Sehemu za viwango vya Titanium

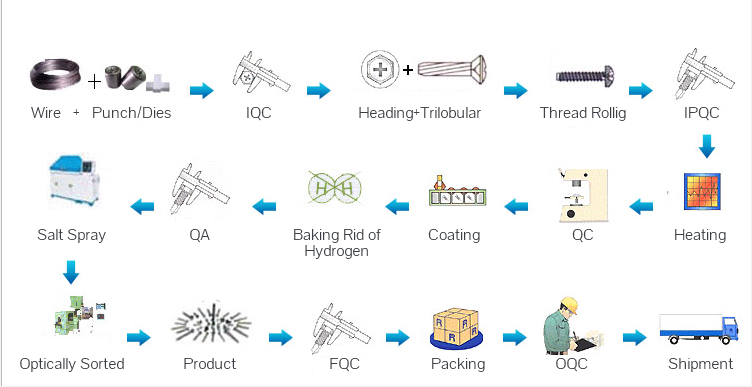

Uzalishaji wa DIN, ANSI/AMSE, ISO, JIS na viwango vingine na viambatanisho vya titanium visivyo na viwango vya kawaida.Kawaida hujumuisha bolts, screws, karanga, washers, pete ya kubaki, na vipande mbalimbali vya umbo maalum.Kwanza, tutafanya matibabu ya joto, upimaji wa muundo wa kemikali, upimaji wa mali ya mitambo ya baa za titani, sahani za titani na vifaa vingine vya msingi.Baada ya mchakato wa kunyoosha, kusawazisha na polishing, kata kwa ukubwa unaofaa.Na kisha endelea kugeuza, kukanyaga moto, skrubu ya kukandamiza, matibabu ya joto, kung'arisha, kusafisha, kukagua na mfululizo wa taratibu, hatimaye kuzalisha viungio vya ubora wa juu vya titani.Tuna vifaa vya juu vya uzalishaji ambavyo vilihakikisha bidhaa zetu kufikia bora katika kila kiungo cha uzalishaji.

Kampuni yetu ina hesabu nyingi za viunga vya titanium, ambazo zinaweza kukidhi kiasi kidogo cha maagizo na wateja hao kwa mahitaji ya haraka ya uwasilishaji.Wakati huo huo, sisi pia hutoa bidhaa zisizo za kawaida kulingana na michoro zinazotolewa na wateja.

Maombi

Petroli, madini, kemikali, elektroniki, dawa, uhandisi wa baharini, sehemu za magari, sehemu za pikipiki, sehemu za baiskeli, vifaa vya yacht, vifaa vya kuishi kwa nje, bidhaa za michezo na nyanja zingine.

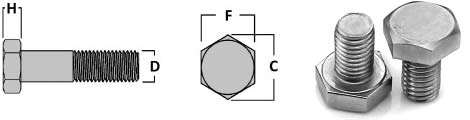

Bolt ya titani

| Bidhaa | Bolt ya aloi ya Titanium na Titanium |

| Ukubwa | Kipenyo: M1.6-M30, Urefu: 10mm-300mm (0.39″-11.8″) |

| Nyenzo | Gr.1, Gr.2, Gr.5, Gr.7 n.k |

| Kawaida | DIN912, DIN6912, DIN933, DIN931 nk |

Titanium hex nut

| Bidhaa | Titanium na alloy nut |

| Ukubwa | M8-M 80 x 6 |

| Nyenzo | Gr1, Gr2, Gr5, Gr7, Ti6Al4V ELI, nk |

| Kawaida | DIN, ISO, JIS, nk. |

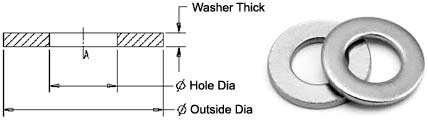

Twasher wa itanium

| Bidhaa | Washer wa aloi ya Titanium na Titanium |

| Ukubwa | OD: 5mm-200mm (0.20″-7.87″), Kitambulisho: 1mm-100mm (0.04″-3.94″), Unene: 0.1mm-30mm (0.004″-1.18″) |

| Nyenzo | Gr.2, Gr.5 n.k |

| Kawaida | DIN125 na kadhalika |

Screw ya Titanium

| Bidhaa | Screw ya aloi ya Titanium na Titanium |

| Ukubwa | M1 hadi M42, Urefu: 10mm-300mm (0.39″-11.8″) |

| Nyenzo | Gr1, Gr.2, Gr.5, Gr.7, Gr.12 n.k |

| Kawaida | DIN912, DIN933, DIN84, DIN85, DIN963, DIN7991, DIN6912, DIN931, ISO7380, nk. |

