Nickel Legierung Päif

| Material | Monel / Inconel / Hastelloy / Duplex Stol / PH Stol / Néckel Legierung |

| Form | Ronn, Schmiede, Ring, Coil, Flange, Disc, Folie, Kugelgestalt, Ribbon, Quadrat, Bar, Päif, Blat |

| Grad | N02200, N02201, N04400, N06600, N06601, N06625, N06690, N08810, N08825, N08020, N08020, N0802801, N0802801, N0802801, N0802801 665, N06022, N06030, GH3030, GH3036 GH5188 Inconel706 Inconel600 InconelX-750 Inconel718 Inconel625 Inconel 617 Inconel601 Inconel690 NS1NS1 NS31 NS112, Incoloy800H, NO8810 NS111 NS336 NS142 Incoloy825 NS355 Hastelloy C-4 Monel K500, N05500 |

| Spezifizéierung | Anerer: 253Ma, 254 SMo, 654 SMo, F50 (UNS S32100) F60, F61, F65, 1J22, N4, N6 etc |

| Legierung:Legierung 625, Legierung 20/28/31 | |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g; | |

| Hastelloy B / UNS N10001,Hastelloy B-2 / UNS N10665 / DIN W. Nr.2.4617,Hastelloy C,Hastelloy C-4 / UNS N06455 / DIN W. Nr.2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr.2.4602,Hastelloy C-276 / UNS N10276 / DIN W. Nr.2.4819,Hastelloy X / UNS N06002 / DIN W. Nr.2,4665 | |

| Haynes: Haynes 230/556/188; | |

| Inconel Serie:Inconel 600/601/602CA/617/625/690/713/718/738/X-750,Schräiner 20; | |

| Inconel 718 / UNS N07718 /N04400/N06600/N08825/DIN W. Nr.2.4668,Inconel 601 / UNS N06601 / DIN W. Nr.2,4851, Inconel 625 / UNS N06625 / DIN W. Nr.2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr.2.4669,Inconel 600 / UNS N06600 / DIN W. Nr.2.4816 | |

| Inkoloy:Inkoloy 800/8 00h/800HT/825/925/926; | |

| GH: GH2132, GH3030, GH3039, GH3128, GH4180, GH3044 | |

| Monel:Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60; | |

| Nimonic: Nimonic 75/80A/90/A263 ; | |

| Drot: 0,01-10mm Sträif: 0,05 * 5,0-5,0 * 250mm Bar: φ4-50mm; Längt 2000-5000mm Pipe: φ6-273mm;δ1-30mm;Längt 1000-8000mm Blat: δ 0,8-36 mm; Breet 650-2000 mm; Längt 800-4500 mm | |

