Tiyo alyaj nikèl

| Materyèl | Monel/Inconel/Hastelloy/Duplex Steel/PH Steel/Nikèl Alloy |

| Fòm | Wonn, fòje, bag, bobin, bride, disk, papye, esferik, riban, kare, ba, tiyo, fèy |

| Klas | N02200 、 N02201 、 N04400 、 N06600 、 N06601 、 N06625 、 N06690 、 N08810 、 N08825 、 N08020 、 N08020 、 N0802801 2 0 6 0 1 0 1 0 1 665、N06022、N06030、GH3030、GH3036 GH5188 Inconel706 Inconel600 InconelX-750 Inconel718 Inconel625 Inconel 617 Inconel601 Inconel601 Inconel63901 NS1314 NS112, Incoloy800H, NO8810 NS111 NS336 NS142 Incoloy825 NS355 Hastelloy C-4 Monel K500,N05500 |

| Spesifikasyon | Lòt moun: 253Ma,254SMo,654SMo,F50(UNS S32100)F60,F61,F65,1J22,N4,N6 elatriye |

| Alyaj:alyaj 625,Alyaj 20/28/31 | |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/C276/C-2000/G-35/G-30/X/N/g; | |

| Hastelloy B / UNS N10001,Hastelloy B-2 / UNS N10665 / DIN W. Nr.2.4617, Hastelloy C, Hastelloy C-4 / UNS N06455 / DIN W. Nr.2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr.2.4602,Hastelloy C-276 / UNS N10276 / DIN W. Nr.2.4819,Hastelloy X / UNS N06002 / DIN W. Nr.2.4665 | |

| Haynes: Haynes 230/556/188; | |

| Seri Inconel:Inconel 600/601/602CA/617/625/690/713/718/738/X-750,Chapant 20; | |

| Inconel 718 / UNS N07718 /N04400/N06600/N08825/DIN W. Nr.2.4668,Inconel 601 / UNS N06601 / DIN W. Nr.2.4851, Inconel 625 / UNS N06625 / DIN W. Nr.2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr.2.4669,Inconel 600 / UNS N06600 / DIN W. Nr.2.4816 | |

| Incoloy:Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel:Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60; | |

| Nimonic: Nimonic 75/80A/90/A263; | |

| Fil: 0.01-10mm Dezabiye: 0.05 * 5.0-5.0 * 250mm Bar: φ4-50mm; Longè 2000-5000mm Tiyo: φ6-273mm; δ1-30mm; Longè 1000-8000mm Fèy: δ 0.8-36mm; Lajè 650-2000mm; Longè 800-4500mm | |

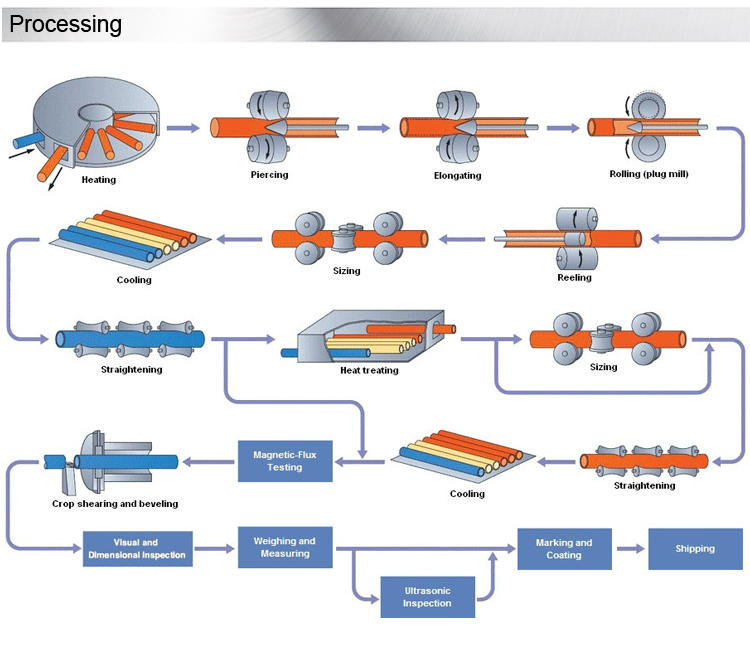

| Pwodwi Karakteristik | 1. Dapre pwosesis preparasyon an ka divize an superalliaj deformation, Distribisyon superalliaj ak superalliaj metaliji poud. 2. Dapre mòd nan ranfòse, gen solisyon solid ranfòse kalite, presipitasyon kalite ranfòse, kalite ranfòse dispèsyon oksid ak kalite ranfòse fib, elatriye. |

| Estanda | GB, AISI, ASTM, DIN, EN, SUS, UNS elatriye |

| Enspeksyon | ISO, SGS, BV, ak sou sa. |

| Aplikasyon | Konpozan wo-tanperati tankou lam turbine, pale gid, disk turbine, presyon ki wo disk COMPRESSOR, fabrikasyon machin ak chanm konbisyon yo itilize nan fabrikasyon turbin gaz aviyasyon, naval ak endistriyèl |