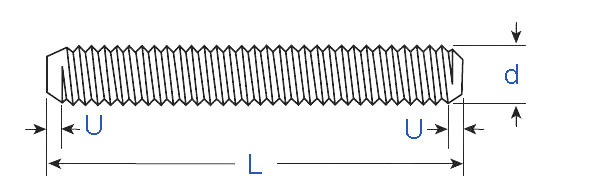

Stud yenye nyuzi za Titanium

| Bidhaa | Aloi ya Titanium na Aloi ya Titanium yenye nyuzi |

| Ukubwa | Kipenyo: M1.6-M30, Urefu: 10mm-300mm (0.39″-11.8″) |

| Nyenzo | Gr.1, Gr.2, Gr.5, Gr.7, Gr.23 n.k |

| Kawaida | DIN912, DIN933, DIN7991, DIN7984, DIN6921, ISO 7380, JIS, BS n.k. |

Vipimo vya Titanium Hex Bolts

| Kipenyo cha Heavy Bolt | D | F | C | H | |||||

| Kipenyo cha Mwili | Upana Katika Flats | Upana Katika Pembe | Urefu | ||||||

| Max | Msingi | Max | Dak | Max | Dak | Msingi | Max | Dak | |

| 1/2 | 0.515 | 7/8 | 0.875 | 0.850 | 1.010 | 0.969 | 11/32 | 0.364 | 0.302 |

| 5/8 | 0.642 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 27/64 | 0.444 | 0.378 |

| 3/4 | 0.768 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 1/2 | 0.524 | 0.455 |

| 7/8 | 0.895 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 37/64 | 0.604 | 0.531 |

| 1 | 1.022 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 43/64 | 0.700 | 0.591 |

| 1-1/8 | 1.149 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 3/4 | 0.780 | 0.658 |

| 1-1/4 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 27/32 | 0.876 | 0.749 |

| 1-3/8 | 1.404 | 2-3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 29/32 | 0.940 | 0.810 |

| 1-1/2 | 1.531 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1 | 1.036 | 0.902 |

| 1-3/4 | 1.785 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-5/32 | 1.196 | 1.054 |

| 2 | 2.039 | 3-1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1-11/32 | 1.388 | 1.175 |

| 2-1/4 | 2.305 | 3-1/2 | 3.500 | 3.388 | 4.041 | 3.862 | 1-1/2 | 1.548 | 1.327 |

| 2-1/2 | 2.559 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 1-21/32 | 1.708 | 1.479 |

Vipimo vya Hex Nuts

| ISO Titanium Hex Nut NB | Katika Pembe | Unene MAX | Unene MIN | MAX Katika Flats | MIN Katika Flats |

| M 8 | 14.38 | 6.8 | 6.44 | 13 | 12.73 |

| M 10 | 17.77 | 8.4 | 8.04 | 16 | 15.73 |

| M 12 | 20.03 | 10.8 | 10.37 | 18 | 17.73 |

| M 14 | 23.35 | 12.8 | 12.1 | 21 | 20.67 |

| M 16 | 26.75 | 14.8 | 14.1 | 24 | 23.67 |

| M 18 | 29.56 | 15.8 | 15.1 | 27 | 26.16 |

| M 20 | 32.95 | 18 | 16.9 | 30 | 29.16 |

| M 22 | 37.29 | 19.4 | 18.1 | 34 | 33 |

| M 24 | 39.55 | 21.5 | 20.2 | 36 | 35 |

| M 27 | 45.2 | 23.8 | 22.5 | 41 | 40 |

| M 30 | 50.85 | 26.6 | 24.3 | 46 | 45 |

| M 33 | 55.37 | 28.7 | 27.4 | 50 | 49 |

| M 36 | 60.79 | 31 | 29.4 | 55 | 53.8 |

| M 39 | 66.44 | 33.4 | 31.8 | 60 | 58.8 |

| M 42 | 71.3 | 34 | 32.4 | 65 | 63.1 |

| M 45 | 76.95 | 36 | 34.4 | 70 | 68.1 |

| M 48 | 82.6 | 38 | 39.4 | 75 | 73.1 |

| M 52 | 88.25 | 42 | 40.4 | 80 | 78.1 |

| M 56 | 93.56 | 45 | 43.4 | 85 | 82.8 |

| M 60 | 99.21 | 48 | 46.4 | 90 | 87.8 |

| M 64 | 104.86 | 51 | 49.1 | 95 | 92.8 |

| M 68 | 110.51 | 54 | 52.1 | 100 | 97.8 |

| M 72 x 6 | 116.16 | 58 | 56.1 | 105 | 102.8 |

| M 76 x 6 | 121.81 | 61 | 59.1 | 110 | 107.8 |

| M 80 x 6 | 127.46 | 64 | 62.1 | 115 | 112.8 |

Vipimo vya Titanium Flat Washer

| Ukubwa wa Bolt ya Ti Aloi | USS | SAE | ||||

| OD (katika.) | Kitambulisho (katika.) | Unene | OD (katika.) | Kitambulisho (katika.) | Unene | |