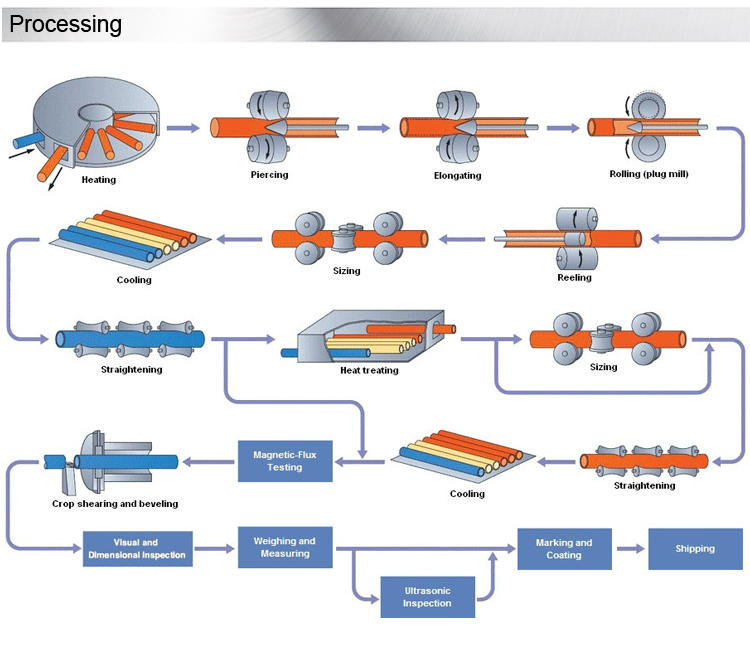

| Produit Charakteristiken | 1. No der Virbereedung Prozess kann an Deformatioun superalloys ënnerdeelt ginn, Guss Superlegierungen a Pulvermetallurgie Superlegierungen. 2. Laut dem Verstäerkungsmodus sinn et zolidd Léisungsverstäerkungstyp, Nidderschlag Verstäerkungstyp, Oxiddispersiounsverstäerkungstyp a Faserverstäerkungstyp, asw. |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Inspektioun | ISO, SGS, BV, etc. |

| Applikatioun | Héich-Temperatur Komponente wéi Turbine Blades, Führerschäiner, Turbinscheiwen, Héichdrock Kompressor Scheiwen, Maschinn Fabrikatioun a Verbrennungskammer, déi an der Fabrikatioun vu Loftfaart, Marine an Industriegasturbinen benotzt ginn |

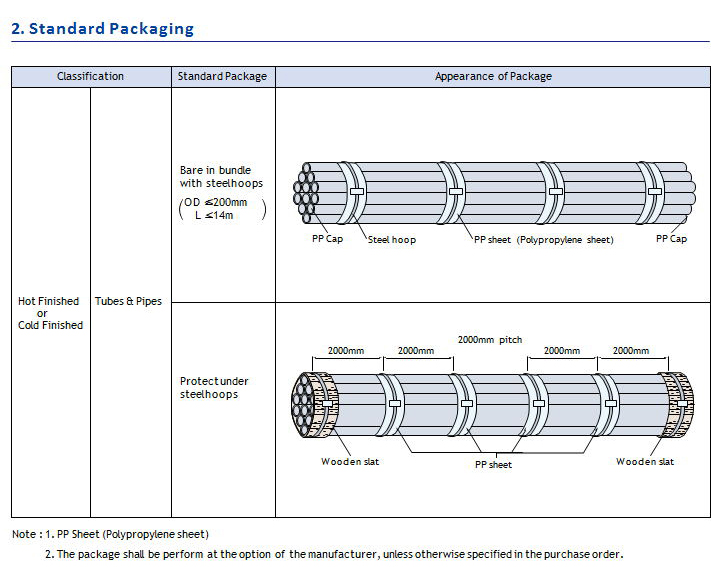

| Verpakung | 1. Fäll an hëlzent Fäll gepackt 2. Pabeier Verpakung 3. Plastiksverpackung 4. Schaum Verpakung Verpakung no Client Ufuerderunge oder Produiten |

| Liwwerung | 7-25 Deeg oder no dem Produkt |

| Bezuelen | L/C, D/A, D/P, T/T, Western Union, MoneyGram, No Client Ufuerderunge Bezuelen fir offline Bestellungen. |

| STOCKED GRÉISST | |||||||||||||

| GRÉISST | NICKEL | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | GRÉISST | |

