Bomba la aloi ya nikeli

| Nyenzo | Monel/Inconel/Hastelloy/Duplex Steel/PH Steel/Nickel Aloy |

| Umbo | Round, Forging,Pete,Coil,Flange,Disc,Foil,Spherical,Ribbon,Square,Bar,Bomba,Laha |

| Daraja | N02200,N02201,N04400、N06600、N06601、N06625、N06690、N08810、N08825、N08020、N08028、N08031、N010276、50106、N0102、30106、N010276、50106、N01020、N08028、N08031、N010276、5010)N0106) 036 GH5188 Inconel706 Inconel600 InconelX-750 Inconel718 Inconel625 Inconel 617 Inconel601 Inconel690 NS143 NS131 NS113 NS112,Incoloy800H, NO8810 NS111 NS336 NS142 Incoloy825 NS355 Hastelloy C-4 Monel K500,N05500 |

| Vipimo | Nyingine: 253Ma,254SMo,654SMo,F50(UNS S32100)F60,F61,F65,1J22,N4,N6 n.k. |

| Aloi:Aloi 625,Aloi 20/28/31 | |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g; | |

| Hastelloy B / UNS N10001,Hastelloy B-2 / UNS N10665 / DIN W. Nr.2.4617,Hastelloy C,Hastelloy C-4 / UNS N06455 / DIN W. Nr.2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr.2.4602,Hastelloy C-276 / UNS N10276 / DIN W. Nr.2.4819,Hastelloy X / UNS N06002 / DIN W. Nr.2.4665 | |

| Haynes: Haynes 230/556/188; | |

| Msururu wa Inconel:Inconel 600/601/602CA/617/625/690/713/718/738/X-750,Seremala 20; | |

| Inconel 718 / UNS N07718 /N04400/N06600/N08825/DIN W. Nr.2.4668,Inconel 601 / UNS N06601 / DIN W. Nr.2.4851, Inconel 625 / UNS N06625 / DIN W. Nr.2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr.2.4669,Inconel 600 / UNS N06600 / DIN W. Nr.2.4816 | |

| Ikoloi:Ikoloi 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel:Monel 400/K500/R405 | |

| Nitroniki: Nitroniki 40/50/60; | |

| Nimonic: Nimonic 75/80A/90/A263 ; | |

| Waya: 0.01-10mm Ukanda: 0.05 * 5.0-5.0 * 250mm Upau: φ4-50mm; Urefu 2000-5000mm Bomba: φ6-273mm;δ1-30mm; Urefu 1000-8000mm Laha: δ 0.8-36mm; Upana 650-2000mm; Urefu 800-4500mm | |

| Bidhaa Sifa | 1. Kulingana na mchakato wa maandalizi inaweza kugawanywa katika superalloys deformation, aloi za aloi na madini ya unga ya juu. 2. Kulingana na hali ya kuimarisha, kuna aina ya kuimarisha suluhisho, mvua aina ya kuimarisha, aina ya kuimarisha utawanyiko wa oksidi na aina ya uimarishaji wa nyuzi, nk. |

| Kawaida | GB,AISI,ASTM,DIN,EN,SUS,UNS n.k |

| Ukaguzi | ISO, SGS, BV, na kadhalika. |

| Maombi | Vipengele vya halijoto ya juu kama vile blade za turbine, vani za mwongozo, diski za turbine, shinikizo la juu diski za compressor, utengenezaji wa mashine na vyumba vya mwako vinavyotumika katika utengenezaji wa mitambo ya anga, majini na gesi ya viwandani |

