125 | X | X | 3.18 | ||||||||||

| 2 1/4 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 57,2 mm | |

| 0,035 | X | .89 mm | |||||||||||

| 0,049 | X | 1,24 mm | |||||||||||

| 0,120 | X | 3,05 mm | |||||||||||

| 2 1/2 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 63,5 mm | |

| 0,065 | X | X | X | X | 1,65 mm | ||||||||

| 0,083 | X | X | 2,11 mm | ||||||||||

| 0,109 | X | 2,77 mm | |||||||||||

| 0,120 | X | X | 3,05 mm | ||||||||||

| 3 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 76,2 mm | |

| 0,065 | X | X | X | X | 1,65 mm | ||||||||

| 0,083 | X | X | X | 2,11 mm | |||||||||

| 0,120 | X | X | 3,05 mm | ||||||||||

| 0,125 | X | 3.18 | |||||||||||

| 0,250 | X | 6,35 | |||||||||||

| 3 1/4 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 82,6 mm | |

| 0,125 | X | 3.18 | |||||||||||

| 3 1/2 duim | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 88,9 mm | |

| 0,375 | 9,53 mm | ||||||||||||

| Standaard | – ASTM A270,ASTM A249,ASTM A511,ASTM A778,ASTM A312,ASTM A358,ASTM A409,ASTM A213,ASTM A790,ASTM A268,ASTM A269,ASTM A554,ASTM B338,ASTM B673,ASTM B673,ASTM B673,ASTM B673. B675, ASTM B676, ASTM B690, ASTM A928, ASME B36.19, ASME B36.10– EN10216-5, EN10217-7, DIN 17456, DIN 17458 – JIS G3463, JIS G3119, JIS G3446, JIS G3218, JIS G3258, JIS G3448, JIS H4631 – DEP 31, DEP 40, DEP 20, DEP 32, DNV-OS-F101 |

| Groottereeks | OD:NPS 1/8 -80, BN 6 – 2000, 10.3 – 2030 , Alao kapilêreWT:Sch5s-Sch160s, SchXXH, STD, XS, XXSLengte:Pasmaak |

| Graad | S32750, 00Cr25Ni7Mo4N, 022Cr25Ni7Mo4N, 1,441, 1,4307/1,4301/304L/3, S30408/S30403, 0Cr18Ni9DQ, 1,409r, S30408/S30403, 0Cr18Ni9DQ, 1,409r, 0,494, S , 1.4948, 06Cr23Ni13, S30908, SUS309S, SUS310S, 1.4845, S31008, S31008S, 06Cr25Ni20, 0Cr25Ni20, 1.4401/1.4404/316/31, S31635, SUS316Ti, 1.4571, 1.4571/316Ti, S31703, 022Cr19Ni13Mo3, 00Cr17Ni12Mo2, S317.L, S314.70, S317.L SUS410S, 1.4, 06Cr13, S11306, 0Cr13, S42000, SUS420J1, 1.4021, SUS420J2, 1,4028, S43020, 430F, SUS430F, 1,4104, , , 301, 302, 303, 305, 309, 310, 316, 317, 321, 347, 403, 402, 403, 405, 4, 4, 4, 4, 5 07, 304/304L, 304DQ , 304H, 309S, 310S, 316/316L, 316Ti, 317L, 410S, 420J1, 420J2, 430F, 254Smo, 1,4529, HC276, 800, 600, 602, 800, 602, 801 0, 630, XM19, C4, S30815 , S31254, 174PH, F51, F60, F53, S32760, 253MA, HC2000, 800H, 926, GH2132, GH4169, GH3030, GH3039, GH4151, N7Br600, N33400, N33400 N08810 |

| ASTM B111 / ASME SB111 | Standaard spesifikasie vir koper en koperlegering naatlose kondensorbuise en ferrule | |

| ASTM B161 / ASME SB161 | Standaardspesifikasie vir Nikkel Naatlose Pyp en Tube | |

| ASTM B163 / ASME SB163 | Standaardspesifikasie vir naatlose nikkel- en nikkellegeringskondensor- en hittewisselaarbuise | |

| ASTM B165 / ASME SB165 | Standaardspesifikasie vir nikkel-koperlegering (UNS N04400)* Naatlose pyp en buis | |

