Titan Standarden Deeler

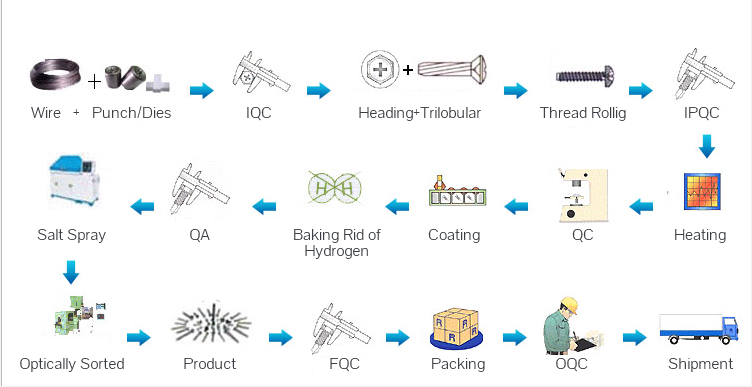

Produktioun vun DIN, ANSI / AMSE, ISO, JIS an aner Standarden an Net-Standard héich-Kraaft Titan fasteners.Normalerweis enthalen Bolzen, Schrauwen, Nëss, Wäschmaschinnen, Haltring a verschidde speziell geformte Stécker.Als éischt wäerte mir d'Hëtztbehandlung, d'chemesch Zesummesetzungstestung, d'mechanesch Eegeschaftentest vun Titanbarren, Titanplacken an aner Basismaterialien maachen.Nom Prozess vun der Ausrichtung, Ausgläichung a Polieren, schneiden an déi entspriechend Gréisst.An da fuert weider fir ze dréinen, waarm Stamping, Kompressiounsschrauwen, Wärmebehandlung, Polieren, Botzen, Inspektioun an eng Rei vu Prozeduren, schliisslech fir déi héichqualitativ Titanbefestigungen ze produzéieren.Mir hunn déi fortgeschratt Produktiounsausrüstung déi eis Produkter gesuergt huet fir dat Bescht an all Produktiounslink z'erreechen.

Eis Gesellschaft huet vill Titan Befestigungsinventar, déi d'global kleng Quantitéit vun Bestellungen an déi Clienten mat dréngend Liwwerfuerderung erfëllen.Zur selwechter Zäit liwwere mir och net-Standardprodukter no Zeechnunge vun de Clienten.

Applikatioun

Pëtrol, Metallurgie, chemesch, elektronesch, pharmazeutesch, Marine Engineering, Autosdeeler, Motorraddeeler, Vëlosdeeler, Yacht Accessoiren, Outdoor Iwwerliewensmaterial, Sportsartikelen an aner Felder.

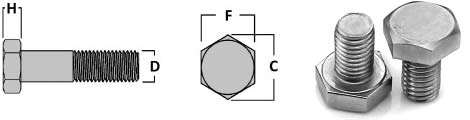

Titan Bolzen

| Produit | Titan an Titan Legierung Bolzen |

| Gréisst | Duerchmiesser: M1.6-M30, Längt: 10mm-300mm (0.39"-11.8") |

| Material | Gr.1, Gr.2, Gr.5, Gr.7 etc |

| Standard | DIN 912, DIN 6912, DIN 933, DIN 931 etc |

Titan Hexemutter

| Produit | Titan an Titan Legierung Mutter |

| Gréisst | M8-M 80 x 6 |

| Material | Gr1, Gr2, Gr5, Gr7, Ti6Al4V ELI, etc |

| Standard | DIN, ISO, JIS, etc. |

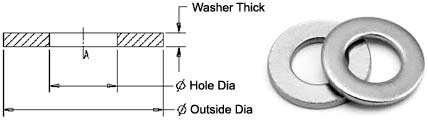

Titanium Wäschmaschinn

| Produit | Titan an Titan Legierung Wäschmaschinn |

| Gréisst | OD: 5mm-200mm (0.20"-7.87"), ID: 1mm-100mm (0.04"-3.94"), deck: 0.1mm-30mm (0.004"-1.18") |

| Material | Gr.2, Gr.5 etc |

| Standard | DIN 125 etc |

Titan Schraube

| Produit | Titan an Titan Legierung Schraube |

| Gréisst | M1 bis M42, Längt: 10mm-300mm (0.39"-11.8") |

| Material | Gr1, Gr.2, Gr.5, Gr.7, Gr.12 etc |

| Standard | DIN 912, DIN 933, DIN 84, DIN 85, DIN 963, DIN 7991, DIN 6912, DIN 931, ISO 7380, etc. |