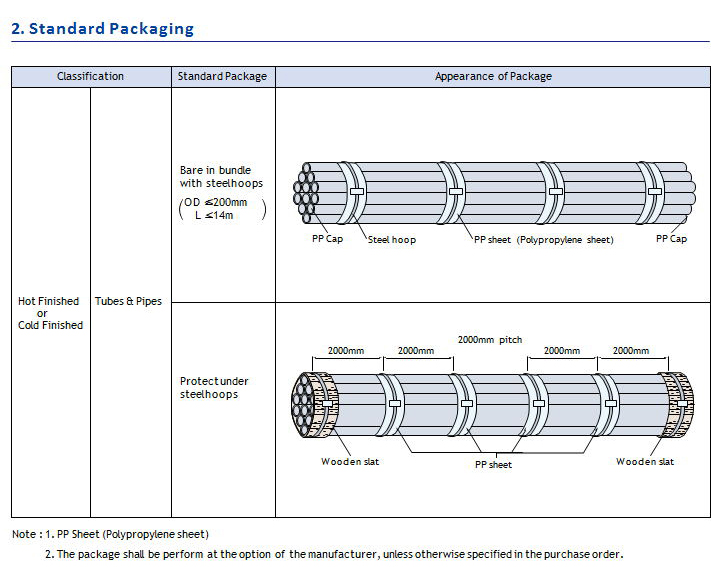

| Ufungaji | 1. kesi zilizojaa katika kesi za mbao 2. ufungaji wa karatasi 3. kufunga plastiki 4. ufungaji wa povu Ufungaji kulingana na mahitaji ya mteja au bidhaa |

| Uwasilishaji | Siku 7-25 au kulingana na bidhaa |

| Malipo | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Kulingana na malipo ya mahitaji ya mteja kwa maagizo ya nje ya mtandao. |

| UKUBWA WA HIFADHI | |||||||||||||

| SIZE | NICKEL | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | SIZE | |

| 1/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 1.65 mm | |

| 0.010 | X | X | .25mm | ||||||||||

| 0.020 | X | .51mm | |||||||||||

| 1/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 3.18mm | |

| 0.010 | X | 0.25 | |||||||||||

| 0.012 | X | 3.05mm | |||||||||||

| 0.016 | X | .31mm | |||||||||||

| 0.020 | X | X | X | .51mm | |||||||||

| 0.028 | X | X | X | X | .71mm | ||||||||

| 0.035 | X | X | X | X | .89mm | ||||||||

| 3/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 4.76 mm | |

| 0.010 | X | .25mm | |||||||||||

| 0.016 | X | X | .31mm | ||||||||||

| 0.020 | X | .51mm | |||||||||||

| 0.028 | X | X | X | .71mm | |||||||||

| 0.035 | X | X | X | X | X | X | .89mm | ||||||

| 0.049 | X | X | X | 1.24 mm | |||||||||

| 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 6.35 mm | |

| 0.016 | X | .31mm | |||||||||||

| 0.020 | X | X | X | .51mm | |||||||||

| 0.028 | X | X | X | X | X | .71mm | |||||||

| 0.035 | X | X | X | X | X | X | X | X | .89mm | ||||

| 0.049 | X | X | X | X | X | X | X | X | 1.24 mm | ||||

| 0.065 | X | X | X | X | X | X | X | 1.65 mm | |||||

| 0.083 | X | 2.11 mm | |||||||||||

| 5/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 7.94 mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | 1.24 mm | |||||||||||

| 0.065 | X | X | X | 1.65 mm | |||||||||

| 3/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 9.53 mm | |

| 0.020 | X | .51mm | |||||||||||

| 0.028 | X | X | X | X | .71mm | ||||||||

| 0.035 | X | X | X | X | X | X | X | X | .89mm | ||||

| 0.049 | X | X | X | X | X | X | X | 1.24 mm | |||||

| 0.065 | X | X | X | X | X | X | X | 1.65 mm | |||||

| 0.083 | X | X | 2.11 mm | ||||||||||

| 7/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 11.1mm | |

| 0.035 | X | .89mm | |||||||||||

| 0.065 | X | 1.65 mm | |||||||||||

| 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 12.7 mm | |

| 0.028 | X | X | X | X | .71mm | ||||||||

| 0.035 | X | X | X | X | X | X | X | X | X | .89mm | |||

| 0.049 | X | X | X | X | X | X | X | 1.24 mm | |||||

| 0.058 | X | X | 1.47 mm | ||||||||||

| 0.065 | X | X | X | X | X | X | X | X | 1.65 mm | ||||

| 0.083 | X | X | X | 2.11 mm | |||||||||

| 0.095 | X | X | 2.41 mm | ||||||||||

| 0.109 | X | 2.77 mm | |||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 9/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 14.3 mm | |