| 1/16" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 1,65 mm | |

| 0,010 | X | X | .25 mm | ||||||||||

| 0,020 | X | .51 mm | |||||||||||

| 1/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 3,18 mm | |

| 0,010 | X | 0,25 | |||||||||||

| 0.012 | X | 3,05 mm | |||||||||||

| 0,016 | X | .31 mm | |||||||||||

| 0,020 | X | X | X | .51 mm | |||||||||

| 0,028 | X | X | X | X | .71 mm | ||||||||

| 0,035 | X | X | X | X | .89mm | ||||||||

| 3/16" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 4,76 mm | |

| 0,010 | X | .25 mm | |||||||||||

| 0,016 | X | X | .31 mm | ||||||||||

| 0,020 | X | .51 mm | |||||||||||

| 0,028 | X | X | X | .71 mm | |||||||||

| 0,035 | X | X | X | X | X | X | .89mm | ||||||

| 0.049 | X | X | X | 1,24 mm | |||||||||

| 1/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 6,35 mm | |

| 0,016 | X | .31 mm | |||||||||||

| 0,020 | X | X | X | .51 mm | |||||||||

| 0,028 | X | X | X | X | X | .71 mm | |||||||

| 0,035 | X | X | X | X | X | X | X | X | .89mm | ||||

| 0.049 | X | X | X | X | X | X | X | X | 1,24 mm | ||||

| 0,065 | X | X | X | X | X | X | X | 1,65 mm | |||||

| 0,083 | X | 2,11 mm | |||||||||||

| 5/16" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 7,94 mm | |

| 0,028 | X | .71 mm | |||||||||||

| 0,035 | X | X | X | .89mm | |||||||||

| 0.049 | X | 1,24 mm | |||||||||||

| 0,065 | X | X | X | 1,65 mm | |||||||||

| 3/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 9,53 mm ép | |

| 0,020 | X | .51 mm | |||||||||||

| 0,028 | X | X | X | X | .71 mm | ||||||||

| 0,035 | X | X | X | X | X | X | X | X | .89mm | ||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | X | 1,65 mm | |||||

| 0,083 | X | X | 2,11 mm | ||||||||||

| 7/16" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 11,1 mm | |

| 0,035 | X | .89mm | |||||||||||

| 0,065 | X | 1,65 mm | |||||||||||

| 1/2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 12,7 mm ép | |

| 0,028 | X | X | X | X | .71 mm | ||||||||

| 0,035 | X | X | X | X | X | X | X | X | X | .89mm | |||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,058 | X | X | 1,47 mm | ||||||||||

| 0,065 | X | X | X | X | X | X | X | X | 1,65 mm | ||||

| 0,083 | X | X | X | 2,11 mm | |||||||||

| 0,095 | X | X | 2,41 mm ép | ||||||||||

| 0.109 | X | 2,77 mm ép | |||||||||||

| 0,120 | X | 3,05 mm | |||||||||||

| 9/16" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 14,3 mm ép | |

| 0,035 | X | X | X | .89mm | |||||||||

| 0.049 | X | X | X | X | 1,24 mm | ||||||||

| 0,065 | X | X | X | 1,65 mm | |||||||||

| 0,083 | X | 2,11 mm | |||||||||||

| 5/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 15,9 mm | |

| 0,035 | X | X | X | X | X | .89mm | |||||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | 1,65 mm | ||||||

| 0,083 | X | X | 2,11 mm | ||||||||||

| 0,095 | X | X | 2,41 mm ép | ||||||||||

| 0,120 | X | 3,05 mm | |||||||||||

| 3/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 19,1 mm ép | |

| 0,028 | X | .71 mm | |||||||||||

| 0,035 | X | X | X | X | X | X | X | .89mm | |||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | X | X | X | X | 1,65 mm | ||

