Paipa uamea le kaponi

Pipa Uamea Su'esu'e e faia mai se u'amea lapotopoto mafiafia'pili'lea e faavevela ma tulei pe toso i luga o se fomu seia oo ina fau le uamea i se paipa omo.Ona fa'auma loa lea o le paipa e le'i fa'aogaina i le fua ma le mafiafia o puipui i lapopo'a mai le 1/8 inisi i le 32 inisi OD.Uamea uamea (Carbon Steel Seamless Pipes / Tubes) O le uamea uamea o se fa'amea e aofia ai le u'amea ma le kaponi.O le pasene o le carbon i totonu o le uamea e afaina ai le maaa, malosi o le elasticity ma le ductility o le carbon steel.Seamless carbon uamea paipa po o uamea malo ingot ua faia i le capillary faagaau e ala i le pu, ona e ala i le vevela-taai, taai malulu po o le valaau malulu ua faia.Seamless carbon uamea paipa i Saina alamanuia uamea ei ai se tulaga taua.Seamless carbon uamea mea paipa o se paipa lapotopoto, embryos masini tipi paipa e alu i le tipiina e uiga i le 1 mita le umi avanoa, ma auina atu e conveyor fusi ogaumu faamafanafana.Billet e fafagaina i totonu o le ogaumu faʻamafanafana, o le vevela e tusa ma le 1200 tikeri Celsius.Ole suauu ole hydrogen po'o le acetylene.O le pulea o le vevela o le ogaumu o le mataupu autu lea.Sa sau le paipa lapotopoto e tu'i le masini e ala i le mamafa o le ea.E masani lava o le tu'i masani e tapered lola perforation masini, o le punch maualuga gaosiga lelei, tulaga lelei o oloa, faalautele pu lapoa, e mafai ona ofuina ituaiga u'amea.Perforation, faagaau lapotopoto ua i luga o le tolu-roll koluse taʻavale, taʻavale poʻo extrusion.Oomi ese le faagaau pe a uma ona fua.Fa'afuaina e ala i pu e vili i totonu o le pili e fai ai se paipa.O le ta'amilosaga o paipa i le mill sizing e iloa ai le umi o le vili vili.A maeʻa le paipa e ala i le sizing i totonu o le olo malulu, faʻamafanafanaina e ala i le suauʻu vai, uʻamea pe a maeʻa le malulu, e tatau ona faʻasaʻo.A maeʻa le fusi uʻamea lafo e faʻasaʻo masini suʻega uʻamea (poʻo suʻega mamafa) mo suʻega i totonu.Afai e ta'e le paipa i totonu, o le a iloa ai le pulu ma isi fa'afitauli.A maeʻa le paipa ae faʻapea foʻi e ala i le filifilia lelei o le tusi lesona.Tulaga uamea, le faʻaogaina o numera vali vali, faʻamatalaga, numera o le gaosiga.E ala i se crane i totonu o le faleteuoloa.

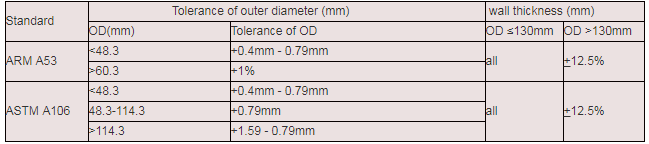

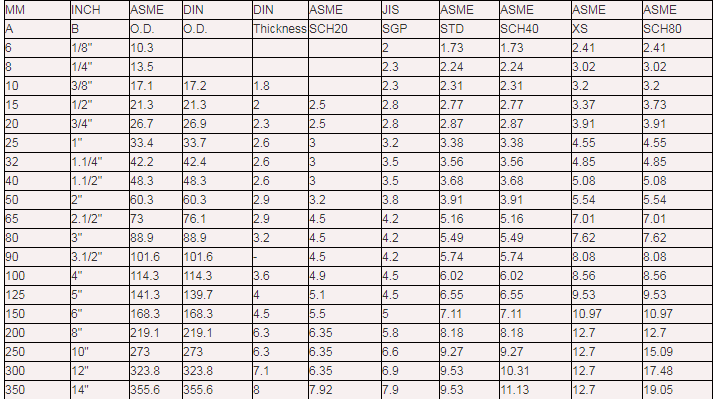

O le mafiafia o le puipui o le paipa le lelei

Fa'apalepale i fafo o le lautele ma le mafiafia o puipui

| Tulaga | Fa'amatalaga |

| ASTM A179/A179M | Su'ega malulu toso maualalo u'amea su'isu'i vevela ma condenser paipa. |

| API 5L | Laina paipa. |

| ASTM A53M | U'ele'ele & Zinc U'umea Uila ma Seamless Paipa. |

| ASTM A106M | Pipa uamea kaponi seamless mo auaunaga vevela maualuga. |

| ASTM A105M | u'amea uamea kabonu mo talosaga paipa. |

| ASTM A234M | Fa'apipi'i paipa o uamea kaponi ga'o ma uamea u'amea mo auaunaga feololo ma maualuga. |