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | X | X | X | 1.24 mm | ||||||||

| 0.065 | X | X | X | 1.65 mm | |||||||||

| 0.083 | X | 2.11 mm | |||||||||||

| 5/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 15.9mm | |

| 0.035 | X | X | X | X | X | .89mm | |||||||

| 0.049 | X | X | X | X | X | X | X | 1.24 mm | |||||

| 0.065 | X | X | X | X | X | X | 1.65 mm | ||||||

| 0.083 | X | X | 2.11 mm | ||||||||||

| 0.095 | X | X | 2.41 mm | ||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 3/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 19.1mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | X | X | X | X | X | .89mm | |||||

| 0.049 | X | X | X | X | X | X | X | 1.24 mm | |||||

| 0.065 | X | X | X | X | X | X | X | X | X | X | 1.65 mm | ||

| 0.083 | X | X | X | X | X | X | X | 2.11 mm | |||||

| 0.095 | X | X | 2.41 mm | ||||||||||

| 0.109 | X | X | X | X | 2.77 mm | ||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | X | 3.18 | ||||||||||

| 7/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 22.2mm | |

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | X | X | 1.24 mm | |||||||||

| 0.065 | X | X | X | X | 1.65 mm | ||||||||

| 0.083 | X | X | 2.11 mm | ||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 1″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 25.4mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | X | X | X | X | .89mm | ||||||

| 0.049 | X | X | X | X | X | X | X | 1.24 mm | |||||

| 0.065 | X | X | X | X | X | X | X | X | 1.65 mm | ||||

| 0.083 | X | X | X | X | X | X | X | 2.11 mm | |||||

| 0.095 | X | X | 2.41 mm | ||||||||||

| 0.109 | X | X | X | X | 2.77 mm | ||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | 3.18 | |||||||||||

| 0.134 | X | X | |||||||||||

| 1 1/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 28.6 mm | |

| 0.049 | X | ||||||||||||

| 1 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 31.8mm | |

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | 1.24 mm | |||||||||||

| 0.065 | X | X | X | X | X | X | 1.65 mm | ||||||

| 0.083 | X | X | X | X | 2.11 mm | ||||||||

| 0.095 | X | 2.41 mm | |||||||||||

| 0.109 | X | 2.77 mm | |||||||||||

| 0.120 | X | X | 3.05mm | ||||||||||

| 0.125 | X | 3.18 | |||||||||||

| 1 1/2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 38.1mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | .89mm | ||||||||||

| 0.049 | X | X | X | 1.24 mm | |||||||||

| 0.065 | X | X | X | X | X | X | 1.65 mm | ||||||

| 0.083 | X | X | X | 2.11 mm | |||||||||

| 0.095 | X | X | 2.41 mm | ||||||||||

| 0.109 | X | X | X | 2.77 mm | |||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | 3.18 | |||||||||||

| 1 5/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 41.3 mm | |

| 0.065 | X | 1.65 mm | |||||||||||

| 0.083 | X | 2.11 mm | |||||||||||

| 1 3/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 44.5mm | |

| 0.065 | X | X | X | 1.65 mm | |||||||||

| 1 7/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 47.6 mm | |

| 0.083 | X | 2.11 mm | |||||||||||

| 2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 50.8mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | .89mm | ||||||||||

| 0.049 | X | X | 1.24 mm | ||||||||||

| 0.065 | X | X | X | X | X | 1.65 mm | |||||||

| 0.083 | X | X | X | X | 2.11 mm | ||||||||

| 0.095 | X | 2.41 mm | |||||||||||

| 0.109 | X | X | 2.77 mm | ||||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | X | 3.18 | ||||||||||

| 2 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 57.2mm | |

| 0.035 | X | .89mm | |||||||||||

| 0.049 | X | 1.24 mm | |||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 2 1/2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 63.5 mm | |