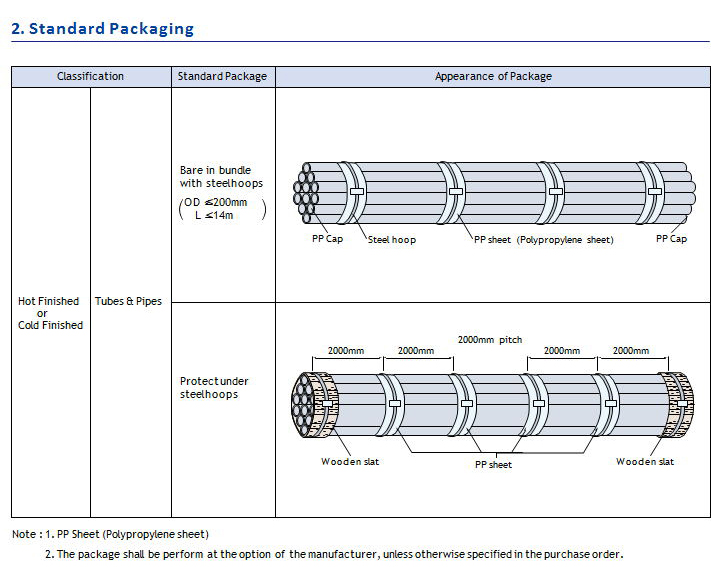

| Anbalaj | 1. ka chaje nan ka an bwa 2. anbalaj papye 3. plastik anbalaj 4. kim anbalaj Anbalaj selon kondisyon kliyan oswa pwodwi yo |

| Livrezon | 7-25 jou oswa selon pwodwi a |

| Peman | L/C, D/A, D/P, T/T, Western Union, MoneyGram, selon kondisyon kliyan peman pou lòd offline. |

| GWO STOCKED | |||||||||||||

| SIZE | NIKÈL | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | SIZE | |

| 1/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 1.65mm | |

| 0.010 | X | X | .25mm | ||||||||||

| 0.020 | X | .51mm | |||||||||||

| 1/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 3.18mm | |

| 0.010 | X | 0.25 | |||||||||||

| 0.012 | X | 3.05mm | |||||||||||

| 0.016 | X | .31mm | |||||||||||

| 0.020 | X | X | X | .51mm | |||||||||

| 0.028 | X | X | X | X | .71mm | ||||||||

| 0.035 | X | X | X | X | .89mm | ||||||||

| 3/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 4.76mm | |

| 0.010 | X | .25mm | |||||||||||

| 0.016 | X | X | .31mm | ||||||||||

| 0.020 | X | .51mm | |||||||||||

| 0.028 | X | X | X | .71mm | |||||||||

| 0.035 | X | X | X | X | X | X | .89mm | ||||||

| 0.049 | X | X | X | 1.24mm | |||||||||

| 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 6.35mm | |

| 0.016 | X | .31mm | |||||||||||

| 0.020 | X | X | X | .51mm | |||||||||

| 0.028 | X | X | X | X | X | .71mm | |||||||

| 0.035 | X | X | X | X | X | X | X | X | .89mm | ||||

| 0.049 | X | X | X | X | X | X | X | X | 1.24mm | ||||

| 0.065 | X | X | X | X | X | X | X | 1.65mm | |||||

| 0.083 | X | 2.11mm | |||||||||||

| 5/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 7.94mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | 1.24mm | |||||||||||