| 0,083 | X | X | X | X | X | X | X | 2,11 mm | |||||

| 0,095 | X | X | 2,41 mm ép | ||||||||||

| 0.109 | X | X | X | X | 2,77 mm ép | ||||||||

| 0,120 | X | X | X | 3,05 mm | |||||||||

| 0,125 | X | X | 3.18 | ||||||||||

| 7/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 22,2 mm ép | |

| 0,035 | X | X | X | .89mm | |||||||||

| 0.049 | X | X | X | 1,24 mm | |||||||||

| 0,065 | X | X | X | X | 1,65 mm | ||||||||

| 0,083 | X | X | 2,11 mm | ||||||||||

| 0,120 | X | 3,05 mm | |||||||||||

| 1" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 25,4 mm ép | |

| 0,028 | X | .71 mm | |||||||||||

| 0,035 | X | X | X | X | X | X | .89mm | ||||||

| 0.049 | X | X | X | X | X | X | X | 1,24 mm | |||||

| 0,065 | X | X | X | X | X | X | X | X | 1,65 mm | ||||

| 0,083 | X | X | X | X | X | X | X | 2,11 mm | |||||

| 0,095 | X | X | 2,41 mm ép | ||||||||||

| 0.109 | X | X | X | X | 2,77 mm ép | ||||||||

| 0,120 | X | X | X | 3,05 mm | |||||||||

| 0,125 | X | 3.18 | |||||||||||

| 0.134 | X | X | |||||||||||

| 1 1/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 28,6 mm | |

| 0.049 | X | ||||||||||||

| 1 1/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 31,8 mm | |

| 0,035 | X | X | X | .89mm | |||||||||

| 0.049 | X | 1,24 mm | |||||||||||

| 0,065 | X | X | X | X | X | X | 1,65 mm | ||||||

| 0,083 | X | X | X | X | 2,11 mm | ||||||||

| 0,095 | X | 2,41 mm ép | |||||||||||

| 0.109 | X | 2,77 mm ép | |||||||||||

| 0,120 | X | X | 3,05 mm | ||||||||||

| 0,125 | X | 3.18 | |||||||||||

| 1 1/2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 38,1 mm ép | |

| 0,028 | X | .71 mm | |||||||||||

| 0,035 | X | X | .89mm | ||||||||||

| 0.049 | X | X | X | 1,24 mm | |||||||||

| 0,065 | X | X | X | X | X | X | 1,65 mm | ||||||

| 0,083 | X | X | X | 2,11 mm | |||||||||

| 0,095 | X | X | 2,41 mm ép | ||||||||||

| 0.109 | X | X | X | 2,77 mm ép | |||||||||

| 0,120 | X | X | X | 3,05 mm | |||||||||

| 0,125 | X | 3.18 | |||||||||||

| 1 5/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 41,3 mm ép | |

| 0,065 | X | 1,65 mm | |||||||||||

| 0,083 | X | 2,11 mm | |||||||||||

| 1 3/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 44,5 mm ép | |

| 0,065 | X | X | X | 1,65 mm | |||||||||

| 17/8" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 47,6 mm ép | |

| 0,083 | X | 2,11 mm | |||||||||||

| 2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 50,8 mm ép | |

| 0,028 | X | .71 mm | |||||||||||

| 0,035 | X | X | .89mm | ||||||||||

| 0.049 | X | X | 1,24 mm | ||||||||||

| 0,065 | X | X | X | X | X | 1,65 mm | |||||||

| 0,083 | X | X | X | X | 2,11 mm | ||||||||

| 0,095 | X | 2,41 mm ép | |||||||||||

| 0.109 | X | X | 2,77 mm ép | ||||||||||

| 0,120 | X | X | X | 3,05 mm | |||||||||

| 0,125 | X | X | 3.18 | ||||||||||

| 2 1/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 57,2 mm | |

| 0,035 | X | .89mm | |||||||||||

| 0.049 | X | 1,24 mm | |||||||||||

| 0,120 | X | 3,05 mm | |||||||||||

| 2 1/2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 63,5 mm ép | |

| 0,065 | X | X | X | X | 1,65 mm | ||||||||

| 0,083 | X | X | 2,11 mm | ||||||||||

| 0.109 | X | 2,77 mm ép | |||||||||||

| 0,120 | X | X | 3,05 mm | ||||||||||

| 3" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 76,2 mm ép | |

| 0,065 | X | X | X | X | 1,65 mm | ||||||||

| 0,083 | X | X | X | 2,11 mm | |||||||||

| 0,120 | X | X | 3,05 mm | ||||||||||

| 0,125 | X | 3.18 | |||||||||||

| 0,250 | X | 6,35 | |||||||||||

| 3 1/4" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 82,6 mm | |

| 0,125 | X | 3.18 | |||||||||||

| 3 1/2" | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 9 04l | 88,9 mm | |