| 0.065 | X | X | X | X | 1.65 mm | ||||||||

| 0.083 | X | X | 2.11 mm | ||||||||||

| 0.109 | X | 2.77 mm | |||||||||||

| 0.120 | X | X | 3.05mm | ||||||||||

| 3″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 76.2 mm | |

| 0.065 | X | X | X | X | 1.65 mm | ||||||||

| 0.083 | X | X | X | 2.11 mm | |||||||||

| 0.120 | X | X | 3.05mm | ||||||||||

| 0.125 | X | 3.18 | |||||||||||

| 0.250 | X | 6.35 | |||||||||||

| 3 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 82.6 mm | |

| 0.125 | X | 3.18 | |||||||||||

| 3 1/2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 88.9mm | |

| 0.375 | 9.53 mm | ||||||||||||

| Kawaida | – ASTM A270,ASTM A249,ASTM A511,ASTM A778 ,ASTM A312,ASTM A358,ASTM A409,ASTM A213,ASTM A790,ASTM A268,ASTM A269,ASTM A554,ASTM B333,4,7BASTM67BASTM67 B675, ASTM B676, ASTM B690,ASTM A928,ASME B36.19,ASME B36.10– EN10216-5,EN10217-7,DIN 17456,DIN 17458 – JIS G3463,JIS G3119,JIS G3446,JIS G3218,JIS G3258,JIS G3448,JIS H4631– DEP 31,DEP 40,DEP 20,DEP 32,DNV-OS-F101 |

| Saizi ya Ukubwa | OD:NPS 1/8 -80, BN 6 – 2000, 10.3 – 2030 , Kapilari ya AlaoWT:Sch5s-Sch160s, SchXXH, STD,XS,XXSUrefu:Kubinafsisha |

| Daraja | S32750, 00Cr25Ni7Mo4N, 022Cr25Ni7Mo4N, 1.441, 1.4307/1.4301/304L/3, S30408/S30403, 0Cr18Ni9DQ, 1.4941, 3048/07, 3048/3048 4948, 06Cr23Ni13, S30908, SUS309S, SUS310S, 1.4845, S31008, S31008S, 06Cr25Ni20, 0Cr25Ni20, 1.4401/1.4404/316/31, S31635, SUS316Ti, 1.4571, 1.4571/316Ti, S31703, 022Cr19Ni13Mo3, 00Cr17Ni12Mo2, S3141403, S314140, S3141403, S3141403. 410S, 1.4, 06Cr13, S11306, 0Cr13, S42000, SUS420J1, 1.4021, SUS420J2, 1.4028. 07, 304/304L, 304DQ . 0, 630, XM19, C4, S30815 . 08810 |

| ASTM B111 / ASME SB111 | Uainisho wa Kawaida wa Mirija ya Kondesha ya Shaba na Aloi isiyo na mshono na Hifadhi ya Ferrule | |

| ASTM B161 / ASME SB161 | Viainisho vya Kawaida vya Bomba na Tube ya Nickel Isiyofumwa | |

| ASTM B163 / ASME SB163 | Vipimo vya Kawaida vya Nikeli Isiyofumwa na Aloi ya Nikeli na Mirija ya Kubadilisha joto | |

| ASTM B165 / ASME SB165 | Viainisho vya Kawaida vya Aloi ya Nickel-Copper (UNS N04400)* Bomba na Mirija Isiyofumwa | |

| ASTM B167 / ASME SB167 | Vipimo vya Kawaida vya Aloi za Nikeli-Chromium-Iron, Aloi ya Nickel-Chromium-Cobalt-Molybdenum (UNS N06617), na Aloi ya Nickel-Iron-Chromium-Tungsten (UNS N06674) Bomba na Mirija isiyo na Mfuko | |

| ASTM B395 / ASME SB395 | Uainisho Wastani wa Kibadilishaji Joto cha Shaba ya U-Bend isiyo na Mfumo na Mirija ya Condenser | |