| 1/8 (#6) | - | - | - | 0.375 | 0.156 | .036/.065 |

| 5/32 (#8) | - | - | - | 0.438 | 0.188 | .036/.065 |

| 3/16 (#10) | 0.560 | 0.250 | .036/.065 | 0.500 | 0.220 | .036/.065 |

| 7/32 (#12) | - | - | - | 0.562 | 0.250 | .051/.080 |

| 1/4 (#14) | 0.734 | 0.312 | .051/.080 | 0.625 | 0.281 | .051/.080 |

| 5/16 | 0.875 | 0.375 | .064/.104 | 0.688 | 0.344 | .051/.080 |

| 3/8 | 1,000 | 0.438 | .064/.104 | 0.812 | 0.406 | .051/.080 |

| 7/16 | 1.250 | 0.500 | .064/.104 | 0.922 | 0.469 | .051/.080 |

| 1/2 | 1.375 | 0.562 | .086/.132 | 1.062 | 0.531 | .074/.121 |

| 9/16 | 1.469 | 0.625 | .086/.132 | 1.156 | 0.594 | .074/.121 |

| 5/8 | 1.750 | 0.688 | .108/.160 | 1.312 | 0.656 | .074/.121 |

| 3/4 | 2,000 | 0.812 | .122/.177 | 1.469 | 0.812 | .108/.160 |

| 7/8 | 2.250 | 0.938 | .136/.192 | 1.750 | 0.938 | .108/.160 |

| 1 | 2.500 | 1.062 | .136/.192 | 2,000 | 1.062 | .108/.160 |

| 1 1/8 | 2.750 | 1.250 | .136/.192 | 2.250 | 1.250 | .108/.160 |

| 1 1/4 | 3,000 | 1.375 | .136/.192 | 2.500 | 1.375 | .136/.192 |

| 1 3/8 | 3.250 | 1.500 | .153/.213 | 2.750 | 1.500 | .136/.213 |

| 1 1/2 | 3.500 | 1.625 | .153/.213 | 3,000 | 1.625 | .153/.213 |

| 1 5/8 | 3.750 | 1.750 | .153/.213 | - | - | - |

| 1 3/4 | 4,000 | 1.875 | .153/.213 | - | - | - |

| 1 7/8 | 4.250 | 2,000 | .153/.213 | - | - | - |

| 2 | 4.500 | 2.125 | .153/.213 | - | - | - |

| 2 1/4 | 4.750 | 2.375 | .193/.248 | - | - | - |

| 2 1/2 | 5,000 | 2.625 | .210/.280 | - | - | - |

| 2 3/4 | 5.250 | 2.875 | .228/.310 | - | - | - |

| 3 | 5.500 | 3.125 | .249/.327 | - | - | - |

Vipimo vya Parafujo ya Kichwa cha Soketi

| Ti Aloi Parafujo Nom.Lamu ya Uzi wa Ukubwa | Mwili | Kichwa | Kichwa | Chamfer | Hexagon | Spline | Ufunguo | Mpito | |||