| 0.065 | X | X | X | 1.65mm | |||||||||

| 3/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 9.53mm | |

| 0.020 | X | .51mm | |||||||||||

| 0.028 | X | X | X | X | .71mm | ||||||||

| 0.035 | X | X | X | X | X | X | X | X | .89mm | ||||

| 0.049 | X | X | X | X | X | X | X | 1.24mm | |||||

| 0.065 | X | X | X | X | X | X | X | 1.65mm | |||||

| 0.083 | X | X | 2.11mm | ||||||||||

| 7/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 11.1mm | |

| 0.035 | X | .89mm | |||||||||||

| 0.065 | X | 1.65mm | |||||||||||

| 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 12.7mm | |

| 0.028 | X | X | X | X | .71mm | ||||||||

| 0.035 | X | X | X | X | X | X | X | X | X | .89mm | |||

| 0.049 | X | X | X | X | X | X | X | 1.24mm | |||||

| 0.058 | X | X | 1.47mm | ||||||||||

| 0.065 | X | X | X | X | X | X | X | X | 1.65mm | ||||

| 0.083 | X | X | X | 2.11mm | |||||||||

| 0.095 | X | X | 2.41mm | ||||||||||

| 0.109 | X | 2.77mm | |||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 9/16″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 14.3mm | |

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | X | X | X | 1.24mm | ||||||||

| 0.065 | X | X | X | 1.65mm | |||||||||

| 0.083 | X | 2.11mm | |||||||||||

| 5/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 15.9mm | |

| 0.035 | X | X | X | X | X | .89mm | |||||||

| 0.049 | X | X | X | X | X | X | X | 1.24mm | |||||

| 0.065 | X | X | X | X | X | X | 1.65mm | ||||||

| 0.083 | X | X | 2.11mm | ||||||||||

| 0.095 | X | X | 2.41mm | ||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 3/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 19.1mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | X | X | X | X | X | .89mm | |||||

| 0.049 | X | X | X | X | X | X | X | 1.24mm | |||||

| 0.065 | X | X | X | X | X | X | X | X | X | X | 1.65mm | ||

| 0.083 | X | X | X | X | X | X | X | 2.11mm | |||||

| 0.095 | X | X | 2.41mm | ||||||||||

| 0.109 | X | X | X | X | 2.77mm | ||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | X | 3.18 | ||||||||||

| 7/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 22.2mm | |

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | X | X | 1.24mm | |||||||||

| 0.065 | X | X | X | X | 1.65mm | ||||||||

| 0.083 | X | X | 2.11mm | ||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 1″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 25.4mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | X | X | X | X | .89mm | ||||||

| 0.049 | X | X | X | X | X | X | X | 1.24mm | |||||

| 0.065 | X | X | X | X | X | X | X | X | 1.65mm | ||||

| 0.083 | X | X | X | X | X | X | X | 2.11mm | |||||

| 0.095 | X | X | 2.41mm | ||||||||||

| 0.109 | X | X | X | X | 2.77mm | ||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | 3.18 | |||||||||||

| 0.134 | X | X | |||||||||||

| 1 1/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 28.6mm | |

| 0.049 | X | ||||||||||||

| 1 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 31.8mm | |

| 0.035 | X | X | X | .89mm | |||||||||

| 0.049 | X | 1.24mm | |||||||||||

| 0.065 | X | X | X | X | X | X | 1.65mm | ||||||

| 0.083 | X | X | X | X | 2.11mm | ||||||||

| 0.095 | X | 2.41mm | |||||||||||

| 0.109 | X | 2.77mm | |||||||||||

| 0.120 | X | X | 3.05mm | ||||||||||

| 0.125 | X | 3.18 | |||||||||||

| 1 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 38.1mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | .89mm | ||||||||||

| 0.049 | X | X | X | 1.24mm | |||||||||

| 0.065 | X | X | X | X | X | X | 1.65mm | ||||||

| 0.083 | X | X | X | 2.11mm | |||||||||

| 0.095 | X | X | 2.41mm | ||||||||||

| 0.109 | X | X | X | 2.77mm | |||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | 3.18 | |||||||||||