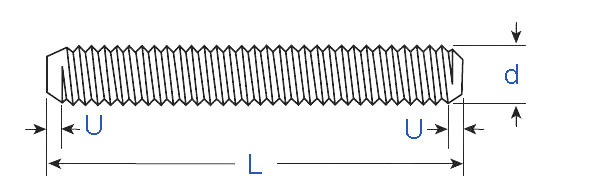

Titan threaded Stud

| Produit | Titan an Titan Legierung threaded Stud |

| Gréisst | Duerchmiesser: M1.6-M30, Längt: 10mm-300mm (0.39"-11.8") |

| Material | Gr.1, Gr.2, Gr.5, Gr.7, Gr.23 etc |

| Standard | DIN912, DIN933, DIN7991, DIN7984, DIN6921, ISO 7380, JIS, BS etc. |

Titan Hex Bolts Dimensiounen

| Heavy Hex Bolt Duerchmiesser | D | F | C | H | |||||

| Kierper Duerchmiesser | Breet iwwer Flats | Breet iwwer Ecker | Héicht | ||||||

| Max | Basis | Max | Min | Max | Min | Basis | Max | Min | |

| 1/2 | 0,515 | 7/8 | 0,875 | 0,850 | 1.010 | 0,969 | 11/32 | 0,364 | 0,302 |

| 5/8 | 0,642 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 27/64 | 0,444 | 0,378 |

| 3/4 | 0,768 | 1-1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 1/2 | 0,524 | 0,455 |

| 7/8 | 0,895 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 37/64 | 0,604 | 0,531 |

| 1 | 1.022 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 43/64 | 0.700 | 0.591 |

| 1-1/8 | 1.149 | 1-13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 3/4 | 0,780 | 0,658 |

| 1-1/4 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 27/32 | 0,876 | 0.749 |

| 1-3/8 | 1.404 | 2-3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 29/32 | 0,940 | 0,810 |

| 1-1/2 | 1.531 | 2-3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1 | 1.036 | 0,902 |

| 1-3/4 | 1.785 | 2-3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1-5/32 | 1.196 | 1.054 |

| 2 | 2.039 | 3-1/8 | 3.125 | 3.025 | 3,608 | 3.449 | 1-11/32 | 1.388 | 1.175 |

| 2-1/4 | 2.305 | 3-1/2 | 3.500 | 3.388 | 4,041 | 3.862 | 1-1/2 | 1.548 | 1.327 |

| 2-1/2 | 2.559 | 3-7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 1-21/32 | 1.708 | 1.479 |

Hex Nëss Dimensiounen

| ISO Titan Hex Nëss NB | Across Corners | MAX Dicke | MIN Dicke | MAX Iwwert Appartementer | MIN iwwer Flats |