| ASTM B167 / ASME SB167 | Standaardspesifikasie vir nikkel-chroom-ysterlegerings, nikkel-chroom-kobalt-molibdeenlegering (UNS N06617), en nikkel-yster-chroom-wolframlegering (UNS N06674) naatlose pyp en buis | |

| ASTM B395 / ASME SB395 | Standaardspesifikasie vir U-Bend Naatlose Koper- en Koperlegeringshittewisselaar en Kondensorbuise | |

| ASTM B407 | Standaardspesifikasie vir nikkel-yster-chroomlegering naatlose pyp en buis | |

| ASTM B423 / ASME SB423 | Standaardspesifikasie vir Nikkel-Chroom-Molibdeen-Columbium Allooie (UNS N06625 en UNS N06852) en Nikkel-Chroom-Molibdeen-Silicon Alloy (UNS N06219) pyp en buis | |

| ASTM B444 / ASME SB444 | Standaardspesifikasie vir Nikkel-Chroom-Molibdeen-Columbium Allooie (UNS N06625 en UNS N06852) en Nikkel-Chroom-Molibdeen-Silicon Alloy (UNS N06219) pyp en buis | |

| ASTM B622 / ASME SB622 | Standaardspesifikasie vir naatlose pyp en buis van nikkel en nikkel-kobaltlegering | |

| ASTM B668 / ASME SB668 | Standaardspesifikasie vir UNS N08028 en N08029 Naatlose pyp en buis | |

| ASTM B677 / ASME SB677 | Standaardspesifikasie vir UNS N08925, UNS N08354 en UNS N08926 Naatlose pyp en buis | |

| ASME SB690 / ASME SB690 | Standaardspesifikasie vir yster-nikkel-chroom-molibdeenlegerings (UNS N08366 en UNS N08367) naatlose pyp en buis | |

| ASTM B705 / ASME SB705 | Standaardspesifikasie vir Nikkellegering (UNS N06625, N06219 en N08825) gelaste pyp | |

| ASTM B729 / ASME SB729 | Standaardspesifikasie vir naatlose UNS N08020, UNS N08026 en UNS N08024 nikkellegeringspyp en -buis | |

| ASTM B829 / ASME SB829 | Standaardspesifikasie vir algemene vereistes vir nikkel- en nikkellegerings naatlose pyp en buis |

Chemiese samestelling:

| Graad | Chemiese samestelling | ||||||||

| C | Si maks | Mn maks | P | S | Ni | Cr | Mo | Ti | |

| 200 | 0,15 | 0,35 | 0,35 | 0,010 | 99 min | ||||

| 201 | 0,02 | 0,35 | 0,35 | 0,010 | 99 min | ||||

| 400 | 0.30 | 0,50 | 2.00 | 0,024 | 63 min | ||||

| 600 | 0,15 | 0,50 | 1.00 | 0,015 | 72 min | 14 – 17 | |||

| 601 | 0,10 | 0,50 | 1.00 | 0,015 | 58 – 63 | 21 – 25 | |||

| 625 | 0,10 | 0,50 | 0,50 | 0,015 | 0,015 | 58 min | 20 – 23 | 8 – 10 | 0,40 maksimum |

| 800 | 0,10 | 1.00 | 1,50 | 0,03 | 0,015 | 30 – 35 | 19 – 23 | 0,15 0,60 | |

| 800H | 0,05 0,10 | 1.00 | 1,50 | 0,015 | 30 – 35 | 19 – 23 | 0,15 0,60 | ||

| 825 | 0,05 | 0,50 | 1.00 | 0,03 | 38 – 46 | 19,5 23,5 | 2.5 3.5 | 0,6 1,2 | |

| 904L | 0,02 | 1.00 | 2.00 | 0,030 | 0,015 | 24 – 26 | 19 23 | 4 5 | |

Nikkellegering Fisiese Eienskappe

| LEGERING | NIKKEL-LEGERING DIGTHEID | TERMIESE GELEIDINGSVERMOË | TERMIESE LINEÊRE, UITBREIDINGSKOEF., (20-95 °C) | ELEKTRIESE WEERSTAND, BY 20°C |

| G/CM³ | W/MK | 10-6/K | ΜΩ-CM | |

| NI 200/201 | 8,89 | 70,20 | 13.3 | 9 |

| NI 205/205 LC | 8,89 | 75,00 | 13.3 | 8.9 |