| 1 5/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 41.3mm | |

| 0.065 | X | 1.65mm | |||||||||||

| 0.083 | X | 2.11mm | |||||||||||

| 1 3/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 44.5mm | |

| 0.065 | X | X | X | 1.65mm | |||||||||

| 1 7/8″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 47.6mm | |

| 0.083 | X | 2.11mm | |||||||||||

| 2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 50.8mm | |

| 0.028 | X | .71mm | |||||||||||

| 0.035 | X | X | .89mm | ||||||||||

| 0.049 | X | X | 1.24mm | ||||||||||

| 0.065 | X | X | X | X | X | 1.65mm | |||||||

| 0.083 | X | X | X | X | 2.11mm | ||||||||

| 0.095 | X | 2.41mm | |||||||||||

| 0.109 | X | X | 2.77mm | ||||||||||

| 0.120 | X | X | X | 3.05mm | |||||||||

| 0.125 | X | X | 3.18 | ||||||||||

| 2 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 57.2mm | |

| 0.035 | X | .89mm | |||||||||||

| 0.049 | X | 1.24mm | |||||||||||

| 0.120 | X | 3.05mm | |||||||||||

| 2 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 63.5mm | |

| 0.065 | X | X | X | X | 1.65mm | ||||||||

| 0.083 | X | X | 2.11mm | ||||||||||

| 0.109 | X | 2.77mm | |||||||||||

| 0.120 | X | X | 3.05mm | ||||||||||

| 3″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 76.2mm | |

| 0.065 | X | X | X | X | 1.65mm | ||||||||

| 0.083 | X | X | X | 2.11mm | |||||||||

| 0.120 | X | X | 3.05mm | ||||||||||

| 0.125 | X | 3.18 | |||||||||||

| 0.250 | X | 6.35 | |||||||||||

| 3 1/4″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 82.6mm | |

| 0.125 | X | 3.18 | |||||||||||

| 3 1/2″ | 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | C276 | 20 | 904L | 88.9mm | |

| 0.375 | 9.53mm | ||||||||||||

| Estanda | - ASTM A270,ASTM A249,ASTM A511,ASTM A778,ASTM A312,ASTM A358,ASTM A409,ASTM A213,ASTM A790,ASTM A268,ASTM A269,ASTM A554,ASTM B338,ASTM BASTM BASTM BASTM B66773 B675, ASTM B676, ASTM B690, ASTM A928, ASME B36.19, ASME B36.10- EN10216-5, EN10217-7, DIN 17456, DIN 17458 – JIS G3463,JIS G3119,JIS G3446,JIS G3218,JIS G3258,JIS G3448,JIS H4631– DEP 31,DEP 40,DEP 20,DEP 32,DNV-OS-F101 |

| Gwosè Range | OD:NPS 1/8 -80, BN 6 – 2000, 10.3 – 2030, Alao kapilèWT:Sch5s-Sch160s, SchXXH, STD,XS,XXSLongè:Personnalisation |

| Klas | S32750, 00Cr25Ni7Mo4N, 022Cr25Ni7Mo4N, 1.441, 1.4307/1.4301/304L/3, S30408/S30403, 0Cr18Ni9DQ, 1.4941, 1.4941, 1.4941, 1.4948, 1.4301/304L/3. 4948, 06Cr23Ni13, S30908, SUS309S, SUS310S, 1.4845, S31008, S31008S, 06Cr25Ni20, 0Cr25Ni20, 1.4401/1.4404/316/31, S31635, SUS316Ti, 1.4571, 1.4571/316Ti, S31703, 022Cr19Ni13Mo3, 00Cr17Ni12Mo2, S317040, S317040, S31704, S31704, S31703 410S, 1.4, 06Cr13, S11306, 0Cr13, S42000, SUS420J1, 1.4021, SUS420J2, 1.4028, S43020, 430F, SUS430F, 1.4104, , 301, 302, 303, 305, 309, 310, 316, 317, 321, 347, 403, 1, 403, 16, 4, 5, 4, 5, 4, 5 07, 304/304L, 304DQ , 304H, 309S, 310S, 316/316L, 316Ti, 317L, 410S, 420J1, 420J2, 430F, 254Smo, 1.4529, HC276, 800, 800, 800, 800, 600, 80, 80, 80 0, 630, XM19, C4, S30815 , S31254, 174PH, F51, F60, F53, S32760, 253MA, HC2000, 800H, 926, GH2132, GH4169, GH3030, GH3039, GH4151, N0439, GH4151, N0438400, N0438400 08810 |

| ASTM B111 / ASME SB111 | Espesifikasyon estanda pou tib kondansateur san pwoblèm kòb kwiv mete ak alyaj kòb kwiv mete ak stock férule | |

| ASTM B161 / ASME SB161 | Espesifikasyon estanda pou tiyo ak tib san pwoblèm nikèl | |

| ASTM B163 / ASME SB163 | Espesifikasyon estanda pou nikèl san pwoblèm ak nikèl alyaj kondansateur ak tib chalè-chanjeur | |

| ASTM B165 / ASME SB165 | Espesifikasyon estanda pou alyaj nikèl-kwiv (UNS N04400)* Tiyo ak tib san pwoblèm | |