| M 8 | 14.38 | 6.8 | 6,44 | 13 | 12.73 |

| M 10 | 17.77 | 8.4 | 8.04 | 16 | 15.73 |

| M 12 | 20.03 | 10.8 | 10.37 | 18 | 17.73 |

| M 14 | 23.35 | 12.8 | 12.1 | 21 | 20.67 |

| M 16 | 26,75 | 14.8 | 14.1 | 24 | 23,67 |

| M 18 | 29,56 | 15.8 | 15.1 | 27 | 26.16 |

| M 20 | 32,95 | 18 | 16.9 | 30 | 29.16 |

| M 22 | 37,29 | 19.4 | 18.1 | 34 | 33 |

| M 24 | 39,55 | 21.5 | 20.2 | 36 | 35 |

| M 27 | 45,2 | 23.8 | 22.5 | 41 | 40 |

| M 30 | 50,85 | 26.6 | 24.3 | 46 | 45 |

| M 33 | 55,37 | 28.7 | 27.4 | 50 | 49 |

| M 36 | 60,79 | 31 | 29.4 | 55 | 53,8 |

| M 39 | 66,44 | 33.4 | 31.8 | 60 | 58,8 |

| M 42 | 71,3 | 34 | 32.4 | 65 | 63,1 |

| M 45 | 76,95 | 36 | 34.4 | 70 | 68,1 |

| M 48 | 82,6 | 38 | 39,4 | 75 | 73,1 |

| M 52 | 88,25 | 42 | 40,4 | 80 | 78,1 |

| M 56 | 93,56 | 45 | 43,4 | 85 | 82,8 |

| M 60 | 99,21 | 48 | 46,4 | 90 | 87,8 |

| M 64 | 104,86 | 51 | 49,1 | 95 | 92,8 |

| M 68 | 110,51 | 54 | 52.1 | 100 | 97,8 |

| m72x6 | 116.16 | 58 | 56,1 | 105 | 102,8 |

| m76x6 | 121,81 | 61 | 59,1 | 110 | 107,8 |

| m80x6 | 127,46 | 64 | 62,1 | 115 | 112,8 |

Titan flaach Washer Dimensiounen

| Ti Legierung Bolt Gréisst | USS | SAE | ||||

| OD (eng.) | ID (eng) | Dicke | OD (eng.) | ID (eng) | Dicke | |

| 1/8 (#6) | - | - | - | 0,375 | 0,156 | .036/.065 |

| 5/32 (#8) | - | - | - | 0,438 | 0.188 | .036/.065 |

| 3/16 (#10) | 0,560 | 0,250 | .036/.065 | 0.500 | 0,220 | .036/.065 |

| 7/32 (#12) | - | - | - | 0,562 | 0,250 | .051/.080 |

| 1/4 (#14) | 0,734 | 0,312 | .051/.080 | 0,625 | 0,281 | .051/.080 |

| 5/16 | 0,875 | 0,375 | .064/.104 | 0,688 | 0,344 | .051/.080 |

| 3/8 | 1.000 | 0,438 | .064/.104 | 0,812 | 0,406 | .051/.080 |

| 7/16 | 1.250 | 0.500 | .064/.104 | 0,922 | 0,469 | .051/.080 |

| 1/2 | 1.375 | 0,562 | .086/.132 | 1.062 | 0,531 | .074/.121 |

| 9/16 | 1.469 | 0,625 | .086/.132 | 1.156 | 0,594 | .074/.121 |

| 5/8 | 1.750 | 0,688 | .108/.160 | 1.312 | 0,656 | .074/.121 |

| 3/4 | 2.000 | 0,812 | .122/.177 | 1.469 | 0,812 | .108/.160 |

| 7/8 | 2.250 | 0,938 | .136/.192 | 1.750 | 0,938 | .108/.160 |

| 1 | 2.500 | 1.062 | .136/.192 | 2.000 | 1.062 | .108/.160 |

| 1 1/8 | 2.750 | 1.250 | .136/.192 | 2.250 | 1.250 | .108/.160 |

| 1 1/4 | 3.000 | 1.375 | .136/.192 | 2.500 | 1.375 | .136/.192 |

| 13/8 | 3.250 | 1.500 | .153/.213 | 2.750 | 1.500 | .136/.213 |

| 1 1/2 | 3.500 | 1.625 | .153/.213 | 3.000 | 1.625 | .153/.213 |

| 15/8 | 3.750 | 1.750 | .153/.213 | - | - | - |

| 1 3/4 | 4.000 | 1.875 | .153/.213 | - | - | - |

| 17/8 | 4.250 | 2.000 | .153/.213 | - | - | - |

| 2 | 4.500 | 2.125 | .153/.213 | - | - | - |

| 2 1/4 | 4.750 | 2.375 | .193/.248 | - | - | - |

| 2 1/2 | 5.000 | 2.625 | .210/.280 | - | - | - |

| 2 3/4 | 5.250 | 2.875 | .228/.310 | - | - | - |

| 3 | 5.500 | 3.125 | .249/.327 | - | - | - |

Socket Head Cap Schrauwen Dimensiounen

| Ti Legierung Schraube Nom.Gréisst Thread Pitch | Kierper | Kapp | Kapp | Chamfer | Hexagon | Spline | Schlëssel | Iwwergank | |||

| Max | Min | Max | Min | Max | Min | Max | Nom. | Nom. | Min | Max | |

| M1,6 × 0,35 | 1,60 | 1.46 | 3.00 | 2,87 | 1,60 | 1.52 | 0.16 | 1.5 | 1.829 | 0,80 | 2.0 |

| M2 × 0,4 | 2.00 | 1,86 | 3,80 | 3,65 | 2.00 | 1.91 | 0.20 | 1.5 | 1.829 | 1.00 | 2.6 |

| M2,5 × 0,45 | 2,50 | 2.36 | 4,50 | 4.33 | 2,50 | 2.40 | 0,25 | 2.0 | 2.438 | 1.25 | 3.1 |

| M3 × 0,5 | 3.00 | 2,86 | 5,50 | 5.32 | 3.00 | 2,89 | 0.30 | 2.5 | 2.819 | 1,50 | 3.6 |

| M4 × 0,7 | 4.00 | 3,82 | 7.00 | 6,80 | 4.00 | 3,88 | 0,40 | 3.0 | 3.378 | 2.00 | 4.7 |

| M5 × 0,8 | 5.00 | 4,82 | 8,50 | 8.27 | 5.00 | 4,86 | 0,50 | 4.0 | 4.648 | 2,50 | 5.7 |

| M6 × 1 | 6.00 | 5,82 | 10.00 | 9,74 | 6.00 | 5,85 | 0,60 | 5.0 | 5.486 | 3.00 | 6.8 |

| M8 × 1,25 | 8.00 | 7.78 | 13.00 Auer | 12.70 | 8.00 | 7.83 | 0,80 | 6.0 | 7.391 | 4.00 | 9.2 |