| Max | Dak | Max | Dak | Max | Dak | Max | Nom. | Nom. | Dak | Max | |

| M1.6 × 0.35 | 1.60 | 1.46 | 3.00 | 2.87 | 1.60 | 1.52 | 0.16 | 1.5 | 1.829 | 0.80 | 2.0 |

| M2 × 0.4 | 2.00 | 1.86 | 3.80 | 3.65 | 2.00 | 1.91 | 0.20 | 1.5 | 1.829 | 1.00 | 2.6 |

| M2.5 × 0.45 | 2.50 | 2.36 | 4.50 | 4.33 | 2.50 | 2.40 | 0.25 | 2.0 | 2.438 | 1.25 | 3.1 |

| M3 × 0.5 | 3.00 | 2.86 | 5.50 | 5.32 | 3.00 | 2.89 | 0.30 | 2.5 | 2.819 | 1.50 | 3.6 |

| M4 × 0.7 | 4.00 | 3.82 | 7.00 | 6.80 | 4.00 | 3.88 | 0.40 | 3.0 | 3.378 | 2.00 | 4.7 |

| M5 × 0.8 | 5.00 | 4.82 | 8.50 | 8.27 | 5.00 | 4.86 | 0.50 | 4.0 | 4.648 | 2.50 | 5.7 |

| M6 × 1 | 6.00 | 5.82 | 10.00 | 9.74 | 6.00 | 5.85 | 0.60 | 5.0 | 5.486 | 3.00 | 6.8 |

| M8 × 1.25 | 8.00 | 7.78 | 13.00 | 12.70 | 8.00 | 7.83 | 0.80 | 6.0 | 7.391 | 4.00 | 9.2 |

| M10 × 1.5 | 10.00 | 9.78 | 16.00 | 15.67 | 10.00 | 9.81 | 1.00 | 8.0 | … | 5.00 | 11.2 |

| M12 × 1.75 | 12.00 | 11.73 | 18.00 | 17.63 | 12.00 | 11.79 | 1.20 | 10.0 | … | 6.00 | 14.2 |

| M14 × 2b | 14.00 | 13.73 | 21.00 | 20.60 | 14.00 | 13.77 | 1.40 | 12.0 | … | 7.00 | 16.2 |

| M16 × 2 | 16.00 | 15.73 | 24.00 | 23.58 | 16.00 | 15.76 | 1.60 | 14.0 | … | 8.00 | 18.2 |

| M20 × 2.5 | 20.00 | 19.67 | 30.00 | 29.53 | 20.00 | 19.73 | 2.00 | 17.0 | … | 10.00 | 22.4 |

| M24 × 3 | 24.00 | 23.67 | 36.00 | 35.48 | 24.00 | 23.70 | 2.40 | 19.0 | … | 12.00 | 26.4 |

| M30 × 3.5 | 30.00 | 29.67 | 45.00 | 44.42 | 30.00 | 29.67 | 3.00 | 22.0 | … | 15.00 | 33.4 |

| M36 × 4 | 36.00 | 35.61 | 54.00 | 53.37 | 36.00 | 35.64 | 3.60 | 27.0 | … | 18.00 | 39.4 |

| M42 × 4.5 | 42.00 | 41.61 | 63.00 | 62.31 | 42.00 | 41.61 | 4.20 | 32.0 | … | 21.00 | 45.6 |

| M48 × 5 | 48.00 | 47.61 | 72.00 | 71.27 | 48.00 | 47.58 | 4.80 | 36.0 | … | 24.00 | |

Stud yenye nyuzi za Titanium

| ANSI /ASMEB 18.31.2 Fimbo-Kitengo cha Threaded:inch | ||||

| d | lami | |||

| UNC | UNF | 8UN | ||

| 1/4 | 0.25 | 20 | 28 | / |

| 5/16 | 0.3125 | 18 | 24 | / |

| 3/8 | 0.375 | 18 | 24 | / |

| 7/16 | 0.4375 | 14 | 20 | / |

| 1/2 | 0.5 | 13 | 20 | / |

| 9/16 | 0.5625 | 12 | 18 | / |

| 5/8 | 0.625 | 11 | 18 | / |

| 3/4 | 0.75 | 10 | 16 | / |

| 7/8 | 0.875 | 9 | 14 | / |

| 1 | 1 | 8 | 12 | 8 |

| 1-1/8 | 1.125 | 7 | 12 | 8 |

| 1-1/4 | 1.25 | 7 | 12 | 8 |

| 1-3/8 | 1.375 | 6 | 12 | 8 |

| Kitengo: inchi | ||||

| d | lami | |||

| UNC | UNF | 8UN | ||

| 1-1/2 | 1.5 | 6 | 12 | 8 |

| 1-5/8 | 1.625 | / | / | 8 |

| 1-3/7 | 1.75 | 5 | / | 8 |

| 1-7/8 | 1.875 | / | / | 8 |

| 2 | 2 | 4-1/2 | / | 8 |

| 2-1/4 | 2.25 | 4-1/2 | / | 8 |

| 2-1/2 | 2.5 | 4 | / | 8 |

| 2-3/4 | 2.75 | 4 | / | 8 |

| 3 | 3 | 4 | / | 8 |

| 3-1/4 | 3.25 | 4 | / | 8 |

| 3-1/2 | 3.5 | 4 | / | 8 |

| 3-3/4 | 3.75 | 4 | / | 8 |

| 4 | 4 | 4 | / | 8 |

| L | 1/2<L≤2-1/2 | 2-1/2<L≤4 | 4<L≤8 | 8<L≤16 | 16<L |

| Ustahimilivu wa urefu wa stud | ±0.04 | ±0.08 | ±0.10 | ±0.12 | ±0.18 |

| Kawaida | Maelezo | Kawaida | Maelezo |

| DIN 84 | Slotted cheese kichwa screws | DIN 439 | Jam karanga |

| DIN 125 | Washers wa gorofa | DIN 963 | skrubu za kichwa tambarare zilizozama |