| ASTM 3799 | Fa'apipi'i paipa u'amea, fa'avili ma socket weldability mo pisinisi suau'u. |

| AS 1163 | Vaega o'o'o uamea faufale |

| AS 1074 | Uamea paipa ma tubula mo auaunaga masani |

| BS13872 | Faagaau u'amea faavalevalea ma fa'amau ma fa'apa'au |

| Tulaga | Ituaiga paipa | Vasega | Vasega |

| API SPEC 5L ISO 3183 | SMLS | PLS1 | L245B, L290 X42, L320 X46 , L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| PLS2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q , L485Q X70Q

| ||

| PLS2 Siosiomaga Oona | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS

| ||

| WELD | PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| PLS2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, | ||

| Tulaga | Vasega |

| ASTM A 53 M | A , B |

| ASTM A 106M | A, B, C |

| JIS G 3454 | STPG 370, STPG 410 |

| JIS G 3455 | STPG370, STPG410, STPG480 |

| JIS G 3456 | STPG370, STPG410, STPG480 |

Vasega: Tulaga Vailaau Fa'asaina (%):

| Tulaga | Vasega | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTMA 53M | A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | - | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| ASTM A 106M | A | ≤0.25 | ≥0.10 | 0.27-0.93 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| JIS G 3454 | STPG 370 | ≤0.25 | ≤0.35 | 0.30-0.90 | ≤0.040 | ≤0.040 | - | - | - | - | - |

| STPG 410 | ≤0.30 | ≤0.35 | 0.30-1.00 | ≤0.040 | ≤0.040 | - | - | - | - | - | |

| JIS G 3455 | STS 370 | ≤0.25 | 0.10-0.35 | 0.30-1.10 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STS 410 | ≤0.30 | 0.10-0.35 | 0.30-1.40 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STS 480 | ≤0.33 | 0.10-0.35 | 0.30-1.50 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| JIS G 3456 | STPT 370 | ≤0.25 | 0.10-0.35 | 0.30-0.90 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STPT 410 | ≤0.30 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STPT 480 | ≤0.33 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - |

Fa'asagaga i luga ole paipa u'amea: Ina ia fa'aleleia le ola tautua o le paipa suauu, e masani lava ona fa'atinoina togafitiga i luga e fa'afaigofie ai le tu'ufa'atasiga mautu o paipa u'amea ma le coating anticorrosive.Metotia fa'agaoioiga masani e: fa'amamāina, fa'atosina meafaigaluega, piki, fana blasting derusting fa vaega.1 cleaningGrease, pefu, lubricant, mea faʻalaʻau faʻapipiʻi i luga o le paipa uʻamea, e masani ona faʻaaogaina le solvent, emulsion e faʻamamā ai luga. e manaomia auala togafitiga.Meafaigaluega ele removalSteel paipa i luga o le oxide, ele, uʻamea slag, e mafai ona faaaoga uaea pulumu uamea e faamama ma polesi luga treatment.Tool derusting e mafai ona vaevaeina i tusi lesona ma le mana, meafaigaluega tusi lesona derusting e mafai ona ausia Sa 2 tulaga, mana. e mafai ona oʻo atu le faʻaleagaina o meafaigaluega i le tulaga Sa3. Afai o loʻo faʻapipiʻi le pito i luga o le paipa uʻamea ma se paʻu oxide malosi, atonu e le mafai ona aveese le ele ma le fesoasoani a meafaigaluega, o lea e manaʻomia ai ona tatou suʻeina isi auala.3 pickling O auala masani pickling e aofia ai le kemisi ma le electrolysis.Ae na'o le vaila'au vaila'au e fa'aaogaina mo le puipuiga o le corrosion pipeline.Chemical pickling e mafai ona ausia se tikeri patino o le mama ma le gaoa i luga o le paipa uamea, lea e faigofie mo laina taula mulimuli. fana (one) pe a uma ona toe gaosia.4 fana fana mo ele aveeseE ala i le malosi maualuga le afi afi le maualuga-saosaoa rotating lau, uʻamea uʻamea, fana uʻamea, vaega, minerale ma isi uaea abrasive i lalo o le gaioiga o le malosi centrifugal i luga o paipa uʻamea i luga o le pulumu ma le tele o le ejection, matua aveese ele, oxides ma palapala i luga o le tasi lima, i le isi itu, paipa uamea i lalo o le gaioiga o le abrasive aʻafiaga ma le malosi o le feteʻenaʻiga, e ausia ai le roughness toniga manaʻomia.Amo le fa auala togafitiga, fana blasting ma derusting o se auala lelei togafitiga mo derusting paipa.E masani lava, fana blasting ma derusting e masani ona faʻaaogaina mo togafitiga pito i totonu o le paipa uʻamea, ma fana fana ma derusting e masani ona faʻaaogaina mo togafitiga pito i fafo o paipa uʻamea.

Sausau vali

Sausau vali

afifiina e le vai