| M10 × 1,5 | 10.00 | 9,78 | 16.00 Auer | 15.67 | 10.00 | 9,81 | 1.00 | 8.0 | … | 5.00 | 11.2 |

| M12 × 1,75 | 12.00 | 11.73 | 18.00 Auer | 17.63 | 12.00 | 11.79 | 1.20 | 10.0 | … | 6.00 | 14.2 |

| M14 × 2b | 14.00 Auer | 13.73 | 21.00 Auer | 20.60 | 14.00 Auer | 13.77 | 1.40 | 12.0 | … | 7.00 | 16.2 |

| M16 × 2 | 16.00 Auer | 15.73 | 24.00 Auer | 23.58 | 16.00 Auer | 15,76 | 1,60 | 14.0 | … | 8.00 | 18.2 |

| M20 × 2,5 | 20.00 Auer | 19.67 | 30.00 | 29,53 | 20.00 Auer | 19.73 | 2.00 | 17.0 | … | 10.00 | 22.4 |

| M24 × 3 | 24.00 Auer | 23,67 | 36,00 | 35,48 | 24.00 Auer | 23.70 | 2.40 | 19.0 | … | 12.00 | 26.4 |

| M30 × 3,5 | 30.00 | 29,67 | 45,00 | 44,42 | 30.00 | 29,67 | 3.00 | 22.0 | … | 15.00 Auer | 33.4 |

| M36 × 4 | 36,00 | 35,61 | 54,00 | 53,37 | 36,00 | 35,64 | 3,60 | 27.0 | … | 18.00 Auer | 39,4 |

| M42 × 4,5 | 42,00 | 41,61 | 63,00 | 62,31 | 42,00 | 41,61 | 4.20 | 32,0 | … | 21.00 Auer | 45,6 |

| M48 × 5 | 48,00 | 47,61 | 72,00 | 71,27 | 48,00 | 47,58 | 4,80 | 36,0 | … | 24.00 Auer | |

Titan threaded Stud

| ANSI /ASMEB 18.31.2 Threaded Rods-Eenheet: Zoll | ||||

| d | Terrain | |||

| UNC | UNF | 8 UN | ||

| 1/4 | 0,25 | 20 | 28 | / |

| 5/16 | 0,3125 | 18 | 24 | / |

| 3/8 | 0,375 | 18 | 24 | / |

| 7/16 | 0,4375 | 14 | 20 | / |

| 1/2 | 0,5 | 13 | 20 | / |

| 9/16 | 0,5625 | 12 | 18 | / |

| 5/8 | 0,625 | 11 | 18 | / |

| 3/4 | 0,75 | 10 | 16 | / |

| 7/8 | 0,875 | 9 | 14 | / |

| 1 | 1 | 8 | 12 | 8 |

| 1-1/8 | 1.125 | 7 | 12 | 8 |

| 1-1/4 | 1.25 | 7 | 12 | 8 |

| 1-3/8 | 1.375 | 6 | 12 | 8 |

| Eenheet: Zoll | ||||

| d | Terrain | |||

| UNC | UNF | 8 UN | ||

| 1-1/2 | 1.5 | 6 | 12 | 8 |

| 1-5/8 | 1.625 | / | / | 8 |

| 1-3/7 | 1,75 | 5 | / | 8 |

| 1-7/8 | 1.875 | / | / | 8 |

| 2 | 2 | 4-1/2 | / | 8 |

| 2-1/4 | 2.25 | 4-1/2 | / | 8 |

| 2-1/2 | 2.5 | 4 | / | 8 |

| 2-3/4 | 2,75 | 4 | / | 8 |

| 3 | 3 | 4 | / | 8 |

| 3-1/4 | 3.25 | 4 | / | 8 |

| 3-1/2 | 3.5 | 4 | / | 8 |

| 3-3/4 | 3,75 | 4 | / | 8 |

| 4 | 4 | 4 | / | 8 |

| L | 1/2–L≤2-1/2 | 2-1/2 L≤4 | 4.L≤8 | 8. L≤16 | 16 l |

| Befestegt Stud Längt Toleranz | ± 0,04 | ± 0,08 | ± 0,10 | ± 0,12 | ± 0,18 |

| Standard | Beschreiwung | Standard | Beschreiwung |

| DIN 84 | Slotted Kéis Kapp Schrauwen | DIN 439 | Jam Nëss |

| DIN 125 | Flaach Wäschmaschinnen | DIN 963 | Slotted countersunk flaach Kapp Schrauwen |