| ASTM B167 / ASME SB167 | Espesifikasyon estanda pou alyaj nikèl-kwòm-fè, nikèl-kwòm-kobalt-molybdène alyaj (UNS N06617), ak nikèl-fè-kwòm-tengstèn alyaj (UNS N06674) tiyo san pwoblèm ak tib | |

| ASTM B395 / ASME SB395 | Espesifikasyon estanda pou U-Bend Seamless Copper ak kwiv alyaj echanjeur chalè ak tib kondansateur | |

| ASTM B407 | Espesifikasyon estanda pou nikèl-fè-kwòm alyaj san pwoblèm tiyo ak tib | |

| ASTM B423 / ASME SB423 | Espesifikasyon estanda pou alyaj nikèl-kwòm-molybdène-kolonbyòm (UNS N06625 ak UNS N06852) ak alyaj nikèl-kwòm-molybdène-silikon (UNS N06219) tiyo ak tib | |

| ASTM B444 / ASME SB444 | Espesifikasyon estanda pou alyaj nikèl-kwòm-molybdène-kolonbyòm (UNS N06625 ak UNS N06852) ak alyaj nikèl-kwòm-molybdène-silikon (UNS N06219) tiyo ak tib | |

| ASTM B622 / ASME SB622 | Espesifikasyon estanda pou tiyo ak tib alyaj nikèl san pwoblèm ak nikèl-cobalt | |

| ASTM B668 / ASME SB668 | Espesifikasyon estanda pou UNS N08028 ak N08029 tiyo ak tib san pwoblèm | |

| ASTM B677 / ASME SB677 | Espesifikasyon estanda pou UNS N08925, UNS N08354, ak UNS N08926 tiyo ak tib san pwoblèm | |

| ASME SB690 / ASME SB690 | Espesifikasyon estanda pou alyaj fè-nikèl-kwòm-molybdène (UNS N08366 ak UNS N08367) tiyo san pwoblèm ak tib | |

| ASTM B705 / ASME SB705 | Espesifikasyon estanda pou Nickel-Alloy (UNS N06625, N06219 ak N08825) Tiyo soude | |

| ASTM B729 / ASME SB729 | Espesifikasyon estanda pou UNS N08020 san pwoblèm, UNS N08026, ak UNS N08024 nikèl alyaj tiyo ak Tib | |

| ASTM B829 / ASME SB829 | Espesifikasyon estanda pou egzijans jeneral pou nikèl ak alyaj nikèl san pwoblèm tiyo ak tib |

Konpozisyon chimik:

| Klas | Konpozisyon chimik | ||||||||

| C | Si max | Mn max | P | S | Ni | Cr | Mo | Ti | |

| 200 | 0.15 | 0.35 | 0.35 | 0.010 | 99 min | ||||

| 201 | 0.02 | 0.35 | 0.35 | 0.010 | 99 min | ||||

| 400 | 0.30 | 0.50 | 2.00 | 0.024 | 63 min | ||||

| 600 | 0.15 | 0.50 | 1.00 | 0.015 | 72 min | 14-17 | |||

| 601 | 0.10 | 0.50 | 1.00 | 0.015 | 58-63 | 21-25 | |||

| 625 | 0.10 | 0.50 | 0.50 | 0.015 | 0.015 | 58 min | 20-23 | 8-10 | 0.40 max |

| 800 | 0.10 | 1.00 | 1.50 | 0.03 | 0.015 | 30-35 | 19-23 | 0.15 0.60 | |

| 800H | 0.05 0.10 | 1.00 | 1.50 | 0.015 | 30-35 | 19-23 | 0.15 0.60 | ||

| 825 | 0.05 | 0.50 | 1.00 | 0.03 | 38-46 | 19.5 23.5 | 2.5 3.5 | 0.6 1.2 | |

| 904L | 0.02 | 1.00 | 2.00 | 0.030 | 0.015 | 24-26 | 19 23 | 4 5 | |

Pwopriyete fizik alyaj nikèl

| ALLOY | DENSITE NIKÈL ALOYY | Tèmik, konduktivite | Tèmik lineyè, ekspansyon koef., (20-95 °C) | RESISTIVITE ELEKTRIK, A 20°C |

| G/CM³ | W/MK | 10-6/K | ΜΩ-CM | |

| NI 200/201 | 8.89 | 70.20 | 13.3 | 9 |

| NI 205/205 LC | 8.89 | 75.00 | 13.3 | 8.9 |