| ASTM B407 | Uainisho Wastani wa Bomba na Mirija ya Nikeli-Iron-Chromium | |

| ASTM B423 / ASME SB423 | Vipimo vya Kawaida vya Aloi za Nickel-Chromium-Molybdenum-Columbium (UNS N06625 na UNS N06852) na Aloi ya Nickel-Chromium-Molybdenum-Silicon (UNS N06219) Bomba na Tube | |

| ASTM B444 / ASME SB444 | Vipimo vya Kawaida vya Aloi za Nickel-Chromium-Molybdenum-Columbium (UNS N06625 na UNS N06852) na Aloi ya Nickel-Chromium-Molybdenum-Silicon (UNS N06219) Bomba na Tube | |

| ASTM B622 / ASME SB622 | Viainisho vya Kawaida vya Nikeli Isiyofumwa na Bomba na Aloi ya Nickel-Cobalt | |

| ASTM B668 / ASME SB668 | Vipimo vya Kawaida vya UNS N08028 na N08029 Bomba na Mrija usio na Mfuko | |

| ASTM B677 / ASME SB677 | Viainisho vya Kawaida vya UNS N08925, UNS N08354, na UNS N08926 Bomba na Mirija Isiyofumwa | |

| ASME SB690 / ASME SB690 | Vipimo vya Kawaida vya Aloi za Iron-Nickel-Chromium-Molybdenum (UNS N08366 na UNS N08367) Bomba na Mirija Isiyo na Mifuko | |

| ASTM B705 / ASME SB705 | Vipimo vya Kawaida vya Nikeli-Aloi (UNS N06625, N06219 na N08825) Bomba Lililochomezwa | |

| ASTM B729 / ASME SB729 | Vipimo vya Kawaida vya UNS N08020 isiyo na mshono, UNS N08026, na bomba la aloi ya nikeli ya UNS N08024 na Tube | |

| ASTM B829 / ASME SB829 | Viainisho vya Kawaida vya Mahitaji ya Jumla ya Aloi za Nickel na Nickel Bomba na Mirija Isiyofumwa |

Muundo wa kemikali:

| Daraja | Muundo wa Kemikali | ||||||||

| C | Si max | Mn max | P | S | Ni | Cr | Mo | Ti | |

| 200 | 0.15 | 0.35 | 0.35 | 0.010 | Dakika 99 | ||||

| 201 | 0.02 | 0.35 | 0.35 | 0.010 | Dakika 99 | ||||

| 400 | 0.30 | 0.50 | 2.00 | 0.024 | Dakika 63 | ||||

| 600 | 0.15 | 0.50 | 1.00 | 0.015 | Dakika 72 | 14 - 17 | |||

| 601 | 0.10 | 0.50 | 1.00 | 0.015 | 58 - 63 | 21 - 25 | |||

| 625 | 0.10 | 0.50 | 0.50 | 0.015 | 0.015 | Dakika 58 | 20 - 23 | 8 - 10 | 0.40 juu |

| 800 | 0.10 | 1.00 | 1.50 | 0.03 | 0.015 | 30 - 35 | 19 - 23 | 0.15 0.60 | |

| 800H | 0.05 0.10 | 1.00 | 1.50 | 0.015 | 30 - 35 | 19 - 23 | 0.15 0.60 | ||

| 825 | 0.05 | 0.50 | 1.00 | 0.03 | 38 - 46 | 19.5 23.5 | 2.5 3.5 | 0.6 1.2 | |

| 904L | 0.02 | 1.00 | 2.00 | 0.030 | 0.015 | 24 - 26 | 19 23 | 4 5 | |

Sifa za Kimwili za Aloi ya Nickel

| ALLOY | MFUMO WA Aloi ya NICKEL | THERMAL , MWENENDO | THERMAL LINEAR , COEFF YA UPANUZI., (20-95 °C) | UKUMBUFU WA UMEME , KWA 20°C |

| G/CM³ | W/MK | 10-6/K | ΜΩ-CM | |

| NI 200/201 | 8.89 | 70.20 | 13.3 | 9 |

| NI 205/205 LC | 8.89 | 75.00 | 13.3 | 8.9 |