| DIN 127 | Fréijoer Spär washers | DIN 965 | Phillips flaach Kapp Maschinn Schrauwen |

| DIN 912 | Hex Socket Kapp Cap Schrauwen | DIN 985 | Sperrmutter (mat net-metalleschen Insert) |

| DIN 913/DIN 914/DIN 915/DIN 916 | Stellschrauwen | DIN 1665/DIN 6921 | Hex Bolzen mat Flange |

| DIN 931 | Hexkopfschrauwen (Deelgewiicht) | DIN 6912/DIN 7984 | Hexagon Socket dënn Kapp Cap Schrauwen |

| DIN 933 | Hexkopfschrauwen (voll Fuedem) | DIN 7991 | Flaach Kapp countersunk Socket Cap Schrauwen |

| DIN 934 | Hex Nëss | DIN 9021 | Flaach Wäschmaschinn |

Material gläichwäerteg Qualitéiten Fir Titan Fasteners

| STANDARD | WERKSTOFF NR. | UNS |

| Titan Grad 2 | 3.7035 | R50 400 |

| Titan Grad 5 | 3,7165 | R56400 |

Mechanesch Charakteristiken vun Titan Fasteners

| Grad | Kraaftkraaft (min) | Ausbezuele Kraaft 0,2% Offset | Verlängerung an 2 Zoll oder 50 mm % (min) | ||

| KSI | MPa | KSI | MPa | ||

| Gr.1 | 35 | 240 | 20-45 Uhr | 138-310 | 24 |

| Gr.2 | 50 | 345 | 40-65 | 275-450 | 20 |

| Gr.3 | 65 | 450 | 55-80 | 380-550 | 18 |

| Gr.4 | 80 | 550 | ≥70 | ≥483 | 15 |

| Gr.5 | 138 | 950 | ≥128 | ≥880 | 14 |

| Gr.7 | 50 | 345 | ≥40 | ≥275 | 24 |

| Gr.9 | 125 | 860 | ≥105 | ≥725 | 10 |

| Gr.12 | 70 | 483 | ≥50 | ≥345 | 18 |

| Gr.23 | 125 | 860 | ≥115 | ≥790 | 15 |

| Element | Dicht | Schmëlzpunkt | Tensile Stäerkt | Yield Stäerkt (0,2% Offset) | Verlängerung |

| Titan Gr.2 | 4,5 g/cm3 | 1665 °C (3030 °F) | Psi - 49900, MPa - 344 | Psi - 39900, MPa - 275 | 20 % |

| Titan Gr.5 | 4,43 g/cm3 | 1632 °C (2970 °F) | Psi - 138000, MPa - 950 | Psi - 128000, MPa - 880 | 14 % |

Chemesch Material Zesummesetzung vun Titan Fasteners

| Grad | Fe% | C% | N% | H% | O% | Al% | V% | Mo% | Ni% | Pd% | Ti |

| Gr 1 | 0.2 | 0,08 | 0,03 | 0,015 | 0.18 | - | - | - | - | - | BAL. |

| Gr 2 | 0.3 | 0,08 | 0,03 | 0,015 | 0,25 | - | - | - | - | - | BAL. |

| gr3 | 0.3 | 0,08 | 0,05 | 0,015 | 0,35 | - | - | - | - | - | BAL. |

| gr4 | 0.3 | 0,08 | 0,05 | 0,015 | 0,40 | - | - | - | - | - | BAL |

| gr5 | 0,25 | 0,08 | 0,03 | 0,015 | 0,02 | 5,5 - 6,75 | 3,5-4,5 | - | - | - | BAL |

| gr7 | 0.3 | 0,08 | 0,03 | 0,015 | 0,25 | - | - | - | - | 0,12 - 0,25 | BAL. |

| gr9 | 0,25 | 0,08 | 0,03 | 0,015 | 0.15 | 2,5 - 3,3 | 2,0 - 3,0 | - | - | - | BAL. |

| Gr 12 | 0.3 | 0,08 | 0,03 | 0,015 | 0,25 | - | - | 0,2 - 0,4 | 0,6 - 0,9 | - | BAL. |

| Gr23 | 0.3 | 0,08 | 0,03 | 0,015 | 0.13 | 5,5 - 6,75 | - | - | - | - | B |