| DIN 127 | Vioo vya kufuli vya spring | DIN 965 | screws za mashine ya kichwa gorofa ya Phillips |

| DIN 912 | skrubu za kofia ya kichwa cha tundu la hex | DIN 985 | Funga karanga (na kichocheo kisicho cha metali) |

| DIN913/DIN 914/DIN915/DIN916 | Weka screws | DIN 1665/DIN 6921 | Bolts za hex na flange |

| DIN 931 | skrubu za kofia ya kichwa cha hex (sehemu ya uzi) | DIN 6912/DIN 7984 | Soketi ya tundu la hexagons nyembamba ya kofia ya kichwa |

| DIN 933 | skrubu za kofia ya kichwa cha hex (uzi kamili) | DIN 7991 | Kichwa cha gorofa kinakabiliwa na skrubu za kofia ya tundu |

| DIN 934 | Karanga za hex | DIN 9021 | Washer wa gorofa |

Madaraja ya Nyenzo Sawa kwa Vifunga vya Titanium

| KIWANGO | WERKSTOFF NR. | UNS |

| Titanium daraja la 2 | 3.7035 | R50400 |

| Titanium daraja la 5 | 3.7165 | R56400 |

Tabia za Mitambo za Vifunga vya Titanium

| Daraja | Nguvu ya Mkazo (dakika) | Nguvu ya Mavuno 0.2%. | Kurefusha kwa inchi 2 au 50mm % (dakika) | ||

| KSI | MPa | KSI | MPa | ||

| Gr.1 | 35 | 240 | 20 - 45 | 138 - 310 | 24 |

| Gr.2 | 50 | 345 | 40 - 65 | 275 - 450 | 20 |

| Gr.3 | 65 | 450 | 55 - 80 | 380 - 550 | 18 |

| Gr.4 | 80 | 550 | ≥70 | ≥483 | 15 |

| Gr.5 | 138 | 950 | ≥128 | ≥880 | 14 |

| Gr.7 | 50 | 345 | ≥40 | ≥275 | 24 |

| Gr.9 | 125 | 860 | ≥105 | ≥725 | 10 |

| Gr.12 | 70 | 483 | ≥50 | ≥345 | 18 |

| Gr.23 | 125 | 860 | ≥115 | ≥790 | 15 |

| Kipengele | Msongamano | Kiwango cha kuyeyuka | Nguvu ya Mkazo | Nguvu ya Mavuno (0.2% Offset) | Kurefusha |

| Titanium Gr.2 | 4.5 g/cm3 | 1665 °C (3030 °F) | Psi - 49900 , MPa - 344 | Psi - 39900 , MPa - 275 | 20% |

| Titanium Gr.5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi - 138000 , MPa - 950 | Psi - 128000 , MPa - 880 | 14% |

Muundo wa Nyenzo za Kemikali za Vifunga vya Titanium

| Daraja | Fe% | C% | N% | H% | O% | Al% | V% | Mo% | Ni% | Pd% | Ti |

| Gr1 | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 | - | - | - | - | - | BAL. |

| Gr2 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | - | - | - | BAL. |

| Gr3 | 0.3 | 0.08 | 0.05 | 0.015 | 0.35 | - | - | - | - | - | BAL. |

| Gr4 | 0.3 | 0.08 | 0.05 | 0.015 | 0.40 | - | - | - | - | - | BAL |

| Gr5 | 0.25 | 0.08 | 0.03 | 0.015 | 0.02 | 5.5 - 6.75 | 3.5 - 4.5 | - | - | - | BAL |

| Gr7 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | - | - | 0.12 - 0.25 | BAL. |

| Gr9 | 0.25 | 0.08 | 0.03 | 0.015 | 0.15 | 2.5 - 3.3 | 2.0 - 3.0 | - | - | - | BAL. |

| Gr12 | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | - | - | 0.2 - 0.4 | 0.6 - 0.9 | - | BAL. |

| Gr23 | 0.3 | 0.08 | 0.03 | 0.015 | 0.13 | 5.5 - 6.75 | - | - | - | - | B |