ASTM A335 Steel Tiyo

| Non pwodwi | Alloy Steel Tiyo |

| Materyèl | Alloy Steel |

| Longè tiyo | Single Random Length ak doub Random Length.SRL: 3M-5.8M DRL: 10-11.8M oswa Kòm kliyan mande longè |

| Gwosè | Gwosè 1/4”rive 24”Deyò Dyamèt 13.7 mm a 609.6 mm |

| Epesè miray la | SCH10, SCH20, SCH30, STD, SCH40, SCH60, SCH80, SCH100 SCH120, SCH160, XS, XXS |

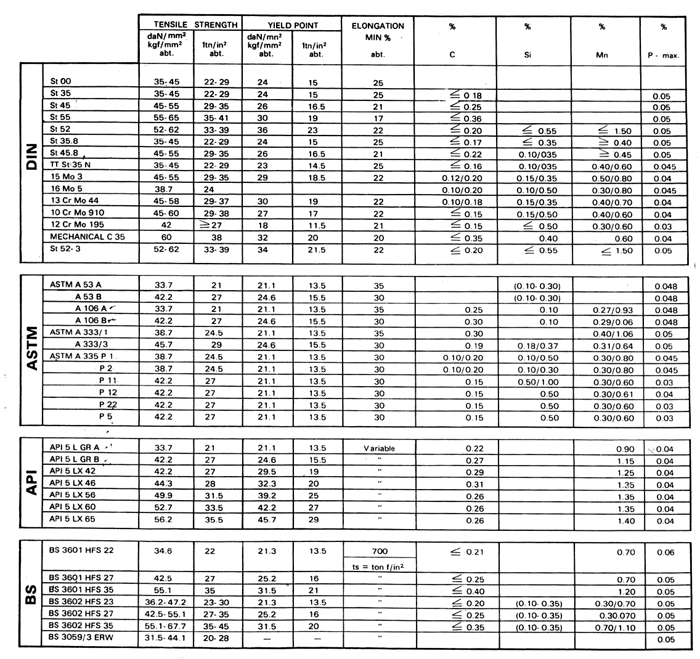

| Estanda | ASTM A 335 Klas P1, P2, P5, P9, P9A, P11, P22.ASTM A213 T1B, T1, T2, T5, T9, T9A, T11, T12, T22.A199 T5, T9, T11, T22.BS 3604 Klas 621, 622, 625, 629-470, 629-590, 660, 762.DIN 17175 15 Mo 3, 13 Cr Mo 44, 10 Cr Mo 910, 14 Mo V 63, X 20 Cr Mo V 30219 Mo 10219 , 620-460, 622-490, 629-470, 629-590, 762. JISG3458/G3462/3467 ak DIN17175-79. |

| Aplikasyon | 1.Fluid tiyo 2. Plant pouvwa 3. Tiyo estrikti 4. Segondè ak ba presyon Chodyè tib 5. Tib asye san pwoblèm pou fann petwòl 6. Tiyo konduit 7. Echafodaj tiyo pharmaceutique ak batiman elatriye |

| Sètifika | ISO/PED/TUV/SGS/LR/BV |

| Mache prensipal la | Azi, Mwayen Oryan, Ewòp, Amerik, Afrik, Ostrali, elatriye |

Konpozisyon chimik (%):

| Klas | Deziyasyon UNS | Konpozisyon, % | |||||||

| Kabòn | Manganèz | Fosfò, | Souf | Silisyòm | Kwòm | Molybdène | Lòt moun | ||

| max | max | ||||||||

| P1 | K11522 | 0.10-0.20 | 0.30-0.80 | 0.025 | 0.025 | 0.10-0.50 | — | 0.44–0.65 | — |

| P2 | K11547 | 0.10-0.20 | 0.30–0.61 | 0.025 | 0.025 | 0.10-0.30 | 0.50–0.81 | 0.44–0.65 | — |

| P5 | K41545 | 0.15 max | 0.30-0.60 | 0.025 | 0.025 | 0.50 max | 4.00–6.00 | 0.45-0.65 | — |

| P9 | S50400 | 0.15 max | 0.30-0.60 | 0.025 | 0.025 | 0.25-1.00 | 8.00–10.00 | 0.90-1.10 | — |

| P11 | K11597 | 0.05–0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50-1.00 | 1.00–1.50 | 0.44–0.65 | — |

| P12 | K11562 | 0.05–0.15 | 0.30–0.61 | 0.025 | 0.025 | 0.50 max | 0.80-1.25 | 0.44–0.65 | — |

| P15 | K11578 | 0.05–0.15 | 0.30-0.60 | 0.025 | 0.025 | 1.15–1.65 | — | 0.44–0.65 | — |

| P21 | K31545 | 0.05–0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50 max | 2.65–3.35 | 0.80-1.06 | — |

| P22 | K21590 | 0.05–0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50 max | 1.90–2.60 | 0.87–1.13 | — |

| P23 | K41650 | 0.04–0.10 | 0.10-0.60 | 0.03 | 0.01 | 0.50 max | 1.90–2.60 | 0.05–0.30 | V 0.20–0.30 |

| Cb 0.02–0.08 | |||||||||

| B 0.0005–0.006 | |||||||||

| N 0.030 max | |||||||||

| Al 0.030 max | |||||||||

| W 1.45–1.75 | |||||||||

| P91 | K91560 | 0.08–0.12 | 0.30-0.60 | 0.02 | 0.01 | 0.20-0.50 | 8.00–9.50 | 0.85–1.05 | V 0.18–0.25 |

| N 0.030-0.070 | |||||||||

| Ni 0.40 max | |||||||||

| Al 0.04 max | |||||||||

| Cb 0.06–0.10 | |||||||||

| P92 | K92460 | 0.07–0.13 | 0.30-0.60 | 0.02 | 0.01 | 0.50 max | 8.50–9.50 | 0.30-0.60 | V 0.15–0.25 |

| N 0.03-0.07 | |||||||||

| Ni 0.40 max | |||||||||

| Al 0.04 max | |||||||||

| Cb 0.04–0.09 | |||||||||

| W 1.5–2.00 | |||||||||

| B 0.001–0.006 | |||||||||

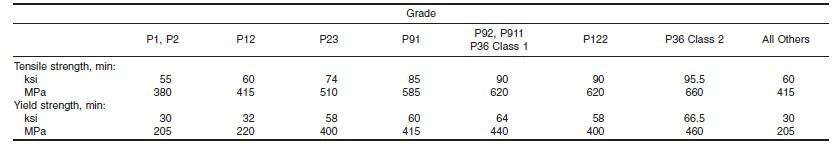

Pwopriyete mekanik:

Nwa kouch, lwil oliv / vèni, FBE, 2PE, 3PE, galvanised elatriye Detay anbalaj: anbalaj nan pake oswa pou kondisyon kliyan an