| 0,375 | 9,53 mm ép | ||||||||||||

| Standard | – ASTM A270,ASTM A249,ASTM A511,ASTM A778,ASTM A312,ASTM A358,ASTM A409,ASTM A213,ASTM A790,ASTM A268,ASTM A269,ASTM A554,ASTM B338,ASTM B673,ASTM B7,ASTM B7 B675, ASTM B676, ASTM B690, ASTM A928, ASME B36.19, ASME B36.10– EN10216-5, EN10217-7, DIN 17456, DIN 17458 – JIS G3463, JIS G3119, JIS G3446, JIS G3218, JIS G3258, JIS G3448, JIS H4631 – DEP 31, DEP 40, DEP 20, DEP 32, DNV-OS-F101 |

| Gréisst Range | OD:NPS 1/8 -80, BN 6 – 2000, 10.3 – 2030 , Alao capilaryWT:Sch5s-Sch160s, SchXXH, STD,XS,XXSLängt:Personnalisatioun |

| Grad | S32750, 00Cr25Ni7Mo4N, 022Cr25Ni7Mo4N, 1.441, 1.4307/1.4301/304L/3, S30408/S30403, 0Cr18Ni9DQ, 0Cr18Ni9DQ, 1.409r, S3049, S30408 , 1.4948, 06Cr23Ni13, S30908, SUS309S, SUS310S, 1.4845, S31008, S31008S, 06Cr25Ni20, 0Cr25Ni20, 1.4401/1.4404/316/31, S31635, SUS316Ti, 1.4571, 1.4571/316Ti, S31703, 022Cr19Ni13Mo3, 00Cr17Ni12Mo2, S31703, S31703, S31703, S31703 SUS410S, 1.4, 06Cr13, S11306, 0Cr13, S42000, SUS420J1, 1.4021, SUS420J2, 1.4028, S43020, 430F, SUS430F, 1.4104, , 301, 302, 303, 305, 309, 310, 316, 317, 321, 347, 403, 425, 4, 4, 4, 4, 4, 4, 4, 4, 4, 07, 304/304L, 304DQ , 304H, 309S, 310S, 316/316L, 316Ti, 317L, 410S, 420J1, 420J2, 430F, 254Smo, 1.4529, HC276, 800, 602, 800, 602, 800, 602 0, 630, XM19, C4, S30815 , S31254, 174PH, F51, F60, F53, S32760, 253MA, HC2000, 800H, 926, GH2132, GH4169, GH3030, GH3039, GH4151, N8C0, N8C0, N8C0, N8C0, N7C0, N7C0, N7C0, N7C00 N08810 |

| ASTM B111 / ASME SB111 | Standard Spezifizéierung fir Kupfer a Kupferlegierung Nahtlos Kondensatortubes a Ferrule Stock | |

| ASTM B161 / ASME SB161 | Standard Spezifikatioun fir Nickel Nahtlos Pipe a Tube | |

| ASTM B163 / ASME SB163 | Standard Spezifizéierung fir Nahtlos Nickel an Nickellegierung Kondensor an Wärmetauscher Tubes | |

| ASTM B165 / ASME SB165 | Standard Spezifikatioun fir Nickel-Kupferlegierung (UNS N04400)* Nahtlos Pipe a Tube | |

| ASTM B167 / ASME SB167 | Standard Spezifikatioun fir Nickel-Chrom-Eisenlegierungen, Nickel-Chrom-Kobalt-Molybdänlegierung (UNS N06617), an Nickel-Eisen-Chrom-Wolframlegierung (UNS N06674) Nahtlos Pipe a Tube | |

| ASTM B395 / ASME SB395 | Standard Spezifikatioun fir U-Bend Nahtlos Kupfer a Kupferlegierung Wärmetauscher a Kondensortubes | |

| ASTM B407 | Standard Spezifizéierung fir Nickel-Eisen-Chromlegierung Nahtlos Pipe a Tube | |

| ASTM B423 / ASME SB423 | Standard Spezifikatioun fir Nickel-Chrom-Molybdän-Columbium Legierungen (UNS N06625 an UNS N06852) an Nickel-Chrom-Molybdän-Silisiumlegierung (UNS N06219) Pipe a Tube | |

| ASTM B444 / ASME SB444 | Standard Spezifikatioun fir Nickel-Chrom-Molybdän-Columbium Legierungen (UNS N06625 an UNS N06852) an Nickel-Chrom-Molybdän-Silisiumlegierung (UNS N06219) Pipe a Tube | |

| ASTM B622 / ASME SB622 | Standard Spezifikatioun fir Nahtlos Nickel a Nickel-Kobaltlegierung Pipe a Tube | |

| ASTM B668 / ASME SB668 | Standard Spezifizéierung fir UNS N08028 an N08029 Nahtlos Pipe a Tube | |

| ASTM B677 / ASME SB677 | Standard Spezifikatioun fir UNS N08925, UNS N08354, an UNS N08926 Nahtlos Pipe a Tube | |

| ASME SB690 / ASME SB690 | Standard Spezifizéierung fir Eisen-Nickel-Chrom-Molybdän Alliagen (UNS N08366 an UNS N08367) Nahtlos Pipe a Tube | |

| ASTM B705 / ASME SB705 | Standard Spezifikatioun fir Nickel-Alloy (UNS N06625, N06219 an N08825) geschweißte Pipe | |

| ASTM B729 / ASME SB729 | Standard Spezifizéierung fir nahtlos UNS N08020, UNS N08026, an UNS N08024 Nickellegierung Pipe a Tube | |

| ASTM B829 / ASME SB829 | Standard Spezifizéierung fir Allgemeng Ufuerderunge fir Nickel a Nickellegierungen Nahtlos Pipe a Tube |

Chemesch Zesummesetzung:

| Grad | Chemesch Zesummesetzung | ||||||||

| C | Si max | Mn max | P | S | Ni | Cr | Mo | Ti | |

| 200 | 0.15 | 0,35 | 0,35 | 0,010 | 99 min | ||||

| 201 | 0,02 | 0,35 | 0,35 | 0,010 | 99 min | ||||

| 400 | 0.30 | 0,50 | 2.00 | 0,024 | 63 min | ||||

| 600 | 0.15 | 0,50 | 1.00 | 0,015 | 72 min | 14-17 Uhr | |||

| 601 | 0.10 | 0,50 | 1.00 | 0,015 | 58-63 | 21-25 Uhr | |||

| 625 | 0.10 | 0,50 | 0,50 | 0,015 | 0,015 | 58 min | 20-23 Uhr | 8-10 | 0,40 max |

| 800 | 0.10 | 1.00 | 1,50 | 0,03 | 0,015 | 30-35 Uhr | 19-23 Uhr | 0,15 0,60 | |

| 8 00h | 0,05 0,10 | 1.00 | 1,50 | 0,015 | 30-35 Uhr | 19-23 Uhr | 0,15 0,60 | ||

| 825 | 0,05 | 0,50 | 1.00 | 0,03 | 38-46 | 19,5 23,5 | 2,5 3,5 | 0,6 1,2 | |

| 9 04l | 0,02 | 1.00 | 2.00 | 0,030 | 0,015 | 24-26 | 19 23 | 4 5 | |

Néckel Legierung Physikalesch Eegeschaften

| ALLOY | NICKEL LEGERING DENSITET | THERMAL, CONDUKTIVITET | THERMAL LINEAR, EXPANSION COEFF., (20-95 °C) | ELEKTRISK RESISTIVITÉIT, OP 20°C |

| G/CM³ | W/MK | 10-6/K | ΜΩ-CM | |

| NI 200/201 | 8,89 | 70,20 | 13.3 | 9 |

| NI 205/205 LC | 8,89 | 75,00 | 13.3 | 8.9 |